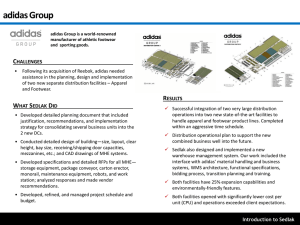

Adidas Apparel Safety Stock Thesis: Probabilistic Demand Model

advertisement