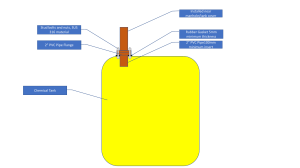

L&T-CHIYODA LIMITED FLANGES & DESIGN OF NON STANDARD FLANGE NON-STANDARD TABLE OF CONTENTS •Introduction •Type of Flanges •Classification of flanges based on Pressure temperature rating •Type of Flange faces •Gasket and their properties •Bolting data as per TEMA •Forces acting g on a flange g •Design of Loose Ring Flange •Design of Weld Neck Flange FLANGES Flanges are piping Fl i i components t usedd for f connecting ti pipes i which needs dismantling & periodic maintenance, other piping components like valves, specialties, instrument items like orifice, flow meters etc on to the pipes. A flanged joint is composed of three separate & independent although interrelated components; the flanges, the gaskets & the fasteners. FLANGE TYPES ¾Welding neck flange ¾Slip-on flange ¾Lap joint flange ¾Screwed flange ¾Blind flange WELDING NECK FLANGE They have Th h a long, l tapered t d hub h b between the flange ring and the weld joint. This hub provides a gradual transition from the flange ring thickness to the pipe wall thickness thereby decreasing the discontinuity and increasing the strength. Preferred P f d ffor extreme t service i conditions diti suchh as high hi h temperature, t t high hi h pressure, wide fluctuations in pressure and temperature and subzero temperature. SLIP-ON SLIP ON FLANGE The use of this type of flange should be limited to moderate services where pressure fluctuations, fl i temperature fluctuations, vibrations and shock are not expected to be severe. The strength of this flange is around 2/3 times to that of weld neck flange. The fatigue life of this type of flange is 1/3 that of a weld neck flange. The slip-on type of flange is widely used because of its greater ease of alignment li t in i welding ldi assembly bl and d bbecause off it its llow iinitial iti l cost. t LAP JOINT FLANGE The principal advantage of these flanges is that the bolt holes are easily aligned, and this simplifies the erection of the vessel. They are also useful in cases where frequent dismantling for cleaning or inspection is required Its fatigue life is about 10% of the fatigue life of the weld neck flanges. flanges SCREWED FLANGE The screwed flanges are used on pipelines where welding cannot be carried out. BLIND FLANGE The blind flanges are used to close the ends which need to be reopened later. FLANGE CLASSIFICATION BASED ON PRESSURE TEMPERATURE RATING • • • • • • • • • • • 125 # (CI) 150 # 250 # (CI) 300 # 400 # 600 # 900 # 1500 # 2500 # 5000 # 10000 # TYPES OF FLANGE FACE • Raised Face (RF) • Tongue g & Groove (T/G) ( ) • Male & Female (M/F) • Ring Type Joint (RTJ) • Flat Face (FF) RAISED FACE (RF) •Theyy are suitable for average g service conditions. For severe service involving high pressure, high temperature, thermal shock, or cyclic operations, this type of flange facing may not be satisfactory. satisfactory •Raised face is 1/16” for 150# & 300# which ¼” for higher rating. •Unconfined gasket. MALE & FEMALE (M/F) •Male & Female facings have the advantage of confining the gasket and thereby minimizing the possibility of blowout of the gasket. gasket •The two mating flanges are not identical. For this reason these flanges are not widely used on pipe-line connections as are the raised i d face f flanges. fl •They offer no protection against forcing the gasket into the vessel. •Recessed O.D. normally is not more than 1/16" larger than the O.D. of the male face. •Joint must be pried apart for disassembly TONGUE & GROOVE (T/G) ( ) •Fully Confined Gasket •Groove usuallyy not over 1/16" wider than tongue g •Gasket dimensions will match tongue dimensions •The flange is less subject to erosive and corrosive contact with the vessel •The tongue is more likely to get damaged than the groove. Therefore the tongue is normally attached to the part which can b easily be il removedd from f the h vessel. l RING TYPE JOINT (RTJ) •This type of facing is used severe service conditions and for hazardous fluids . •It is used in petroleum, petrochemical