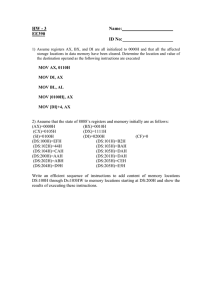

The Story of the Varistor and the Often-Unappreciated Ways It Can Fail How and Why Varistor Failure Occurs Including the Effect of Multipulse Surges - In Compliance Magazine The year was 2011, and an experiment was being done in China to record the effects of a triggered lightning flash on an overhead transmission line. The line was instrumented to record the induced currents, and the instruments were protected with a metal oxide varistor (MOV). A varistor is often called an MOV (Metal Oxide Varistor). The lightning flash recorded consisted of multiple return strokes, none of which exceeded the Imax rating of the MOV. But, much to the surprise of the experimenters, the MOV was damaged. How could this happen? And more importantly, why might Imax not be a good basis for selecting an MOV for lightning protection, and are there alternatives? To help answer these questions, we’ll discuss in this article what an MOV is and how the way it is made influences its behavior when surged, how failures occur, and how multipulse surges differ from single surges in their effect on MOV properties. Varistor Basics In order to understand failure, it’s useful to discuss how varistors are made. In this regard, there are three things of note. First, varistors are a ceramic material composed primarily of zinc oxide (ZnO). At ambient conditions, ZnO crystallizes into a hexagonal wurtzite structure, as shown in Figure 1, where the large balls represent Zn and the small balls represent oxygen (O). This is a complicated structure that, if it crystallized perfectly, would be an insulator. But because the crystallization process isn’t perfect, the resulting oxygen vacancies or zinc interstitials cause this structure to become a wide-gap semiconductor having a relatively low resistivity of 1 – 100 Ω-cm at room temperature. Figure 1: Wurt zite structure . The large balls r epresent Zn and the smaller balls rep resent o x ygen. Second, a varistor is not one uniform wurtzite crystal, but many which coalesce into grains. To make ZnO into a varistor, a small amount of Bi2O3 is added. The Bi2O3 goes into the grain boundaries, as shown in Figure 2. In addition to Bi2O3, MnO may be added to enhance the nonlinear properties; Sb2O3 to control the ZnO grain growth, and a small amount of Al2O3 to increase the ZnO grain conductivity. Figure 2: Typical micrograph of varistor structure The Bi2O3 between two ZnO grains results in the formation of back-back Schottky diodes. So essentially, a varistor is a series-parallel arrangement of n-type material separated by back-back Schottky diodes having a voltage drop of about 2V-3V per grain boundary Junction (independent of grain size). According to He [1], this structure can be characterized electrically by Equation (1). (1) Where V is the applied voltage and I is the current through the varistor. Here, E, A 1, A2, Vth and m are constants related to the electrical characteristics of varistor, and α is the usual nonlinear coefficient of the varistor. Equation (1) is useful for explaining the shape of the varistor V-I curve. E is the excitation energy of varistor, K Boltzmann’s constant, A1, A2, and m are constants related to the electrical characteristics of varistor, Vth is the threshold voltage. The first term in Equation (1) is seldom included in the V-I description of a varistor. It is the Schottky emission current in the low current region of the varistor. The second term is the usual nonlinear current in the high current region. The constants in Equation (1) are controlled by varying the composition of the varistor material and sintering time of the manufacturing process. The threshold voltage Vth also depends on composition and sintering conditions. These control the number of grain boundaries between the two electrodes. Since Vth is proportional to the number of grain boundaries, more grain boundaries result in a higher Vth. Third, this variation in the varistor fabrication process and the accompanying statistical fluctuations in properties that generally occur in polycrystalline materials cause the resulting varistors to have inhomogeneous electrical properties. That suggests that: 1. 2. The constants in a varistor model like Equation (1) are likely to be different for every varistor; and Not all varistors of the same dimensions have the same properties – an important consideration when choosing a MOV for protection. Varistor Failure Varistors need to absorb the energy deposited by temporary overvoltage, switching surges, or lightning impulses. Experiments show that differences in grain sizes and grain boundary characteristics cause nonuniform microstructure. Nonuniform microstructure results in the variability of varistor current handling capabilities and related energy absorption capability. That in turn has a direct relation to failure modes, which include electrical puncture, physical cracking, and thermal runaway. The energy absorption capability can be divided into thermal energy absorption capability and impulse energy absorption capability. Impulse energy absorption capability depends on how the impulse is applied: o o o Single impulse stress Multiple impulse stress (without sufficient cooling between the impulses) Repeated impulse stress (with sufficient cooling between the stresses) Thermal energy absorption capability, on the other hand, is mainly affected by the heat dissipation capability of the overall arrester design, in addition to the electrical properties of the varistors. Figure 3: Typical micrograph of grain boundary hot spots Let’s first consider varistor failure caused by heating. At lower currents, the heating localizes in strings of tiny hot spots, which occur at the grain boundaries where the potential is dropped across Schottky-type barriers (see Figure 3). The heat transfer in this case is too fast to permit temperature differences that could cause failure. Now consider higher currents. In small varistors (e.g., <25 mm) where the number of ZnO grains between the electrodes might be only about 40, a variation of 3 – 4 grains can cause the current flow in a given path to be an order of magnitude different from surrounding paths. The paths with low breakdown voltages carry most of the current and become hotter, with consequences noted in the study of Sargent et al [4]. In that study, analysis of the failed MOV samples showed cracking and a formation of new amorphous material near the conduction channel. Examination of this amorphous material suggested that local hot spots (actually hot channels) were formed when the energy resulting from a current pulse applied to the MOV was absorbed faster than it could be dissipated. The amorphous material in these hot spots likely resulted from a plasma formed during the current pulse. The hot spots rapidly cooled afterward due to heat conduction to the surrounding ZnO grains. Under different current conditions, failure modes include electrical puncture (see Figure 4), physical cracking (see Figure 5), and thermal runaway. Cracking happens because varistors are basically a ceramic material, and hitting them with a sharp high-amplitude surge is like hitting a