Maharashtra State Board of Technical

Education,Mumbai

A

PROJECT REPORT ON

"AUTOMATIC WATER IRRIGATION SYSTEM"

SUBMITTED BY

MR. KARTIK CHAURANGNATH PALVE

MR. ASHWIN JANARDAN ZIJNJAL

GUIDED BY

PROF. VIJAY J. SHRINATH

DEPARTMENT OF ELECTRONICS AND

TELECOMMUNICATION ENGINEERING

ACADEMIC YEAR

2022-23

GOVERNMENT POLYTECHNIC, VIKRAMGAD

AT:-SHIL, POST:-ONDE,ZADPOLI SHIL ROAD,

TAL:- VIKRAMGAD, DIST:- PALGHAR, 401 605

E-MAIL:-gpvikramgad11@gmail.com

WEBSITE:- gpvikramgad.ac.in

"Automatic water irrigation system"

Diploma Engineering in

(Electronics and Telecommunication Engineering)

By

MR. Kartik Chaurangnath Palve

MR. Ashwin Janardan Zinjal

Under The Guidance of

Prof. Vijay J. Shrinath Sir

Department of Electronics and Telecommunication

Engineering

Government Polytechnic Vikramgad

At. Shil, Post-Onde, Zadpoli Shil Road. Tal-Vikramgad

Dist-Palghar-401605

GOVERNMENT POLYTECHNIC VIKRAMGAD

DIST-PALGHAR, 401605

CERTIFICATE

This is to certify That

1) Kartik Chaurangnath Palve

2) Ashwin Janardan Zinjal

Have satisfactorily completed the requirements of

the PROJECT

As prescribed by the Maharashtra State Board of

Technical Education Mumbai

Under the Guidance of

Prof. Vijay J. Shrinath

Guide

H.O.D

Prof. Vijay J. Shrinath

Prof.R.D.MOON

Principal

Shri. Jagdish P.Kshirsagar

INDEX

SR NO

CHAPTER NAME

ACKNOWLEDGEMENT

1)

ABSTRACT

2)

INTRODUCTION

3)

4)

BLOCK

DIAGRAM

CIRCUIT DIAGRAM

DISCRIPTION

HARDWARE DESIGN:

5)

PCB DESIGNING & LAYOUT

6)

SOFTWARE PROGRAMMING

7)

APPLICTION

8)

BIBLIOGRAPHY

9)

CONCLUSION

AND

4.1)ARDUINO UNO

4.2)LCD Display

4.3)Soil Moisture Sensor

4.4)Relay

4.5)BC 547 Transistor

4.6)LM324

4.7) IN4007 Diode.

4.8)12V DC Adapter

4.9)12V DC Motor-

ACKNOWLEDGEMENT

We take the opportunity to express gratitude towards the

people who have rendered valuable help in completing this

project. The successful completion of our project within the

stipulated time frame is a result of collective efforts our group

as well as many people who proved to be instrumental in this

course of completing this project. Here, we would like to thank

all those people for their help and guidance.

We would like to thank our principle Shri. Jagdish

P.Kshirsagar sir & also H.O.D. Dept. of E&TC, Prof. Mr. R. D.

Moon Sir for his encouragement in completing this project.

We would also like to thank our project coordinator and

project guide prof. Mr. Vijay J. Shrinath Sir.

PROJECT DEFINATION

P-Planning Before Carrying Out the Work

R-Raw Material Required To the Work

O-Opportunity to Show Our Skill

J-Joint Efforts Put Together In Work

E-Enthusiasm for Making Project

C-Consumption Of Less Material And Expenditure

T-Technical Knowledge Improvement

Chapter-1

ABSTRACT

ABSTRACT

India is the agriculture based country. Our ancient

people completely depended on the agriculture harvesting.

Agriculture is a source of livelihood of majority Indians and

has great impact on the economy of the country. In dry areas

or in case of inadequate rainfall, irrigation becomes difficult.

