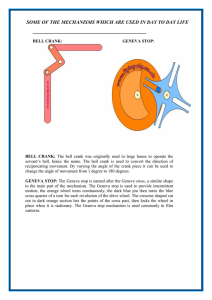

PLATE NO.2 Use an A4 paper for this activity. Research about the different kinds of mechanism then write at least 3 pages of discussion about the different kinds of mechanism. Note: Write ONLY in Engineering lettering. Height of lettering should be 4mm. Space between paragraph line is 1mm. Have a word count of atleast 800 words. In kinematics, a mechanism is a means of transmitting, controlling, or constraining relative movement. Movements which are electrically, magnetically, pneumatically operated are excluded from the concept of mechanism. The central theme for mechanisms is rigid bodies connected together by joints. 1. Linkage mechanisms Linkage mechanisms consist of interconnected rigid bodies, often referred to as links, joined together by movable joints. These mechanisms convert input motion or force into the desired output motion or force, enabling machines and devices to perform complex tasks with remarkable efficiency and precision. 1.1 Four bar linkages a mechanical linkage which consists of four rigid bars connected by joints or pivots. It forms a closed loop and exhibits a range of motion and mechanical advantages. Four-bar linkages are widely used in various applications, such as in machinery, robotics, and automotive systems, to achieve controlled and predictable movements, including rotation, translation, and oscillation. Linkages have different functions. The functions are classified depending on the primary goal of the mechanism: Function generation: the relative motion between the links connected to the frame, Path generation: the path of a tracer point, or Motion generation: the motion of the coupler link Examples: Crane - An application of path generation is a crane in which an approximate horizontal trace is needed. Hood - An example of motion generation is a hood which opens and closes. Parallelogram Mechanism - In a parallelogram four-bar linkage, the orientation of the coupler does not change during the motion. 1.2 Slider-crank mechanisms The slider crank mechanism is a typical mechanical linkage that changes rotational motion into linear motion or the other way around. It is widely used in various applications, including internal combustion engines, pumps and compressors, presses, robotics, toy cars, and human-powered vehicles. The slider-crank mechanism consists of three main components: a crank, a connecting rod, and a slider. The crank is a rotating shaft driven by a motor or other power source. The connecting rod is a linear link that connects the crank to the slider. The slider is a sliding element that moves back and forth along a straight line. As the crank rotates, it drives the connecting rod and slider through a series of pivot points, causing the slider to move back and forth. The speed and distance of the slider’s movement can be controlled by adjusting the connecting rod’s length, the crank’s speed, or the pivot points’ position. Examples: Crank and Piston - You can also use the slider as the input link and the crank as the output link. In this case, the mechanism transfers translational motion into rotary motion. The pistons and crank in an internal combustion engine are an example of this type of mechanism. Block Feeder - The block feeding mechanism comprises a mechanical arm used for picking up blocks and a first power part used for driving the mechanical arm to carry out feeding, and the first power part is fixedly connected with the mechanical arm. 2. Cam mechanisms Linkages, while useful, cannot achieve all possible motions. For example, if the output link must remain stationary for a certain period of time while the input link keeps turning, linkages cannot be used. Cam mechanisms can realize any required output motion. The composition of a cam mechanisms is simple: a cam, a follower and a frame. 3. Gears Gears are mechanisms that mesh together via teeth and are used to transmit rotary motion from one shaft to another. Gears are defined by two important items: radius and number of teeth. They are typically mounted, or connected to other parts, via a shaft or base. EXAMPLES Rack and pinion - A rack and pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack). Together, they convert rotational motion into linear motion. Rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. Ordinary gear trains - Gear trains consist of two or more gears that transmit motion from one axis to another. Ordinary gear trains have axes, relative to the frame, for all gears comprising the train. Planetary gear train - Generally, planetary gears are used as speed reducers. They are used to slow down motors and increase the torque. Torque is the working power of the machine. 4. Ratchet mechanism Ratchets are mechanisms that serve to limit either rotary or linear motion to only one direction. A ratchet is composed of three main parts: a round gear, a pawl, and a base. A ratchet mechanism is based on a wheel that has teeth cut out of it and a pawl that follows as the wheel turns. Studying the diagram you will see that as the ratchet wheel turns and the pawl falls into the 'dip' between the teeth. A wheel with suitably shaped teeth, receiving an intermittent circular motion from an oscillating member, is a ratchet wheel. 5. Geneva Wheel The Geneva wheel, or Maltese cross, is a cam like mechanism that provides intermittent rotary motion & is widely used in both low and high-speed machinery. Although originally developed as a stop to prevent over winding of watches, it is now extensively used in automatic machinery, e.g. where a spindle, turret, or worktable must be indexed. It is also used in motion picture projectors to provide the intermittent advance of the film.