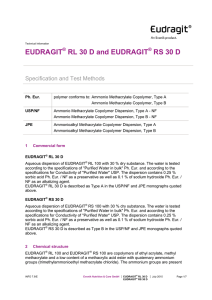

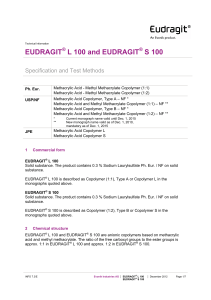

Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 Contents lists available at ScienceDirect H O S T E D BY Future Journal of Pharmaceutical Sciences journal homepage: http://www.journals.elsevier.com/future-journal-ofpharmaceutical-sciences/ Pharmaceutical significance of Eudragit: A review Ch. Niranjan Patra a, *, Richa Priya a, Suryakanta Swain b, Goutam Kumar Jena a, Kahnu Charan Panigrahi a, Debashish Ghose a a b Roland Institute of Pharmaceutical Sciences, Berhampur, 760010, India SIMS College of Pharmacy, Guntur, India a r t i c l e i n f o Article history: Received 19 September 2016 Accepted 13 February 2017 Available online 9 March 2017 1. Introduction The Eudragit® range of polymers, like the versatile acrylic material Plexiglas (introduced in 1933), grew out of Dr. Rohm’s deep knowledge of acrylic acid and its derivatives. In the year 1954 first two polymers Eudragit L and Eudragit S for enteric coating were launched. It offered a synthetic polymer for film-coating of improved quality than materials such as sugar and shellac. Eudragit based products for rapidly disintegrating and sustained release coatings were added during the 1960s, expanding the widening potential applications considerably. The introduction of aqueous polymer dispersion forms of Eudragit in 1972 was a major milestone, making the process of coating easier, safer, more versatile and economical. With the development of various grades of Eudragit, it became possible to handle many aspects of formulation development such as film coating, granulation, direct compression, melt extrusion and mastery of technologies to engineer immediate or sustained release, as well as GI targeting, enteric coatings, pulsed release and transdermal formulations. Hence Eudragit a versatile polymer for drug delivery was selected for extensive review. Polymethacrylates are synthetic cationic and anionic polymers of dimethylaminoethyl methacrylates, methacrylic acid, and methacrylic acid esters in varying ratios. Several types are commercially available and may be obtained as the dry powder, aqueous dispersion, organic solution [1]. The most commonly used organic phase used was a (60:40) mixture of acetone and propan-2ol. Polymethacrylates are primarily used as film-coating agents in * Corresponding author. Roland Institute of Pharmaceutical Sciences, Berhampur, 760010, Ganjam, Odisha, India. E-mail address: drniranjanrips@gmail.com (Ch.N. Patra). Peer review under responsibility of Future University. tablet and capsule dosage forms. Films of different solubility can be produced by using different polymer grades. Table 1 outlines the solubility profile of each grade of Eudragit. Broadly polymethacrylates are used as film former, tablet binder and tablet diluents. Apart from the above applications, recent studies revealed that polymethacrylates have got widespread applications in -vis taste masking, better permeation across skin, formulation vis-a intestinal epithelium and corneal permeation, dissolution enhancement, bioavailability enhancement, enteric coating, sustain release, radioprotection, pH dependent release, colon targeting etc. Therefore polymethacrylates play a pivotal role in formulation and development of different type of dosage forms with versatile applications. Hence the objective of the present manuscript is to make a compilation review on research publications and patents on various applications of Eudragit. Polymethacrylates are known with various synonyms such as Acryl-EZE, Acryl-EZE MP, Eastacryl 30D; Eudragit; Kollicoat MAE 30 D; Kollicoat MAE 30 DP; polymeric methacrylates. This present review focused on various grades of Eudragit which is a trademark of GmbH & Co.K.G Darmastadt in Germany, first marketed in 1950s. polymerization of acrylic & methacrylic acids or their esters was adopted to obtain Eudragit e.g. butyl ester or dimethylaminoethyl ester. Chemical structure of Eudragit is shown in Fig. 1. Eudragit was included in USPNF, BP and PhEur. Dry powder polymer forms are stable at temperatures less than 30 C. Dry powders are stable for at least 3 years if stored in a tightly closed container at less than 30 C. Dispersions should be stored at temperatures between 5 and 25 C and are stable for at least 18 months. Eudragits are generally regarded as nontoxic and nonirritant materials. A daily intake of 2 mg/kg body-weight in humans is regarded as essentially safe. It is included in the FDA Inactive Ingredients Guide (oral capsules and tablets), nonparenteral medicines licensed in the UK, Canadian list of acceptable nonmedicinal ingredients. 2. Literature review A comprehensive review of literature is discussed in length highlighting their applications. Research articles reported for each grade are enlisted in tabular form. Some of those articles are discussed critically with special reference to eudragit. http://dx.doi.org/10.1016/j.fjps.2017.02.001 2314-7245/© 2017 Future University. Production and hosting by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/ licenses/by-nc-nd/4.0/). 34 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 Table 1 Tabulation for solubility of various grades of Eudragit [1]. Grades of Eudragit Recommended solvents Solubility/Permeability Eudragit E12,5, Eudragit E100, Eudragit EPO Eudragit L 100-55, Eudragit L 30 D-55, Eastacryl 30D, Kollicoat 30D Kollicoat 30DP Acryl EZE Acryl EZE MP Eudragit L-12.5P, Eudragit L-12.5, Eudragit L 100 Eudragit S 12.5P, Eudragit S 12.5, Eudragit S 100 Eudragit FS 30D Eudragit RL12.5, Eudragit RL100, Eudragit RD 100 Eudragit RL PO Eudragit RL 30D Eudragit RS 12.5 Eudragit RS 100 Eudragit RS PO Eudragit RS 30D Eudragit NE 30D, Eudragit NE 40D Acetone, alcohol Soluble in gastric fluid to pH 5 Acetone, alcohol for L100-55 Water Soluble in intestinal fluid from pH 5.5 Acetone, alcohol Soluble in intestinal fluid from pH 6 Acetone, alcohol Soluble in intestinal fluid from pH 7 Water Acetone, alcohol High permeability Water Acetone, alcohol Low permeability Water Water Swellable, permeable 2.1. Eudragit E100, E12,5 and EPO In this series there are three different grades of Eudragit vis-avis Eudragit E100, E12,5 and EPO. All the three are cationic copolymer based on dimethylaminoethyl methacrylate, butylmethacrylate and methyl methacrylate. Chemically they are known as poly(butyl methacrylate-co-(2-dimethylaminoethyl) methacrylateco-methyl methacrylate. They possess a molecular weight of approximately (47,000 g/mole), alkali value (180 mg KOH/g of polymer) and glass transition temperature (48 C). They are soluble in gastric pH up to 5.0. Low viscosity, high pigment binding capacity, good adhesion and low polymer weight gain are the Fig. 1. Chemical structure of Eudragit, For Eudragit E: R1, R3]CH3, R2] CH2CH2N(CH3)2, R4]CH3, C4H9 For Eudragit L and Eudragit S: R1, R3]CH3, R2]H, R4]CH3 For Eudragit FS: R1]H, R2]H, CH3, R3]CH3, R4]CH3 For Eudragit RL and Eudragit RS: R1]H, CH3, R2]CH3, C2H3, R3]CH3, R4]CH2CH2N(CH3)þ3Cl For Eudragit NE 30 D and Eudragit NE 40 D: R1, R3]H, CH3, R2, R4]CH3, C2H3 For AcrylEZE and Acryl-EZE MP; Eudragit L 30 D-55 and Eudragit L 100-55, Eastacryl 30 D, Kllicoat MAE 30D, and Kollicoat MAE 30 DP: R1, R3]H, CH3, R2]H, R4]CH3, C2H3. characteristic properties of Eudragit E series. They are commonly used in film coating, odour and taste masking, moisture and light protection. They differ from each other in terms of their physical appearance. Eudragit S100 is available in the form of granules which consists of colourless to yellow tinged granules with a characteristic amine like odour. Eudragit E 12,5 is available in the form of organic solution which is a light yellow liquid of low viscosity, clear to slightly cloudy with characteristic odour of solvent. Eudragit EPO is available in the form of powder with a characteristic amine like odour. A current literature review on Eudragit E 100 reveals that it has been used in nanoparticles, microparticles, transdermal spray, ophthalmic solution, floating drug delivery system etc as shown in Table 2. Quinteros et al. [2] proposed a novel ophthalmic solution based on the ionic complexation between Eudragit E 100 and flurbiprofen. Dispersion of the drug and Eudragit complex in 0.9% w/v sodium chloride (NaCl) increased flurbiprofen release through an ionic exchange, providing a controlled release and more effective corneal permeation without any irritation. Paradkar et al. [3] formulated clotrimazole transdermal spray using different ratios of ethanol and acetone and various grades of eudragit and ethyl cellulose. The following parameters like viscosity, drying time, stickiness, appearance, integrity on skin and water washability were evaluated. The desired criteria was achieved by using Eudragit E100 and mixture of ethanol and acetone (80:20). The optimized formulation exhibited improved drug permeation through the rat skin and improved antifungal efficacy as evidenced from higher zone of inhibition. Dominguez et al., [4] prepared triclosan nanoparticles suspension by the emulsification-diffusion by solvent displacement method, using Eudragit® E 100 as polymer. Triclosan was molecularly dispersed in the nanoparticle batches containing triclosan. Nanoparticles exhibited higher permeation compared to solutions and creams. Patil et al. [5] explored the application of Eudragit E 100 as taste masking agent in orally disintegrating tablet of tramadol hydrochloride. The results demonstrated successful masking of bitter taste. Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 35 Table 2 Reported literature on Eudragit E 100, E 12,5 and EPO. * Drug name Dosage form/delivery system Method of Preparation Applications References Eudragit E 100 Flurbiprofen Opthalmic aqueous solution Ionic complexation [2] Clotrimazole Triclosan Transdermal spray Nanoparticles Tramadol Hydrochloride Carvidilol Orally disintegrating tablet Nanoparticles Eutectic mixture Emulsification-diffusion by solvent displacement method Mass extrusion technique Nanoprecipitation Constant rate of delivery and improved permeation Improved drug transport across the skin Improved drug delivery [5] [10] Ranitidine hydrochloride Floating microspheres Solvent evaporation method Bitter taste masking Improved therapeutic efficacy (Faster dissolution) Improved absorption and bioavailability [3] [4] [11] Eudragit E 12,5 * Eudragit EPO Clindamycin HCl * * * * Oral disintegrating tablet Improved pediatric and geriatric patient compliance by taste masking. [6] Osthole Solid dispersion Drug coated to MCC beads followed by coating of eudragit EPO suspension followed by compression Hot-melt extrusion [12] Atorvastatin Bifendate Meloxicam Amorphous solid dispersions compressed to orally disintegrating tablet solid dispersions Nanoparticles Hot-melt extrusion Nanoprecipitation method Andrographolide pH sensitive nanoparticle suspension Nanoprecipitation technique Aciclovir and Minoxidil liposomes High-pressure homogenization Diclofenac sodium and Theophylline Polycomplex matrices Interpolyelectrolyte complexes (IPEC) between countercharged polymers Improved dissolution rate and bioavailability Improved bioavailability by increasing its gastric solubility in a stable oral disintegration tablet Enhanced bioavailability Improved anti-inflammatory activity compared to suspension. Improved the oral bioavailability with shorter Tmax Cationic polymers had a stabilising effect Considerable pH-sensitive swelling in acidic and neutral media Direct compression [7] [13] [8] [14] [9] [15] No literature found. No literature was found for Eudragit 12,5 in pubmed indexed journals. An extensive review on applications of Eudragit EPO revealed that it can be used in formulations such as solid dispersions, orally disintegrating tablets, nanoparticles, nanosuspensions, stabilization of liposomes, superior moisture protection for solid dosage forms etc are shown in Table 2. Cantor et al. [6] explored taste masking potential of Eudragit EPO by formulating orally disintegrating tablets of clindamycin HCl. Coating of Clindamycin HCl with Eudragit EPO suspension subsequent compression into tablet showed improved pediatric and geriatric patient compliance for clindamycin. Salmani et al. [7] investigated solubility and bioavailability enhancement potential of orally disintegrating tablet compressed from solid dispersions of atrovastatin with Eudragit EPO. Solid dispersions significantly improved the dissolution of atrovastatin. In vivo study showed. 434% more bioavailability than plain atrovastatin tablets. Khachane et al. [8] investigated the potential of Eudragit EPO nanoparticles in improving therapeutic efficacy of meloxicam and compared with conventional meloxicam suspension. Meloxicam loaded eudragit EPO nanoparticles were prepared by nanoprecipitation method. Improved anti-inflammatory activity with lesser ulcerogenicity was observes with optimized nanoparticles. Hasanovic et al. [9] improved physicochemical properties of liposomes by using cationic polymer i.e. chitosan and Eudragit EPO. 1,2-Dipalmitoyl-snglycero-3-phosphocholine (DPPC) liposomes were prepared by high-pressure homogenization. Zeta potential and mean particle size revealed that the polymeric liposomes are stable. In the presence of the drugs (acyclovir and minoxidil), the polymeric liposomes still showed constant particle size and zeta potential. Moreover, the coating of liposomes with chitosan or Eudragit EPO led to higher skin diffusion for both drugs. The interaction between the skin (negatively charged surface) and liposomes (positively charged) was the probable reason for increased skin diffusion. 2.2. Eudragit L 100 and 12,5 Eudragit L 100 and L 12,5 are anionic copolymers based methacrylic acid and methyl methacrylic acid. Both the polymers possess similar molecular weight 1,25,000 g/mol, acid value 315 mg KOH/g of polymer and glass transition temperature greater than 150 C. Targeted drug release area for both the polymer is jejunum and dissolves at pH above 6. They are used for effective and stable coatings with fast dissolution in the upper bowel, granulation of drug substance in powder form for controlled release, site specific drug delivery in intestine etc. The only difference between these two grades is Eudragit L 100 is available in the form of solid powder with a faint characteristic odour whereas Eudragit 12,5 is a organic solution which is colourless and clear to slightly cloudy liquid with the characteristic odour of isopropyl alcohol. A current review on Eudragit L 100 exhibits that it has been used in various formulations such as microspheres, microsponges, nanoparticles, liposomes, lipotomes, tablets etc for different applications such as enteric coating, sustain release, insulin permeation, bioavailability enhancement etc as shown in Table 3. Li et al. [16] filled self nanoemulsifying drug delivery systems (SNEEDS) of insulin into Eudragit L100 based enteric coated capsules. A pHdependent insulin release profile was observed. In healthy fasted rats, administration of SNEDDS produced a 2.7 and 3.4 fold enhancement in the relative bioavailability and glucose reduction, respectively. This study showed enhanced oral absorption and efficacy of insulin. Sareen et al. 2014 [17] evaluated colon specific drug delivery potential of Eudragit L100 by formulating microponges of curcumin. Release studies revealed that microsponges prevented the premature release of curcumin in upper GIT and specifically released the drug at colonic pH. Microsponges with Eudragit L 100 can be used as a promising drug delivery system for treatment of ulcerative colitis. Hosny et al. [18] made a novel 36 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 approach to overcome barriers for the treatment of osteoporosis by formulating enteric-coated alendronate sodium (ALS) nanoliposomes. Optimized nanoliposome coated with Eudragit L 100 successfully resisted the release of ALS in acidic environments and enhanced the bioavailability in rabbits. Wilson et al., [19] prepared and evaluated sustain release enteric coated tablets of pantoprazole. The prepared tablets were dip coated using an enteric coating polymer such as cellulose acetate phthalate and eudragit L100. The study revealed that the prepared tablets were able to sustain drug release into the intestine. The enteric coated pantoprazole tablets significantly reduced ulcer formation. No literature found for Eudragit 12,5 in pubmed indexed journals. 2.3. Eudragit L 30 D 55 and L 100-55 Eudragit L 30 D 55 is the aqueous dispersion of anionic polymers with methacrylic acid as a functional group. It is a low viscosity liquid of white color with faint characteristic odour. It is obtainable in the form of aqueous dispersion (30%) whereas eudragit L 100-55 is an anionic copolymer based on methacrylic acid and ethyl acrylate. It is a white powder with a faint characteristic odour. Both grades of Eudragit have molecular weight 3,20,000 g/mol, acid value 315 mg KOH/g of polymer and glass transition temperature 110 C. Targeted drug release area for both is duodenum and they dissolve at pH of 5.5. Both the polymers are used for effective and stable coating with fast dissolution in the upper bowel, controlled release, site specific drug delivery in intestine etc. An up to date literature review on the applications of Eudragit L 30 D 55 polymer suggests that it has been used in the formulation of microspheres, microparticles, film coated tablets, pellets, transdermal film, enteric coating etc with various objectives such as improving bioavailability, drug release at intestine, sustain release etc as shown in Table 4. Nair et al. [23] evaluated four different polymers such as Eudragit L-30 D-55, hydroxy propyl methylcellulose phthalate, cellulose acetate phthalate and Acryl-EZE® by formulating enteric coated tablets of esomeprazole magnesium trihydrate. Tablets with 5% weight gain, failed disintegration test in 0.1 N HCl media. It was observed that 8% w/w enteric coating passed disintegration test. Methacrylic polymers (Eudragit L 30 D 55 and Acryl EZE) exhibited better dissolution rate than the cellulose polymers. Naseem et al. [24] designed transdermal films of tenoxicam with Eudragit L 30D55 along with permeation enhancers like polyethylene glycol (PEG) and propylene glycol (PG). A drag effect was observed due to interaction between tenoxicam and Eudragit L30D-55 leading to a delay of the tenoxicam release. Bendas et al. [25] attempted extrusion-spheronization followed by spray coating for leaky enteric-coated pellets of ranitidine HCl. Pellets were prepared using Eudragit L 30 D-55, combined with soluble lactose, PEG 8000 and surfactants (span 60 (hydrophobic) or tween 80 (hydrophilic). Leaky enteric coated pellets allowed the release of some amount of drug in gastric fluid. Similarly an extensive up to date review on the polymer Eudragit L100-55 suggests that this can be used in the formulations for various applications such as pH responsive drug release, taste masking, drug release at intestine, radioprotection etc as shown in Table 4. Lotikar et al. [26] designed multiparticulate dosage form of ketoprofen by extrusion and spheronization technique. It was based on pH-responsive dual pulse release concept. Pellets were coated with pH sensitive Eudragit L 100-55 and Eudragit S 100 for site-specific drug release with lag time. The dual pulse release after a lag time of 2 and 5 h was observed. The first dose release was established in pH 1.2 for a period of 2 h, followed by pH 6.8. The second dose pellets were passed through pH 1.2, pH 6.8 followed by pH 7.5 for the rest of the study. The authors concluded that multiparticulate dosage form of ketoprofen was able to relieve circadian symptoms of rheumatoid arthritis during midnight and early morning. Maniruzzaman et al. [27] prepared extrudes of cationic model drug propranolol HCl by extrusion and spheronization technique with the anionic polymers Eudragit L100 and Eudragit L100-55. Taste masking was determined by using e tongues. Intermolecular interactions as the mechanism of successful taste masking was ascertained from FT-IR spectroscopy and NMR studies. Aguilar et al. [28] used polyurethane and Eudragit® L10055 as nanofiber by belectrospinning technique. The composite mat has adequate mechanical properties and in vitro cell biocompatibility indicating that the material can be used for drug eluting stent cover application. De Barros et al. [29] designed a laminated polymer film formulation for enteric delivery of live vaccine and probiotic bacteria. Eudragit L 100-55 based polymeric laminate successfully protected dried probiotic or vaccine live bacterial cells from SGF for 2 h, and subsequently released all viable cells within 60 min of transfer into simulated intestinal fluid. 