So, it needs to be automated for proper yield and handle

remotely for farmer safety. Increasing energy cost and

decreasing water supplies point out the need for better

management. Irrigation management is a complex decision

making process determine when and how much water to

apply to a growing crop to meet specific management

objectives. If the farmer is a far from the agriculture land he

will not be noticed of current condition. So, efficient water

management plays an important role in the irrigated

agriculture cropping systems.

This embedded project is to design and develop a low

cost feature which is based on embedded platform for water

irrigation system. This project uses soil moisture sensor to

detect the water quantity present in agriculture.

The project uses Arduino micro-controller which is

controller to process the information.

The aim of the implementation was to demonstrate that

the automatic irrigation can be used to reduce water use.

Chapter-2

INTRODUCTION

INTRODUCTION

By using the concept of modern irrigation system a farmer

can water up to 50%. This concept depends on two irrigation

methods those are: conventional irrigation method like

overhead sprinklers, flood type flooding system i.e. wet the

lower leaves and stem of the plants. The area between the crop

rows become dry as the large amount of water is consumed by

the flood type methods, in which case the farmers depends only

on the incidental rainfalls. The crops are been infected by the

leaf mold fungi as the soil surface often stays wet and is

saturated after irrigation is completed.

Overcoming these drawbacks new techniques are been

adopted in the irrigation techniques, through which small

amount of water applies to the parts of root zone of a plant. The

plant soil moisture stress is prevented by providing required

amount of water resources frequently or often daily by which the

moisture condition of the soil will retain well. The diagram below

shows the entire concept of the modern irrigation system. The

traditional technique like sprinkler or surface irrigation requires

/ uses nearly half of water sources. Even more precise amounts

of water can be supplied for plants. As far as the foliage is

dry the plant damage due to disease and insects will be

reduced, which further reduces the operating cost.

The dry rows between plants will lead to continuous

federations during the irrigation process. Fertilizer can be

applied through this type of system, and the cost required for

will also reduce. The erosion of soil and wind is much reduced

by the technique when compare with overhead sprinkler

system. The soil characteristics will define the form of the

dripping nature in the root zone of a plant which receives

moisture.

As the method of dripping will reduce huge water losses it

became a popular method by reducing the labor cost and

increasing the yields. When the components are activated, all

the components will read and gives the output signal to the

controller, and the information will be displayed to the user

(farmer). The sensor readings are analog in nature so the ADC

pin in controller will convert the analog signals into digital

format. Then the controller will access information and when the

motors are turned on/off it will be displayed on the LCD panel.

Chapter-3

Block Diagram and Circuit

Diagram Description

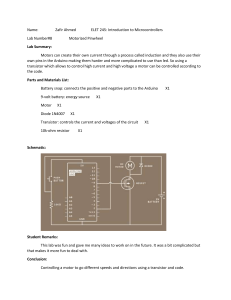

BLOCK DIAGRAM:

Fig: Block Diagram

There are two functional components in this project. They are

the moisture sensors module and the motor driver for motor

pump. Thus the Arduino Board is programmed using the

Arduino IDE software. The function of the moisture sensor is to

sense the temperature content present in the soil, and also it

measure moisture level in the soil. The motor driver interrupts

the signal to, water pump supplies water to the plants. This

project uses microcontroller Arduino Uno board to controls the

motor and monitor soil moisture. Follow the schematic to

connect the Arduino to the motor driver, and the driver to the

water pump.The motor can be driven by a 5 volt battery, we can

also supplies power from external source or from Arduino

board. The Arduino Board is programmed using the Arduino

IDE software.

Circuit Diagram:

Fig: Circuit Diagram

Here In this figure: soil moisture sensors are connected

to Arduino A0 pin for analog input, so we can get temperature

content present in soil. Vcc pin is

connected through 5V Arduino pin; GND pin is representing

ground to connect all components. D7 is known as a digital pin,

so it connected with transistors to amplifying low power. Motor

driver module VCC pin connected through D13 pin of Arduino

board, based on temperature monitor it pass the current to the

motor pump, D7 pin is used for Ground. We can write values as

output. D7 connected through resistors 1k and same

connection goes through transistors for low amplifying current.

