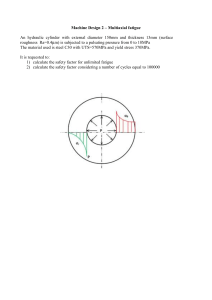

Mechanical Design 机械设计 About this course: (1)A total of 48 classes:32 classes teaching and 16 classes project design (2)Will have test at the end of the course. (3)Two scores at the end of the semester: Course for ”Mechanical Design“= 70%test+20%presentation(2 presentations)+10%attendance Course for “project design” =The quality of the Design Report Bing Zhang College of Mechanical Engineering Yangzhou University Email: bingzhang2021@yzu.edu.cn Mechanical Design 机械设计 Chapter 1 Introduction to Mechanical Design 第一章 绪论 1. The backgrounds and needs of Mechanical Design Vehicles Engineering trucks Industrial production Weapons Aircrafts Mechanical Design 1. The backgrounds and needs of Mechanical Design Parts manipulation Mechanical reducer Slider motion system The functions and applications of machines need a well designed mechanical system automobiles Mechanical Design 1. The backgrounds and needs of Mechanical Design Mechanical Design Frontier Mechanical Design 1. The backgrounds and needs of Mechanical Design Mechanical Design Frontier Mechanical spiders Smart insect Mechanical Design crawling robot 2. Introduction of Design 机械原理 机械设计 机械:machinery 原理:theory; principle 机械 machinery Theory of machines and mechanisms Mechanical Design 机械:machinery 设计:design 机构: mechanism 机器: machine Design of machines and mechanisms 2.1 Main contents of: Mechanical Design 1. Basic knowledge about Mechanical Design: selection of materials; working stresses and fatigue(工作应力与疲劳/失效); friction(摩擦); lubrication(润滑), etc. 2. Connections: screw joint(螺纹连接); splined joint(花键连接); key /no key links(键/无 键连接); pin joint(销连接) 3. Transmission part: screw drive(螺旋传动); belt drive (带传动); chain drive(链传 动) ;gear transmission(齿轮传动);worm gear(蜗杆传动);friction gearing(摩擦轮 传动) 4. Shafts and associated parts: journal sliding bearing(径向/滑动轴承); rolling bearing(滚动 轴承); Shaft coupling(联轴器); clutch(离合器) 5. Others:spring(弹簧);transmission(变速器);housing(箱体) Mechanical Design Classification of machine elements Normal load transmitter: sliding bearings, rolling-element bearings Torque transmitter: gears, traction drives, chain drives, belt drives, power screws /to:k/ Energy absorber: brakes and dampers Supporting elements: shafts, springs, seals(密封件) Connection and joints: thread fasteners(螺纹紧固件), keys, couplings联轴器 Classification of machine elements internal spline external spline /splaɪn/花键 bearings pin joint screw key link Mechanical Design shaft coupling clutch Classification of machine elements chain springs belt gears shaft Mechanical Design Typical machines 2.2 The Design Process Recognize the need Create a design Prepare a model Test and evaluate the model Communicate the design Improve the design 1. Definition of the problem by stating the given quantities(数量)and appropriate assumptions. 2. Preliminary design decisions and sketches. 3. Mathematical models, detailed design analysis, and evaluation. 4. Documentation of results and comment about the solution. Mechanical Design Engineering and the Engineering Design Process https://www.youtube.com/watch?v=nMwG1wnESDA 2.3 The Design Analysis 1. The engineering modelling: geometric modelling is (1) Structure is simple enough: theoretical solutions for basic configurations may be adequate for obtaining the stresses involved. (2) For more complicated structures: finite-element models not only can estimate the stresses but also utilize them to evaluate the failure criteria for each element in a member. 2. Rational理性 design procedure: to meet the strength requirements, tension, compression, fatigue, all complicated and involved situations… 3. Methods of analysis:-mechanics of materials-the basic principle of analysis can be summarized as follows: (1) Statics. The equations of equilibrium(平衡, ˌiːkwɪˈlɪbriəm) must be satisfied. (2) Deformations(变形). Stress-strain or force-deformation relations (e,g., Hooke’s law) must apply to the behavior of materials. (3) Geometry. The conditions of compatibility of deformations must be satisfied; that is, each deformed part of the member must fit together with adjacent(临近的) parts. Mechanical Design 2.4 Computer tools A wide variety of computational tools can be used to perform design calculations with success. Mathematical Software Packages: MATLAB,… Computer Aided