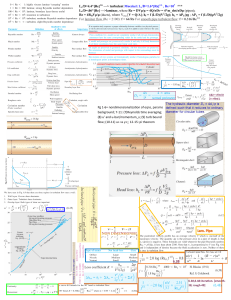

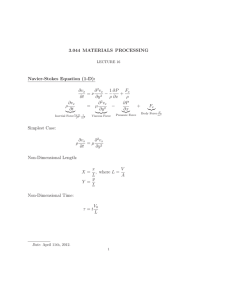

PROBLEM 5.7 KNOWN: Diameter and initial temperature of steel balls cooling in air. FIND: Time required to cool to a prescribed temperature. SCHEMATIC: D = 0. 01 m h = 25 W/m2• K ASSUMPTIONS: (1) Negligible radiation effects, (2) Constant properties. ANALYSIS: Applying Eq. 5.10 to a sphere (Lc = r o /3), = Bi 2 hLc h ( ro / 3) 25 W/m ⋅ K ( 0.005 m/3) = = = 0.001. k k 40 W/m ⋅ K Hence, the temperature of the steel remains approximately uniform during the cooling process, and the lumped capacitance method may be used. From Eqs. 5.4 and 5.5, t = t= ( ) 3 Ti − T∞ ρ p D / 6 cp Ti − T∞ ln ln = hAs T − T∞ T − T∞ hp D 2 ρ Vcp 7800 kg/m3 ( 0.01 m ) 600 J/kg ⋅ K 6 × 25 W/m 2 ⋅ K ln 1150 − 325 450 − 325 = t 589 = s 0.164 h COMMENTS: Due to the large value of T i , radiation effects are likely to be significant during the early portion of the transient. The effect is to shorten the cooling time. < PROBLEM 5.9 KNOWN: The temperature-time history of a pure copper sphere in a hydrogen stream. FIND: The heat transfer coefficient between the sphere and the hydrogen stream. SCHEMATIC: T(0) = 75°C T(97s) = 55°C D = 20 mm ASSUMPTIONS: (1) Temperature of sphere is spatially uniform, (2) Negligible radiation exchange, (3) Constant properties. 3 PROPERTIES: Table A-1, Pure copper (338 K): r = 8933 kg/m , cp = 384 J/kg⋅K, k = 399 W/m⋅K. ANALYSIS: The time-temperature history is given by Eq. 5.6 with Eq. 5.7. θ (t) t exp − where = θi R t Ct 1 p D2 Rt = As = hAs p D3 C t r= Vcp V = 6 θ= T − T∞ . Recognize that when t = 97 s, θ (t) = θi ( 55 − 27 ) C = ( 75 − 27 ) C t 0.583 = exp − tt 97 s = exp − tt and solving for t t find t t = 180 s. Hence, = h ρ Vcp = Ast t ( ) 8933 kg/m3 p 0.023 m3 / 6 384 J/kg ⋅ K p 0.022 m 2 ×180 s = h 63.5 W/m 2 ⋅ K. COMMENTS: Note that with Lc = Do/6, Bi = hLc 0.02 = 63.5 W/m 2 ⋅ K × m/399 W/m ⋅ K = 5.3 ×10-4 . k 6 Hence, Bi < 0.1 and the spatially isothermal assumption is reasonable. < PROBLEM 6.8 KNOWN: Smooth flat plate with either laminar or turbulent conditions starting at the leading edge. Corresponding heat transfer coefficient correlations. FIND: Average heat transfer coefficients for both conditions for plates of length L = 0.1 m and 1 m. SCHEMATIC: Laminar: hx = 1.74 W/m1.5·K x—0.5 Turbulent: hx = 3.98 W/m1.8·K x-0.2 T∞, u∞ Laminar or turbulent conditions L= 0.1 m or 1 m x ASSUMPTIONS: (1) Steady-state conditions, (2) Two-dimensional flow and heat transfer. ANALYSIS: The average heat transfer coefficient is defined as: hL = 1 L hx dx L ∫0 For laminar flow, hx = Alam x −0.5 where Alam 1.74 W/m1.5 ⋅ K. Thus, = h= L ,lam Alam L ∫ L 0 0.5 x −= dx 2 Alam 0.5 L 2 Alam 3.48 W/m1.5 ⋅ K x= = 0 L L0.5 L0.5 The results for the two plate lengths are: 11.0 W/m 2 ⋅ K, L = 0.1 m hL ,lam = 2 1m 3.48 W/m ⋅ K, L = < For turbulent flow, hx = Aturb x −0.2 where = A 3.98 W/m1.8 ⋅ K. Thus, turb hL ,turb = Aturb L ∫ L 0 −0.2 x= dx Aturb 0.8 L Aturb 4.98 W/m1.8 ⋅ K x = = 0 L0.2 0.8 L 0.8 L0.2 The results for the two plate lengths are: 7.88 W/m 2 ⋅ K, L = 0.1 m hL ,turb = 2 1m 4.98 W/m ⋅ K, L = < COMMENTS: For L = 1 m, the turbulent heat transfer coefficient is larger than the laminar one, as is usually the case. However, for L =0.1 m, the situation is reversed. PROBLEM 6.24 KNOWN: Heat transfer rate from a turbine blade for prescribed operating conditions. FIND: Heat transfer rate from a larger blade operating under different conditions. SCHEMATIC: ASSUMPTIONS: (1) Steady-state conditions, (2) Constant properties, (3) Surface area A is directly proportional to characteristic length L, (4) Negligible radiation, (5) Blade shapes are geometrically similar. ANALYSIS: For a prescribed geometry, Nu = hL = f ( ReL , Pr ) . k The Reynolds numbers for the blades are = ReL,1 V1L1 / ν ) (= 15 / ν = ReL,2 ( V= 2L2 /ν ) 15 / ν . Hence, with constant properties, ReL,1 = ReL,2 . Also, Pr1 = Pr2 . Therefore, Nu 2 = Nu 1 ( h 2L2 / k ) = ( h1L1 / k ) L1 L1 q1 = h2 = h1 . L2 L 2 A1 Ts,1 − T∞ ( ) Hence, the heat rate for the second blade is ( ( ) ) L1 A 2 Ts,2 − T∞ q1 L 2 A1 Ts,1 − T∞ Ts,2 − T∞ ( 400 − 35) 1500 W q2 = q1 = ( ) Ts,1 − T∞ ( 300 − 35) ( ) q 2 h 2 A 2 Ts,2 −= T∞ = q 2 = 2066 W. < COMMENTS: The slight variation of ν from Case 1 to Case 2 would cause Re L,2 to differ from Re L,1 . However, for the prescribed conditions, this non-constant property effect is small.