In transistor has three pin which we called as Emitter, base and

collector.

Chapter-4

Hardware

Hardware

4.1 Arduino

Fig 4.1: Arduino

Arduino is an open-source prototyping platform based on

easy-to-use hardware and software. Arduino boards are able to

read inputs - light on a sensor, a finger on a button, or a twitter

message and turn it into an output - activating a motor, turning

on an LED, publishing something online. We can tell our board

what to do by sending a set of instruction to the microcontroller

on the board. To do so we use the Arduino programming

language (based on wiring), and the Arduino software (IDE),

based on processing.

The arduino Uno can be powered via the USB connection with

or with an external power supply. The power source is selected

automatically. External (non- USB) power can come from an ACto-DC adapter (wall- wart) or battery. The adapter can be

connected by plugging a 2.1mm center-positive plug into the

board's power jack. Leads from battery can be inserted in the

Gnd and Vin pin headers of the POWER connector. The board

can operate on external supply of 6 to 20nvolts. If supplied with

less than 7V, however, the 5V pin may supply less than five volts

and the board may be unstable. If using more than 12V, the

voltage regulator may overheat and damage the board. The

recommended range is 7 to 12 volts.

FEATURE

SPECIFICATION

Microcontroller

Operating voltage

Input voltage

(recommended).

Input voltage (limits).

Digital I/O pins

Analog input pins

DC current per I/O pin

DC current for 3.3V pin

Flash memory

ATmega328

5V

7-12 volts

SRAM

EEPROM

Clock speed

6-20V

14

6

40mA

50mA

52 KB (ATmega328) of which

0.5KB used by boot loader

2KB (ATmega328)

1KB (ATmega328)

16 MHz

4.2 LCD Display:

Fig. Liquid Crystal Display

A liquid-crystal display (LCD) is a flat-panel display or other

electronically modulated optical device that uses the lightmodulating properties of liquid crystals. Liquid crystals do not

emit light directly, instead using a backlight or reflector to

produce images in color or monochrome. LCDs are available to

display arbitrary images (as in a general-purpose computer

display) or fixed images with low information content, which can

be displayed or hidden, such as preset words, digits, and seven

segment display, as in digital clock.

LCD (Liquid Crystal Display) screen is an electronic display

module and find a wide range of applications. A 16x2 display is

very basic module and is very commonly used in various devices

and circuits. Here we connected 2&15 no. pin in Vcc and 1,

3, 5 & 16 no. pin connected in ground. A 16*2 LCD means

it can display 16 Character per line and there are 2 such

lines.

Pin No:

Name

Function

1

VSS

This pin must be

connected to the

ground

Positive supply

2

VCC

3

VEE

4

RS

5

R/W

Contrast

adjustment

Register

selection

Read or Write

6

E

Enable

7

DBO

Data

8

DB1

Data

9

DB2

Data

10

DB3

Data

11

DB4

Data

12

DB5

Data

13

DB6

Data

14

DB7

Data

15

LED+

Back light LED+

16

LED-

Back light LED-

4.3 Soil Moisture Sensor:

Fig: Soil Moisture Sensor

Although soil water status can be determined by direct (soil

sampling) and indirect (soil moisture sensing) method. Direct

method of monitoring soil moisture are not commonly used for

irrigation scheduling because they are intrusive and labor

intensive and cannot provide immediate feedback. Soil

moisture probes can be permanently installed t representative

points in an agricultural field to provide repeated moisture

reading overtime that can be used for irrigation management.

Special care is needed when using soil moisture devices in

coarse soil since most device require close contact with soil

matrix that is sometime difficult to achieve in this soils.

