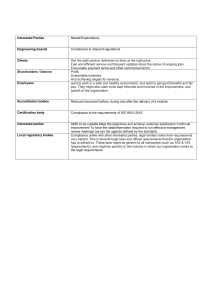

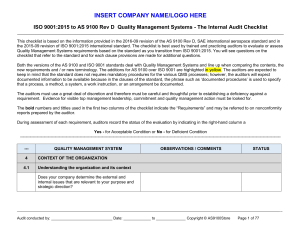

ISO 9001:2015 QUALITY MANAGEMENT SYSTEM 09 August 2023 Presented By: Mr. Ambadas Goli 1 ISO 9001:2015 (5th Edition) ISO STANDS FOR INTERNATIONAL ORGANIZATION FOR STANDARDIZATION Non government organization established in 1947 , based in Geneva, Switzerland Has a membership of 160 national standards institutes from countries in all regions of the world Why ISO 9001 Global Recognition Improved Customer Satisfaction Improved the Efficiency & Effectives organisation processes. Periodic self & third party assessment 2 ISO 9001:2015 (5th Edition) 9001 IDENTIFICATION NUMBER OF THE STANDARD 2015 YEAR OF EDITION 3 TRANSITION PHASES OF ISO 9001 ISO 9001:1987 ISO 9001:1994 ISO 9001:2000 ISO 9001:2008 PROCEDURES PREVENTIVE ACTION PROCESS APPROACH & PDCA PROCESS APPROACH, PDCA 4 ISO 9001:2015 RISK BASED THINKING PREVENTIVE ACTION OTHER RELATED STANDARDS There are many other standards in the ISO 9000 series that can help you reap the full benefits of a quality management system and put customer satisfaction at the heart of your business. ISO 9000 contains detailed explanations of the seven quality management principles with tips on how to ensure these are reflected in the way you work. It also contains many of the terms and definitions used in ISO 9001. ISO 9004 provides guidance on how to achieve sustained success with your quality management system. ISO 19011 gives guidance for performing both internal and external audits of ISO 9001. This will help ensure your quality management system delivers on promise and will prepare you for an external audit, should you decide to seek third-party certification. 5 BENEFITS OF ISO 9001:2015 6 DEFINATIONS QMS : Organisational Structure , responsibilities , procedures & resources used to ensure products , process or services to satisfy stated or implicit need Quality : The ability to satisfy the expectations of the customer Quality Control : Defect Identification-activities to identify defects in actual products Produced Quality Assurance : Defect Prevention- Activities for ensuring quality in the process by which products are developed Process : Set of interrelated or interacting activities that use inputs to deliver an intended result. Non-conformity(NC) : Non-fulfilment of requirement. Corrective Action : Action to eliminate the cause of a non-conformity to prevent its recurrence" Preventive Action: Action to eliminate the potential cause of a nonconformity to prevent its occurrence" Risk: The effect of uncertainty Resource: Resource is the source of supply such as places, people or things which is useful or can be transformed into more valuable and useful items 7 QUALITY MANAGEMENT PRINCIPLES 8 ISO 9001:2015-KEY POINTS ISO 9001:2015 Number of clauses- 10 (High Level Structure) Risk based thinking No any mandatory requirement of MR (Replaced as Process Owners) Evidence based decision making TERMINOLOGY Products and services Documented information Environment for the operation of processes Monitoring and measuring resources Externally provided products and services 9 HIGH LEVEL STRUCTURE(HLS)-10 CLAUSES Purpose of HLS: Alignment of Management System Standards. New Structure for Management System Standards. Identical title & core text. Generic Basic Vocabulary. Common main structure, common subclauses, common terms & definition. 10 PDCA CYCLE (Deming) PLAN : Establish the objectives of the system and its processes, and the resources needed to deliver results in accordance with customers’ requirements and the organization’s policies, and identify and address risks and opportunities. DO : Implement & control what was panned. CHECK : Monitor and (where applicable) measure processes and the resulting products and services against policies, objectives, requirements and planned activities, and report the results. ACT : Take actions to improve performance, as necessary. 11 PDCA CYCLE (Deming) 12 PROCESS APPROACH 13 PROCESS APPROACH (EXAMPLE) RISK SINGLE SUPPLY SOURCE HIGH FRIEGHT COST OPPORTUNITY MULTIPLE SUPPLIER DEVELOP NEARBY SUPPLIER OUTPUTS INPUTS PROCEDURES PURCHASE REQUISITION MATERIAL SPECIFICATION APPROVED SUPPLIER LIST LEAD TIME SUPPLIER CAPABILITY PURCHASING PROCESS INTERELAATED ACTIVITIES STORAGE INSPECTION & TESTING FACILITY MANUFACTURING FINANCE VENDOR DEVELOPMENT 14 RECIEPT OF MATERIAL AS PER SPECIFICATION ON TIME DELIVERY REQUIRED QUANTITY TEST CERTIFICATE RISK BASED THINKING RISK Effect of uncertainty UNCERTAINTY Lack of information - Quality of water in another pot? Poor understanding - How to do jump? Not sufficient knowledge - How much force is required? Consequence or likelihood - What if not able get in another pot? RISK BASED THINKING RISK Effect of uncertainty Identify what the risks and opportunities are in your organization- this depends on the context of your organization. Analyse and prioritize the risks and opportunities in your organization identify what is acceptable and what is not. Plan actions to address the risks, can the risks be avoided, mitigated or eliminated? Take action and implement the plan to address the risks. Check the effectiveness of your plan 16 RISK ANALYASIS EXAMPLE Purchasing Process : RISK- Single Source Supplier • Single Source supplier is wiped out by Natural disaster What is the impact? • You are shut down. What is the likelihood? • Unlikely How do you mitigate the risk? • Find another supplier • Revise product design to allow other options • Purchase insurance that covers business interruption 17 PROCESS APPROACH – PDCA - RISK ANALYSIS 18 IN ISO 9001:2015 VERBAL FORM USED ARE “shall” indicates a requirement “should” indicates a recommendation “may” indicates a permission “can” indicates a possibility or a capability 19 1. SCOPE ISO 9001:2015 standard specifies requirements for a quality management system when an organization: A) Needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements B) Aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements. All the requirements of this International Standard are generic and are intended to be applicable to any organization, regardless of its type or size, or the products and services it provides 20 2. NORMATIVE REFERENCES The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. The committee responsible for this document is Technical Committee ISO/TC 176 21 3. TERMS & DEFINATION For the purposes of this document, the terms and definitions given in ISO 9000:2015 apply 22 4. CONTEXT OF ORGANIZATION Context: The set of circumstances or facts that surround a particular event, situation etc. Address the internal & external issues: • Determine the internal Issues • Determine the external Issues • Monitor & review these issues on regular basis That affects the performance (Intended Output) External Issue Internal Issue Stringent Legal Compliances High Cost of Compliance Rapid Change in Technology Lack of skilled Manpower High Competition Lack of awareness Poor availability of resources High employees turnover 23 4. CONTEXT OF ORGANIZATION Understanding the need & expectations of Interested Parties (IPs): • Interested Parties: Person or organisation that can affect, be affected by, or perceive itself to be affected by a decision or activity. Internal Interested Parties External Interested Parties EMPLOYEES MANAGEMENT TEAM CONSUMERS INTERNAL INTRESTED PARTIES EXTERNAL INTRESTED PARTIES TOP MANAGEMENT CONTRACTORS REGULATORS COMMUNITY UNIONS SUPPLIERS COMPITITORS BOARD OF DIRECTOR MEDIA 24 4. CONTEXT OF ORGANIZATION Understanding the need & expectations of Interested Parties: • Need: Necessity or obligation • Expectations: A strong belief (associated with need) Interested Parties Needs Customers products/services as per specification Employees Livelihood and fair compensation Regulatory Compliance with laws and regulations Expectations • Timely delivery of high quality products/services • Clear and effective communication throughout the customer journey • Prompt resolution of customer complaints. • Access to training programs and resources for skill enhancement and career advancement • Opportunities for promotion and professional growth • Job security and stability through fair employment practices and policies. • 100 % Compliance • On time compliance • Transparency of data or information 25 4. CONTEXT OF ORGANIZATION Understanding the need & expectations of Interested Parties: Interested Parties Regulatory Needs Expectations Internal Issues Compliance with environmental laws and regulations •100 % Compliance • Non availability of skilled man power • Frequent changes in rules & regulation • Non availability of re-sources • Stringent compliance requirement • On time compliance • Transparency of data or information External Issues • Limitation of budget • Delayed information • Poor understanding of requirement •Poor communication with team 26 4. CONTEXT OF ORGANIZATION External Issues - Risk, opportunity, monitoring and control Sr. No. External issues Risk Stakeholders Monitoring and review Responsibility Opportunity 1. Very limited project in market to bid Loss of business Sales Achievement of budgetedsales from new markets Head Sales & Proposal 2. Impact of statutory compliances –labour, licenses, Penalty Non Projects, HR Maintain updated statusspecific for site location Head HR & Administration,Head Projects Improved Changes in applicable Pollution control board norms Up gradation , validation of technology Loss of business Projects, HR Review scope requirements Head Sales Improved new business Loss of business Sales Achievement of sales withnew technology Maintain margin Head Sales & Proposal Improved new business Head Sales &Proposal /CEO Improved business CEO, All Function Heads Business continuity Head Sales & Proposal, Head Finance New business withimproved margins 3. 4. compliance 5. Currency fluctuations Low Sales realizations Sales 6. Unforseen events Resource loss Organization Emergency preparednessplan Adequate insurance coverage 7. Awareness of Forex in customer country Low margins Sales, Finance Maintain updated status inclient country 27 Improved new business compliance adherence Reduce penalty costs with pricemargins 4. CONTEXT OF ORGANIZATION Internal Issues - Risk, 0pportunity, Monitoring and Control Sr. No. 1 Internal issues Risk Stakeholders Penalty 2 (Workmen compensation policy) Delay / non receipt of Workmen Contract Act certificate 3 Product failure at site Resource loss 4 Awareness of terms and conditions – taxation, duties applicable (state wise) Low margins Unaware of new technologies in market Loss of business Liquidated damages due to delay in project execution Delay in engineering document preparation Loss of margins Projects, Finance Delayed approvals Engineering, Proposal 5 6 7 Projects, HR Non compliance Monitoring and review Maintain updated status specific for site location No. of instances of delay in Non compliance receipt of certificate Projects No. of