2.4. Eudragit S (S-100, 12,5 and FS 30 D) Eudragit S 100 and S 12,5 are anionic copolymers based on methacrylic acid and methyl methacrylate. Eudragit S100 is solid substance in the form of white powder with a faint characteristic odour. Eudragit S12,5 is a colourless and clear to slightly cloudy liquid with characteristic odour of isopropyl alcohol. Both grades Table 3 Reported literature on Eudragit L 100 and 12,5. Drug name Dosage form/delivery system Oral insulin Combination of Self nanoemulsifying DDS In-situ emulsification & enteric coated capsules Microsponge for colon targeting Quasi emulsion solvent diffusion method Lyophilised Lipotomes filled into enteric Thin film hydration technique coated capsules. floating alginate beads combined with the Ionic cross linking and solid solid dispersion dispersion technique Enteric-coated nanoliposomes Nanotechnology Curcumin Lacidipine Dipyridamole Alendronate sodium (ALS) Pantoprazole Delayed release tablets Insulin Thiolated eudragit based nanoparticles with reduced glutathione. Eudragit L 12,5 * * * No literature found. Method of Preparation Application Reference [16] Wet granulation method followed by enteric coating Nanotechnology Enhancing the oral absorption and efficacy of insulin and eudragit L 100 as a enteric polymer. Eudragit L 100 prevented the premature release of curcumin in upper GIT. Lipotomes enhanced oral bioavailability and Eudragit L 100 as a enteric polymer. Prolonged stomach retention time due to CaCO3 and modified drug release due to Eudragit L100 and RLPO. Resist the release of ALS in acidic environments and enhanced the bioavailability Sustained release in intestine and significant reduction in ulcer formation Facilitate insulin permeation through the intestinal epithelium. * * [17] [20] [21] [18] [19] [22] * Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 37 Table 4 Reported literature on Eudragit L30 D-55 and L 100-55. Drug name Dosage form/delivery system Eudragit L 30D-55 Oral Chlorea Microparticles vaccine Tenoxicam Transdermal self-adhesive films Enteric coated tablet Esomeprazole magnesium trihydrate Tamsulosin Controlled-release hydrochloride capsule Ranitidine leaky enteric-coated hydrochloride pellets Diclofenac sodium Enteric coated pellets compressed into tablets Microsphere Mycoplasma hyopneumoniae oral vaccine Eudargit L 100e55 Ketoprofen pH-responsive dual pulse multiparticulate dosage form Propranolol HCl Taste mask formulation Amifostine Enteric microcapsules Omeprazole Nanoparticles Gemcitabine Domperidone Paclitaxel Live bacterial cells as attenuated vaccines Cinnarizine Insulin Method Application References Spray dried technique An approach to a cold chain free and effective oral cholera vaccine. [30] Casting evaporation technique Coating Sustain drug release [24] Better dissolution & stable for a period of 3 months. [23] Extrusion/ Controlled release spheronization method Maintain or increase the bioavailability of drugs that have a window of absorption Extrusionspheronization followed by spray coating Fluidized-bed coating The mixture of Eudragit NE30D and Eudragit L30D-55 could be used to prepare enteric pellets. Co spray drying Oral microspheres vaccine prepared by a co-spray drying method can provide effective protection against M M. hyopneumoniae infection in pigs. Extrusionspheronization & Fluid bed coating. Hot melt extrusion (Single screw) Spray drying technique Ultrasonic dispersion and diffusion solidification Enteric Microparticles Double emulsion method Oral disintegrating tablet Direct compression method Nanofiber composite mat Electrospinning process Polymer film laminate Film casting Microparticles Enteric nanoparticles Coacervation technique Complex coacervation method [31] [25] [32] [33] To relieve circadian symptoms of rheumatoid arthritis during midnight and early [26] morning Drug polymer intermolecular interactions as the mechanism of successful taste [27] masking. Oral administration of amifostine microcapsules provided effective radioprotection [34] compared to the bulk drug. Nanoparticles showed a strong pH-sensitive release in vitro. [35] Oral absorption could be increased with mucoadhesive polymer [36] Fast and pH-dependent release [37] pH dependent release of paclitaxel on duodenal stent cover application. [28] Eudragit alone successfully protected dried probiotic or vaccine LBC from SGF for [29] 2 h, and subsequently released all viable cells within 60 min of transfer into SIF. pH responsive drug release [38] Complex coacervation process using chitosan and Eudragit L100-55 polymers may [39] provide a useful approach for entrapment of hydrophilic polypeptides without affecting their conformation. have molecular weight, acid value and glass transition temperature approximately 125,000 g/mol, 190 mg KOH/g polymer and >150 C respectively. Eudragit S 100 is available in the form of powder. Eudragit S 12,5 is available in the form of organic solution (12.5%). Both grades dissolve at pH 7.0 and used for colon targeted drug delivery. Eudragit FS 30D is a milky white liquid of low viscosity with a faint characteristic odour. It is the aqueous dispersion of an anionic copolymer based on methyl acrylate, methylmethacrylate and methacrylic acid. It is insoluble in acidic media, but dissolves by salt formation above pH 7.0. Apart from its enteric properties, its dissolution at a higher pH value allows targeted colon drug delivery. Its molecular weight, acid value and glass transition temperature are approximately 2,80,000 g/mol, 70 mg KOH/g polymer and 48 C respectively. Due to low minimum film forming temperature only small amounts of plasticizer are required to get a smooth film formation. It is available in the form of aqueous dispersion (30%). A current review on recent research publications based on Eudragit S 100 is described as follows. It is used in formulation of transdermal patch, nanoparticles, microparticles, microballons, solid dispersions and spherical crystals. It has been used for various applications such as colon specific drug delivery, sustain release, bioavailability enhancement, improvement in micromeritic properties etc as shown in Table 5. Madan et al. [40] evaluated the sustain release potential of Eudragit S100 by formulating transdermal patches of donepezil using various polymers along with plasticizer and penetration enhancer. Eudragit S100, Eudragit E100 and HPMC were used as matrix forming agents in the formulation of patches. They concluded that transdermal patch can extend the release of donepezil for many hours with enhanced bioavailability. Hence Eudragit S 100 can be used to extend release of domepezil in transdermal patches. Li et al. [16] evaluated colon specific drug delivery potential of Eudragit S 100 based enteric coating of model drug. Enteric coating was achieved by applying Eudragit S 100 to microencapsulated 5-Flurouracil and leucovorin coloaded with folate-chitosan nanoparticles. When the pH value reached the soluble threshold of Eudragit S-100, a constant and slow drug release was observed. Eudragit S100 can be used for selectively targeting drugs to colon in the chemotherapy of colon cancer. Nandy et al. [41] formulated and characterized delayed release multi particulates system of indomethacin. Microspheres were formulated by using a novel quasi emulsion solvent diffusion technique using combination of ethyl cellulose (EC) and Eudragit RS 100/Eudragit S100 . Drug release decreased significantly (p < 0.05) with increase in amount of Eudragit polymer. Therefore this approach suggested that the combination of EC and Eudragit S100 microspheres may be useful for the delivery of maximum amount of indomethacin to the colon. No literature was found for Eudragit S 12,5 in pubmed indexed 38 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 Table 5 Reported literature on Eudragit S 100, 12,5 and FS 30 D. Drug name Eudragit S 100 Donepezil 5-fluourouacil (5FU) and leucovorin Raloxifene hydrochloride Indomethacin Dosage form/delivery system Method of Preparation Transdermal Patches Solvent casting technique Nanoparticles microencapsulated with enteric polymers Nanocapsules Interfacial deposition of preformed polymer Tartrazine (model substance) Thymidine * References Extended release, enhanced bioavailability, avoids the first [40] pass effect Ionic gelation followed by solvent evaporation Selectively targeting drugs to colon in the chemotherapy of [16] method colon cancer. Emulsion solvent diffusion method Best activity was observed for RH-loaded Eudragit S100 nanocapsules after 72 h Combination of EC and Eudragit S100 delivered maximum amount of drug to colon. Solid dispersion of drug-Eudragit S 100 to overcome the problems of dose dumping after the rupture of the pH dependent alginate gels. Sustain release and increased residence time Enteric coated nanoparticles Dextran Microspheres by emulsificationcrosslinking method and enteric coating by oilin-oil solvent evaporation method. Double emulsion method followed by freeze drying [47] Eudragit S100 retard the release of drug in gastric and intestinal pH and the drug released in colon due to the degradation of dextran by colonic enzymes. Nanoparticles almost completely released at pH 7.4 after 8 h [48] reduced blood pressure for more than 30 h Microspheres Spherical crystals Oil/oil emulsification method Solvent change method Colon specific drug delivery Spherical crystals with improved micromeritic