and high-pressure equipments. •Close tolerances and high standards of machining are required , as a result this type of flange is seldom used for diameters larger than 36”. •The main disadvantage of this type of facing is the high cost of manufacturing. It is the most expensive face. FLAT FACE (FF) They are mainly used for rubber lined equipments for chemical plants. plants They are used for equipments operating under low pressure. Since the width of the gasket is more, the gasket seating force is more. GASKETS Gaskets are relatively softer material which are inserted between flanges to avoid leakage. Tightening the bolts causes the gasket material to flow into the minor machining imperfections, p , resultingg in a fluid tight g seal. Gaskets are made of materials which are not chemically affected by the fluid in the pipe and which are resistant to deterioration by temperature. temperature PROPERTIES OF IDEAL GASKET •Be sufficiently deformable to flow into imperfections on the seating surfaces to create an initial seal. seal •Have sufficient strength to resist crushing under the applied load and defyy rupture p under ppressure. •Chemically resist fluid under all temperatures and pressures. •Never Never promote corrosion of the seating surface. surface DESIGN OF FLANGE 1-BOLT LOAD 2-HYDROSTATIC END FORCE 3-INTERNAL PRESSURE 1 3 2 OPERATING CONDITION Required bolt load for the operating conditions Wm1 should be sufficient enough to resist the hydrostatic end force H and also maintain the gasket joint-contact surface load Hp Wm1 = H + Hp = 0.785G2P + 2b x 3.14GmP G = Diameter at the gasket load reaction b = Effective ff i gasket k width id h P = Internal pressure m = Gasket factor ( It is ration of the gasket stress when the vessel is under internal pressure to the internal pressure ) GASKET SEATING CONDITION Minimum required bolt load for gasket seating Wm2 = 3.14bGy y = gasket-contact surface seating stress LOOSE RING FLANGE 4.00 70 CAF 650 Select M20 x 24 No. of bolts Fillet size = 8 mm BCD C = 650 + 2 x 8 + 2 + 23.81 OD of flange A = 725 + 2 x 23.81 Width of gasket Gasket OD Gasket ID Minimum spacing of bolts = 725 mm = 775 mm = 20 mm = 690 mm = 650 mm = 52.39 mm b0 = basic gasket seating width = N / 2 = 10 mm b = effective ff ti gasket k t width idth = b0 when h b0 < ¼ “ else b = 0.5 ( b0)0.5 G = O.D. of gasket – 2b 20 b0 b 10 7.97 674.06 112.49 2 Maximum bolt spacing = 2d + 6t / ( m+0.5) = 2x20 + 6x40/(2+0.5) = 136 mm assumedd thk hk off fl flange is i 40 mm 94.9 52.39 29 5 29.5 23 81 23.81 25 23.81 1406.17 1758 1406.17 1758 19185 86 19185.86 1079 98 1079.98 2698.9 5209.22 14268.5 55250.15 16967.48 19.355 HD = hydrostatic end force on the area inside of flange HT = difference between the hydrostatic end force & hydrostatic end force on the area inside of flange HP = gasket load 13273.23 37.5 497.745 2698.9 25.46 68.76 1000.5 31.48 31.51 598.032 55250.22 650 1407.72 25.46 11.13 1.19 26.98 41.4 41.4 62 1 FLANGE ROTATION OR FLANGE RIGIDITY Angular distortion of a flange under the influence of bolt and reaction forces. Measured with respect p to the center of the cross section of the flange. Flanges have been designed based on allowable stress limits alone may not be sufficiently rigid enough to control leakage. J =109.4M 109 4MO / Et3ln(K)K l (K)KL = 109.4 x 1407720 / 19475.03 x 623 In(1.19) x 0.2 = 0.953 WELD NECK FLANGE 343.00 fgg fgg fgg fgg FLANGE ROTATION OR FLANGE RIGIDITY J =52.14MOV / LEgo2hoKI = 52.14 x 19657140 x 0.3375 10.44 x 18280.25 x 102 x 129.23 x 0.3 = 0.46 OPTIONAL TYPE FLANGE This type covers designs where the attachment of the flange to the nozzle neck vessel or pipe wall is such that the assembly is considered to act as a unit, i which hi h shall h ll be b calculated l l d as an integral i l flange, fl except that h for f simplicity the designer may calculate the construction as a loose type flange provided none of the following values is exceeded : go = 5/8” 5/8 ( 16 mm ) B / go = 300 P = 300 psi Operating temperature = 700 oF