failures reported QC No. of vendors supplying Purchase Proposal products resulting in failures No. of instances of non Proposals, Projects, Accounts compliances Proposals No. of new technologies identified Achievement of sales with new technologies No. of instances damages incurred Value of damages Timely preparation of engineering documents as per MDL 28 Responsibility Head HR & Administration,Head Projects Head Projects Head QC Head PurchaseHead Sales & Proposal Head Projects, Head Finance Head Sales & Proposal Head Projects, Head Finance, CEO Head Engineering, Head Sales & Proposal Opportunity Improved compliance adherence Reduce penalty costs Customer satisfaction Improved compliance adherence Improved margins Improved new business Improved business with margins On time project completion 4. CONTEXT OF ORGANIZATION Interested parties - Risk, Opportunity, Monitoring and Control Interested parties Customer Vendor Third party inspection (TPI) Identify Needs & expectations Risks Stakeholders Customer dissatisfaction Organization Scope clarity of purchase order alongwith approved documents and payment terms Non fulfillment of contract requirements Purchase, Projects, Design Clear purchase order Advance intimation Non fulfillment of contract requirements Project QC Timely submission of documents Timely deliveries Quality of products Good workmanship Timely execution After sales support for inspection Monitoring and review On time completion of deliveries On time submission of documents No. of complaints of quality No. of complaints of workmanship On time after sales support provided delays in payments No. of Purchase Orders without scope clarity No. of purchase order submitted without approved documents No. of incorrect Purchase Orders submitted Instances of delay in intimation of inspection No. of delay in payments On time coordination with client Approved document with quality plan Timely 29 Responsibility Opportunity Head Projects Head Sales & Proposal Improved business margins Head Purchase, Head Projects, Head Engineering Cost reductions Head Projects, Head QC Improved business 4. CONTEXT OF ORGANIZATION Understanding the need & expectations of Interested Parties: 1. Determine Relevant Interested Parties 4. Monitoring & Review Of Needs & Expectations On Regular Basis 2. Determine Relevant Needs & Expectations 3. Determine Which Needs & Expectations Are Compliance Obligations 30 4. CONTEXT OF ORGANIZATION Determining the Scope of Management System: When determining this scope, the organization shall consider: • External & internal issues • Requirement of relevant interested parties • Product & Services • Physical & Functional Boundaries The scope of the organization’s quality management system shall be: • Available at point of use • Maintain as documented information 31 • Justify for any non applicability 4. CONTEXT OF ORGANIZATION Management System & Processes: PROCESS : Set of interrelated or interacting activities that use inputs to deliver an intended result (Output) PROCEDURE : Set of activities, in sequence, from input to output EX: Purchase Order Creation INPUT Purchase Requisition OUTPUT Purchase Order INTENDED OUTCOME Right material in right time PROCESS INDICATOR Converting PR into PO within required days ACTIVITIES: Purchase Requisition (INPUT) Enquiry to Vendors Quotation Comparative Statement Technical Approval Negotiation Budget Approval PO Preparation & Preparation Review & 32 PO Review PO Release (OUTPUT) 4. CONTEXT OF ORGANIZATION 4.4 Quality Management & its Processes: Supplier, Input, Process, Output, Customer (SIPOC) Sheet Department- QA Input from Input (S) (I) RM Suppliers Material, QA report Production Control plan / Drawings / WI Production Dispatch plan, Materials from Production, Control Plan Process/Sub Process (P) Resources Inward Inspection Measuring instruments, manpower, communication facility Inprocess Inspection Measuring instruments, Inspector Final Inspection Measuring instruments, manpower, communication facility Output Output to (O) (C) QA report Stores , production Control Measurement Monitoring Receiving Inspection report, Work Instruction/SOP No of incidents of incoming material rejection in production Daily In-process PPM Daily Monitoring Final PPM Daily Monitoring Setup Approval Setup Approval Report, Report, In-process In-process inspection Inspection report, Production report, In-process In-process Rejection Rejection report, report. Final Inspection Quality Dispatch plan, Control plan, SOP, WI Final Inspection Report, PDIR 33 5. LEADERSHIP 5.1.1 Leadership & Commitment : Top Management shall Take accountability for effectiveness of QMS Define policy & Objectives Communicate importance of requirements of QMS Integration of QMS requirements into business process Use of process approach & risk based thinking Engage, direct & support persons to contribute to the effectiveness of QMS Provide resources & promote continual improvement Ensure that QMS achieved its intended outcome Support other management roles to demonstrate their leadership TOP MANAGEMENT DEFINE POLICY PROVIDE RESOURCES SET OBJECTIVE 34 MANAGEMENT REVIEW 5. LEADERSHIP 5.1.2 Customer Focus : Top management shall demonstrate leadership and commitment with respect to customer focus by ensuring that: a) Customer requirements & applicable statutory and regulatory requirements are determined, understood and consistently met b) The risks and opportunities that can affect conformity of products and