properties. [49] [50] * * * * Multiparticulate (enteric coated with FS 30 D) compressed in to tablets Multiple-unit tablet compressed from entericcoated pellets Enteric-coated HPMC capsules Direct compression Delayed release property was preserved. [51] Multi-particulates system in the form of microspheres Dextromethorphan Solid dispersion (modified in situ gelling alginate formulations). Nizatidine Encapsulated microballoons 5-Flurouracil Enteric coated dextran microspheres Peptide Val-LeuPro-Val-Pro-Arg (VLPVPR) Flurbiprofen Mebendazole Eudragit S 12,5 * Eudragit FS 30 D Theophyline Application Novel quasi emulsion solvent diffusion technique Solvent evaporation method [44] [41] [45] [46] Film coating technique An optimal coating was obtained by mixing two acrylic [42] polymers: relatively brittle Eudragit® L30 D-55 with more ® flexible Eudragit FS 30 D. Optimized coating process(fluid bed apparatus) Ready-to-use enteric-coated HPMC capsules for the use in [43] retail or hospital pharmacy or R&D sections of pharmaceutical industry. No literature found. journals. But few articles were published on the use of Eudragit FS 30 D in various dosage forms such as multiparticles, tablets and capsules for enteric coating as shown in Table 5. Dreu et al. [42] produced multiple-unit tablet compressed from enteric-coated pellets. An optimal coating was obtained by mixing two acrylic polymers: relatively brittle Eudragit® L30 D-55 with more flexible Eudragit® FS 30 D. The final formulation released 9% drug in acidic medium. In addition to coating, biconvex shape of tablet and protective coating of Kollidon VA 64 also played a significant role in achieving enteric coating. Huyghebaert et al. [43] developed an alternative method for enteric coating of HPMC capsules that avoids the sealing step before coating, resulting in ready-to-use enteric-coated capsules for the use in retail or hospital pharmacy or R&D sections of pharmaceutical industry and for the production of enteric-coated heat and moisture sensitive biomaterials. The release of thymidine in 0.1 N HCl after 2 h from capsules coated with Eudragit L30D-55, Eudragit FS 30 D, Aqoat AS-HF and Sureteric was 0.6 ± 0.03, 0.6 ± 0.3, 1.2 ± 0.2 and 7.3 ± 1.9% respectively. The alternative method was reproducible and offered a way to overcome the time-consuming and expensive sealing step required using the conventional coating procedure. 2.5. Eudragit NE 30D, NE 40D and NM 30D Eudragit NE 30D, NE 40D and NM 30 D are the aqueous dispersion of a neutral copolymer based on ethyl acrylate and methyl methacrylate. These are milky white liquid of low viscosity with a faint characteristic odour. All the three grades have minimum film forming temperature of 5 C. Both NE 30D and 40 D are having a molecular weight of approximately 7,50,000 g/mol whereas NM30 D have molecular weight of 6,00,000 g/mol. Glass transition temperature (Tg) of NE 30 D and 40D are ~8 C whereas NM 30 D is having glass transition temperature of ~11 C. Eudragit NE 30D, NE 40 D and NM 30 D are available in the form of aqueous dispersion 30, 40 and 30% respectively. All are highly flexible in nature and does not require incorporation of plasticizer. They are used in formulation of controlled release products which are independent of pH of gastrointestinal tract. An extensive review on Eudragit NE 30D revealed that it is used for modified release formulations in various dosage forms such as multiparticles, microparticles, pellets, films etc as shown in Table 6. Amrutkar et al. [52] designed multiparticulate floating drug delivery system of zolpidem tartarate to prolong the gastric residence time and to improve bioavailability. The system consists of effervescent layer (sodium bicarbonate) and polymeric layer (Eudragit NE 30D) membrane. In-vitro drug release of the system were dependent on Coating level of the polymeric membrane (Eudragit(®) NE 30D) played a significant role in drug release. Kumaria et al. [53] developed and evaluated Loratidine buccal films for allergic rhinitis. Polymeric buccoadhesive films of loratidine were prepared using hydroxypropylmethyl cellulose (HPMC)-E5 and K100 blend and Eudragit® NE 30D as retardant. Films were prepared using solvent-casting method. Increase in Eudragit® NE 30 D content in the film decreased the hydration, erosion and drug release, but enhanced the mucoadhesion time. Current literature review on Eudragit NE 40 D suggests that it is used for various pharmaceutical applications like modified release, enhancement of bioavailability etc as bucoadhesive films and non Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 39 Table 6 Reported literature on Eudragit NE 30 D. Drug name Dosage form/delivery system Method of Preparation Application References Coated with effervescent layer and polymeric membrane Solvent-casting method Theophylline or cimetidine Multiparticulate DDS Venlafaxine hydrochloride Pellets Extrusion-spheronization followed by coating. Extrusion/spheronization followed by coating Rapid floating and modified drug release was obtained. Mucoadhesion and release retardation was achieved with HPMC and eudragit NE 30 D respectively. Modified release [52] Loratidine Multiparticulate floating drug delivery system (pellets) Prolonged release Buccoadhesive film Tamsulosin hydrochloride Sustain Release microparticles Single-step matrix coating Urapidil Drug layer pellets followed by coating Centrifugal granulation and fluid bed coating Buccoadhesive films Nonocclusive dermal therapeutic system * Eudragit NE 30 D Zolpidem tartarate Eudragit NE 40 D Prednisolone Miconazole nitrate Eudragit NM 30 D * * [53] [56] Differences in the film micro-structure and surface roughness influence the in vivo release Optimum ratio of Aquacoat® and Eudragit® NE30D in the matrix (9:1) provides a sustained-release Improvement in bioavailability [57] solvent-casting method Matrix system Enhanced bioavailability In vitro control of drug release for at least 24 h [54] [55] * * * [58] [59] No literature found. occlusive dermal therapeutic systems as shown in Table 6. Kumria et al. [54] prepared buccoadhesive films of prednisolone by solventcasting method using hydroxyl propyl methyl cellulose (K100), Carbopol 940 and/or Eudragit® NE 40 D. Buccal route was found as a viable option for delivery of prednisolone. Minghetti et al. [55] prepared self-adhesive matrix made of a mixture of Plastoid E 35 L, an adhesive hydrophilic polymer, and eudragit NE 40 D, a nonadhesive hydrophobic polymer able to modify the drug release. All systems sustained drug release for at least 24 h. No literature was found for Eudragit NM 30D based formulations in pubmed indexed journals. 2.6. Eudragit RL 30 D, RLPO, RL100 and RL 12,5 Eudragit RL 30 D, RLPO, RL100 and RL 12,5 are copolymers of ethyl acrylate, methyl methacrylate and a low content of methacrylic acid ester with quaternary ammonium groups. The ammonium groups are present as salts and make the polymers permeable. RL 30D is a milky white liquid of low viscosity with a faint characteristic odour. Molecular weight of RL 30D is approximately 32,000 g/mol. Its minimum film forming temperature and glass transition temperature are 40 C and 55 C respectively. Alkali value of RL 30D is 32.3 mg KOH per g of polymer. RL 30D is available in the form of 30% aqueous dispersion. RL 30D exhibit pH dependent swelling. RL 30D is primarily used in the formulation of sustained release products. Eudragit RLPO is a solid substance available in the form of white powder with a faint amine like odour whereas eudragit RL100 is a solid substance available in the form of colourless, clear to cloudy granules with a faint amine like odour. Molecular weight, alkali value and glass transition temperature of both RLPO and RL 100 are same i.e. 32,000 g/mol, 28.1 mg KOH/g polymer and 70 C respectively. RLPO and RL100 is mainly used for customized release profile by combination of RL and RS grades in different ratios and they are also suitable for matrix structures. Eudragit RL 12,5 is light yellow liquid of low viscosity, clear to slightly cloudy with a characteristic odour of solvents. RL 12,5 is available in the form of a 12.5% organic solution. Its molecular weight, alkali value and applications are same as RLPO. An extensive literature review on Eudragit RL 30D revealed that this polymer is primarily used for controlled release DDS as shown in Table 7. Kibria et al. [60] investigated the effect of physico- -vis eudragit RL30D and chemical properties of the polymers vis-a RS30D on the release profile of ketoprofen from pellets. Extruded and spheronized pellets were coated with 15% (w/w) polymers Eudragit RL 30 D and Eudragit RS 30 D. It was revealed that Eudragit RL 30 D has the effect to increase the initial drug release more significantly than RS 30D. Lingam et al. [61] formulated matrix type multiple-unit (minitablets) floating drug delivery system for captopril. The system consists of core units which are coated with -vis inner seal coat, effervescent layer three successive layers vis-a and an outer gas-entrapped polymeric membrane of an polymethacrylates. Eudragit RL30D and its combination formulations exhibited floating. Review on Eudragit RLPO is primarily used for sustaining drug release in diverse drug delivery systems like nanoparticles, mucoadhesive tablets and patches, solid dispersions etc as shown in Table 7. Singh et al. [62] investigated the effect of iron oxide in the development of mucoadhesive tablets of cinnarizine using Eudragit RLPO. Eudragit RLPO and iron oxide exhibited potential for gastroretentive and mucoadhesive drug delivery systems. Pandey et al. [63] attempted site specific drug delivery by formulating bilayered gastroretentable mucoadhesive patch (stomach). Both Eudragit RSPO and RLPO were used for formulation of patch. Patches could control the drug release up to 12 h, with mucoadhesion. Sahoo et al. [64] formulated solid dispersion of verapamil using Eudragit RLPO or Kollidon SR to sustain drug release. Extended the drug release upto 12 h was attained in case of Eudragit RLPO. A widespread literature review on Eudragit