Design (CAD): AutoCAD, Pro E, UG, Solidworks, Catia,… Finite Element Analysis (FEA:): Ansys, Abaqus, ... Dynamic Simulation Software: Adams,… Professional Simulation Software: Kisssoft, Masta, Romax,… Mechanical Design 2.4 Computer tools Mechanical Design 2.4 Computer tools Top 10 Software for Mechanical Engineers https://www.youtube.com/watch?v=KQjXs9iXa38 Mechanical Design 2.5 Fundamental design considerations 1 Strength 2 Reliability(可靠性) 4 Corrosion(腐蚀) 5 Wear(磨损) 6 Friction(摩擦) 7 Processing 8 Utility功用 9 Cost 10 Safety 11 Weight 12 Noise 13 Styling 14 Shape 15 Size 16 Flexibility 17 Control 18 Stiffness 19 Surface finish 20 Lubrication 21 Maintenance保养 22 Volume Mechanical Design 3 Thermal effect(热效应) 3. Basic Requirements for Machine Design ◼ Economics and functionality are always pressing concerns, and good design inherently means safe, economical, and functional design. ◼ A primary responsibility of any mechanical designer is to ensure that the proposed design will function as intended, safely and reliably, for the prescribed design lifetime and, at the same time, compete successfully in the marketplace. Mechanical Design 3.1Functional Requirements The machine to be designed should fulfill specified functions. This requires: Fundamental decisions regarding loading, kinematics, and the choice of materials must be made properly during the design of a machine. Besides, strength, reliability, deformation, tribology (friction, wear, and lubrication), also need to be considered. Mechanical Design 3.2 Economic Demands The objective is to produce a machine that not only is to function properly for a reasonable time but is also economically feasible. The economic requirements need to be addressed over the entire life circle of design, manufacturing and operation of the product. Functional demands and economic demands are generally contradictory(对立的). Mechanical Design 3.3 Other Demands Safety, labor protection requirements, reliability requirements and space requirements, convenience in transportation also need to be considered. Non-engineering decisions regarding marketability 适 销 性 , product liability产品责任, ethics伦理道德, politics政治, etc., must be integrated into the design process early. Mechanical Design 4. Contents and Purpose of the Course Fundamental design principles of various machine elements. Even the design of a single bolt螺栓 or spring弹簧 needs the designer’s thorough understanding of the principles and methods of machinery design and more. Master the basic knowledge, methods and procedures and gain the competence in applying them into practical design. Mechanical Design 4. Contents and Purpose of the Course Develop competence of creative design and solving practical problem ◆ Mechanical system design requires considerable 相 当 大 的 flexibility and creativity to obtain good solutions. ◆ Creativity seems to be aided by familiarity with known successful designs of related systems, components or elements. Mechanical Design 5 Failure Prevention the Basis for Successful Design of Machine Element ▪ Designer must have a good working knowledge of analytical and/or empirical techniques for predicting potential failures at the design stage. ▪ These predictions must then be transformed into selection of a material, determination of a shape, and establishment of the dimensions for each part to ensure safe, reliable operation throughout the design lifetime. Mechanical Design 5 Failure Prevention Improper functioning of a machine or machine part constitutes 构成 failure. When it becomes completely inoperable When it is still operable but is unable to perform its intended function satisfactorily When serious deterioration(恶化) has made it unreliable or unsafe for continued use. When a mechanical part fails to work properly for some reason, which is called failure Mechanical Design 5.1 Failure Modes Failure of a machine part might be brought about by any one or a combination of many different responses to loads and environments while in service. 