services and the ability to enhance customer satisfaction are determined and addressed c) The focus on enhancing customer satisfaction is maintained 35 5. LEADERSHIP 5.2 Quality Policy : Policy- Intention & direction of an organization as formally expressed by top management Top management shall establish, implement and maintain a Quality Policy that : 1) Appropriate to context of the organization & Support its strategic direction 2) Provide basics to the objectives 3) Commitment to continual improvement 4) Commitment to satisfy applicable requirement (Related to Product / Service) Quality Policy Shall be : 1) Maintain as documented information 2) Communicate & understood within organization 3) Available to relevant interested parties 36 5. LEADERSHIP QUALITY POLICY Ion Exchange Projects & Engineering Management is committed to sustain and enhance satisfaction of its customers, interested parties and to exceed their expectations by Continuous endeavours to process and service improvements through standardization, value engineering and reengineering. Being responsive to the external and internal issues which influence our origination performance. Installing a culture of risk based thinking in the organisation. Establishing quality objectives in line with strategic direction of the organization. Ensuring effective implementation and continuous improvement of quality management system though periodic reviews Monitoring & measuring the achievement of quality objectives and processes for increased efficiency and productivity Achieving employee satisfaction by providing resources, training and healthy work environment. Ensuring compliance to the applicable statutory and regulatory requirements. 37 5. LEADERSHIP 5.3 Organizational roles, responsibilities and authorities : Role: Designation or Position Responsibilities: The duty assigned to a position Authority: Power assigned to a position Top management shall ensure : 1) Different roles are defined 2) Responsibilities and authorities are assigned 3) Communicated & understood 4) Assigning responsibility & authority for reporting on performance of the management system 5) Assigning responsibility & authority for reporting on opportunities for improvement 38 6. PLANNING 6.1 Actions to address risks and opportunities Sr. No Risk Impact resulting failure Are current controls adequate Y/N Current controls Additional controls required Opportunity PROJECTS 1 No scope clarity in customer requirements eg. termination points /MOC/detailed specifications of material & equipment, statutory requirement of Project & Project site. MOC change Delay in engineering. Delay in Handing over the plant. Cost implication. Delay in execution Identify gaps in specifications/scope and get resolution from Proposal or decide Extra claim to be submitted to client for identified cases. Review with seniors (Head – Field, Logistic, Stores, Project, Finance & Procurement). Review of Techno commercial prior to bidding. Review of Techno commercial before LOI. N Incur LD Cost reduction Cost controls Support delayanalysis and delivery extension Updated vendor list (internally 2 Non availability ofsufficient vendor options Cost implication Delayed delivery Quality issues Alternate vendor credentials are sent and approved through customer approved by IEI) to be quarterly circulated to proposal for making part of new bids Still, any additional vendor approval to be expedited N Establish Approval protocol with Master drawing list with 3 Delay in Engineering document approval from customer Resource loss Cost implication LD cases customer to fit in with L2 schedule monitoring Project review meetings with focus on Engineering Cost control Timely delivery Better quality control L2 schedule to be monitored to avoid N slippages Maintain documentary evidence of delays from customer Force approval across the Follow up for timely Pos and vendor 39 Project completion ontime Timely delivery Cost control 6. PLANNING 6.2 Quality objectives and planning to achieve them: Objective : Something aimed to achieve Target : Measurable part of the objective The Quality Objective shall be: Consistent with policy Measurable Monitored on regular basis Communicate Update as appropriate Maintain documentation 40 6. PLANNING 6.2 Quality objectives and planning to achieve them Sources of setting objective: Product & Service Legal & Other Risk & Opportunity Planning to achieve objective: What will done What resources will be required Who will be responsible When it will be completed Update as appropriate How the results will be evaluated 41 6. PLANNING 6.2 Quality objectives and planning to achieve them Specific Measurable Achievable 42 Relevant Time Based 6. PLANNING 6.2 Quality objectives and planning to achieve them: Examples: Quality Objective To increase sales turn over 15 Cr/Month to 25 Cr/Month by March 2024 To improve OEE from 60% to 85% by by March 2024 To reduce water consumption from 50 KL/MT to 30 KL/MT by by March 2024 To reduce NC product generation from 5 % to 1 % by by March 2024 To generate waste generation from 20 Kg/MT to 5 Kg/MT by by March 2024 To develop 5 new vendors from domestic market by by March 2024 To achieve Zero accident by by March 2024 43 6. PLANNING 6.3 Planning of changes : When the organization determines the need for changes to the quality management system, the changes shall be carried out in a planned manner (4.4) The organization shall consider: Identify the need for change Identify