dinner plate with a hammer. Figure 4: Typical micrograph of a puncture Figure 5: Typical crack formation Puncture destruction occurs in small varistors when the current is relatively low and of long duration (for example, see Figure 6). The net effect is that the varistor heats up. The analysis of a puncture in these varistors strongly indicates that a filament forms with temperatures high enough to melt the Bi2O3 (817o C). When this happens the back-to-back Schottky diodes are destroyed, resulting in reduced filament resistance [1]. Reduced filament resistance permits higher current density, sometimes causing a high enough temperature to melt the ZnO (2000o C). Figure 6: Example of current d ensity and pulse duration com binations that cause failure in varistors. This plot is fo r a specific varistor. For any other varistor , the scales could be different f rom those shown. If the current is continued long enough, the energy deposited in the varistor may raise its temperature to the point of thermal runaway due to the material’s negative temperature coefficient of resistivity [1]. Most high impulse currents with short duration can cause a cracking failure (see Figure 5), which typically occurs at the edge of the varistor, since the temperature increases more at the edge of the chip (the white area in Figure 7). The reason is that grain growth during sintering is often more rapid in the outer part of the block than in the center of the block, resulting in fewer and larger grains between the electrodes, and hence a lower breakdown voltage. Figure 7: Typical thermal scan of a varistor pulsed under hi gh current Figure 6 illustrates the conditions under which cracking and puncture can occur. For a given varistor the red solid line shows cases under which cracking might occur, and the black dashed line cases under which puncture might occur. Failures Due to Multipulse Lightning Why are we talking about multipulse lightning? Well, lightning observations and artificially triggered lightning data summarized in [6] show that nearly 70% of cloud-to-ground lightning strokes involve from two and up to 26 strikes. These strikes have a geometric mean interstroke interval of about 60 ms. They can also have a long continuing current with an interstroke interval as large as several hundreds of milliseconds. A typical multipulse sequence is illustrated in Figure 8. Figure 8: Example of a multipulse lightning flash Multipulse lightning of the type just described is important because it is capable of producing the temperature rises that lead to the kind of failures just discussed, whereas a single surge might not. For example, in the study by Sargent et al [4], half a set of 18 mm MOV samples were subjected to a multipulse burst of 8/20 surges at rated current. These samples showed signs of damage, whereas the other half of the samples tested with a single 8/20 surge at rated current repeated at intervals of 60 seconds or more showed no damage. In another multipulse burst test, Rousseau et al [7] subjected a MOV to 60 20 kA 8/20 surges spaced 60 seconds apart, with no failure. But when the same type of MOV was subjected to as few as five 20 kA 8/20 surges spaced 50 ms apart, failure occurred. In these cases, varistor failure was likely caused by heat accumulation due to the relatively long thermal time constant of varistors (Figure 9), illustrated for a single surge using thermal modeling as shown in Figure 10 (for details, see [8]). Figure 9: Thermal time constan t of a varistor Figure 10: Example of tempera ture rise in a 25 mm MOV sub jected to one 10 /63 6 kA surge As noted previously, in the study of Sargent et al, analysis of the failed 18 mm MOV samples subjected to a multipulse burst test showed the formation near the conduction channel of a new amorphous material, which was thought to require a local temperature around 1000o C. Thermal modeling suggested that this temperature rise would occur if the pulse power was concentrated in about 2% of the MOV volume. This is an important observation because a calculation of the energy absorbed in the multipulse burst test showed that the temperature rise of the MOV would only have been 231o C if the temperature distribution were uniform, much less than the temperature thought to have caused the damage. The results of Sargent et al suggest that the criterion for failure of an MOV is a localized temperature rise to 1000o C (or the vicinity thereof). So for an MOV under consideration, we need to determine if a localized area might reach 1000o C. Figure 11 shows the additional temperature rise that happens when the surge used to create Figure 10 is applied to the same MOV a second time after 30 ms. The additional temperature rise is due to the relatively long thermal time constant of the MOV, which prevents the MOV from dissipating much heat energy (and hence cooling) before the second surge arrives. The temperature rise is now in the red area above 1000o C, where failure is expected. So this is an example of how a varistor can be destroyed by multipulse surges. Figure 11: Example of tempera ture rise for a 25 mm MOV sub jected to two 10/63 6 kA sur ge s In another look at the effects of multipulse lightning, a study by Zhang et al [5] explored the progression of failure in varistors under multiple lightning strokes, using a series of five-pulse groups of 8/20 lightning surges having pulse intervals of 50 ms and pulse amplitudes set at the 20 kA nominal discharge current. The time between the application of one group of impulse currents to a varistor and that of the next group of impulse currents was 30 minutes, allowing a return to the original conditions. Varistors were judged as having failed when a change greater than ±10% of the original varistor voltage U 1mA; the leakage current Iie exceeded 20 µA; or direct damage occurred (typically by edge cracking). The average level change of the U 1mA and Iie for the series of impulse groups is shown in Figure 12. Figure 12: Varistor vol tage U 1 m A and leakage current I i e vari ation of the varisto rs under multiple lightning impulse current (source: Zhang e t al [5 ]) Figure 12 shows that in the absence of continuing current a single multipulse burst didn’t deliver enough energy to the MOV to cause failure. Repeated application of the multipulse burst did eventually lead to failure. So it is possible that a single non-destructive multipulse burst conditions the MOV for failure from future multipulse bursts, as suggested by the continually increasing leakage current. This conditioning could be viewed as a kind of accelerated wear-out process. Microstructural examination of the failed varistors indicated that after the multiple lightning strokes, the grain size decreased and the proportion of Bi in the grain boundary layer increased significantly. These effects were the cumulative result of multiple lightning currents, and were caused by thermal damage and grain boundary structure damage due to temperature gradient thermal stress. This damage eventually led to failure of the MOV. Note that a single surge test would miss this wear-out mechanism. Comments It appears that repeated surging of an