Measuring soil moisture is very important in agriculture to

help to help farmer for managing the irrigation system. Soil

moisture sensor is one who solves this. This sensor measures

the content of water. Soil moisture sensor uses the capacitance

to measure the water content of soil. It easy to use this sensors.

Simply insert this rugged sensor into the soil to be tested, and

the volumetric content of the soil is

reported in percent. Soil moisture sensors measure the

volumetric water content in soil.

Since the direct gravimetric measurement of free soil

moister requires removing, drying, and weighting of a sample,

soil moisture sensor measure the volumetric water contents

indirectly by using some other property of the soil, such as

electrical resistance,dielectric constant, or interaction with

neutrons, as a proxy for the moisture content the relation

between the measure property and soil moisture must be

calibrated and may vary depending on environmental factors

such as soil type, temperature, or electric conductivity.

Reflected microwave radiation is affected by the soil moisture

and is use for remote sensing in hydrology and agriculture.

Portable probe instruments can be used by farmers of

gardeners.

moisture sensors typically refer to sensors typically refers

to sensors that volumetric water content. Another class of

sensors measure another property of moisture in soils called

water potential; these sensors are usually referred to as the soil

water potential sensors and include tensiometers and gypsum

block.

4.4 Relay:

Fig: Relay

A relay is an electrically operated switch. Many relays use

an electromagnet to mechanically operate a switch, but other

operating principles are also used such as solid-state relays.

Relays are used where it I necessary to control a circuit by a

separate low-power signal, or where several circuits must be

controlled by one signal. The first relays were used in long

distance telegraph circuits as amplifiers: they repeated the

signal coming in from one circuit and retransmitted it on another

circuit. Relays were used extensively in telephone exchanges

and early computers to perform logical operation.

4.5 BC 547 Transistor:

Fig 4.5 BC 547 Transistor & Symbol

BC547 is an NPN transistor. A transistor, stands for transfer of

resistance, is commonly used to amplify current. A small

current at its base controls a larger at collector & emitter

terminals.

BC547 is mainly used for amplification and switching purposes.

It has a maximum current gain of 800. Its equivalent transistors

are BC548 and BC549.

The transistor terminals require a fixed DC voltage to operate in

the desired region of its characteristic curves. This is known as

the biasing. For amplification

applications, the transistor is biased such that it is partly on for

all input conditions. The input signal at base is amplified and

taken at the emitter. BC547 is used in common emitter

configuration for amplifiers. The voltage divider is the commonly

used biasing mode. For switching applications, transistor is

biased so that it remains fully on if there is a signal at its base.

In the absence of base signal, it gets completely off.

4.6 10K Preset:

Fig: Preset

This article is about the electrical component. For the

measuring instrument, see Potentiometer (measuring

instrument).

A typical single-turn potentiometer

Type

-

Passive

Electronic symbol

(IEC Standard)

(ANSI Standard)

A potentiometer is a three-terminal resistor with a sliding or

rotating contact that forms an adjustable voltage divider. If only

two terminals are used, one end and the wiper, it acts as a

variable resistor or rheostat.

The measuring instrument called a potentiometer is

essentially a voltage divider used for measuring electric potential

(voltage); the component is an implementation of the same

principle, hence its name.

Potentiometers are commonly used to control electrical

devices such as volume controls on audio equipment.

Potentiometers operated by a mechanism can be used as

position transducers, for example, in a joystick. Potentiometers

are rarely used to directly control significant power (more than a

watt), since the power dissipated in the potentiometer would be

comparable to the power in the controlled load.

4.7IN4007 Diode:

Fig: IN4007 Diode

It is a PN junction diode. Diodes can be made by combining

two different types of semiconductor e.g. P and N. PN junction is

a junction formed between P and N types of semiconductors.

You guys should also have a look at introduction of IN4007

diode.