purpose of change & its Consequences Ensure QMS Integrity Assign resources Identify & communicate changes & responsibilities Implement the changes Ensure effectiveness of changes implemented 44 7. SUPPORT 7.1.1 & 7.1.2: General Resources & People 45 7. SUPPORT 7.1.1 & 7.1.2: General Resources & People Man Method Machine Resources Measurement Material Mother Earth Money 46 7. SUPPORT 7.1.3: Infrastructure- The organization shall determine, provide and maintain the infrastructure necessary for the operation of its processes and to achieve conformity of products and services 47 7. SUPPORT 7.1.3: Infrastructure- Information Technology Transportation Utilities Equipment-Hardware Equipment-Software Buildings Communication Technology 48 7. SUPPORT 7.1.3: Infrastructure PREVENTIVE MAINTENANCE BREAKDOWN MAINTENANCE 49 PREDICTIVE MAINTENANCE 7. SUPPORT 7.1.4 Environment for the operation of processes : The organization shall determine, provide and maintain the environment necessary for the operation of its processes and to achieve conformity of products and services. A suitable environment can be a combination of human and physical factors, such as: Social (e.g. non-discriminatory, calm, non-confrontational) Psychological (e.g. stress-reducing, burnout prevention, emotionally protective) Physical (e.g. temperature, heat, humidity, light, airflow, hygiene, noise) 50 7. SUPPORT 7.1.4 Environment for the operation of processes : 51 7. SUPPORT 7.1.4 Environment for the operation of processes : 52 7. SUPPORT 7.1.5.1 Monitoring and measuring resources : General The organization shall ensure that the resources provided Are suitable for the specific type of monitoring and measurement activities being undertaken Are maintained to ensure their continuing fitness for their purpose The organization shall retain appropriate documented information as evidence of fitness for purpose of the monitoring and measurement resources 53 7. SUPPORT 7.1.5.1 Monitoring and measuring resources : General Gold Shop Vegetable Shop Highly Precise Highly Accurate Less Precise Less Accurate 54 7. SUPPORT 7.1.5.2 Measurement Traceability Suitable Type Fit For Measurement Re-Calibrate when Repaired Safeguard From Adjustment Acceptance Criteria Identification 55 Frequency Of Calibration 7. SUPPORT 7.1.6 Organizational Knowledge: The organization shall determine the knowledge necessary for the operation of its processes and to achieve conformity of products and services Organizational knowledge can be based on: Internal sources (e.g. intellectual property; knowledge gained from experience; lessons learned from failures and successful projects; capturing and sharing undocumented knowledge and experience; the results of improvements in processes, products and services) External sources (e.g. standards; academia; conferences; gathering knowledge from customers or external providers) 56 7. SUPPORT 7.2 Competence: 57 7. SUPPORT 7.2 Competence: Education Training Skill 58 Experience 7. SUPPORT 7.2 Competence: • Identify People who affect requirements • Define minimum level of competency • Check actual competency against minimum requirement • Determine gap in competency (Training need & Identification) • Prepare Training Plan • Conduct training as per plan & check effectiveness • Check & verify the effectiveness of training taken • Update the Actual competency level 59 7. SUPPORT 7.3 Awareness: The organization shall ensure that persons doing work under the organization’s control are aware of • Quality Policy • Relative Quality Objectives • Employees contribution for effectiveness of QMS & improved Performance • The implication of not confirming to QMS requirements 60 7. SUPPORT 7.4 Communication: The organization shall determine the internal and external communications relevant to the quality management system, including: Ex- HR Policy How What to communicate- HR Policy With Whom What When to communicate- @ Joining Communication How to communicate- Induction Training Who Who will communicate- HR Department When With whom to communicate- New Joining 61 7. SUPPORT 7.5 Documented Information: Documented Information- Examples Scope Policy Objectives Risk & opportunity Compliance Register Quality Manual Procedures Work Instructions Checklists Vendor List Production Report Calibration Report 62 7. SUPPORT 7.5 Documented Information: Documented information shall be • Indentified (Title, Date, Author, Document number, Revision Number) • Storage & Preservation, including preservation of legibility • Control of changes • Retention & disposition • Available at point of use • Protected from loss of confidentiality • Control of distribution of external origin documents 63 7. SUPPORT 7.5 Documented Information: Retrieval Disposal Documented Information Retention 64 Access 8. OPERATION 8.1 Operational planning and control: The organization shall plan, implement & control the processes by: Establishing criteria for the processes & the acceptance of products and service Determine resources needed to achieve conformity to the product and service requirements Implementing control of the processes in accordance with the criteria Department Maintenance QC Activities • Breakdown Maintenance • Preventive Maintenance • Calibration of Instruments • Incoming Material Inspection Purchase • Vendor development & evaluation • Procurement Marketing • Enquiry handling • Customer Satisfaction survey Production • Manufacturing • Handling of NC Product 65 8. OPERATION 8.1 Operational