MOV alters its microstructure, and understanding how that happens is important to understanding how MOVs fail. Which raises some questions. In particular, is the microstructure degradation cumulative as suggested by the current plot in the previous figure? Or are the effects of degradation obscured until it reaches a critical point as suggested by the voltage plot in the previous figure? The answer is likely to depend on the magnitude and spacing of the surges, and there may be a threshold of surge magnitude and surge spacing below which no significant degradation occurs. More research is needed to answer the questions. High amplitude short-duration single pulse tests (e.g., 6 kV, 3kA 8/20) are typically used to evaluate varistor failure. This type of test may cause a failure mode different from that in a varistor subjected to multipulse lightning at lower amplitude (e.g., cracking vs. wear-out). Single-pulse tests could also miss heat accumulation failures that multipulse lightning can cause, especially multipulse lightning that includes continuing current. Case in Point Back to the failure described at the beginning, a triggered lightning flash having multiple return strokes was recorded during a lightning Experiment. This flash damaged the SPD even though the Imax rating of the SPD (determined by a single surge test) was much higher than the recorded lighting peak current [9]. Why? As pointed out in [10], what caused failure was the continuing current part of the multipulse sequence, and continuing current is not comprehended in the Imax rating. The continuing current deposited enough energy in the MOV to fail it. Another Consideration Since we generally live in a multipulse lightning flash environment, the typical derating plot (created with single surges) as shown in Figure 13 would need to be altered if it is to be used for an MOV that has been installed to protect against multipulse lightning. In particular, the lines in Figure 13 resulting from the (repeated) application of single surges would likely need to be lowered to take into account the microstructural degradation effect suggested by the studies of Zhang et al [5]. A multipulse derating plot could be created by repeating Zhang’s multipulse group test in the same way as used to create the derating figure Figure 13, but now using multipulse groups instead of single surges. So, for example, for the one-hit line, a group of surges with a relatively narrow waveshape would be applied at a current that would cause failure on the second application. The process would then be repeated using groups of surges with wider waveshapes. The result would be something like the top line in Figure 13. Figure 13: Typical derating curves fo r an MOV Similarly, the amplitude of the current would be decreased such that a for the two-hit line, a second group of surges would cause failure on the third application, and the process repeated using groups of surges with wider waveshapes. This process would be continued until enough lines had been generated to adequately characterize the product. Final note For more information about varistors, see IEEE PC62.33 ™ Standard for Test Methods and Performance Values for Metal-Oxide Varistor Surge Protective Components [11]. Summary The varistor fabrication process and the statistical fluctuations in properties that generally occur in polycrystalline materials cause varistors to have inhomogeneous electrical properties. The result is that a few conducting paths with low breakdown voltages to carry most of the current and become hotter. If the temperature of these paths reaches the vicinity of 1000o C, melting occurs and the MOV is destroyed. In the case of 18 mm MOVs, this temperature rise would occur if the inhomogeneities in the MOV cause the pulse power to be concentrated in about 2% of the MOV volume (the 2% may differ in other sizes of MOVs). This temperature rise could be the cause of puncture failure, noted for the case of long-duration lower amplitude surges. In the case of short-duration high amplitude surges, MOV failure may occur by cracking before melting happens. Single short-duration high amplitude surges might occur on power lines, so MOV ratings established this way can be appropriate for power-line applications For protection against lightning, ratings established by multipulse testing may be more important. This is because a multipulse lightning surge is often the driver for the temperature rise since it causes energy to accumulate in the MOV due to its long thermal time constant. This is why multipulse testing is important since a single surge test might miss failures that multipulse lightning can cause, notably wear-out, and especially multipulse lightning that includes continuing current. And most lightning is of the multipulse type. The microstructure degradation effect of repeated multipulse surges may need to be considered when constructing derating curves. Understanding the mechanism of how surging an MOV alters its microstructure is important to understanding how MOVs fail. It is a topic that needs further research. References 1. 2. 3. 4. 5. 6. 7. 8. 9. Jinliang He, Metal Oxide Varistors: From Microstructure to Macro-Characteristics, John Wiley and Sons, 2019 M. Bartkowiak, “Current Localization, Non-Uniform Heating, and Failures oF ZnO Varistors,” Fall Meeting of the Materials Research Society, Boston, MA, December 1-5, 1997 Gordon Pike, “Breakdown in ZnO Varistors by High Power Electrical Pulses,” Sandia Report SAND2001-2160, July 2001. R. A. Sargent, G. L. Dunlop, and M. Darveniza. “Effects of Multiple Impulse Currents on the Microstructure and Electrical Properties of Metal-oxide Varistors”, IEEE Transactions on Electrical Insulation Vol. 27 No. 3, June 1992. Chunlong Zhang, Hongyan Xing, Pengfei Li, Chunying Li, Dongbo Lv and Shaojie Yang, “An Experimental Study of the Failure Mode of ZnO Varistors Under Multiple Lightning Strokes,” Electronics, February 2019. CIGRE WG C4.407, “TB549 Lightning Parameters for Engineering Applications,” 2013. A. Rousseau, X. Zhang, and M. Tao, “Multiple Shots on SPDs – Additional Tests,” International Conference on Lightning Protection (ICLP), Shanghai, 2014. A.R. Martin, “Effects of Multi-burst Lightning Flashes on Surge Protective Devices using MOVs,” In Compliance Magazine, November 2017, pp32-39. S. J. Yang, S. D. Chen, Y. J. Zhang, W.S. Dong, J. G. Wang, M. Zhou, D. Zheng, and H. Y Hui, “Triggered Lightning Analysis Gives New Insight into Over Current Effects on Surge Protective Devices,” http://www.ten350.com/papers/icae-conghua.pdf, 2011. 10. M. Maytum, “CIGRÉ (Council on Large Electric Systems) Technical Bulletin (TB) 549 (2013) Lightning Parameters for Engineering Applications,” The Alliance for Telecommunications Industry Solutions Protection Engineers Group Conference, Littleton, CO, 2014. 