IN4007 belongs to the series of 1NXXXX devices. Its an

American standard numbering system standard used for

semiconductor devices. This standard has been adopted

globally now. In 1N 4007 the first part 1N indicates single junction

semiconductor. 1N indicates junction 1 junction whereas N

indicates the semiconductor diode. 4007 is the specific number

to indicate the particular diode. From the electrical point of view,

1N 4007 is compatible with other rectifier diodes. The diodes

belonging to 1N400X series can be replaced by this particular

diode. They are normally used in Embedded Systems

Projects. So, let's get started with IN4007:

4.8 12V DC Adapter:

Fig: 12V AC/DC Adapter

A "wall wart" type AC adapter for a household game console

A power brick for Lenovo laptop

Internal adapter circuitry

An AC adapter, AC/DC adapter,or AC/DC converter is a

type of external power supply, often enclosed in a case similar

to an AC plug. Other common names include plug pack, plugin adapter, adapter block, domestic mains adapter, line

power adapter, wall wart, power brick, and power adapter.

Adapters for battery-powered equipment may be described as

chargers or rechargers (see also battery charger). AC adapters

are used with electrical devices that require power but do not

contain internal components to derive the required voltage and

power from mains power. The internal circuitry of an external

power supply is very similar to the design that would be used for

a built-in or internal supply.

External power supplies are used both with equipment with

no other source of power and with battery-powered equipment,

where the supply, when plugged in, can sometimes charge the

battery in addition to powering the equipment.

Use of an external power supply allows portability of

equipment powered either by mains or battery without the added

bulk of internal power components, and makes it unnecessary to

produce equipment for use only with a specified power source;

the same device can be powered from 120 VAC or 230 VAC

mains, vehicle or aircraft battery by using a different adapter.

Another advantage of these designs can be increased safety;

since the hazardous 120 or 240 volt mains power is transformed

to a lower, safer voltage at the wall outlet and the appliance that

is handled by the user is powered by this lower voltage.

4.9 12V DC Motor (100 rpm):

Fig: DC motor

Introduction

100RPM Centre Shaft Economy Series DC Motor is high

quality low cost DC geared motor.It has steel gears and pinions

to ensure longer life and better wear and tear properties.The

gears are fixed on hardened steel spindles polished to a mirror

finish.The output shaft rotates in a plastic bushing.The whole

assembly is covered with a plastic ring.Gearbox is sealed and

lubricated with lithium grease and require no maintenance.The

motor is screwed to the gear box.Although motor gives 100 RPM

at 12V but motor

runs smoothly from 4V to 12V and gives wide range of RPM, and

torque. Tables below gives fairly good idea of the motor's

performance in terms of RPM and no load current as a function

of voltage and stall torque, stall current as a function of voltage.

For compatible wheels refer to Wheels and Accessories

product category.

You can also mount this motor on the chassis using Motor

Mount for Centre Shaft Economy Series DC Motor

For adding Position Encoder, refer to Encoder Kit for

Centre Shaft Economy Series DC Motor.

Specifications

•

•

•

•

•

•

•

•

•

•

•

DC supply: 4 to 12V

RPM: 100 at 12V

Total length: 46mm

Motor diameter: 36mm

Motor length: 25mm

Brush type: Precious metal

Gear head diameter: 37mm

Gear head length: 21mm

Output shaft: Center

Shaft diameter: 6mm

Shaft length: 22mm

• Gear assembly: Spur

• Motor weight: 100gms

Inside view of Centre Shaft Economy Series DC Motor

Motor Mounting Clamp and Position Encode

Kit for Centre Shaft Economy Series DC

Motor

Fig: DC motor

Chapter-5

PCB Designing and Layout

PCB LAYOUT PROCESS

A printed circuit board, or PCB, is used to mechanically

support and electrically connect electronic components using

conductive pathways, track or etched from copper sheets

laminated on to anon-conductive substrate. It also referred to as

printed wiring board. A PCB populated with electronics

components is printed circuit Assembly (PCA), also Known as a

printed circuit board assembly (PCBA).

