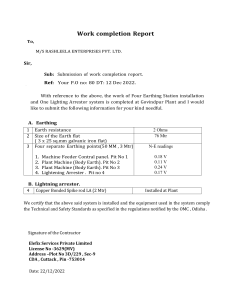

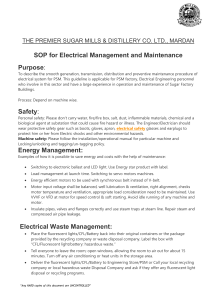

ELECTRICAL SAFETY ELECTRICAL SAFETY AT CONSTRUCTION SITE ELECTRICAL SAFETY NATIONAL ELECTRICAL SAFETY WEEK “Avoid Loose Wires – Prevent Electrical Fires” ELECTRICAL SAFETY WORKING WITH ELECTRICITY MAY BE DANGEROUS IF: SOP’s not followed Safety precautions not taken care off Elect safety vids\Elect safety 2.mp4 Overlooking hazards Improper PPE ELECTRICAL SAFETY SOME COMMON ELECTRICAL HAZARDS AT CONSTRUCTION SITE Poor Cable Management Power Supply Boards Earthing • Loose Wires • Poor Cable laying • Temp Cable Joints • Cable Terminations • Welding rectifier • DG Sets ELECTRICAL SAFETY POOR CABLE MANAGEMENT ➢ Elect safety vids\Elect safety 4.mp4 ELECTRICAL SAFETY POWER SUPPLY BOARDS / JOINTS ELECTRICAL SAFETY EARTHING Elect safety vids\Elect safety 3.mp4 ELECTRICAL SAFETY UNSAFE PRACTICES ELECTRICAL SAFETY UNSAFE PRACTICES Elect safety vids\Elect safety 5_lock Out.mp4 ELECTRICAL SAFETY UNSAFE PRACTICES ELECTRICAL SAFETY FOR SAFE ELECTRICAL WORKS ELECTRICAL SAFETY STANDARD OPERATING PROCEDURE ✓ Specific job-related procedure to be defined clearly ✓ Electricians must be educated / trained on job ✓ SOP’s to be followed ✓ Specific job must be mentioned on the work permit ✓ Job related hazards to be identified and maintained in Job safety Plan ✓ Lock Out / Tag Out FUNDAMENTALS OF EARTHING PERSONAL PROTECTOVE EQUIPMENT (PPE) Elect safety vids\Elect safety 6.mp4 Contd. ELECTRICAL SAFETY ELECTRICAL SAFETY DURING MONSOON Contd. ELECTRICAL SAFETY ✓ All DG Sets, welding rectifiers, electrical concrete mixers, grinders etc. should be connected with earthing system and checked for continuity on daily basis before commencement of job. ✓ Make sure that any electric equipment should not come under submergence. ✓ Ensure all outdoor electrical equipment are provided with suitable canopies / covers. ✓ Ensure all earthing connections have been checked for continuity. ✓ Ensure cable glands have been checked for their soundness. ✓ Ensure temporary power connection (switchboard / panel) are provided ELECTRICAL SAFETY ✓ Ensure electrical Insulation rubber mats are in place. ✓ Ensure use of necessary PPE by electricians and all operating personnel. ✓ Ensure proper shed/ canopy for rain protection for the electrical panels, automation equipment etc. has been provided. ✓ Ensure outdoor terminal boxes/ junction boxes/ push button stations, pillar box, distribution boards etc. should have proper sealing gaskets to prevent short circuit due to entry of rainwater. ✓ Ensure the emergency DG set is in working condition. Keep sufficient stock of fuel for running of DG. ELECTRICAL SAFETY DO’s & DON’T’s Contd. ELECTRICAL SAFETY DO’s: ✓ Operate / Maintain the panel with valid permit / information. ✓ Strictly adhere to PPE’s as mentioned in the permit. ✓ Discharge the static charge present on inductive / capacitive circuits on isolated equipment prior to commencement of work. ✓ Follow system LOTO strictly as per LOTO SOP. ✓ Power restoration to be done as per power restoration procedure. ✓ Before working on any circuit or apparatus, make sure that the controlling switches are open and locked (AC/DC Supply of spring charged is de-energized). ELECTRICAL SAFETY DO’s: ✓ Housekeeping to be done after work completion. ✓ Read the Single Line Diagram and wiring – know your switchboard. ✓ Inspect the tools prior to usage. ✓ Check that electrical connections are tight & dust free. ✓ Temporary supply should be given from proper as per load. ✓ Report