11. IEEE PC62.33 ™ Standard for Test Methods and Performance Values for Metal-Oxide Varistor Surge Protective Components Distinguishing between Surge- and Temporary Overvoltage-Related Failures of Metal Oxide Varistors in End-Use Equipment Designs Distinguishing between Surge- and Temporary Overvoltage-Related Failures of Metal Oxide Varistors in End-Use Equipment Designs | Interference Technology Equipment failure resulting from TOVs can be reduced by proper coordination of the line fuse and MOV. Philip F. Keebler, Kermit O. Phipps and Doni Nastasi EPRI Solutions Knoxville, Texas, USA Real world electrical environments in residential, commercial, and industrial facilities experience the gamut of undervoltage and overvoltage disturbances. Examples of undervoltage disturbances include voltage sags, momentary interruptions, and long-term undervoltages. Examples of overvoltage disturbances include surges and temporary overvoltages (TOVs). There are also a number of surge sub-categories—ring wave surges and combination wave surges, for example. Ring wave surges typically do not cause damage to line fuses and metal oxide varistors (MOVs). The combination wave surge, on the other hand, typically does cause line fuse and MOV damage and failure in end-use equipment. MOVs are designed to dissipate the energy that results from a surge voltage. This energy is a product of the clamping voltage and the resulting flow of surge current when the MOV clamps the surge voltage. With proper coordination of the line fuse and MOV, equipment can be protected from multiple ring wave and combination wave surges of less than 4,000 volts. MOVs are not designed to protect equipment from TOVs, but equipment failure resulting from short duration and lower magnitude TOVs may be reduced by proper coordination of the line fuse and MOV. This article first discusses the industry standard definitions for a surge and a TOV and describes the basic overcurrent and overvoltage protection circuits used in enduse equipment. Next, the article describes some characteristics of real MOV failures caused by surges and TOVs and provides some brief discussion on the coordination of line fuses and MOVs. Finally, the article presents a basic approach for determining how a line fuse and MOV will react to surges and TOVs, followed by actual test data. This information can be useful to equipment designers in determining the cause of line fuse and MOV failures and in sizing the line fuse and MOV to provide adequate protection against surges and thus reduce nuisance equipment failures that can drive up the cost of repairs and warranty claims. WHAT IS A SURGE VERSUS A TEMPORARY OVERVOLTAGE? Because TOVs and surges are both overvoltages and can cause damage to equipment, beginning equipment designers just becoming familiar with the different types of overvoltage electrical disturbances in the areas of power quality and system compatibility engineering may confuse a TOV with a surge. Also, designers may not be familiar with TOVs. A TOV can easily be confused with a surge. To distinguish the differences, let’s start by examining the industry standard definitions developed by the IEEE for both surges and TOVs. SURGE DEFINITIONS Because surges are the result of natural and man-made electrical phenomenon and are present on different types of power and signal circuits in the electrical environment, the word surge is defined in various IEEE surge-related standards as it applies to specific electrical environments and/or equipment. Examples of these standards include those under the auspices of the IEEE Power Engineering Society (PES), namely several of the C62 standards [including the recently revised Trilogy sponsored by the Surge Protective Devices (SPD) Committee], the IEEE Standard 100-2000 – The Authoritative Dictionary of IEEE Standards Terms, and the IEEE Standard 1250-1995 (R2002) – IEEE Guide for Service to Equipment Sensitive to Momentary Voltage Disturbances. The Trilogy includes three documents: IEEE Standard C62.41.1-2002 – IEEE Guide on the Surge Environment in Low-Voltage (1000 V and Less) AC Power Circuits IEEE Standard C62.41.2-2002 – IEEE Recommended Practice on Characterization of Surges in Low-Voltage (1000 V and Less) AC Power Circuits IEEE Standard C62.45-2002 – IEEE Recommended Practice on Surge Testing for Equipment Connected to Low-Voltage (1000 V and Less) AC Power Circuits The IEEE Standard C62.41.1-2002 is the document that provides the best comprehensive technical definition and description of surges and TOVs. According to IEEE Standard C62.41.1-2002, the word surge has the following definition: Definition 1: “A transient wave of current, potential, or power in an electric circuit. NOTE: The use of this term to describe a momentary overvoltage consisting of a mere increase of the mains voltage for several cycles is deprecated. Comment: This is a generalized definition of surge. For power systems, surge (also called a transient) is a subcycle overvoltage with a duration of less than a half-cycle of the normal voltage waveform. A surge can be of either polarity, can be additive to or subtractive from the normal voltage waveform, and is often oscillatory-decaying.” IEEE Standard C62.41.1-2002. According to IEEE Standard 100-2000, the word surge has the following definitions: Definition 2: “A transient voltage or current, which usually rises rapidly to a peak value and then falls more slowly to zero, occurring in electrical equipment or networks in service” (PE/PSIM1) 4-1995 Definition 3: “A transient wave of voltage or current. (The duration of a surge is not tightly specified, but it is usually less than a few milliseconds.)” ([T&D/PE/SPD2] 1250-1995, C62.34- 1996, C62.48-1995) Definition 4: “A transient wave of current, potential, or power in an electronic circuit.” ([SPD/PE3] C62.22-1997, C62.11-1999, C62.62-2000) Each of these definitions of the word surge was developed by the IEEE PES during various standards development activities. Definition 2 was developed for power systems instrumentation and measurements within power engineering. Here, surges that occur on the power system can affect instrumentation and measurement equipment used in the power system. Definition 3 was developed for transmission and distribution systems within power engineering and SPD applications. The previously mentioned IEEE 1250-1995 (R2002) also adopted this definition with reference to upsetting equipment sensitive to voltage disturbances. Definition 4 was also developed with application to SPDs within power engineering. Definition 4 is the more recent definition of the word surge as developed by the IEEE SPD committee within C62.41 and is most widely applied to end-use equipment. This definition defines a surge as a transient wave that can be a current, a potential, or a power wave. It is also described as a subcycle overvoltage event with a duration less than ½ cycle (i.e., 8.33 milliseconds for 60 hertz systems and 20 milliseconds for 50 hertz systems). Reviewing each of these definitions, one can see that a surge is technically described as a transient (i.e., short-lived disturbance) phenomenon of positive or negative polarity that can be representative of a rapidly rising voltage, current, and/or power, and that a surge may occur in the power system, electrical networks (e.g., facility power systems), and/or within equipment (i.e., end-use devices). TEMPORARY OVERVOLTAGE DEFINITIONS Temporary overvoltages (TOVs) are best defined in IEEE Standard 