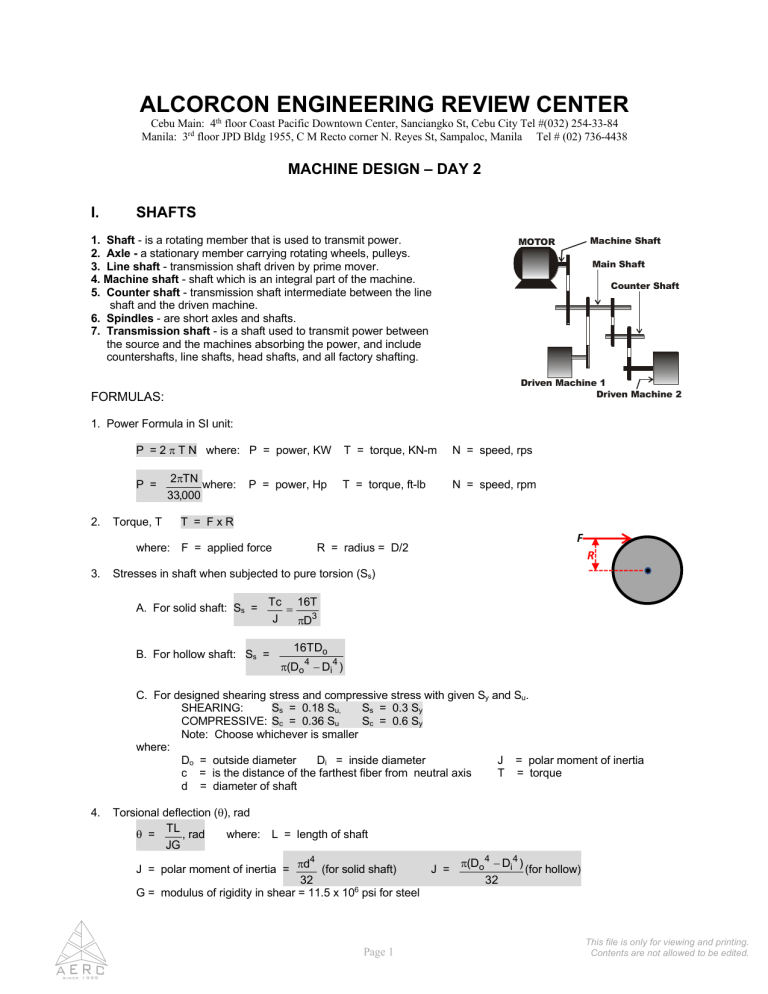

ALCORCON ENGINEERING REVIEW CENTER Cebu Main: 4th floor Coast Pacific Downtown Center, Sanciangko St, Cebu City Tel #(032) 254-33-84 Manila: 3rd floor JPD Bldg 1955, C M Recto corner N. Reyes St, Sampaloc, Manila Tel # (02) 736-4438 MACHINE DESIGN – DAY 2 I. SHAFTS 1. Shaft - is a rotating member that is used to transmit power. 2. Axle - a stationary member carrying rotating wheels, pulleys. 3. Line shaft - transmission shaft driven by prime mover. 4. Machine shaft - shaft which is an integral part of the machine. 5. Counter shaft - transmission shaft intermediate between the line shaft and the driven machine. 6. Spindles - are short axles and shafts. 7. Transmission shaft - is a shaft used to transmit power between the source and the machines absorbing the power, and include countershafts, line shafts, head shafts, and all factory shafting. Machine Shaft MOTOR Main Shaft Counter Shaft Driven Machine 1 Driven Machine 2 FORMULAS: 1. Power Formula in SI unit: P = 2 p T N where: P = power, KW P = 2. Torque, T 2pTN where: 33,000 P = power, Hp N = speed, rps T = torque, ft-lb N = speed, rpm T = FxR where: F = applied force 3. T = torque, KN-m R = radius = D/2 F R Stresses in shaft when subjected to pure torsion (Ss) A. For solid shaft: Ss = Tc = 16T J pD3 B. For hollow shaft: Ss = 16TDo p(Do 4 - Di 4 ) C. For designed shearing stress and compressive stress with given Sy and Su. SHEARING: Ss = 0.18 Su, Ss = 0.3 Sy COMPRESSIVE: Sc = 0.36 Su Sc = 0.6 Sy Note: Choose whichever is smaller where: Do = outside diameter Di = inside diameter J = polar moment of inertia c = is the distance of the farthest fiber from neutral axis T = torque d = diameter of shaft 4. Torsional deflection (q), rad q = TL , rad where: L = length of shaft JG 4 p(Do 4 - Di 4 ) (for hollow) J = polar moment of inertia = pd (for solid shaft) J = 32 32 G = modulus of rigidity in shear = 11.5 x 106 psi for steel Page 1 This file is only for viewing and printing. Contents are not allowed to be edited. FROM MACHINERIES HANDBOOK: A. For solid shaft: Θ = 584 T L D4 G , deg B. Using ALCORCON’S FORMULA for hollow shaft: Θ = Θ T L D Do, Di G Degrees in-lb in in in Psi Degrees N-mm mm mm mm MPa 584 T L (Do 4 - Di4 ) G , deg degrees KN-m m m m KPa 5. Stress in shaft when subjected to Torsion and Bending loads: a. For solid shaft: Ss = 16 (K mM)2 + (K t T )2 pd3 St = 16 é 2 2ù êKmM + (KmM) + (K t T ) úû pd3 ë Note: Km and Kt not known, assume 1.0 where: b. T = torque M = moment Ss = maximum shear stress St = maximum tensile or compressive stress For hollow shaft: 16Do Ss = p(Do 4 - Di4 ) (K mM)2 + (K t T )2 St = 16Do 4 4 p(Do - Di ) é 2 2ù êëKmM + (KmM) + (K t T ) úû 6. Strength of shaft with assumed allowable stresses (PSME Code p. 18) a. For Main Shafts: (S = 4000 psi) 3 P = D N 80 b. For Line Shafts: (S = 6000 psi) P = c. For short shafts: (S = 8500 psi) 3 P = D N 38 where: P = power, Hp D3N 53.5 N = speed, rpm D = diameter, inch 7. From