EUDRAGIT® RL 30 D/RS 30 D - Sustained Release with Talc as

advertisement

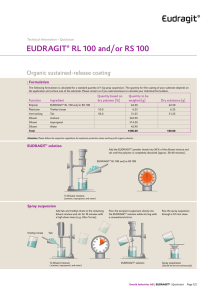

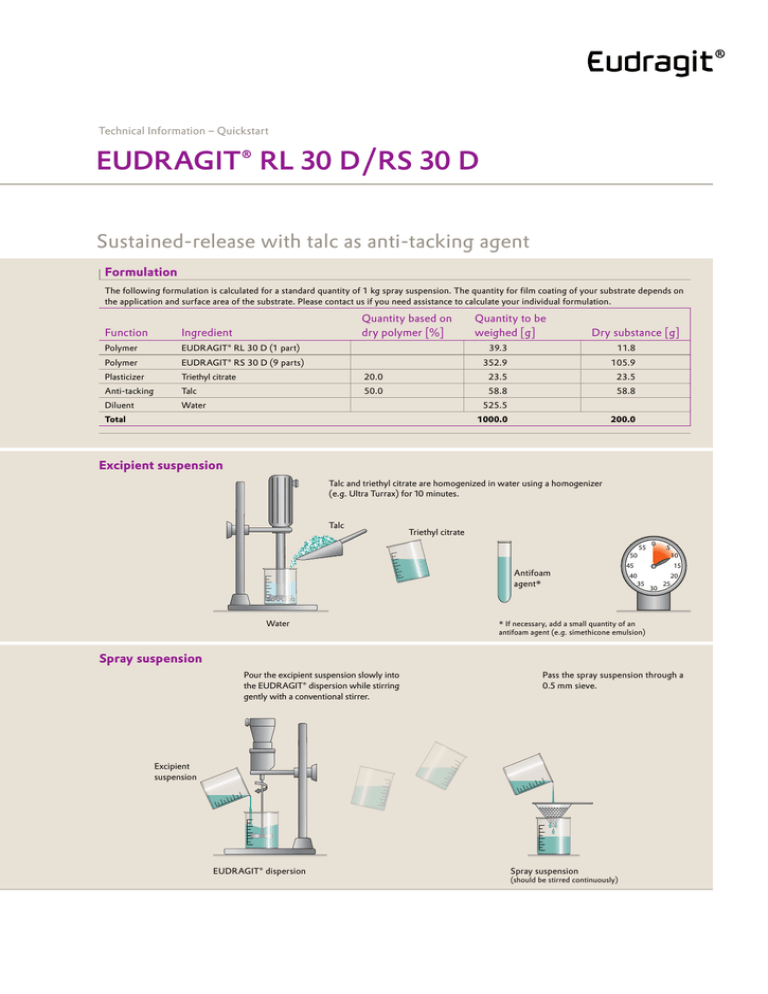

Technical Information – Quickstart EUDRAGIT® RL 30 D/RS 30 D Sustained-release with talc as anti-tacking agent Formulation The following formulation is calculated for a standard quantity of 1 kg spray suspension. The quantity for film coating of your substrate depends on the application and surface area of the substrate. Please contact us if you need assistance to calculate your individual formulation. Quantity based on dry polymer [%] Quantity to be weighed [g] Function Ingredient Polymer EUDRAGIT® RL 30 D (1 part) Dry substance [g] Polymer EUDRAGIT® RS 30 D (9 parts) Plasticizer Triethyl citrate 20.0 23.5 23.5 Anti-tacking Talc 50.0 58.8 58.8 Diluent Water 39.3 11.8 352.9 105.9 525.5 Total 1000.0 200.0 Excipient suspension Talc and triethyl citrate are homogenized in water using a homogenizer (e.g. Ultra Turrax) for 10 minutes. Talc Triethyl citrate 55 0 50 Antifoam agent* Water 10 45 40 35 5 15 30 20 25 * If necessary, add a small quantity of an antifoam agent (e.g. simethicone emulsion) Spray suspension Pour the excipient suspension slowly into the EUDRAGIT® dispersion while stirring gently with a conventional stirrer. Pass the spray suspension through a 0.5 mm sieve. Excipient suspension EUDRAGIT® dispersion Spray suspension (should be stirred continuously) Coating parameters: The tables below give examples of process parameters for film coating. Please do not hesitate to contact us if you need assistance to find the right parameters for your specific equipment, batch size, and substrate combination. EUDRAGIT® RL 30 D/RS 30 D on particles (1 kg) in Glatt GPCG 1.1, top spray Equipment setup Nozzle bore mm 1.2 Distance nozzle/product cm 10 Internal silicone tube diameter mm 2 Atomizing air pressure bar 2.0 Filter rattling time s 5 Filter rattling interval s 45 Drying air volume m³/h 45 –90 Drying air capacity m³/min/kg 0.75 –1.5 Inlet air temperature °C 35 –50 Exhaust air temperature °C 25 –30 Product temperature °C 25 –30 Spray rate g/min/kg 8 –12 Inlet air temperature °C 20 –55 Drying air capacity m3/min/kg 1.2 –1.7 Exhaust air temperature °C 30 –50 Product temperature °C 45 –50 Exhaust air humidity % r.h. 10 –15 Water spray rate ml/kg 240 Spraying time min 30 Process parameter setup Process data In process curing ® = registered trademark EUDRAGIT is a registered trademark of Evonik Röhm GmbH, Darmstadt, Germany. Evonik Industries AG Kirschenallee, 64293 Darmstadt, Germany eudragit@evonik.com www.eudragit.com www.eudragit.com/e-lab www.evonik.com Dec 2011, V 3.0 This information and all further technical advice is based on our present knowledge and experience. However, it implies no liability or other legal responsibility on our part, also with regard to existing third party intellectual property rights, especially patent rights. In particular, no warranty, whether express or implied, or guarantee of product properties in the legal sense is intended or implied. We reserve the right to make any changes according to technological progress or further developments. The customer is not released from the obligation to conduct careful inspection and testing of incoming goods. Performance of the product described herein should be verified by testing, which should be carried out only by qualified experts in the sole responsibility of a customer. Reference to trade names used by other companies is neither a recommendation, nor does it imply that similar products could not be used.