100-2000 and in IEEE Standard C62.41.1-2002. According to IEEE Standard 100-2000, a TOV is defined as: Definition 1: “An oscillatory phase-to-ground or phase-to-phase overvoltage that is at a given location of relatively long duration (seconds, even minutes) and that is undamped or only weakly damped. Temporary overvoltages usually originate from switching operations or faults (for example, load rejection, single-phase fault, fault on a high-resistance grounded or ungrounded system) or from nonlinearities (ferroresonance effects, harmonics), or both. They are characterized by the amplitude, the oscillation frequencies, the total duration, or the decrement. ([C/PE4] 1313.1-1996, C57.12.80-1978r) Definition 2: “An oscillatory overvoltage, associated with switching or faults (for example, load rejection, single-phase faults) and/or nonlinearities (ferroresonance effects, harmonics), of relatively long duration, which is undamped or slightly damped. ([SPD/PE] C62.22-1997)) Figure 1. Basic relationship between magnitude, duration, rate of change, and equipment damage for voltage disturbances. IEEE C62.41.1-2002 also defines surges and TOVs graphically on a magnitude- duration plot with respect to the duration of an event (in milliseconds) and the magnitude of an event (in volts). According to these definitions, surges are transients of positive and/or negative polarity with duration less than ½ cycle (e.g., a few microseconds to a few milliseconds), and TOVs are positive polarity events of long term duration ranging from seconds to minutes. In Figure 1, the surges cover a wider area on the magnitude-duration plot than TOVs. Surges incident upon enduse equipment (either through the AC power input or through communication or network cables) can damage, upset, or have no effect on equipment. TOVs are only incident upon the AC power input of equipment and typically cause damage to equipment. With respect to magnitude, surges reach much higher magnitudes in the few thousands volt range with the higher magnitude events occurring in the positive region of the plot—above the normal line voltage. TOVs reach much lower magnitudes in the overvoltage range within a few hundred percent of the line voltage with the higher magnitude events being of shorter duration than the lower magnitude events, but often with much higher energy effect. Figure 2. Basic AC power input protection circuit for end-use equipment. BASIC CIRCUIT PROTECTION Figure 3. Basic low-voltage protection circuit for enduse equipment. By design, MOVs are located in various circuitry locations of end-use equipment to provide protection of the equipment from surges. To provide protection against surges incident on the AC power input of equipment, they are located at the AC power input. Although most MOV applications are on AC power input circuits, like that shown in Figure 2, they may also be used on low-voltage control wiring such as in electrically activated lawn sprinkler systems and on the inputs of dimming circuits in electronic fluorescent and high-intensity discharge (HID) lighting ballasts like that shown in Figure 3. MOVs and other SPDs located on AC power inputs and low-voltage control circuits are vulnerable to failure. MOVs are designed to absorb the electrical energy contained in surges to prevent that energy from causing damage to active and passive electronic components located downstream of the line fuse and upstream of a connection to a DC low-voltage control circuit. Upon activation by a surge voltage incident upon the AC line input, for example, MOVs effectively reduce the surge voltage to levels that will not cause damage to electronic components. In the course of dissipating energy and reducing the surge voltage, MOVs heat up, As a result, the amount of temperature rise in an MOV is related to the amount of energy that the MOV must absorb from the surge. It is the area under the curve of the resulting surge power waveform that determines how much energy the MOV must absorb. Surges of higher voltage magnitude (e.g., 3.2 kilovolts) and shorter duration (e.g., 50 microseconds) will cause less MOV heating than surges of lower voltage magnitude (e.g., 1.3 kilovolts) and the same duration. Also, larger diameter (e.g., 20 millimeter) MOVs are designed to handle more surge energy than smaller diameter (e.g., 14 millimeter) MOVs. Figure 4. Location categories A, B, and C as defined in IEEE Standard C62.41.1-2002. In designing any MOV into end-use equipment, the energy- handling capability of the MOV is one critical factor in selecting the MOV for the application. For end-use equipment applications with a higher exposure to surges of higher energy, an MOV with a higher energy-handling capability will survive longer than an MOV with a lower energy-handling capability. If a proposed location for equipment is at a high exposure to surges of higher energy, such as Location Category C, where surge voltages in a facility are of a higher magnitude, in Figure 4, and if an MOV is undersized, then the MOV will likely fail. On the other hand, if an MOV is improperly sized for the expected surge exposure level such that it does not dissipate the resulting energy, then the equipment may still be at a high risk arising from the possible loss of the MOV. In the course of forensic analysis of failed equipment, is it possible to determine if the MOV failure was caused by surges or by TOVs? CHARACTERISTICS OF MOV FAILURES MOV failures result from the inability of the MOV to withstand the electrical energy applied to it during a surge. The energy that the MOV must absorb is a function of several variables including the maximum overvoltage occurring on line and the duration of the overvoltage. The energyhandling capability of the MOV is a function of the energy rating of= the MOV, which is a function of the diameter and thickness of the MOV, and the ability to remove the heat effectively before the MOV suffers permanent damage. Whether the overvoltage that occurs on the line voltage is a surge or a TOV, the MOV will begin to conduct current at some voltage level. The current that flows through an MOV during conduction is defined by the IEEE Standard C62.41.1 as the surge current. If the MOV must conduct current as a result of a TOV, then the resulting TOV initial current that flows may damage the MOV. As described earlier for the case of MOV conduction attributable to surge currents, MOV damage from conduction of TOV-initiated currents will depend upon how much TOV energy the MOV must dissipate. If the energy-handling capability of the MOV is exceeded, then the MOV will fail. After an MOV failure, the only way to tell whether the failure was caused by a surge or a TOV is physical inspection of the MOV and the line fuse. Little to no electrical properties will be present in an MOV after its failure. Thus, using a digital ohmmeter or an MOV tester will be virtually useless in determining the cause of an MOV failure after it has been removed from a piece of equipment. Physical inspection will require that the equipment be opened to reveal the protection circuitry on the AC power input section. Inspection of the line fuse is also necessary