Table of Contents

advertisement

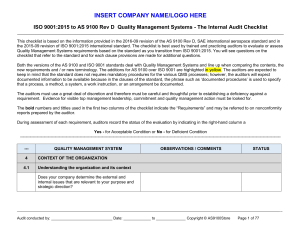

QUALITY MANAGEMENT SYSTEM MANUAL Table of Contents INTRODUCTION ........................................................................................................................................................... 4 1. SCOPE .................................................................................................................................................................. 5 1.1 1.2 1.3 DESCRIPTION OF ORGANIZATION................................................................................................................................. 5 SCOPE OF CERTIFICATION .......................................................................................................................................... 5 THIRD PARTY CERTIFICATION ...................................................................................................................................... 5 2. REFERENCES ........................................................................................................................................................ 6 3. TERMS & DEFINITIONS ........................................................................................................................................ 7 3.1 3.2 4 DESCRIPTION .......................................................................................................................................................... 7 IMPLEMENTATION AND MAINTENANCE ........................................................................................................................ 7 QUALITY MANAGEMENT SYSTEM ........................................................................................................................ 8 4.1 GENERAL REQUIREMENTS .......................................................................................................................................... 8 4.2 DOCUMENTATION REQUIREMENTS .............................................................................................................................. 8 4.2.1 General ........................................................................................................................................................ 8 4.2.2 Quality Management System Manual ........................................................................................................ 9 4.2.3 Document and Data Control ....................................................................................................................... 9 4.2.4 Control of Records ...................................................................................................................................... 9 5. MANAGEMENT RESPONSIBILITY ........................................................................................................................ 10 5.1 MANAGEMENT COMMITMENT ................................................................................................................................. 10 5.2 CUSTOMER FOCUS ................................................................................................................................................. 10 5.3 POLICY STATEMENT ................................................................................................................................................ 10 5.4 PLANNING ............................................................................................................................................................ 11 5.4.1 Quality Objectives ..................................................................................................................................... 11 5.4.2 Quality Management System Planning ..................................................................................................... 11 5.5 RESPONSIBILITY, AUTHORITY AND COMMUNICATION .................................................................................................... 12 5.5.1 Responsibility and Authority ..................................................................................................................... 12 5.5.2 Management Representative ................................................................................................................... 13 5.5.3 Communication & Participation ................................................................................................................ 13 5.6 MANAGEMENT REVIEW .......................................................................................................................................... 13 5.6.1 General ...................................................................................................................................................... 13 5.6.2 Review Input ............................................................................................................................................. 13 5.6.3 Review Output .......................................................................................................................................... 14 6 RESOURCE MANAGEMENT ................................................................................................................................ 15 6.1 PROVISION OF RESOURCES ....................................................................................................................................... 15 6.2 HUMAN RESOURCES ............................................................................................................................................... 15 6.2.1 General ...................................................................................................................................................... 15 6.2.2 Competence, Awareness & Training ......................................................................................................... 15 6.3 INFRASTRUCTURE ................................................................................................................................................... 15 6.4 WORK ENVIRONMENT ............................................................................................................................................ 16 7 PRODUCT REALIZATION ..................................................................................................................................... 17 7.1 PRODUCT REALIZATION PLANNING ............................................................................................................................ 17 7.2 CUSTOMER RELATED PROCESSES............................................................................................................................... 17 7.2.1 Determination of Requirements Related to Product ................................................................................ 17 7.2.2 Review of Requirements Related to Product ............................................................................................ 17 7.2.3 Customer Communication ........................................................................................................................ 17 7.3 DESIGN & DEVELOPMENT........................................................................................................................................ 18 7.3.1 Planning .................................................................................................................................................... 18 7.3.2 Input .......................................................................................................................................................... 