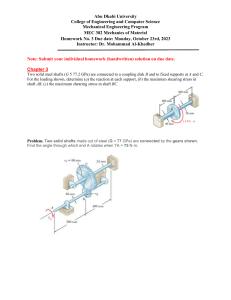

Design of Shafts MaE 4043 – Design of Machine Elements 8/10/2023 MaE 4043 - Design of Machine Elements - KH 1 Outline • Introduction • Types of shafts • Standard sizes of shafts • Design of Shafts • • • • • Design considerations Stresses in shafts Design of shafts on the basis of strength Design of shafts on the basis of rigidity Design of shafts for fatigue 8/10/2023 MaE 4043 - Design of Machine Elements - KH 2 Introduction • • • • Shaft is a machine element used for power transmission Transmit power by twisting Other machine elements such as Pulleys and gears are mounted on shafts Shafts usually have circular cross-section 8/10/2023 MaE 4043 - Design of Machine Elements - KH 3 Transmission Shafts • Transmit power between the source and the machine e.g. Line shaft, propeller shaft Line Shaft Propeller Shaft Machine Shafts • Shafts which are integral part of a machine e.g. Crank shaft Mounting of Shafts … 8/10/2023 MaE 4043 - Design of Machine Elements - KH 6 Standard Sizes … The following are the common sizes (in mm) of the transmission shafts: 25, 30, 35, 40, 45, 55, 60, 70, 80, 90, 100, 110, 125, 140, 160, 180, 200, 220, 240, 260, 300, 320, 340, 360, 380, 400, 420, 440, 460, 480, 500. Machine shaft sizes vary from: • 10 to 75mm by increment of 5mm • 40 to 100mm by increment of 5mm The maximum length of shaft usually does not exceed 7m 8/10/2023 MaE 4043 - Design of Machine Elements - KH 7 Design of Shafts Shafts must be designed so that: • The deflections are within acceptable levels • High deflections cause noise and vibration while in operation • Critical speed • Start vibrating violently Design Considerations: • Size and spacing of components, tolerances • Type of material to be used • Deflection and rigidity • Stress and strength (static strength, fatigue, reliability) • Type of loading (static, shock or cyclic) • Manufacturing constraints 8/10/2023 MaE 4043 - Design of Machine Elements - KH 8 Typical Shaft Loading and Deflection 8/10/2023 MaE 4043 - Design of Machine Elements - KH 9 Design of Shafts Based on Strength: Stresses in Shafts • • • 8/10/2023 Shear stresses due to torsional load Bending stresses due to the forces coming from gears, pulleys, etc. Stresses due to combined torsional and bending loads MaE 4043 - Design of Machine Elements - KH 10 Shafts Subjected to Twisting Moment Only A line shaft rotating at 200 r.p.m. is to transmit 20 kW. The shaft may be assumed to be made of mild steel with an allowable shear stress of 42 MPa. Determine the diameter of the shaft, neglecting the bending moment on the shaft. If a hollow shaft is to be used in place of the solid shaft, find the inside and outside diameter when the ratio of inside to outside diameters is 0.5. 8/10/2023 MaE 4043 - Design of Machine Elements - KH 11 Shafts Subjected to Bending Moment Only A pair of wheels of a railway wagon carries a load of 50 kN on each axle box, acting at a distance of 100 mm outside the wheel base. The gauge of the rails is 1.4 m. Find the diameter of the axle between the wheels, if the stress is not to exceed 100 Mpa. 8/10/2023 MaE 4043 - Design of Machine Elements - KH 12 Combined Twisting Moment and Bending Moment • Shaft should be designed by taking two moments simultaneously • Maximum shear stress theory – ductile materials • Maximum normal stress theory – brittle materials Example A solid circular shaft is subjected to a bending moment of 3000 N-m and a torque of 10 000 N-m. The shaft is made of 45 C 8 steel having ultimate tensile stress of 700 MPa and an ultimate shear stress of 500 MPa. Assuming a factor of safety as 6, determine the diameter of the shaft 8/10/2023 MaE 4043 - Design of Machine Elements - KH 13