because the fuse also may or may not be damaged as a result of a surge or TOV. Most importantly, an opened fuse may be the result of one or more failed power electronic components in the equipment’s power supply or other power-related circuit inside the equipment with no involvement of surges, TOVs, or the MOV. After the fuse and MOV have been located, the investigator should determine if the fuse is open. If the MOV appears to be intact, then it can be removed and can be tested with an MOV tester. If the MOV test is acceptable, then it is likely that the equipment failure did not involve surges, TOVs, or the MOV. However, in testing the fuse, the investigator will need to use an ohmmeter to determine if the fuse element has been damaged and/or has opened. In most cases, it will be obvious that the fuse has been damaged as evidenced by a disintegrated fuse element and/or charred glass (if the fuse container is made of glass). In the case of some fuses, especially the ones with an inherent time delay, element damage can be “hidden”, and a visual inspection may not reveal the damage (i.e., the fuse may appear to be good, when it is actually bad).. In fuse failures, it is also possible that the element has not been totally severed (i.e., it has a very small but measurable impedance). Using a milli-ohmmeter will be useful in determining if this is the case. Upon opening a piece of equipment, one may find that, in most applications, the fuse and MOV will be located on the top or on the bottom of a printed circuit board in plain sight. This location makes the visual inspection of the fuse and MOV easy. The location of the fuse and MOV will be near the point where the AC power is brought into the equipment and close to the electromagnetic interference (EMI) filter. One may also find that the fuse and MOV are not visible. In an increasing number of equipment designs where a composite EMI filter is used, the fuse and MOV may actually be inside a metal can that is used to house the EMI filter. A composite EMI filter typically includes the line fuse, MOV, over-temperature protection device, and EMI filter components (i.e., capacitors and inductors). One may ask why the line fuse and MOV are included in the composite EMI filter. If the EMI filter includes an International Electrotechnical Commission (IEC)-type female connector for the AC line power cord, then the fuse and MOV must be located inside the can for the fuse and MOV to be located upstream of the input to the EMI filter. In other cases, the EMI filter may be required to be shielded from radiated emissions sources nearby inside the equipment. In these cases, the fuse and the MOV must also be located inside the filter can to preserve the electromagnetic integrity of the AC line input. Most importantly, note that the can of the filter may be filled with some type of potting material. The use of potting material helps to reduce arcing between component traces on the EMI filter circuit board and between component surfaces and the grounded EMI filter can. Potting material also helps to improve heat dissipation of the fuse, MOV, and filter elements inside the can. Dissipation of heat ability in this case is especially important in helping to extract heat from the MOV when it passes surge current. Heat dissipation through potting material will also help to reduce MOV failure caused by short duration TOVs. When conducting fuse and MOV failure investigations, the potting material must be removed to expose the surfaces of the fuse and MOV. Removal of potting material should be accomplished in such a way as not to cause further damage to the fuse and MOV. Mechanical removal of the potting material is the best method. Another benefit of the composite EMI filter is that it can act to provide a fire barrier against hot and molten material that may be expelled from a fuse and/or MOV during a failure. In cases where the fuse and MOV are inside a filter can, the investigator will have to open the can to inspect the fuse and MOV. Figure 5. Failure of circuit traces connecting the line fuse to the MOV inside an EMI filter can. Figure 5 shows three examples of how TOVs may damage an MOV (middle) and other electronic components such as an electrolytic capacitor (left) and an inductor (right) used in a switched mode power supply. Damage to circuit traces on printed circuit boards may also occur where the line fuse and MOV are improperly coordinated. Traces may be lifted from the board due to the forces created when high currents flow. It is important to illustrate these cases because failures associated with AC line input circuitry sometimes do not result in the failure of other components in addition to fuses and MOVs. Figure 6. MOV partially embedded in potting material; MOV is split as a result of a TOV (fuse is also opened but not shown here). Figure 6 shows an example of an MOV failure in end-use equipment. This MOV is partially potted and the line fuse is fully potted (not shown). The blue capacitors below the MOV and the common mode inductor above the MOV are both part of the EMI filter for this equipment. This MOV failed as a result of a TOV incident upon the AC line input. The potting material helped to absorb heat from the MOV and helped prevent the MOV from disintegrating. The MOV failure resulted in the epoxy coating of the MOV being pushed away from the surge absorbing material. This fuse and MOV failure resulted in full equipment failure resulting in the necessity of returning the equipment to the manufacturer. Figure 7. MOV failure caused by thermal runaway and internal equipment fire in a surge protective device. MOV failure caused by thermal runaway and internal equipment fire in another surge protective device. Figure 8. In visually inspecting MOV failures, thermal runaway may also occur if an MOV with too low of a maximum continuous operating voltage (MCOV) is applied in end-use equipment. In such a case, exposure of the MOV to a longterm overvoltage may be higher than the maximum allowable voltage for the MOV, and thermal runaway of the MOV may occur without blowing the line fuse. Figure 7 and Figure 8 show two examples of MOVs in surge protectors that failed as a result of MOV thermal runaway. In both examples, the MOV ignited and a significant part of the MOV material was burned by the fire caused by its own thermal runaway. If an investigator discovers this type of MOV failure surrounded by other burned insulation and electronic components, then thermal runaway can be suspected. COORDINATION OF METAL OXIDE VARISTORS AND FUSES TO ACHIEVE ADEQUATE LEVELS OF PROTECTION Design requirements imposed by Underwriters Laboratories (UL) require that the fuse be located upstream of the MOV. In MOV applications where equipment immunity from surges occurring from line to neutral is desired, the fuse location requirement imposed by UL is required because the MOV is connected from a source of power (i.e., line) to neutral. The same is true for MOVs connected from line to ground when surge immunity from line to ground is required. MOVs connected from neutral to ground do not require fuse protection. Fuse protection of an MOV will