RL 100 revealed that it is used for controlled release and bioavailability improvement approaches in various dosage forms such as nanoparticles, tablets, buccal films, transdermal patches, ophthalmic inserts etc as shown in Table 7. Singh et al. [65] prepared atazanavir nanoparticles loaded with Eudragit RL 100 to improve oral bioavailability. These nanoparticles were prepared by nanoprecipitation method. Eudragit L100 based nanoparticles showed improved bioavailability potential. Ofokansi et al. [66] prepared ibuprofen tablets from interpolyelectrolyte complexes (IPECs), formed between Eudragit RL100 and chitosan, by nonstoichiometric method, and tablets based on the above complex by wet granulation method. The complex was capable of preventing drug release in the stomach and small intestine and helped colon specific drug delivery. Palem 40 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 Table 7 Reported literature on Eudragit RL 30 D, RLPO, RL100 and RL 12,5. Drug name Dosage form/delivery system Method of Preparation Application References Eudragit RL 30D Diltiazem HCl Matrix Tablets Controlled release [69] Ambroxol hydrochloride Pellets Pellet Captopril Minitablets Stability was dependent on storage condition and physicochemical property of the polymer. Proper selection of polymeric materials based on their physico-chemical properties sustained the drug release. Only the system using Eudragit RL30D and combination of them as a gasentrapped polymeric membrane could float. [70] Ketoprofen Dry mixing and direct compression followed by coating with Eudragit NE 30D Extrusion-spheronization technology followed by coating with Eudragit NE 30D Extrusion spheronisation technique followed by coating with Eudragit Ne 30D and RS 30D Direct compression followed by coating Eudragit RLPO Acyclovir Nanoparticles Nanoprecipitation technique [71] Cinnarizine Mucoadhesive tablets Simplex lattice design Lercanidipine HCl Gastroretentable mucoadhesive patch Layering technique Domperidone Bilayered mucoadhesive buccal patches Solvent casting technique Metoprolol Verapamil hydrochloride Solid dispersion Solid dispersion compressed into a tablet Solid dispersions compressed into tablet Melting and solvent method Direct compression As acyclovir: Eudragit RLPO ratio increased from 1:1.5 to 1:2, particle size and drug entrapment increased It also produced sustain release. Eudragit RLPO and iron oxide combination showed high level potential for fabricating gastroretentive as well as mucoadhesive drug delivery systems. Patches prepared using the combination of Eudragit RSPO and RLPO could control the drug release up to 12 h Bilayered mucoadhesive buccal patches with desired permeability could be prepared RLPO showed higher release than RSPO. The tablet containing Eudragit RLPO has extended the release rate for 12 h Eudragit RLPO coevaporates (1: 5) displayed extended release of drug for 12 h Eudragit RL100 Griseofulvin Polymer-coated drug Nanoparticles Ibuprofen Metformin hydrochloride Domperidone Azithromycin Tablet with interpolyelectrolyte complexes (IPECs), formed between Eudragit RL100 (EL) and chitosan (CS). Matrix tablet Buccal films Opthalmic inserts Coated drug particles can be potentially used for controlled release. To improve bioavailability & in prolonged drug release Exploited successfully for colontargeted delivery of ibuprofen [75] Atazanavir Porous hollow fiber membrane-based antisolvent crystallization Nanoprecipitation method Wet granulation technique Hot-melt extrusion Modified solvent casting method [76] [67] [68] Lercanidipine hydrochloride Sulfacetamide Transdermal patches Nanosuspension Solvent evaporation technique Solvent displacement method Azelastine hydrochloride Microspheres Solvent evaporation technique Zidovudine Cloricromene Transdermal delivery Nanoparticle suspensions Solvent evaporation method Quasi-emulsion solvent diffusion technique used to sustain drug release improved bioavailability Prolonged release time and improved ocular availability. Drug release sustained upto 24 h. Formulation of sulfacetamide in Eudragit RL100 improve the availability of sulfacetamide at the intraocular level. Prolonged release of the drug over the period of 6 h. Increased permeation Improves the shelf life and bioavailability of this drug after ophthalmic application Eudragit RL 12,5 * * * * * Promethazine hydrochloride * Coevaporation and coprecipitation techniques Wet granulation [60] [61] [62] [63] [72] [73] [64] [74] [65] [66] [77] [78] [79] [80] [81] No literature found. et al. [67] prepared domperidone (DOM) hot-melt extruded (HME) buccal films by using combination of HPMC E5 LV or Eudragit RL100 as polymeric carriers along with some other carriers exhibited 1.5 times improved bioavailability. Thakur et al. [68] formulated the bioerodable insert of azithromycin to prolong the release time and improve the ocular availability. Azithromycin insert was prepared using hydroxyl propyl methyl cellulose (HPMC) and Eudragit RL100. The formulation (comprising of 1.5% HPMC and 3% Eudragit RL100) showed release of drug over a 12 h in a steady and controlled manner. No research articles found for Eudragit RL 12,5 in pubmed indexed journals. 2.7. Eudragit RS 30D, RSPO, RS 100 and RS 12,5 Eudragit RS 30D, RSPO, RS100 and RS 12,5 is a copolymer of ethyl acrylate, methyl methacrylate and a low content of Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 methacrylic acid ester with quaternary ammonium groups. The ammonium groups are present as salts. Presence of salts makes them more permeable. Eudragit RS 30 D is a liquid of low viscosity with milky white color showing faint characteristic odour. Eudragit RSPO is white powder with a faint amine like odour. Eudragits RS 100 is colorless granule with a faint amine like odour. Eudragit RS 12,5 is a light yellow liquid of low viscosity, clear to slightly cloudy with a characteristic odour of the solvents. Molecular weight of each of the above grades is 32,000 g/mol. Eudragit RS 30D, RSPO, RS100 and RS 12,5 are available in the form of 30% aqueous dispersion, powder, granules and 12.5% organic solution respectively. All the above four grades of Eudragit are insoluble. They exhibit low permeability with pH independent swelling. These polymers are used for controlled and customized release profile by combination of RL and RS grades in different ratios. Eudragit RS 30 D is extensively used for formulation of sustain release products. The current literature survey suggests that this polymer has been used in formulation of pellets, coating of pellets osmotically driven pellets etc as shown in Table 8. Piao et al. [82] developed sustained release osmotic pellet coated of oxymatrine. Extrusion/spheronization followed by coating with Eudragit RS 30 D was adopted. They found that the F3 formulation, prepared with 20% NaCl and an 8% coating level (Eudragit RS 30 D), showed a continuous NaCl-induced water influx into the pellets providing a 41 gradual sustained release of OMT for over 12 h. Kibria et al. [60] investigated the release of ketoprofen from pellets to study the effect of physico-chemical properties of polymers. The drug containing core pellets were prepared by extrusion spheronisation technique and subsequently coated with 15% (w/w) polymer load of the combination of Eudragit RL 30 D & Eudragit RS 30 D. It was revealed that Eudragit RL 30 D has the effect to increase the initial drug release more significantly where as Eudragit RS 30 D has the effect to minimize the initial drug release but increase the terminal drug release more significantly. An extensive review on research publication on Eudragit RSPO revealed that it is mainly used in the sustaining drug release as shown in Table 8. Eudragit RSPO has been used in the formulation of microballons, tablets, microspheres and microtablets. Porwal et al. [83] prepared microballons of propranolol HCl by the non-aqueous oil in oil emulsion solvent diffusion evaporation method using Eudragit RSPO as polymer. The drug release from microballoons showed a biphasic pattern with an initial burst release, followed by sustained release for 12 h Abbaspour et al. [84] prepared and characterized ibuprofen pellets based on Eudragit RSPO and RLPO or their combination. Eudragit RLPO compare with Eudragit RSPO resulted in pellets with high crushing strength; however, Eudragit type did not have a significant effect on elastic modulus. Literature review on applications of eudragit RS100 suggests Table 8 Reported literature on Eudragit RS 30D, RSPO, RS 100 and RS 12,5. Drug name Dosage form/delivery system Method of Preparation Application References Eudragit RS 30D Oxymatrine Osmotically driven Pellets Gradual sustained release for 12 h [82] Ambroxol hydrochloride Pellets Stable and sustain release formulation [70] Diclofenac sodium Pellets Extrusion/Spheronization followed by fluid bed coating Extrusion-spheronization technology followed by coating Powder layering technology and air suspension technique [87] Ketoprofen Pellets Extrusion and spheronisation followed by coating Diclofenac sodium Pellets Roto-agglomeration Retarded the drug release rate and varied according to the type and amount of plasticizers Eudragit RS 30 D has the effect to minimize the initial drug release but increase the terminal drug release more significantly. Eudragit RS 30 D provided membranes successfully controlling drug release over an extended period of 24 h Eudragit RSPO Propranolol hydrochloride Microballoons Non-aqueous O/O emulsion solvent diffusion evaporation method [83] Alfuzosin hydrochloride Tablets Direct compression Stavudine Ibuprofen Microspheres Pellets Solvent evaporation method Extrusion-spheronization Lobenzarit disodium Theophylline Eudragit RS 100 Genistein Metformin HCl and Acarbose Tablets Microtablets Direct compression Rotary tablet press Drug release showed a biphasic pattern with an initial burst release, followed by sustained release for 12 h The release of Alfuzosin was prolonged for 20 h Sustain release Eudragit RLPO and RSPO did not have a significant effect on elastic modulus. slower