ETCHING

Etching is traditionally the process of using strong acid or

mordant to cut into the unprotected parts of a metal surface to

create a design in intaglio (incised) in the metal.[14] In modern

manufacturing, other chemicals may be on other types of

material. As method a of printmaking, it is, along with engraving,

the most important technique for old master prints, and remains

in wide use today. In a number of modern variants such as

microfabrication etching and photochemical milling it is a crucial

technique inter much modern technology,

including circuit boards.

1)Silk screen printing:

Screen printing is a printing technique whereby a mesh is

used to transfer ink onto a substrate, except in areas made

impermeable to the ink by a blocking stencil. A blade or

squeegee is moved across the screen to fill the open mesh

apertures with ink, and a reverse stroke then causes the screen

to touch the substrate momentarily along a line of contact. This

causes the ink to wet the substrate and be pulled out of the mesh

apertures as the screen springs back after the blade has passed.

One color is printed at a time, so several screens can be used to

produce a multicoloured image or design.

2)Photoengraving:

Photoengraving is a process that uses a light- sensitive

photoresist applied to the surface to be engraved to create a

mask that shields some areas during a subsequent operation

which etches, dissolves, or otherwise removes some or all of the

material from the unshielded areas. Normally applied to metal, it

can also be used on glass, plastic and other materials.

3)PCB milling:

A milled printed circuit board

Printed circuit board milling (also: isolation milling) is the

process of removing areas of copper from a sheet of printed

circuit board material to recreate the pads, signal traces and

structures according to patterns from a digital circuit board

plan known as a layout file. Similar to the more common and

well known chemical PCB etch process, the PCB milling

process is subtractive: material is removed to create the

electrical isolation and ground planes required. However,

unlike the chemical etch process, PCB milling is typically a

non- chemical process and as such it can be completed in a

typical office or lab environment without exposure to

hazardous chemicals.

High quality circuit boards can be produced using either

process. In the case of PCB milling, the quality of a circuit

board is chiefly determined by the system's true, or weighted,

milling accuracy and control as well as the condition

(sharpness, temper) of the milling bits and their respective

feed/rotational speeds. By contrast, in the chemical etch

process, the quality of a circuit board depends on the accuracy

and/or quality of the photomasking and the state of the etching

chemicals.

Fig.5.1Layout

Chapter-6

Software & Programming

SOFTWARE

• Arduino IDE is an open source software that is mainly used

for writing and compiling the code into the Arduino Module.

• It is an official Arduino software, making code compilation too

easy that even a common person with no prior technical

knowledge can get their feet wet with the learning process.

• It is easily available for operating systems like MAC, Windows,

Linux and runs on the Java Platform that comes with inbuilt

functions and commands that play a vital role for debugging,

editing and compiling the code in environment.

• A range of Arduino modules available including Arduino Uno,

Arduino Mega, Arduino Leonardo, Arduino Micro and many

more.

• Each of them contains a microcontroller on the board that is

actually programmed and accepts the information in the form

of code.

• The main code, also known as a sketch, created the IDE

platform will ultimately generate a Hex File which is then

transferred and uploaded in the controller on the board.

• The IDE environment mainly contains two basic parts: Editor

and Compiler where former is used for writing the required

code and later is used for compiling and uploading the code

into the Arduino Module.

• This environment supports both C and C++ languages.

#include<LiquidCrystal.h>

#define moisture_sensorPin A0

#define float_switchPin A1

#define motorPin 4

#define soil_statusPin 2

#define tank_statusPin 3

LiquidCrystal led (13,12,11,10,9,8);

const int avg_moisture = 800;

void setup()

{

Serial.begin(9600);

lcd.begin(16,2);

lcd.clear();

lcd.setCursor(0,0);

lcd.print("AUTOMATIC ");

lcd.setCursor(0,1);

lcd.print("IRRIGATION S/M");

delay(2000);

pinMode(moisture_sensorPin,INPUT);

pinMode(float_switchPin,INPUT);

pinMode(motorPin,OUTPUT);

pinMode(soil_statusPin,OUTPUT);

pinMode(tank_statusPin,OUTPUT);

digitalWrite(motorPin,LOW);

digitalWrite(soil_statusPin,LOW);

digitalWrite(tank_statusPin,LOW);