reduce the likelihood of an MOV fire resulting from extreme surge currents flowing through the MOV. The neutral to ground MOV should have the same MCOV rating when selecting MOVs. Also, it is good design practice to thermally protect the MOV to prevent potential fire hazards due to loss of neutral in facility wiring systems. Some manufacturers with little experience in surge protection design will try to locate the MOV upstream of the fuse in their equipment designs. Without the basic understanding of protecting equipment from fire caused by MOV failures, initially there is more concern with either protecting every component (including the line fuse) from surges and reducing the number of nuisance equipment failures caused by opened fuses. Locating the MOV upstream of the fuse would reduce nuisance equipment failures but would also violate UL requirements. Thus, this practice is not allowed by UL or recommended by the power quality community for obvious reasons. Nuisance equipment failures (caused by opened fuses and failed MOVs) can be avoided and adequate immunity against surges can be provided if the overcurrent protection offered by a fuse and the overvoltage protection offered by an MOV are sized and coordinated in the proper manner. Figure 9. Arrangement of thermal cut-off (TCO) MOVs with one MOV removed from the circuit (to show the TCOs) (adapted from Littlefuse, Inc.). Figure 10. A ceased MOV failure caused by interruption of the conduction current by an external TCO (adapted from Littlefuse, Inc.). An improved MOV design provides for thermal protection for the MOV without the use of coordinating fuses. Thermal protection and prevention of complete MOV destruction are provided by embedded thermal cut offs (TCOs), which are available in different opening temperatures. This new type of MOV is called the TMOV. The TCO must be positioned and oriented with respect to the MOV if it is to be effective in thermally protecting an MOV. When subjected to a TOV, MOVs can short at a random point on the disk and can begin to self-heat rapidly when conduction current is sustained through the MOV. Figure 9 illustrates an example of a typical arrangement of MOVs and TCOs. Figure 11. A ceased MOV failure caused by interruption of the conduction current by an internal TCO (adapted from Littlefuse, Inc.). In recognizing MOV failures, it is worthwhile to illustrate the prevention of an MOV failure that was caused by including an external TCO next to the MOV. Figure 10 illustrates this type of failure. TMOVs are also available with internal TCOs. Figure 11 illustrates how an MOV might look when its conduction current is interrupted by a TCO internal to the MOV. Figure 12. Location of MOV critical v voltage ratings on a voltage magnitude-duration plot. It is not uncommon for manufacturers to receive dysfunctional equipment from the field. Upon failure investigations, manufacturers often find that only the line fuse has been blown with no damage to other components including the MOV. Manufacturers know that there are a number of causes for line fuse failure including internal component failure especially associated with the power supply. In other cases, manufacturers may find that both the fuse and MOV have been destroyed. However, most manufacturers do not think about line fuse failures caused by overcurrent conditions resulting from surges, TOVs, and even inrush currents that occur during a surge or after the return of line voltage after a voltage sag or momentary interruption, respectively. Surge- and TOV-related line fuse failures, addressed in this article, are caused by MOV current conduction. This conduction is a function of the MOV clamping voltage rating of the MOV. If the MOV clamping (suppression) voltage (CSV) is selected too low, then there is a greater chance that the MOV will conduct as a result of a TOV, thus possibly damaging the line fuse and the MOV. The maximum continuous operating voltage (MCOV) rating of an MOV is also another critical specification for MOVs. If the MCOV is selected too low (i.e., too close to the maximum expected line voltage including the expected overvoltage of about 10%), then the MOV will conduct as a result of high line voltage. Figure 12 illustrates an example of the CSV and MCOV rating with respect to the areas in a voltage magnitude-duration plot where surges and TOVs typically occur. In this situation, the MOV is likely to experience thermal runaway (see Figures 7 and 8) and to be damaged, possibly causing a fire inside the equipment. Thus, selecting an MOV with a high CSV and MCOV rating will help avoid line fuse and MOV failures caused by high line voltage conditions and TOVs. On the other hand, the equipment designer must select the clamping voltage low enough to clamp surges before they damage other internal components such as noise capacitors inside an EMI filter and the bridge rectifier. In 120-volt applications, selecting an MOV with a CSV of 395 and a MCOV of 150 will be sufficient. In 277-volt applications, selecting an MOV with a CSV of 845 and a MCOV of 320 will be sufficient. EXAMPLE APPROACH AND TEST DATA Example Approach Well-planned laboratory surge and TOV tests may be carried out to investigate surge- and TOVrelated failures and failure prevention through coordination of line fuses and MOVs. Coordination studies may be aimed at identifying coordination of existing designs with too many fuse and/or MOV failures or targeted coordination for new designs. A single line fuse connected in series with a single MOV may be subjected to various surges and TOVs of various duration to learn more about how to recognize fuse and MOV failures. Single fuse-single MOV and grouped fuse-MOV test circuit configurations should be used to determine coordination. Table 1. Approach for determining fuse and MOV damage resulting from surges and TOVs. Table 1 illustrates an example approach for conducting surge and TOV tests (1) on seriesconnected, single-line fuse-MOV samples, (2) on series-connected line fuse-MOV samples connected in parallel, and (3) on end-use equipment containing a line fuse and MOV. A selected number (e.g., six in these tests) of circuits with a single fuse and a single MOV may be placed in parallel on a test card to investigate how the fuse-MOV combination shares the real overcurrent condition presented by the surge or TOV. This circuit configuration simulates end-use equipment powered by an actual branch circuit in a facility. The number (“X” in the third column of Table 1) of circuits with a single fuse and a single MOV included on a test card can be determined, for a specific enduse equipment application, by determining how many pieces of like equipment can be placed on a single 20-amp branch circuit, for example. In an application where one piece of equipment draws 1.3 Arms at 277 Vrms, 12 pieces of equipment can be placed on a 20-amp circuit (derated to 16 amps). Thus, 12 series circuits with a single fuse and a single MOV can be placed in parallel on a test card for laboratory testing. Table 2. Summary of TOV test data for the line fuse and MOV tested in this case. Table 3. Summary of surge test data for the line fuse