18 www.iso9001help.co.uk © 2013 P a g e | 2 of 29 QUALITY MANAGEMENT SYSTEM MANUAL 7.3.3 Output ....................................................................................................................................................... 18 7.3.4 Review ....................................................................................................................................................... 18 7.3.5 Verification ................................................................................................................................................ 18 7.3.6 Validation .................................................................................................................................................. 19 7.3.7 Control of Design & Development Changes .............................................................................................. 19 7.4 PURCHASING......................................................................................................................................................... 19 7.4.1 Purchasing Process.................................................................................................................................... 19 7.4.2 Purchasing Information ............................................................................................................................. 19 7.4.3 Verification of Purchased Product ............................................................................................................ 19 7.5 PRODUCTION & SERVICE PROVISION.......................................................................................................................... 19 7.5.1 Control of Production & Service Provision ................................................................................................ 19 7.5.2 Validation of Processes for Production & Service Provision ..................................................................... 20 7.5.3 Identification & Traceability ...................................................................................................................... 20 7.5.4 Customer Property .................................................................................................................................... 20 7.5.5 Preservation of Product ............................................................................................................................ 20 7.6 CONTROL OF MONITORING & MEASURING EQUIPMENT................................................................................................ 21 8 MEASUREMENT, ANALYSIS & IMPROVEMENT ................................................................................................... 22 8.1 GENERAL .............................................................................................................................................................. 22 8.2 MONITORING & MEASUREMENT .............................................................................................................................. 22 8.2.1 Customer Satisfaction ............................................................................................................................... 22 8.2.2 Internal Audit ............................................................................................................................................ 22 8.2.3 Process Monitoring & Measurement ........................................................................................................ 23 8.2.4 Product Monitoring & Measurement ....................................................................................................... 23 8.3 CONTROL OF NON-CONFORMANCES .......................................................................................................................... 23 8.4 ANALYSIS OF DATA ................................................................................................................................................. 24 8.5 IMPROVEMENT ...................................................................................................................................................... 24 8.5.1 Continual Improvement ............................................................................................................................ 24 8.5.2 Corrective Action ...................................................................................................................................... 24 8.5.3 Preventive Action ...................................................................................................................................... 25 APPENDICES .............................................................................................................................................................. 26 A.1 ABBREVIATIONS & ACRONYMS ................................................................................................................................. 26 A.2 SEQUENCE & INTERACTION OF QMS PROCESSES ......................................................................................................... 27 A.3 LIST OF KEY MANAGEMENT SYSTEM DOCUMENTS ........................................................................................................ 28 Operational Procedures ............................................................................................................................................ 28 Forms & Records ....................................................................................................................................................... 28 A.4 ORGANIZATION CHART............................................................................................................................................ 29 www.iso9001help.co.uk © 2013 P a g e | 3 of 29 QUALITY MANAGEMENT SYSTEM MANUAL Introduction Your Company has developed and implemented a quality management system (QMS) in order to document the company’s best business practices, to better satisfy the requirements and expectations of its customers and to improve the overall performance of the company. The quality management system of Your Company meets the requirements of international standard ISO 9001:2008. This system addresses the design, development, production, installation and servicing of the company’s products. This document describes the quality management system, delineates authorities, inter-relationships and responsibilities of process owners and personnel that perform within the system. This manual also provides procedures or references for all activities that comprise the system to ensure compliance to the necessary requirements of the standard. This document is also used, externally, to introduce our quality management system to our customers, suppliers and other external organizations or individuals. This document is used to familiarize them with the controls that have been implemented and to assure them that the integrity of our system is maintained and is focused on delivering customer satisfaction and continuous improvement. Outline Structure of the Quality Management System in Terms of the PDCA Process Q Quality Management System Resources & infrastructure System Data Trends Performance ACT PLAN Customer Feedback Customer Requirements Process & Product Design Corrective Action Nonconforming Products Quality Performance Quality Requirements Stakeholder Requirements Continual Improvement Preventive Action Policies, Objectives/Targets CHECK DO Purchasing & Suppliers Design & Developement Calibration The model above illustrates that organizational effectiveness and improvement can be represented as a cyclical; plan, do, check and act process that uses components of the quality management system to analyze data to then direct appropriate changes and initiatives that ensure the system’s continual