release rate Sustained-release Nanostructured lipid carrier (NLC) Bbilayer tablet Matrix tablet followed by coating Terbinafine hydrochloride positively charged controlled-release polymeric Nanoparticles as eye drop Nanopreciptation method Lornoxicam matrix-type transdermal patch Solvent evaporation technique Clotrimazole Bioadhesive Vaginal tablets containing microspheres Spray drying technique 3.3-fold increase in corneal penetration Extended release of metformin HCl for 12 h from one layer Coating with eudragit RS100 polymer minimized initial burst release Increased drug mean residence time and improved its ocular bioavailability four fold. Sustain release and enhanced bioavailability Controlled intravaginal drug release [85] [93] Verapamil hydrochloride Melt-emulsification technique Solvent evaporation and cogrinding techniques Wet granulation method * * * * Eudragit RS 12,5 * * No literature found. [60] [88] [89] [90] [84] [91] [92] [94] [95] [86] [96] 42 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 that it has been used extensively in the formulation of following -vis nanoparticle, bilayer tablet, matrix types of dosage form vis-a tablet, transdermal patch, vaginal tablets etc as shown in Table 8. Zhang et al. [85] formulated nanostructured lipid carrier (NLC) surface modified with Eudragit RS100 Model drug genistein was selected. NLC was produced using the melt-emulsification technique followed by surface absorption of Eudragit RS 100. The Eudragit RS 100 increased the surface zeta potential from 7.46 mV to þ13.60 mV, by uniformly forming a spherical coating outside the NLC surface, as shown by transmission electron microscopy images. Particle size growth was inhibited by Eudragit RS 100. Increased corneal penetration producing a 3.3-fold increase in apparent permeability coefficients was attributed to Eudragit RS100. Baviskar et al. [86] prepared matrix-type transdermal drug delivery system of lornoxicam with the addition of hydrophilic and hydrophobic polymers in different ratios. Transdermal patches of lornoxicam were designed with ethyl cellulose:polyvinylpyrrolidone and Eudragit RL 100:Eudragit RS 100 in different ratios with propylene glycol as plasticizer (5%) and tween 80 as permeation enhancer using the solvent evaporation technique. It was observed that both the patches significantly controlled inflammation and showed analgesic effect from the first hour (P < 0.05). Formulations Table 9 Patents on applications of Eudragit. S. No Title of the patent Invention Patent Number Inventors Date References 1 Colonic delivery using zn/ pectin beads with a eudragit coating. US 20080124279 A. Andremont H. Huguet 05/29/2008 [97] 2 Ursodeoxycholic acid-synthetic hydrotalcite-eudragit hybrid, pharmaceutical composition containing the same and method for preparing the same US 20120156263 J.H. Choy, G.E. Choi, M. C. Park, H. C. Chang 06/21/2012 [98] 3 Modified release tablet formulations with enhanced mechanical properties US 20070104782 S. H. Amir C.E. Melissa 02/08/2007 [99] 4 Curcuminoid complexes with enhanced stability, solubility and/or bioavailability US20140271530 H. Tummala, S. Kumar 09/18/2014 [100] 5 Improved stabilization of misoprostol EP0896823 C. David Tsay, R. Jen Lin Hue In Lu Shu-bin 09/25/2002 [101] 6 Sustained release pharmaceutical composition EP0322277 H. Stevens, M. Chariot, F. Arnold, G. Lewis 01/22/1992 [105] 7 Colonic delivery of metallodependent enzymes US 20080199528 A. Andremont, H. Huguet 08/21/2008 [106] 8 Coated senna extract granules WO/2011/014976 P. H. Jorge 10.02.2011 [102] 9 ketoprofen microgranules, method for preparing same and pharmaceutical compositions Formulation stabilizer for proton pump inhibitors The systems include pectin beads cross linked with zinc or any divalent cation of interest, which beads are then coated with Eudragit®-type polymers. The ursodeoxycholic acidsynthetic hydrotalcite-Eudragit hybrid was used for bittertaste-blocking effect and improved body absorption rate with high solubility. Eudragit L100-55 for said pharmaceutical formulation which achieves a desired hardness for tablets made from the formulation. Curcuminoid-eudragit complex, which enhance the bioavailability of the curcumin component. Misoprostol was complexed with various grades of Eudragit RS series, Eudragit RL series, Eudragit S, Eudragit L., The solid dispersions were stable 6and showed sustain release. Controlled dissolution of the active principle independently of the pH, which consists of micro particles containing the active principle, coated with a mixture of ethylcellulose and Eudragit RS. Pectin beads are crosslinked with zinc ions and the pectin beads are coated with a Eudragit® polymer. Senna extract with 20% sennosides are granulated with Eudragit L 100 and then coated with Eudragit L 30 D 55 ketoprofen micro granules of eudragit RL and RS exhibited prolonged release The polymeric base is cholestyramine-OH, Eudragit EPO, chitosan, or a mixture thereof. The composition stabilizes the benzimidazole derivative proton pump inhibitor in a humid environment One active substance and at least one coat comprising Eudragit E The formulation may be used for releasing up to about 55% of a total dose as a loading dose in order to manage pain. WO/2000/064432 L. C. Marechal, D.S. Pascal 11/02/2000 [103] US 20060013880 F. Robert, R. Narayan, Z. Joseph H. Ping 01/19/2006 [104] US 20150250733 O. Isa 09/10/2015 [107] 10 11 Oral drug delivery formulations Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 A3 and B3 were found to enhance the bioavailability of lornoxicam by 3.1 and 2.7 times, respectively, compared to the oral dosage form. Hence, lornoxicam can be formulated into transdermal patches for sustain release characteristics. As far as Eudragit RS 12,5 is considered no such research article is published in any indexed research journals. 3. Recent patents on eudragit based formulations Recent reviews on various patents published on Eudragit based formulation were collected. It was observed that Eudragit based formulation has been patented for diversified applications. They are used for colonic drug delivery, bitter taste masking, improved hardness, enhanced stability, improved bioavailability, prolonged drug release etc as shown in Table 9. Antoine et al. [97] prepared pectin beads cross linked with zinc or any divalent cation for colonic delivery of drugs. The beads were then coated with Eudragit- FS 30D, LE 30D and NE 30D. The use of zinc cations to crosslink the pectin is particularly preferred to provide a stable metallo-enzyme formulation for the lower intestinal or colonic delivery of such an enzyme. Choy et al. [98] patented hybrid of ursodeoxycholic acid-synthetic hydrotalcite-and Eudragit for bitter-taste-masking and improved body absorption rate with high solubility. Ursodeoxycholic acid is bitter in taste. The inventors found that a hybrid obtained by incorporating ursodeoxycholic acid between the layers of hydrotalcite, which is used as an antacid and a stomachic, and then coating with Eudragit, which is an enteric coating, blocks the bitter taste of ursodeoxycholic acid and simultaneously shows improvement of dissolution rate and high bioavailability. Shojaei et al. [99] patented on how the Eudragit L100-55 played a significant role in achieving desired hardness for tablets. The present invention relates to a pharmaceutical composition comprising a pharmaceutically active agent and a Eudragit L 100-55 which is useful to achieve the required release and desired compressibility. Tummala et al. [100] patented enhancement of bioavailability of the curcumin by complexing curcuminoid with Eudragit®. Chen et al. [101] prepared stable and sustain release solid dispersions of misoprostol with various grades of Eudragit RS series, Eudragit RL series, Eudragit S and Eudragit L. Periano [102] patented stable formulation of sennoside by granulation of senna extract (20% sennosides) with Eudragit L100 and then coated with Eudragit L 30 D 55. This product was stable for a long time and has good organoleptic properties (taste and odour). Christophe et al. [103] patented microgranules of ketoprofen using eudragit RL and RS for prolonged release. Aqueous dispersions of Eudragit RL and RS were used for the preparation of microgranules. Robert et al. [104] attempted to stabilize benzimidazole derivative proton pump inhibitors. The present invention provides a composition containing a benzimidazole derivative proton pump inhibitor and a polymeric base selected from the group consisting of cholestyramine-OH, Eudragit E-PO, chitosan, or a mixture thereof. The composition of the present innovation provides improved stability for the benzimidazole derivative proton pump inhibitor under naturally occurring humidity ranges so that degradation during storage and in the stomach is minimized. It can be easily manufactured by directly admixing the benzimidazole derivative proton pump inhibitor with the polymeric base. 4. Conclusion This represents a comprehensive review of 107 references where various grades of Eudragit were used to develop formulations with widespread applications. The various drugs and techniques used in Eudragit based formulations have been described in sufficient detail to give the reader a basic understanding about the 43 role of Eudragit in different formulations. Hence this review manuscript can be used as ready reckoner for researchers to develop Eudragit based drug delivery systems. Acknowledgements The authors are thankful to management and principal, Roland Institute of Pharmaceutical sciences, Berhampur, India for support and encouragement. References [1] R.C. Rowe, P.J. Sheskey, M.E. Qinn, Handbook of Pharmaceutical Excipients, sixth ed., Pharmaceutical Press, USA, 2009. [2] D.A. Quinteros, L.I. T artara, S.D. Palma, R.H. Manzo, D.A. Allemandi, Ocular delivery of flurbiprofen based on eudragit(®)e-flurbiprofen complex dispersed in aqueous solution: preparation, characterization, in vitro corneal penetration, and ocular irritation, J. Pharm. Sci. 103 (2014) 3859e3868. [3] M. Paradkar, V. Thakkar, T. Soni, T. Gandhi, M. Gohel, Formulation and evaluation ofclotrimazole transdermal spray, Drug Dev. Ind. Pharm. 