and MOV tested in this case. Test Data Figure 13. A 3-amp, slow-blow 350-volt line fuse and 510-volt MOV after one 1.71 p.u. (473.4 V rms ) 64-cycle duration TOV: disintegrated fuse and MOV damaged (epoxy surfaces lifted). Figure 14. Six parallel arrangements of 3-amp, slow-blow fuses in series with 510 volt MOVs on a test card after one 1.71 p.u. (473.4 Vrms) 64-cycle duration TOV: four out of six fuses blown with three out of six MOVs damaged (epoxy surfaces lifted). Table 2 illustrates the summary of TOV test data for the 3-amp, slow-blow line fuse and the 510volt, 20-mm MOV tested in this example case. The arrows in the tables illustrate how the testing was performed. Table 2 contains test data for the single line fuse-MOV sample case and for the group of six series line fuse-MOV samples in parallel. In the TOV testing, TOVs from 1.0 p.u. (per unit) to 2.0 p.u. were planned in steps of 0.1 p.u. with TOV duration starting at 2 cycles and ending in 64 cycles in double steps. In Table 2, one can see that for both cases (single and grouped line fuse and MOV), the line fuse-MOV combination survived the TOVs ranging from 1.0 p.u. at 2 cycles up to a 1.7 p.u. TOV at 32 cycles with failure of the fuse and MOV at 1.7 p.u. at 64 cycles. From Figure 13, one can also see that the line fuse was completely destroyed and that the MOV suffered splitting of its epoxy-covered case. (The MOV was not completely destroyed in terms of its physical structure.) Figure 14 illustrates the results of conducting these tests on parallel-connected line fuse-MOV circuits. Four out of six fuses were blown. Figure 14 also shows that the fuses that suffered the greatest destruction were also supporting TOV current drawn by the MOVs that experienced the most damage resulting from the TOV event. The four fuses that suffered physical damage to their outside cases supported TOV current from the four MOVs that suffered splitting of their epoxy cases. Figure 15. A 3-amp, slow-blow, 350-volt line fuse and 510-volt MOV after one 2.5-kV surge: opened fuse, no damage to MOV. Figure 16. Six parallel arrangements of 3-amp, slowblow fuses in series with 510-volt MOVs on a test card after 39 5.5-kV surges: five out of six fuses blown with no MOV damage. Table 3 illustrates the summary of surge test data for the same 3-amp, slow-blow line fuse and the 510-volt, 20-mmMOV tested in the second part of this example case. Table 3 contains test data for the single line fuse-MOV sample case and for the group of six series line fuse- MOV samples in parallel. In the surge testing, surges from 500 volts to 6000 volts were planned in steps of 500 volts with surge counts (number of surges) starting at 10 and ranging up to 1000. From Table 3, one can see that the test results are different for the single and the grouped line fuse-MOV cases. In the single line fuse-MOV case shown in Figure 15, the line fuse-MOV combination survived the surges ranging from 500 volts at 10 surges up to 2500 volts up to 10 surges with failure of the fuse at 2500 volts at 10 surges. In the grouped case where the line fuses and MOV share the surge current, five out of six line fuses failed when subjected to 40 surges at 5500 volts. No damage to any of the six MOVs occurred in these tests. From Figure 16, one can also see that the line fuses suffered no physical damage to their outside cases (only the fuse element was blown for the five out of six fuses), and the MOVs also suffered no damage (splitting or destruction) of their epoxy covered cases. CONCLUSION The surge and TOV electrical disturbance events are two completely different types of events. As stated earlier, MOVs are designed specifically to reduce surge voltage appearing on input and output circuits in end-use equipment. When surge voltage is reduced to acceptable levels that will not damage internal end-use electronics, surge currents must flow as a result of the voltage clamping action designed into the MOV. However, MOVs are not designed to protect end-use equipment from TOV events. Although TOV events are lowervoltage events, they are much longer in duration than surges. In equipment design, the size and type of fuse and MOV does matter when trying to coordinate the fuse and MOV where the objective is to reduce premature return of failed equipment that otherwise would have continued to operate. As a result though, when the fuse is coordinated closer to the MOV, meaning the fuse is able to withstand the resulting surge current, it is difficult to determine the failure mode (failure caused by surges or TOVs). However, it is very clear where there are multiple failures of like pieces of enduse equipment such as power supplies and corresponding catastrophic fuse failures that it is very probable that the cause of equipment failure is related to TOV events, either internal or external to the facility. In cases where there are two pieces of end-use equipment out of a group of equipment found with benign fuse failure, but not catastrophic, it is reasonable to conclude that the failure is related to a surge event when no other failed components are determined. An Experimental Study of the Failure Mode of ZnO Varistors Under Multiple Lightning Strokes Abstract In this study, in order to explore the failure mode of ZnO varistors under multiple lightning strokes, a five-pulse 8/20 μs nominal lightning current with pulse intervals of 50 ms was applied to ZnO varistors. Scanning electron microscopy (SEM) and X-ray diffractometry (XRD) were used to analyze the microstructure of the material. The failure processes of ZnO varistors caused by multiple lightning impulse currents were described. The performance changes of ZnO varistors after multiple lightning impulses were analyzed from both macro and micro perspectives. According to the results of this study’s experiments, the macroscopic failure mode of ZnO varistors after multiple lightning impulses involved the rapid deterioration of the electrical parameters with the increase of the number of impulse groups, until destruction occurred by side-corner cracking. The microstructural examination indicated that, after the multiple lightning strokes, the proportion of Bi in the crystal phases was altered, the grain size of the ZnO varistors became smaller, and the white intergranular phase (Bi-rich grain boundary layer) increased significantly. The failure mechanism was thermal damage and grain boundary structure damage caused by temperature gradient thermal stress, generated by multiple lightning currents. Figure 9a,b shows the XRD diffraction pattern of the ZnO varistors, before and after the impulses. It can be seen in the figure that the crystal phase compositions mainly include four parts: zincite, syn; manganese oxide; bismuth oxide; and bismite, syn. Through the analysis of the figures, it was determined that the proportion of Bi in the crystal phases before the impulse test was 0.9%, 0.8%, and 0.6%, respectively. The proportion after the impulse test was 0.0%, 1.0%, and 1.3%, respectively. The proportion of Bi in the crystal phases has been converted. Figure 9. XRD diffraction results of the ZnO varistors before (a) and after (b) the impulses.