any abnormality promptly to authorised personnel. ELECTRICAL SAFETY DONT’s: ✓ Do not do operation / maintenance on the panel without valid permit / information. ✓ Do not remove LOTO without closure of electrical isolation permit. ✓ DO not reset relay flags without detailed inspection. ✓ DO not keep loose uninsulated wires in panel or in substation. ✓ Do not wear loose clothing, metal watch straps, bangles or finger rings while working. ✓ Do not use a power tool that smokes, sparks, smells or shocks. ELECTRICAL SAFETY LOCK OUT - TAG OUT Contd. ELECTRICAL SAFETY Procedure to carry Lock Out Tag Out is as follows: ✓ Identify the feeder/contactor as mentioned in the Electrical Isolation Permit (EIP) corresponding to the equipment which has to be electrically isolated. ✓ Strictly adhere to the PPEs as mentioned in the EIP. ✓ Follow the procedure filled in EIP to isolate the equipment. ✓ Once the equipment is electrically isolated, lock out the corresponding feeder / contactor and pit the electrical isolating tag mentioning all the relevant details. Key and the trailing part of isolation tag is to be kept with the authorized person. ✓ Inform all nearby / concerned personnel about the isolation. ✓ Once the equipment is isolated, locked and tagged, inform issuer department so that the maintenance activity can be carried out. ELECTRICAL SAFETY Procedure for restoration of electrical supply / re-energization of equipment: ✓ Identify the feeder / contactor for which electrical isolation is to be removed. ✓ Inform everyone in work area that the isolation is being removed. ✓ De-lock the feeder/contactor. Ensure proper housekeeping, removal of tools tackles and make sure that the system under maintenance is fully assembled. ✓ Re-energize the equipment by following the isolation procedure in reverse manner. ✓ Fill the details of tagging out as mentioned in the second part of electrical isolation tag. ELECTRICAL SAFETY EARTHING Contd. FUNDAMENTALS OF EARTHING ✓ What is Earthing ✓ By Earthing, we mean making the Physical & Electrical connection to the General Mass of Conducting Earth / earth Circuit. Contd. IMPORTANCE OF EARTHING ✓ Safety Provided by Earthing ✓ Safety of Life ✓ Safety of Property / Installation ✓ Safety & Stability of Power System WHY EQUIPMENT EARTHING Equipment earthing provides safety of life & property by: ✓ Ensuring freedom from dangerous electric shock voltage exposure to person present in the area. ✓ Ensuring current carrying capability both in magnitude & duration adequate to accept the ground fault current without creating a fire or explosive hazard. ✓ Ensuring the proper return path for earth fault currents & hence better performance of the electrical system. HOW TO CARRY OUT EQUIPMENT EARTHING ✓ As direct as possible. ✓ By ensuring equipotential bonding between all simultaneously accessible exposed & extraneous conductive parts. EQUIPMENT EARTHING – BASIC RULES ✓ Earth All exposed and extraneous conductive parts. ✓ Earth as directly as possible with minimum impedance. ✓ Simultaneously accessible exposed and extraneous conductive parts must be connected to the same earth electrode / earth grid. ✓ Earth by two separate and distinct connections with earth for operating voltage above 240AC. EQUIPMENT EARTHING – BASIC RULES TYPICAL EARTH ELECTRODE : IS 3043 EARTHING BASICS EARTH VS UN EARTH EARTHING BASICS ELECTRIC SHOCK EARTHING BASICS EFFECT OF CURRENT EARTHING BASICS IS 3043 ON EQUIPMENT GROUNDING EARTHING BASICS TOUCH AND STEP POTENTIAL EARTHING BASICS EARTHING BASICS