Machineries Handbook Formula A. Shaft diameter for 0.08 degrees per foot of length of shaft deflection. For English units: Where: D = diameter, in P = horsepower D = 0.29 4 T or D = 4.6 4 P N T = torque, in-lb N = speed, rpm Page 2 This file is only for viewing and printing. Contents are not allowed to be edited. D = 2.26 4 T For SI units: Where: D = diameter, mm N = speed, rpm or D = 125.70 4 P N P = power, watts T = torque, N-mm B. Shaft deflection of 1 degree for a length of 20 times its diameter. D = 0.10 3 T or D = 4.0 Where: P = power, hp N = speed, rpm 3 P N D = diameter, in T = torque, in-lb C. Linear deflection of shafting a. Shafting subjected to no bending action of pulleys except its own weight b. Shafting subjected to bending action of pulleys, etc Where: L = shaft length, ft II. L = 8.95 3 D2 L = 5.2 3 D2 D = shaft diameter, in KEYS A key is a machine member employed at the interface of a pair of mating male and female circular cross-sectional members to prevent relative angular motion between these mating members. Types of keys: 1. Square key 2. Flat key 3. Round key 4. Barth key 5. Woodruff key 6. Gib-head key 7. Saddle key 8. Kennedy key 9. Feather key Page 3 This file is only for viewing and printing. Contents are not allowed to be edited. FORMULAS: 1. Power of key: P = 2p T N, KW 2. Force transmitted, F where: F = T = T r d/ 2 d = shaft diameter Fc (h / 2)L 3. Compressive Stress (Sc) of key Sc = 4. Shearing Stress (Ss) of key Ss = Fs wL where: L = length of key w = width of key h = height of key 5. Relation of key and shaft for the same material: w = D 4 L = 1.2 D 6. Force tangent to pulley rim T = T’ F . r = F’ . R 7. Ff = force tends to remove key from the hub and shaft = 2 f F F = force tangent to the key F’ = force tangent to pulley rim R = radius of pulley III. SPLINE SHAFT Is recommended when the power transmitted is too high that three keys are not enough. 1. Types of Fits Types of Fits Permanent Fit To slide when not under load To slide when under load 6 Splines 4 Splines 10 Splines d = 0.9D w = 0.25D h = 0.05D d = 0.85D w = 0.25D h = 0.075D d = 0.80D w = 0.25D h = 0.10D d = 0.85D w = 0.241D h = 0.075D d = 0.75D w = 0.24D h = 0.125D d = 0.91D w = 0.156D h = 0.045D d = 0.86D w = 0.156D h = 0.07D d = 0.81D w = 0.156D h = 0.095D Where: d = minor diameter, in or mm D = major diameter, in or mm r = radius, in or mm = d/2; R = D/2 w = width, in or mm L = length of spline Page 4 This file is only for viewing and printing. Contents are not allowed to be edited. 2. Rm = mean radius = r + R 2 Note: If L is not given use the recommended, L = 1.5 D, from Vallance, Machine Design 3. Calculations for safe dimensions of splines: 3.1 Based on shearing of splines Ss = F F = A s Ns w L Since Ts = Fæç d ö÷ or F = 2 T d è2ø 3.2 Based on Compression between splines and hub. Sc = Flange F F = Ac h L Ns T F NS = number of splines Dc Ac = compressive area r +R ) Tc = F Rm = F( 2 or F = 2Tc / ( r +R) 2 Shaft Bolt F = compressive force 3.3. Based on Torsion of splined Shaft Ss = Note: For torque capacity, T for one spline is: 16 Tt p d3 T= Tt (1.1) Ns This recommendation is based by shearing one spline only. IV. T FLANGE COUPLING Fb 1. Coupling - is a mechanical device which is used to connect length of shafts permanently. Dc FORMULAS: 1. Power transmitted: P = 2 p T N , KW 2. Total force transmitted, (F) F = T T = r Dc / 2 Shear Area Page 5 This file is only for viewing and printing. Contents are not allowed to be edited. 3. Force transmitted per bolt, (Fb) Fb = F n Flange where: n = no. of bolts Dc = bolt circle diameter 4. Shearing of bolts(Ss) Ss = Fb p 2 d 4 Dc 5. Compressive stress on bolts and flange (Sc) F Sc = b td where: t = thickness of flange Compressed Area d = bolt diameter PROBLEMS: SHAFTING 1. A line shaft is to transmit 200 HP at 900 rpm. Find the diameter of the shaft. A. 2.18 in B. 2.28 in C. 3.18 in D. 3.28 in 2. A 1/4 in diameter solid shaft has an allowable stress of 6000 psi and is subjected to pure torsion. If its rotational speed is 1800 rpm, how much horsepower can it transmitted safely? A. 0.425 hp B. 0.225 hp C. 0.316 hp D. 0.525 hp 3. Determine the thickness of hollow shaft having an outside diameter of 100 mm if it is subjected to a maximum torque of 5,403.58 N-m without exceeding a shearing stress of 60 MPa or a twist of 0.5 degree per meter length of shaft G=83,000 MPa A. 15 mm B. 86 mm C. 76.8 mm D. 69.96 mm 4. An 80 mm solid shaft is to be replaced with a hallow shaft of equal torsional strength. Find percentage of weight saved, if the outside of the hallow shaft is 100 mm. A. 56.53% B. 67.31% C. 48.49% D. 52.90% 5. A round steel shaft to a torque 200 rpm and is subjected to a torque of 226 N-m, the allowable shearing stress 41.4 MPa. It is also subjected to a bending moment of 339 N-m. The allowable tensile stress is 55 MPa. Find the diameter. A. 37 mm B. 41 mm C. 45 mm D. 51 mm KEYS & COUPLING 1. A rectangular key was used in a pulley connected to a line shaft with a power of 10 KW at a speed of 1200 rpm. If the shearing stress of the shaft and key are 30 N/mm2 and 240 N/mm2, respectively. What is the key length if the width is 10 mm? A. 18.7 mm B. 21.7 mm C. 25.8 mm D. 30.2 mm 2. A flange bolt coupling consists of eight steel 20 mm diameter steel bolts spaced evenly around a bolt circle 300 mm in diameter. if the coupling is subjected to a torque of 15.1 KN-m, determine the maximum shearing stress in the bolts? A. 40450 kPa B. 63320 kPa C. 40054 kPa D. 31298 kPa Page 6 This file is only for viewing and printing. Contents are not allowed to be edited. 3. A flange coupling having 180 mm bolt circle and 19 mm thick uses 8 bolts, 16 mm diameter to connect two shafts. It is used to transmit 60 kw at 180 rpm. Determine the factor of safety in compression if yield point in compression is 448 MPa. A. 15.6 B. 30.8 C. 18.5 D. 25.4 Page 7 This file is only for viewing and printing. Contents are not allowed to be edited.