12 (2015) 1e8. [4] B.C. Nandy, B. Mazumder, Formulation and characterizations of delayed release multi particulates system of indomethacin: optimization by response surface methodology, Curr. Drug Deliv. 1 (2014) 72e86. [5] M.G. Patil, S.M. Kakade, S.G. Pathade, Formulation and evaluation of orally disintegrating tablet containing tramadol hydrochloride by mass extrusion technique, J. App. Pharm. Sci. 01 (2011) 178e181. [6] S.L. Cantor, M.A. Khan, A. Gupta, Development and optimization of tastemasked orally disintegrating tablets (ODTs) of clindamycin hydrochloride, Drug Dev. Ind. Pharm. 41 (2015) 1156e1164. [7] J.M. Salmani, H. Lv, S. Asghar, J. Zhou, Amorphous solid dispersion with increased gastric solubility in tandem with oral disintegrating tablets: a successful approach to improve the bioavailability of atorvastatin, Pharm. Dev. Technol. 20 (2015) 465e472. [8] P. Khachane, A.A. Date, M.S. Nagarsenker, EudragitEPO nanoparticles: application in improving therapeutic efficacy and reducing ulcerogenicity of meloxicam on oral administration, J.Biomed. Nanotechnol. 7 (2011) 590e597. [9] A. Hasanovic, C. Hollick, K. Fischinger, C. Valenta, Improvement in physicochemical parameters of DPPC liposomes and increase in skin permeation of aciclovir and minoxidil by the addition of cationic polymers, Eur. J. Pharm. Biopharm. 75 (2010) 148e153. [10] S. Kalimuthu, A.V. Yadav, Formulation and evaluation of carvedilol loaded Eudragit E 100 nanoparticles, Int. J. PharmTech. Res. 11 (2009) 179e183. [11] K. Punitha, S. Khadhir, V. Ravichandiran, et al., Intragastric floating drug delivery system of ranitidine hydrochloride: formulation and evaluation, Int. J. Pharm. Pharm. Sci. 2 (2010) 105e108. [12] F. Yun, A. Kang, J. Shan, et al., Preparation of osthole-polymer solid dispersions by hot-melt extrusion for dissolution and bioavailability enhancement, Int. J. Pharm. 465 (2014) 436e443. [13] J. Feng, L. Xu, R. Gao, Y. Luo, X. Tang, Evaluation of polymer carriers with regard to the bioavailability enhancement of bifendate solid dispersions prepared by hot-melt extrusion, Drug Dev. Ind. Pharm. 38 (2012) 735e743. [14] B. Chellampillai, A.P. Pawar, Improved bioavailability of orally administered andrographolidefrom pH-sensitive nanoparticles, Eur. J. Drug Metab. Pharmacokinet. 35 (2011) 123e129. [15] R.I. Moustafine, A.V. Bukhovets, A.Y. Sitenkov, V.A. Kemenova, P. Rombaut, G. Van den Mooter, Eudragit EPO as a complementary material for designing oral drug delivery systems with controlled release properties: comparative evaluation of new interpolyelectrolyte complexes with counter charged eudragit L100 copolymers, Mol. Pharm. 10 (2013) 2630e2641. [16] P. Li, Z. Yang, Y. Wang, et al., Microencapsulation of coupled folate and chitosan nanoparticles for targeted delivery of combination drugs to colon, J. Microencapsul. 32 (2014) 40e45. [17] R. Sareen, K. Nath, N. Jain, K.L. Dhar, Curcumin loaded microsponges for colon targeting in inflammatory bowel disease: fabrication, optimization, and in vitro and pharmacodynamic evaluation, BioMed. Res. Int. Jul. 2014 (2014) 7, http://dx.doi.org/10.1155/2014/340701 (Epub ahead of print) article Id 340701. [18] K.M. Hosny, O.A. Ahmed, R.T. Al-Abdali, Enteric-coated alendronate sodium nanoliposomes: a novel formula to overcome barriers for the treatment of osteoporosis, Expert. Opin. Drug Deliv. 10 (2013) 741e746. [19] B. Wilson, P.P. Babubhai, M.S. Sajeev, J.L. Jenita, S.R. Priyadarshini, Sustained release enteric coated tablets of pantoprazole: formulation, in vitro and in vivo evaluation, Acta Pharm. 63 (2013) 131e140. [20] N.A. ElKasabgy, I. Elsayed, A.H. Elshafeey, Design of lipotomes as a novel dual functioning nanocarrier for bioavailability enhancement of lacidipine: invitro and in-vivo characterization, Int. J. Pharm. 472 (2014) 369e379. [21] H. Jiang, R. Tian, W. Hu, et al., Formulation and evaluation of gastroretentive floating drug delivery system of dipyridamole, Drug Dev. Ind. Pharm. 41 (2014) 674e680. 44 Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 [22] Y. Zhang, X. Du, Y. Zhang, et al., Thiolated eudragit-based nanoparticles for oral insulin delivery: preparation, characterization, and evaluation using intestinal epithelial cells in vitro, Macromol. Biosci. 14 (2014) 842e852. [23] A.B. Nair, R. Gupta, R. Kumria, S. Jacob, M. Attimarad, Formulation and evaluation of enteric coated tablets of proton pump inhibitor, J. Basic Clin. Pharm. 1 (2010) 215e221. [24] D.I. Nesseem, S.F. Eid, S.S. El-Houseny, Development of novel transdermal self-adhesive films for tenoxicam, an anti-inflammatory drug, Life. Sci. 89 (2011) 13e14. [25] E.R. Bendas, J.W. Ayres, Leaky enteric coating on ranitidine hydrochloride beads: dissolution and prediction of plasma data, Eur. J. Pharm. Biopharm. 69 (2008) 977e985. [26] V. Lotlikar, U. Kedar, S. Shidhaye, V. Kadam, pH-responsive dual pulse multiparticulate dosage form for treatment of rheumatoid arthritis, Drug Dev. Ind. Pharm. 36 (2010) 1295e1302. [27] M. Maniruzzaman, D. Douroumis, An in-vitro-in-vivo taste assessment of bitter drug: comparative electronic tongues study, J. Pharm. Pharmacol. 67 (2015) 43e55. [28] L.E. Aguilar, A.R. Unnithan, A. Amarjargal, et al., Electrospun polyurethane/ Eudragit® L100-55 composite mats for the pH dependent release of paclitaxel on duodenal stent cover application, Int. J. Pharm. 478 (2014) 1e8. [29] J.M. DeBarros, T. Scherer, D. Charalampopoulos, V.V. Khutoryanskiy, A.D. Edwards, A laminated polymer film formulation for enteric delivery of live vaccine and probiotic bacteria, J. Pharm. Sci. 103 (2014) 2022e2032. [30] M. Pastor, A. Esquisabel, A. Talavera, et al., An approach to a cold chain free oral cholera vaccine: in vitro and in vivo characterization of Vibrio cholerae gastro-resistant microparticles, Int. J. Pharm. 448 (2013) 247e258. [31] X. Zhang, X. Tang, R. Yang, Development of a tamsulosin hydrochloride controlled-release capsule consisting of two different coated pellets, Drug Dev. Ind. Pharm. 35 (2009) 26e33. [32] X.L. Qi, J.B. Zhu, S.J. Chen, Preparation of tablets containing enteric-coated diclofenac sodium pellets, Yao Xue Xue Bao 43 (2008) 97e101. [33] J.H. Lin, C.N. Weng, C.W. Liao, K.S. Yeh, M.J. Pan, Protective effects of oral microencapsulated Mycoplasma hyopneumoniae vaccine prepared by cospray drying method, J. Vet. Med. Sci. 65 (2003) 69e74. [34] A. Gula, L. Ren, Z. Zhou, D. Lu, S. Wang, Design and evaluation of biodegradable enteric microcapsules of amifostine for oral delivery, Int. J. Pharm. 453 (2013) 441e447. [35] S. Hao, B. Wang, Y. Wang, L. Zhu, B. Wang, T. Guo, Preparation of Eudragit L 100-55 enteric nanoparticles by a novel emulsion diffusion method, Colloids Surf. B Biointerfaces 108 (2013) 127e133. [36] J.H. Lim, S.K. You, J.S. Baek, et al., Surface-modified gemcitabine with mucoadhesive polymer for oral delivery, J. Microencapsul. 29 (2012) 487e496. [37] S.M. Assaf, A.M. Qandil, Fast and pH-dependent release of domperidone from orally disintegrating tablets, Pharm. Dev. Technol. 8 (2013) 897e905. [38] S. Thomas, Y.N. Chong, C.S. Chaw, Preparation and characterization of enteric microparticles by coacervation, Drug Dev. Ind. Pharm. 39 (2013) 1142e1151. [39] M. Jelvehgari, P. Zakeri-Milani, M.R. Siahi-Shadbad, et al., Development of pH-sensitive insulin nanoparticles usingEudragit L100-55and chitosan with different molecular weights, AAPS PharmSciTech. 11 (2010) 1237e1242. [40] J.R. Madan, N.S. Argade, K. Dua, Formulation and evaluation of transdermal patches of donepezil, Recent Pat. Drug Deliv. Formul. 9 (2015) 95e103. [41] B.C. Nandy, B. Mazumder, Formulation and characterizations of delayed release multi particulates system of indomethacin: optimization by response surface methodology, Curr. Drug Deliv. 1 (2014) 72e86. [42] R. Dreu, I. Ilic, S. Srcic, Development of a multiple-unit tablet containing enteric-coated pellets, Pharm. Dev. Technol. 16 (2011) 118e126. [43] N. Huyghebaert, A. Vermeire, J.P. Remon, Alternative method for enteric coating of HPMC capsules resulting in ready-to-use enteric-coated capsules, Eur. J. Pharm. Sci. 21 (2004) 617e623. [44] M.C. Fontana, A. Beckenkamp, A. Buffon, R.C. Beck, Controlled release of raloxifene by nanoencapsulation: effect on in vitro antiproliferative activity of human breast cancer cells, Int. J. Nanomedicine 9 (2014) 2979e2991. [45] G.M. ElMaghraby, E.M. Elzayat, F.K. Alanazi, Investigation of in situ gelling alginate formulations as a sustained release vehicle for co-precipitates of dextromethrophan and Eudragit S 100, Acta Pharm. 64 (2014) 29e44. [46] A. Jain, V. Pandey, A. Ganeshpurkar, N. Dubey, D. Bansal, Formulation and characterization of floating microballoons of Nizatidine for effective treatment of gastric ulcers in murine model, Drug Deliv. 22 (2014) 306e311. [47] G. Rai, A.K. Yadav, N.K. Jain, G.P. Agrawal, Eudragit-coated dextran microspheres of 5-fluorouracil for site-specific delivery to colon, Drug Deliv. 21 (2014) 1e10. [48] H. Sun, D. Liu, Y. Li, X. Tang, Y. Cong, Preparation and in vitro/in vivo characterization of enteric-coated nanoparticles loaded with the antihypertensive peptide VLPVPR, Int. J. Nanomedicine 9 (2014) 1709e1716. [49] R. Sareen, N. Jain, K.L. Dhar, Development of colon specific microspheres of flurbiprofen for inflammatory bowel disease, Curr. Drug Deliv. 10 (2013) 564e571. [50] S. Kumar, G. Chawla, A.K. Bansal, Spherical crystallization of mebendazole to improve processability, Pharm. Dev. Technol. 13 (2008) 559e568. [51] S.U. Kucera, J.C. DiNunzio, N. Kaneko, J.W. Mcginity, Evaluation of Ceolus™ microcrystalline cellulose grades for the direct compression of entericcoated pellets, Drug Dev. Ind. Pharm. 38 (2012) 341e350. [52] P.P. Amrutkar, P.D. Chaudhari, S.B. Patil, Design and in vitro evaluation of [53] [54] [55] [56] [57] [58] [59] [60] [61] [62] [63] [64] [65] [66] [67] [68] [69] [70] [71] [72] [73] [74] [75] [76] [77] [78] [79] multiparticulate floating drug delivery system of zolpidem tartarate, Colloids Surf. B Biointerfaces 89 (2012) 182e187. R. Kumria, A.B. Nair, B.E. Al-Dhubiab, Loratidine buccal films for allergic rhinitis: development and evaluation, Drug Dev. Ind. Pharm. 