}

Void loop()

{

lcd.begin(16,2);

lcd.setCursor(0,0);

lcd.print(“MOISTURE”);

if(analogRead(moisture_sensorPin) > avg_moisture)

{

lcd.print ("HIGH");

digitalWrite(soil_statusPin, HIGH);

}

if (analogRead (moisture_sensorPin) < avg_moisture)

{

lcd.print (" LOW");

digitalWrite(soil_statusPin, LOW);

}

lcd.setCursor(0, 1);

led.print ("TANK LEVEL- ");

if(digitalRead(float_switchPin) == HIGH)

{

lcd.print ("HIGH");

digitalWrite(tank_statusPin, LOW);

}

if(digitalRead(float_switchPin) == LOW)

{

lcd.print ("LOW");

digitalWrite(tank_statusPin, HIGH);

if

(analogRead

(moisture_sensorPin)

digitalRead(float_switchPin) == HIGH)

<

avg

moisture

&&

avg_moisture

&&

{

while

(analogRead

(moisture_sensorPin)

digitalRead(float_switchPin) == HIGH)

{

lcd.setCursor (0,0);

lcd.print ("MOISTURE - LOW");

lcd.setCursor(0,1);

lcd.print (" MOTOR IS ON ");

digitalWrite(soil_statusPin, LOW);

digitalWrite(tank_statusPin, LOW);

digitalWrite (motor Pin, HIGH);

}

if (analogRead (moisture sensorPin) > avg_moisture)

{

<

lcd.setCursor(0,0);

lcd.print(" MOISTURE - HIGH");

lcd.setCursor(0,1);

lcd.print (" MOTOR - OFF ");

digitalWrite(soil_status Pin, HIGH);

digitalWrite (motor Pin, LOW);

delay (3000);

if (digitalRead (float_switch Pin) == LOW

{

lcd.setCursor(0,0);

lcd.print (" TANK LEVEL- LOW");

lcd.setCursor(0,1);

lcd.print (" MOTOR - OFF ");

digitalWrite(tank_statusPin, HIGH);

digitalWrite (motor Pin, LOW);

delay (3000);

delay(500);

}

}

Chapter-7

APPLICATION

APLLICATION

Irrigation is the application of controlled amounts of water

to plants at needed intervals. Irrigation helps to grow agricultural

crops, maintain landscapes, and revegetate disturbed soils in

dry areas and during periods of less than average rainfall.

Irrigation also has other uses in crop production, including frost

protection, suppressing weed growth in grain fields and

preventing soil consolidation.In contrast, agriculture that relies

only on direct rainfall is referred to as rain-fed or dry land

farming.

Irrigation systems are also used for cooling livestock, dust

suppression, disposal of sewage, and in mining. Irrigation is

often studied together with drainage, which is the removal of

surface and sub-surface water from a given area.

Chapter-8

Bibliography

Websites:

1) www.google.com

2)www.wikipedia.com

3)www.youtube.com

4)www.electohub.com

5)www.arduino.cc

BOOKS:

1)Principle of electronics

2)Embedded “C” programming

Chapter-9

CONCLUSION

CONCLUSION

The primary applications of this project are for farmer and

gardeners who do not have enough time to water their

crops/plants. It also covers those who are wasteful of water

during irrigation.

As water supplies becomes scarce and polluted, there is

need to irrigate more efficiently in order to minimize water use

and chemical leaching. Recent advances in soil water sensing

make the commercial use of this technology is possible to

automate irrigation management for vegetables production.

However, research indicate that different sensors types

perform under all condition with no negative impact on crop

yields with reduction in water use range as high 70% compared

to traditional practices.

* Thank You *