planning and control: Determining, maintaining and retaining documented information to the extent necessary To have confidence that the processes have been carried out as planned; To demonstrate the conformity of products and services to their requirements The output of this planning shall be suitable for the organization’s operations The organization shall control planned changes and review the consequences of unintended changes, taking action to mitigate any adverse effects, as necessary The organization shall ensure that outsourced processes are controlled 66 8. OPERATION 8.2.1 Customer Communication: Product Boucher Enquiry Handling Complaint & Feedback 67 Customer Property Risk Assessment 8. OPERATION 8.2.2 & 8.2.3 Determine & review the requirements for products and services: a) the requirements for the products and services are defined, including: 1) any applicable statutory and regulatory requirements 2) those considered necessary by the organization b) the organization can meet the claims for the products and services it offers Product • Product Name, Grade / Quality, Quantity Delivery • Location, Date of Delivery, Vehicle for delivery Packing • Labelling instruction, Packing Material Post Delivery Services Other T&C CUSTOMER REQUIREMENT CUSTOMER DOES NOT DEFINE • Installation, Testing, Commissioning, Warranty • Commercial terms, Legal obligations, Disposal Requirements 68 EVERY REQUIREMENT 8. OPERATION 8.2.4 Changes to requirements for products and services: CHANGES BY CUSTOMER CHANGES IN INTERNAL DOCUMENTS ACKNOWLEDGMENT TO CUSTOMER 69 MAKE PEOPLE AWARE ABOUT CHANGES 8. OPERATION 8.3 Design & Development of Product & Services: The organization shall establish, implement and maintain a design and development process that is appropriate to ensure the subsequent provision of products and services. • Design & Development Planning • Design & Development Input • Design & Development Controls • Design & Development Output • Design & Development Changes The organization shall retain documented information on D&D changes, result of reviews, authorization of changes & action to prevent its adverse impacts. 70 8. OPERATION 8.4 Control of externally provided processes, products and services: The organization shall ensure that externally provided processes, products and services conform to requirements. Confirmation of Requirements Externally Provided Product Externally Provided Processes (Raw Material) (Outsource Activity) Raw Material become part of product Out-sourced activity is performed on part of product 71 Externally Provided Service (Third Party Inspection / Calibration) 3rd Party Activity 8. OPERATION 8.4 Control of externally provided processes, products and services: Define criteria for selection Selection of Vendor Monitor the performance of Vendor Re-evaluate on regular basis Initiate action based on evaluation result Maintain record of evaluation & action taken 72 8. OPERATION 8.4.3 Information for external providers: The organization shall communicate to external providers its requirements for • Product & Services • Specification / Acceptance criteria • Method of approval • Delivery requirements -Quantity, Date, Location, Packing • Competency Requirements • Communication at various stages • Verification & verification at supplier end 73 8. OPERATION 8.4.3 Information for external providers: The organization shall communicate to external providers its requirements for Product & Services Specification / Acceptance criteria Method of approval Delivery requirements -Quantity, Date, Location, Packing Competency requirements Communication at various stages Verification & verification at supplier end 74 8. OPERATION 8.5.1 Control of production and service provision: The organization shall implement production and service provision under controlled conditions. Controlled conditions shall include, as applicable: • Availability of document that define Product or Service characteristics • Availability of document that define Product or Service requirements • Availability of suitable measuring / monitoring resources • Monitoring & measurement planning • Use of suitable infrastructure & environment for the operation • Implementation of actions to prevent human errors • Appointment of competent manpower • Validation & periodic re-validation of the ability to achieve planned results • Implementation of release, delivery & post delivery activities 75 8. OPERATION 8.5.1 Control of production and service provision: 76 8. OPERATION 8.5.2 Identification & Traceability: The organization shall use suitable means to identify outputs when it is necessary to ensure the conformity of products and services The organization shall identify the status of outputs with respect to monitoring and measurement requirements throughout production and service provision The organization shall control the unique identification of the outputs when traceability is a requirement, and shall retain the documented information necessary to enable traceability Raw Material Maintain Record Of Batch Number / Lot number Product Traceability 77 Final Product 8. OPERATION 8.5.3 Property belonging to customers or external providers: The organisation shall • Exercise Care When belonging to organisation • Identify, verify, protect & safeguard during use • Return to customer / External provider Organisation shall inform to customer / external provider & maintain record when gets • Lost • Damage 78 • Not suitable 8. OPERATION 8.5.4 Preservation: The organization shall preserve the outputs during production and service provision, to the extent necessary to ensure conformity to requirements Preservation can include: Identification Handling Contamination Control Packaging & Storage Transportation Protection 79 8. OPERATION 8.5.5 Post Delivery Activities: To determine extent of Post delivery activities required, organization shall consider : Statutory and regulatory requirements The potential undesired consequences associated with its products and services The nature, use and intended lifetime of its products and services Customer requirements Customer feedback 80 8. OPERATION 8.5.5 Post Delivery Activities: Post-delivery activities can include Actions under warranty provision Contractual Obligations- Maintenance Services, Installation, Commissioning etc Supplementary Services- Recycling / Final Disposal Installation Commissioning Demonstration Maintenance / Repair Market Return Feedback Complaint Handling Servicing Product Recall Recycling Disposal Legal & other requirement 81 8. OPERATION 8.5.6 Control of Changes: The organization shall review and control changes for production or service provision, to the extent necessary to ensure continuing conformity with requirements. The organization shall retain documented information describing the results of the review of changes, the person(s) authorizing the change, and any necessary actions arising from review. Man Machine Measurement 6M Material Method Mother Earth 82 8. OPERATION 8.6 Release of products and services: The organization shall implement planned arrangements, at appropriate stages, to verify that the product and service requirements have been met. The release of products and services to the customer shall not proceed until the planned arrangements have been satisfactorily completed, unless otherwise approved by a relevant authority and, as applicable, by the customer. Final Product OK Meets Requirements Under Deviation Need Customer Approval Release of the Product 83 8. OPERATION 8.6 Release of products and services: The organization shall retain documented information on the release of products and services. The documented information shall include 1. Evidence of conformity with the acceptance criteria 2. Traceability to the person(s) authorizing the release 84 8. OPERATION 8.7 Control of non-conforming Outputs: The organization shall deal with nonconforming outputs in one or more of the following ways • Correction • Segregation, containment, return or dispose • Informing to customer • Obtaining authorization for acceptance under concession Conformity to the requirements shall be verified when nonconforming outputs are corrected 85 8. OPERATION 8.7 Control of non-conforming Outputs: The organization shall retain documented information that: 1 2 • Describes the actions taken • Describes the non-conformity • Describes the concession obtained • Identify the person authorised to decide the action against NC 86 NON-CONFIRMITY (NC) & CORRECTION Non- Conformity (NC): Non-fulfilment of requirement Examples1. Complaint from the Customer 2. Deviation of effluent discharge quality / quantity 3. Fire event in the factory 4. Rejection of product by quality control Correction: Action to eliminate the NC 87 ROOT CAUSE ANALYSIS ROOT CAUSE ANALYSIS Is the process of discovering the root causes of problems in order to identify appropriate solutions. There are number of RCA tools. Fault Tree Analysis Cause & effect diagram Brainstorming Pareto Analysis Tree Diagram Process Map 5 Why analysis Scatter Diagram 88 PREVENTIVE ACTION AND CORRECTIVE ACTION Preventive Action: Action to eliminate the potential cause of a nonconformity to prevent its occurrence PREVENTIVE CORRECTIVE Corrective Action: Action to eliminate the cause of a nonconformity to prevent its recurrence 89 9. PERFORMANCE EVALUATION 9.1.1 Monitoring, Measurement , Analysis and Evaluation : General Monitoring: Process to determine the status of a system or a process or an activity (Qualitative term) Measurement: Process to determine value . (Quantitative term) Analysis: A set of technique to examine trend & make conclusion based on trend Evaluation: The action to compare process output against set criteria in order to determine conformity. 90 9. PERFORMANCE EVALUATION 9.1.1 Monitoring & Measurement , Analysis and Evaluation : General Quality What to Monitor & Measure When to Monitor & Measure How to Monitor & Measure • pH • After Distillation • pH Meter • Colour • TDS • Physical • Every Hour • Comparison • Acid Value • Purity •Titration • Before Dispatch 91 • Test Certificate 9. PERFORMANCE EVALUATION 9.1.2 Customer Satisfaction: Customers perceptions of the degree to which their needs and expectations have been fulfilled. Examples of monitoring customer perceptions can include: Surveys Market Share Analysis Feedback Customer Satisfaction Dealers Report Customer Meet Customer Complaint Warranty Claims 92 9. PERFORMANCE EVALUATION 9.1.2 Customer Satisfaction: . Less Question & Easy to Understand Expect Answer in Rating Person name who gives the rating Frequency Compile data & information Analysis & identify opportunity 93 9. PERFORMANCE EVALUATION 9.1.3 Analysis & Evaluation: The organization shall analyze and evaluate appropriate data and information arising from monitoring and measurement. The results of analysis shall be used to evaluate • Conformity of product & services • Degree of customer satisfaction • Performance & effectiveness