40 (2014) 625e631. R. Kumria, A.B. Nair, G. Goomber, S. Gupta, Buccal films of prednisolone with enhanced bioavailability, Drug Deliv. 21 (2015) 1e8. P. Minghetti, F. Cilurzo, A. Casiraghi, F. Molla, L. Montanari, Dermal patches for the controlled release of miconazole: influence of the drug concentration on the technological characteristics, Drug Dev. Ind. Pharm. 25 (1999) 679e684. S.L. Cantor, S.W. Hoag, L.L. Augsburger, Formulation and characterization of a compacted multiparticulate system for modified release of water-soluble drugsepart II theophylline and cimetidine, Drug Dev. Ind. Pharm. 35 (2009) 568e582. Y. Liu, Y. Sun, J. Sun, N. Zhao, M. Sun, Z. He, Preparation and in vitro/in vivo evaluation of sustained-release venlafaxine hydrochloride pellets, Int. J. Pharm. 426 (2012) 21e28. A. Maeda, T. Shinoda, N. Ito, Evaluating tamsulosin hydrochloride-released microparticles prepared using single-step matrix coating, Int. J. Pharm. 408 (2011) 1e2. H. He, H. Li, X. Tang, Preparation of pH-dependent modified-release pellets of urapidil to improve its bioavailability, Pharm. Dev. Technol. 16 (2011) 212e218. G. Kibria, M.A. Roni, M.S. Absar, R.U. Jalil, Effect of plasticizer on release kinetics of diclofenac sodium pellets coated with Eudragit RS30D, AAPS PharmSciTech 9 (2008) 1240e1246. L. Meka, A. Thadisetty, V. Vobalaboina, R.Y. Madhusudan, Design and evaluation of a novel matrix type multiple units as biphasic gastroretentive drug delivery systems, AAPS PharmSciTech 9 (2008) 1253e1261. I. Singh, V. Rana, Iron oxide induced enhancement of mucoadhesive potential of Eudragit RLPO: formulation, evaluation and optimization of mucoadhesive drug delivery system, Expert Opin. Drug Deliv. 10 (2013) 1179e1191. S. Pandey, P. Jirwankar, S. Mehta, S. Pandit, P. Tripathi, A. Patil, Formulation and evaluation of bilayeredgastroretentablemucoadhesive patch for stomach-specific drug delivery, Curr. Drug Deliv. 10 (2013) 374e383. J. Sahoo, P.N. Murthy, S. Biswal, Manik, Formulation of sustained-release dosage form of verapamil hydrochloride by solid dispersion technique using Eudragit RLPO or Kollidon SR, AAPS PharmSciTech 10 (2009) 27e33. G. Singh, R.S. Pai, Atazanavir-loaded Eudragit RL 100 nanoparticles to improve oral bioavailability: optimization and in vitro/in vivo appraisal, Drug Deliv. 25 (2014) 1e8. K.C. Ofokansi, F.C. Kenechukwu, Formulation development and evaluation of drug release kinetics from colon-targeted ibuprofen tablets based on eudragit RL 100-chitosan interpolyelectrolyte complexes, ISRN Pharm. 6 (2013) 1e8. C.R. Palem, S.K. Battu, S. Maddineni, R. Gannu, M.A. Repka, M.R. Yamsani, Oral transmucosal delivery of domperidone from immediate release films produced via hot-melt extrusion technology, Pharm. Dev. Technol. 18 (2013) 186e195. R. Thakur, G. Swami, M. Rahman, Development and optimization of controlled release bioerodableanti infective ophthalmic insert, Curr. Drug. Deliv. 11 (2014) 2e10. H. Boyapally, R.K. Nukala, D. Douroumis, Development and release mechanism of diltiazem HCl prolonged release matrix tablets, Drug Deliv. 16 (2009) 67e74. G. Kibria, K.M. Islam, R.U. Jalil, Stability study of ambroxol hydrochloride sustained release pellets coated with acrylic polymer, Pak. J. Pharm. Sci. 22 (2009) 36e43. A. Gandhi, S. Jana, K.K. Sen, In-vitro release of acyclovir loaded Eudragit RLPO nanoparticles for sustained drug delivery, Int. J. BiolMacromol. 67 (2014) 478e482. C.R. Palem, R. Gannu, N. Doodipala, V.V. Yamsini, M.R. Yasmani, Transmucosal delivery of domperidone from bilayered buccal patches: in vitro, ex vivo and in vivo characterization, Arch. Pharm. Res. 34 (2011) 1701e1710. J. Varshosaz, H. Faghihian, K. Rastgoo, Preparation and characterization of metoprolol controlled-release solid dispersions, Drug Deliv. 13 (2006) 295e302. S. Dahiya, K. Pathak, R. Sharma, Development of extended release coevaporates and coprecipitates of promethazine HCl with acrylic polymers: formulation considerations, Chem. Pharm. Bull. 56 (2008) 504e508. D. Chen, D. Singh, K.K. Sirkar, R. Pfeffer, Continuous synthesis of polymercoated drug particles by porous hollow fiber membrane-based antisolvent crystallization, Langmuir 31 (2015) 432e441. H. Roy, C.K. Brahma, S. Nandi, K.R. Parida, Formulation and design of sustained release matrix tablets of metformin hydrochloride: influence of hypromellose and polyacrylate polymers, Int. J. Appl. Basic Med. Res. 3 (2013) 55e63. T. Mamatha, R. Venkateswara, K. Mukkanti, G. Ramesh, Development of matrix type transdermal patches of lercanidipine hydrochloride: physicochemical and in-vitro characterization, Daru 18 (2010) 9e16. B. Mandal, K.S. Alexander, A.T. Riga, Sulfacetamide loaded Eudragit® RL100 nanosuspension with potential for ocular delivery, J. Pharm. Pharm. Sci. 13 (2010) 510e523. U.A. Shinde, J.N. Shete, H.A. Nair, K.H. Singh, EudragitRL100 based Ch.N. Patra et al. / Future Journal of Pharmaceutical Sciences 3 (2017) 33e45 [80] [81] [82] [83] [84] [85] [86] [87] [88] [89] [90] [91] microspheres for ocular administration of azelastine hydrochloride, J. Microencapsul. 29 (2012) 511e519. E.A. Takmaz, O. Inal, T. Baykara, Studies on transdermal delivery enhancement of zidovudine, AAPS PharmSciTech 10 (2009) 88e97. R. Pignatello, N. Ricupero, C. Bucolo, F. Maugari, A. Maltese, G. Puglisi, Preparation and characterization of eudragit retard nanosuspensions for the ocular delivery of cloricromene, AAPS PharmSciTech 24 (2006) E27. H. Piao, S. Liu, H. Piao, Development of an osmotically-driven pellet coated with acrylic copolymers (Eudragit® RS 30D) for the sustained release of oxymatrine, a freely water soluble drug used to treat stress ulcers (I): in vitro and in vivo evaluation in rabbits, Drug Dev. Ind. Pharm. 39 (2013) 1230e1237. A. Porwal, G. Swami, S. Saraf, Preparation and evaluation of sustained release microballoons of propranolol, Daru 19 (2011) 193e201. M.R. Abbaspour, F. Sadeghi, H.A. Garekani, Preparation and characterization of ibuprofen pellets based on Eudragit RS PO and RL PO or their combination, Int. J. Pharm. 303 (2005) 88e94. W. Zhang, X. Li, T. Ye, et al., Nanostructured lipid carrier surface modified with Eudragit RS 100 and its potential ophthalmic functions, Int. J. Nanomedicine 9 (2014) 4305e4315. D.T. Baviskar, V.B. Parik, D.J. Jain, Development of matrix-type transdermal delivery of lornoxicam: in vitro evaluation and pharmacodynamic and pharmacokinetic studies in albino rats, PDA J. Pharm. Sci. Technol. 67 (2013) 9e22. G. Kibria, K.M. Islam, R.U. Jalil, Stability study of ambroxol hydrochloride sustained release pellets coated with acrylic polymer, Pak. J. Pharm. Sci. 22 (2009) 36e43. , M. Rabiskov sek, A. Prokopova , The effect of K. Krejcova a, D. Vetchý, V. Toma polymeric dispersion type on the release of diclofenac sodium from coated pellets, Ceska Slov. Farm. 56 (2007) 190e199. M.A. Roni, G. Kibria, R.F. Jalil, Formulation and in vitro evaluation of alfuzosin extended release tablets using directly compressible Eudragit, Indian J. Pharm. Sci. 71 (2009) 252e258. S.K. Sahoo, S. Dhal, P. Mohapatro, B.C. Behera, B.B. Barik, Effect of processing temperature on Eudragit RS PO microsphere characteristics in the solvent evaporation process, Pharmazie 62 (2007) 638e639. A. Boza, I. Caraballo, J.F. Alvarez, A.M. Rabasco, Evaluation of Eudragit RS-PO and Ethocel 100 matrices for the controlled release of lobenzarit disodium, Drug Dev. Ind. Pharm. 25 (1999) 229e233. 45 , P.C. Schmidt, Development of matrix-based [92] H. Rey, K.G. Wagner, P. Wehrle theophylline sustained-release microtablets, Drug Dev. Ind. Pharm. 26 (2000) 21e26. [93] R. Tiwari, A. Gupta, M. Joshi, G. Tiwari, Bilayer tablet formulation of metformin HCl and acarbose: a novel approach to control diabetes, PDA J. Pharm. Sci. Technol. 68 (2014) 138e152. [94] V. Mathur, K. Nagpal, S.K. Singh, D.N. Mishra, Comparative release profile of sustained release matrix tablets of verapamil HCl, Int. J. Pharm. Investig. 3 (2013) 60e65. [95] S.A. Tayel, M.A. El-Nabarawi, M.I. Tadros, W.H. Abd-Elsalam, Positively charged polymeric nanoparticle reservoirs of terbinafine hydrochloride: preclinical implications for controlled drug delivery in the aqueous humor of rabbits, AAPS PharmSciTech 14 (2013) 782e793. [96] N.V. Gupta, S. Natasha, A. Getyala, R.S. Bhat, Bioadhesive vaginal tablets containing spray dried microspheres loaded with clotrimazole for treatment of vaginal candidiasis, Acta Pharm. 63 (2013) 359e372. le ne, Colonic delivery using zn/pectin beads with a eudragit [97] A. Antoine, H. He coating. US Patent: 20080124279. 2008; May 29. [98] J.H. Choy, G.E. Choi, M.C. Park, et al. Ursodeoxycholic acid-synthetic hydrotalcite-eudragit hybrid, pharmaceutical composition containing the same and method for preparing the same. US Patent: 20120156263. 2012; Jun 21. [99] A.H. Shojaei, E.C. Melissa. Modified release tablet formulations with enhanced mechanical properties. US Patent: 20070104782. 2007; February 08. [100] H. Tummala, S. Kumar. Curcuminoid complexes with enhanced stability, solubility and/or bioavailability.US Patent: 20140271530. 2014; September 18. [101] C. David, T. Rong-jen, L. Hue-in. Improved stabilization of misoprostol. European Patent :0896823. 2002; September 25. [102] P.H. Jorge. Coated senna extract granules. WO/2011/014976. 2011; October 02. [103] C. Lebon, D. Marechal, P. Suplie. ketoprofen microgranules, method for preparing same and pharmaceutical compositions. WO/2000/064432. 2000; November 11. [104] F. Robert, R. Narayan, Z. Joseph et al., Formulation stabilizer for proton pump inhibitors.US Patent :20060013880. 2006; January 19. [105] H. Stevens, M. Chariot, F. Arnold. Sustained release pharmaceutical composition. EP0322277. 1992; January 22. [106] A. Andremont, H. Huguet. Colonic delivery of metallo-dependent enzymes. US Patent: 20080199528. 2008; August 21. [107] O. Isa. Oral drug delivery formulations. US Patent: 20150250733. 2015; September 10.