1. Force - and/or temperature - induced elastic deformation 2. Yielding - plastic deformation 3. Brittle (脆性)fracture(断裂); fatigue fracture 4. Surface failure - Wear, Fatigue, Galling (擦伤), Seizure(咬粘), ductile rupture(韧性断裂), Creep (蠕变), Brinnelling(微动磨损), Corrosion(腐 蚀), spalling(开裂), Fretting ( 微振磨损) 5. Violation(违背) of its intended function - overall slip of belt, Buckling(屈曲) of spring Mechanical Design 5.1 Failure Modes Failure Modes of a Shaft 轴 ▪ Fatigue fracture/ for common shaft ▪ Excessive elastic deformation/ for precision shaft (精密轴) ▪ Resonant vibration / (共振) for rotating shaft at high speed 5.2 Factor of safety Basic definition The factor of safety, S, is the ratio of the maximum load that produces failure of the member to the load allowed under service conditions: S= failure load allowable load The allowable load is also referred to as the service load or working load. This ratio must always be greater than unit: S 1 Mechanical Design A common definition A common method of design is to use a safety factor with respect to strength of member. In most situations, a linear relationship exists between the load and stress produced by the load. Then, the factor of safety may also be defined as: S= material strength allowable stress The material strength represents either static or dynamic properties, if loading is static, the material strength is either the yield strength or the ultimate strength. For fatigue loading, the material strength is based on the endurance limit. The allowable stress is also called the applied stress, working stress, or design stress.-the required strength Mechanical Design Stress-strain Diagram Stress-strain diagram Mechanical Design 6. Some Terminology Concerning Machine Design ▪ 1) Codes and Standards规范和标准 ▪ 2) Reliability可靠性 ▪ 3) Safety and Product Liability责任 Mechanical Design 6.1 Codes and standards Numerous engineering societies and organizations publish standards and codes for specific areas of engineering design. Most are merely recommendations, but some have the force of law. For the majority of applications, relevant factors of safety are found in various construction and manufacturing codes. Factors of safety are usually embodied into computer programs for the design of specific members. Mechanical Design 6.2 Reliability The concept of reliability is closely related to the factor of safety. Reliability is the probability that a member or structure will perform without failure a specific function under given conditions for a given period of time. It is very important for the designer and the manufacturer to know the reliability of the product. The reliability R can be expresses by a number that has the range: 0 R 1 For instance, reliability of R=0.98 means that there is 98% chance(probability), under certain operating conditions, that the part will perform its proper function without failure; that is, if 100 parts are put into service and an average of 2 parts fail, then the parts proved to be 98% reliable. Mechanical Design 6.3 Safety and Product Liability(产品法律责任) ▪ Liability concept states that the manufacturer of a machine is liable for any damage or harm that results because of a defect. ▪ The best approaches to the prevention of product liability are good engineering in all analysis and design, quality control, and comprehensive testing procedures. Mechanical Design 7 Failure Modes of a gear(齿轮) 1) Stress concentration factors 2) Contact stress distributions 3) Scuffing擦伤,磨损,胶合 Mechanical Design 7.1 Stress concentration factors 轮齿折断:一般发生在齿根部分(齿 根弯曲应力最大,且有应力集中)。 Teeth broken: big bending stress, Stress concentration Mechanical Design Stress Concentration ◆ Stress concentration is caused by discontinuity in a machine element. ◆ Discontinuities include changes in the cross section of the parts, holes, grooves凹槽, notches槽口, etc.. ◆ Such discontinuities are called stress raisers应力集中处. Mechanical Design 7.2 Contact stress distributions 齿面点蚀:在载荷多次的重复作用下, 齿面会产生细微的疲劳裂纹,慢慢裂纹 蔓延扩展使齿面微粒脱落形成点蚀。 Pitting and peeling: repeated loading, fatigue crack, particles shedding Mechanical Design 7.2 Contact stress distributions Mechanical Design 7.3 Scuffing(磨损) 齿面胶合:在高速、重载传动 中,因摩擦发热导致齿面金属直 接接触产生粘连,齿面材料发生 移动的现象。 在低速、重载,两啮合齿面间 的润滑油膜不易形成,也容易产 生胶合。提高齿面硬度和减小齿 Scuffing: high speed, heavy loading, frictional heating, no lubricant film, metal bonding Mechanical Design 面表面粗糙度可增强齿面抗胶合 能力。 