of QMS • Effectiveness of planning implemented • Effectiveness of action for risk & opportunity • Effectiveness of action for risk & opportunity • Need for improvements to the QMS 94 9. PERFORMANCE EVALUATION 9.1.3 Analysis & Evaluation: DEPARTMENT PRODUCTION QUALITY MAINTAINANCE PURCHASE SAFETY PERFORMANCE INDICATOR PRODUCTION PLAN VS ACTUAL OVERALL EQUIPMENT EFFECTIVENESS (OEE) CUSTOMER COMPLAINTS REJECTION PPM PM PLAN VS ACTUAL MTBF , MTTR SUPPLIER REJECTION PPM ON TIME DELIVERY (LEAD TIME) LOST TIME INJUREY REPORTED INCIDENTS 95 Audit AUDIT Systematic, independent and documented process for obtaining objective evidence & evaluating it objectively to determine the extent to which audit criteria are fulfilled Obtaining evidences Evaluating audit criteria Determining extent of requirements FULFILLED 96 Types of Audit TYPES OF AUDIT First Party Audit Second Party Audit Third Party Audit INTERNAL AUDIT SUPPLIER AUDIT CERTIFICATION AUDIT 97 9. PERFORMANCE EVALUATION 9.2 Internal Audit: INTERNAL AUDIT: Internal audit is an audit conducted by auditors who are employed by the organization being audited but who have no vested interest in the audit results of the area being audited. WHY TO CONDUCT INTERNAL AUDIT The organization shall conduct internal audits at planned intervals to Confirm : Organizational own requirements for its QMS Requirements of QMS Effectively implement & maintained the QMS 98 9. PERFORMANCE EVALUATION 9.2 Internal Audit: The organization shall: • Plan, Implement & maintain audit programme • Define audit criteria & scope of audit • Select auditors & conduct audit • Audit result are reported to relevant Management • Take appropriate correction & corrective actions in defined time interval • Retain documented information as evidence of effective implementation of audit programme & the audit results 99 9. PERFORMANCE EVALUATION 9.3 Management Review : General Top management shall review the organization’s QMS, at planned intervals, to ensure its continuing suitability, adequacy, effectiveness and alignment with the strategic direction of the organization WHO Top Management WHEN Planned Interval WHY Ensure continuing suitability, adequacy & effectiveness 100 9. PERFORMANCE EVALUATION 9.3.2 Management Review Input The management review shall be planned and carried out taking into consideration : The status of actions from previous management reviews Changes in external and internal issues that are relevant to the quality management system The adequacy of resources The effectiveness of actions taken to address risks and opportunities Opportunities for improvement 101 9. PERFORMANCE EVALUATION 9.3.2 Management Review Input: The management review input shall consider performance and effectiveness of the QMS: • Customer satisfaction & feedback from all the interested parties • The extent to which quality objectives have been met • Process performance & conformity of products & services • NC & Corrective actions • Monitoring & measurement result • Audit results • Performance of external provider 102 9. PERFORMANCE EVALUATION 9.3.3 Management Review Output: The outputs of the management review shall include decisions and actions related to: Management Review Output Opportunity for Improvement Need of Change in QMS Resource Needed The organization shall retain documented information as evidence of the results of management reviews 103 10. IMPROVEMENT 10.1 Improvement: General The organization shall determine and select opportunities for improvement and implement any necessary actions to meet customer requirements and enhance customer satisfaction. These shall include: 2 1 • Current product & services • Future needs & expectations • Correcting, preventing or reducing undesirable effects • Improve the performance & effectiveness of QMS 104 10. IMPROVEMENT 10.2 Non-conformity & corrective action:When a nonconformity occurs, including any arising from complaints, the organization shall • Take action to control & correct it • Deal with consequence • Analyse & determine the cause(s) of NC • Determine if similar NC have occurred or could potentially occur • Take corrective action • Review the effectiveness of corrective action taken • Update risk & opportunities if necessary • Change in QMS if necessary (Update relevant document & provide training) • Communicate lesson learnt with relevant interested parties • Retain documented information as evidence of NC & result of corrective action taken 105 10. IMPROVEMENT 10.2 Non-conformity & corrective action: Example Non conformity (NC) Correction Corrective Action Non fulfillment of the requirement Action to eliminate the NC Action to eliminate the cause of NC (Detected) Fire Incident (NC) Use of power extinguisher Investigation of fire incident resulting detection of mouse as root cause Root cause- Mouse Corrective Action taken: a) Cage to catch mouse b) Pest control c) Sealing Wholes d) Cat 106 10. IMPROVEMENT 10.3 Continual improvement : In a continual improvement approach, there will be phases where there will be improvements and a break to evaluate the success, after which further improvements are made. The organization shall continually improve the suitability, adequacy and effectiveness of the quality management system. As part of continual improvement organisation shall consider: • Audit findings • Corrective Action • Result of analysis & evaluation of (Clause 9.1.3) • Output of Management Review Meeting 107 10. IMPROVEMENT 108 THANK YOU 109