improvement. This also ensures a proactive approach to meeting management system objectives, as well as customer and stakeholder requirements. www.iso9001help.co.uk © 2013 P a g e | 4 of 29 QUALITY MANAGEMENT SYSTEM MANUAL 4 Quality Management System 4.1 General Requirements Your Company has implemented a quality management system that exists as part of a larger, overall management system which has established, documented and implemented our policies and related processes for providing products and services which meet or exceed customer requirements, whilst satisfying the requirements of ISO 9001:2008. Your Company has adopted the process approach advocated by ISO 9000:2005. By defining four key process-groups and by managing their inputs, activities, controls, outputs and interfaces; we ensure that system effectiveness is maintained. Your Company monitors, measures and analyzes relevant processes and takes action to achieve planned results and to deliver the continual improvement of our products, services and to our management system. Four Key QMS Process Groups: Management Orientated Processes Customer Orientated Processes Support Orientated Processes Assessment Orientated Processes Specific responsibilities for, and the sequence and interaction of key quality management system processes are detailed in the management system procedures, some of which contain or make reference to deployment flow charts depicting the process which is also described in the text based narrative of the procedure. Appendix A.2 describes the sequence and interaction of our quality management system. Where Your Company identifies the requirement to outsource any process, or part thereof, that affects conformity with requirements; Your Company identifies control requirements such as; the competence of personnel, the provision of product conformity certificates, contract documentation, specific job files, etc. The controls identified do not absolve us of the responsibility to conform to client, statutory and regulatory requirements but instead they enhance our capacity to manage the supply chain. The controls adopted are influenced by the potential impact of outsourcing on meeting requirements and the degree to which control of the process is shared. Outsourced processes are controlled by internal audits and process performance data review as well as purchasing process and contractual agreements. 4.2 Documentation Requirements 4.2.1 General This document contains documented statements concerning our corporate policies, targets and objectives and references the documented procedures required by ISO 9001:2008 and other documents needed to ensure effective planning, operation and control of our key processes. The quality management system documentation includes: Documented policies and objectives regarding quality performance This quality management system manual Documented procedures (refer to Appendix A.3) Documents required or the effective planning, operation and control our processes Quality records and data The level and type of management system documentation established for our business is continually reviewed to ensure it remains appropriate for the complexity of the interactions of our key processes and the competence of our employees. Quality management system documents and data exist in hard copy and electronic format and include internal and external documents and data needed to manage, perform and verify work that affects product quality. All quality management system documentation that is utilized or generated is categorized by the following hierarchy: www.iso9001help.co.uk © 2013 P a g e | 8 of 29 QUALITY MANAGEMENT SYSTEM MANUAL Quality Management System Documentation Hierarchy: Tier Document Type Purpose 1 Policies Key system driver of process inputs and objectives; statement of corporate vision 2 System manual Describes the corporate approach and responsibilities 3 Procedures Describes the methods required for process implementation 4 Work instructions Describes the operating practices and controls of each process 5 Forms and records Key system outputs; data, records, proof of conformance and evidence of verification 4.2.2 Quality Management System Manual This document has been prepared to describe Your Company’s quality management system and to introduce the associated procedures and processes that are required to implement our policies and processes in order to achieve our targets and objectives. Each section of the manual makes reference to various procedures, forms and process maps relating to the requirements outlined in that section. A list of key quality management system documents; including all procedures, forms and other key management system documents is located in Appendix A.3. 4.2.3 Document and Data Control All quality management system documents are controlled according to the Document and Data Control Procedure which defines the process for: Approving documents for adequacy prior to issue Reviewing and revising as necessary and re-approving documents Ensuring that changes and current revision status of documents are identified Ensuring that relevant versions of applicable documents are available at points of use Ensuring that documents remain legible and readily identifiable Ensuring that documents of external origin are identified and their distribution controlled Preventing the unintended use of obsolete documents Ensuring that documents of external origin are identified and their distribution controlled The company uses standard forms and a local area network computer system with an electronic document management system which is backed up and updated as required <amend as appropriate>. Documents which are controlled include, but not limited to the followings examples: Management system manuals Documented procedures Forms and records (outputs) Customer specifications (inputs) Controlled documents are identified with a document name and document number: Mandatory and operational procedures are prefixed ‘OP and numbered 01 to 20’ Forms and records are prefixed ‘F and numbered according to the procedure they relate to’ Checklists are prefixed ‘CL and numbered according to the procedure they relate to’ 4.2.4 Control of Records Records are established to provide evidence of conformity to the requirements specified by the standards, customer requirements and of the effective operation of the quality management system. Records are formally controlled through the application of the Control of Records Procedure. Records which are controlled include, but not limited to the list of documents that are referenced Appendix A.3. www.iso9001help.co.uk © 2013 P a g e | 9 of 29 QUALITY MANAGEMENT SYSTEM MANUAL A.3 List of Key Management System Documents Operational Procedures Title & Description Document & Data Control Procedure Control of Records Procedure Internal Audit Procedure Non-conforming Product Procedure Corrective & Preventive Action Procedure Objective, Targets & Programmes Procedure Communication & Participation Procedure Management Review Procedure Competence, Awareness & Training Procedure Calibration Procedure Forms & Records Title & Description Master Document Index Document Issue Sheet Document Change Request Master Quality Record Index Internal Audit Schedule Internal Audit Assignment Internal Audit Report Internal Audit Feedback Internal Audit & Gap Analysis Checklist Nonconformity Report Nonconformity Report Log Corrective Action Request Preventive Action Request CAPA Request Log Objectives, Targets & Management Programme Management Review Agenda & Minutes Competency Review Form Training Attendance Form Training Evaluation Form Controlled Equipment Log Calibration Log Software Validation Log www.iso9001help.co.uk © 2013 P a g e | 28 of 29