8 Finite Element Analysis Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what is going to happen when the product is used. Mechanical Design 8 Finite Element Analysis Mechanical Design Examples Mechanical Design The Multibody Dynamics Simulation As the world's most famous and widely used Multibody Dynamics (MBD) software, Adams improves engineering efficiency and reduces product development costs by enabling early system-level design validation. Engineers can evaluate and manage the complex interactions between disciplines including motion, structures, actuation, and controls to better optimize product designs for performance, safety, and comfort. Mechanical Design The Multibody Dynamics Simulation Solution Mechanical Design The Multibody Dynamics Simulation Solution Mechanical Design The Multibody Dynamics Simulation Solution Mechanical Design The Multibody Dynamics Simulation Solution Mechanical Design The Multibody Dynamics Simulation Solution steering Satellites extend solar panels Excavator /ˈekskəveɪtə(r)/ 挖掘机 through obstacle The moving system of a car The internal movement of combustion engine Example:Nonlinear Finite Element Analysis - Ansys analysis (bolted joint) https://www.youtube.com/watch?v=IYGdyTttcOg Mechanical Design 9. Basic requirements of designing mechanical parts Avoid failure within the predetermined life span避免在预定寿命期内失效 Processability of product structure结构工艺性 Economic requirement经济性要求 Lightweight轻量化要求 Reliability requirements可靠性要求 9.1 Avoid failure within the predetermined life span 避免在预定寿命期内失效 Parts should have sufficient strength, stiffness and life.强度、刚 度、寿命 Strength requirements: ✓ Use high strength materials ✓ Make the parts have enough cross section size界面尺寸 ✓ Rationally design the section shape of the part and increase the moment carbonizing phosphorization of inertia ✓ Heat treatment and chemical treatment are used to improve the strength shot blasting properties of the materials ✓ Improve the manufacturing precision of parts to reduce the dynamic load during work ✓ Reasonable configuration of the relative position of the parts to reduce the load of the parts 9.1 Avoid failure within the predetermined life span 避免在预定寿命期内失效 Stiffness requirements: The elastic deformation of a part at work cannot exceed the allowable range , which is known as the stiffness requirement of the part. ✓ Increase the section size of the part or the moment of inertia;增大零件的 截面尺寸或增大惯性矩; ✓ Shorten the span of the support or adopt multi-point support.缩短支承的 跨距或采用多点支承。 9.1 Avoid failure within the predetermined life span 避免在预定寿命期内失效 Life requirements: The main factors affecting the life of parts are fatigue failure, corrosion and wear. Fatigue failure疲劳失效: Most parts work under variable stress, so fatigue failure is the main cause of part failure. Factors affecting fatigue strength include stress concentration, part size, part surface quality, and environmental conditions Corrosion腐蚀: The parts may be corroded when working in corrosive medium. Corrosion resistance measures include surface flange, surface coating, surface anodization, etc. 9.2 Processability of product structure结构工艺性 Mark of good manufacturability of parts - in specific production conditions, parts to facilitate processing and processing costs are very low.零件工艺性良好的标志——在具体的生产条件下,零件要 便于加工而加工费用又很低。 (1)The blank selection is reasonable. Preparation methods: Profile, casting, forging, stamping and welding, etc.制备方 法:选用型材、铸造、锻造、冲压和焊接等。 (2)Simple and reasonable structure结构简单合理 (3)Reasonable manufacturing accuracy and surface roughness合理的制造精度和表面粗糙度 (4)Minimize the amount of parts processed尽量减小零件的加工 量 9.2 Processability of product structure结构工艺性 Economic requirement 经济性要求 Lightweight 轻量化要求 Reliability requirements 可靠性要求 10 Courses learnt before this course 工程制图:设计的图形表达。Engineering drawing: The graphical representation of a design. 工程材料:非金属材料、金属材料及热处理。Engineering materials: non-metallic materials, metallic materials and heat treatment. 机械制造基础:冷加工工艺,热加工工艺。Fundamental of Mechanical Manufacture: cold and hot processing technology. 公差配合与技术测量:解决精度设计问题。Tolerance fit and technical measurement: solve the problem of precision design. 理论力学:解决力分析与动力计算。Theoretical mechanics: Force analysis and dynamic calculation. 材料力学:解决强度分析问题。Mechanics of materials: Solving strength analysis problems. 机械原理:解决机械的方案设计。Mechanical principle: design of mechanical solutions. Mechanical Design Thanks for your attention! Bing Zhang College of Mechanical Engineering Yangzhou University Email: bingzhang2021@yzu.edu.cn Mechanical Design