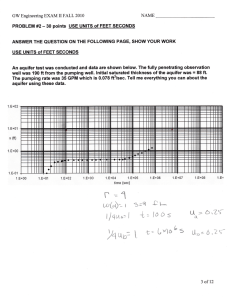

Design of Tube Well At the end of this session, learners will be able to: • Understand particle size analysis • Identify standard curves of grain size distribution • Define effective size and uniformity coefficient • Design the housing pipe and well casing • Select the strata to be screened • Design the well screen Design of Tube well The design of a tube well involves the following steps: 1. Mechanical analysis of samples of the underground formation obtained from various depths and the preparation of a well log 2. Design of housing pipe and well casing (plain pipe) 3. Design of well screen 4. Design of gravel pack Analysis of particle size of the aquifer • The determination of the particle size distribution of aquifer materials collected from various depths is of prime importance in the design of the intake portion of a tube well. • Dry sieve analysis of the formation samples obtained during the drilling of test boreholes or production wells reveals the characteristics of the water-bearing formations. • The results provide the basis for decisions about the specifications of the well screens and the design of the gravel pack. • The standard procedure for analyzing sand/soil samples by the dry sieving method is adopted. • The weight of the material retained on each sieve is recorded. • These weights are then expressed as a percentage of the total weight of the sample and a graph plotted through the cumulative per cent of the sample retained on a given sieve and all the other seives above it, versus the size of the given sieve, expressed in mm (Fig. 2). • The percentage of the sample retained is plotted on the y-axis and the size of the sieve-opening or ‘particle size’ on the x-axis. • It is common practice to plot the graph on semi-log paper, with the x-axis on the logarithmic scale. • The size of the sieve opening is considered to be the diameter of the smallest particle retained by each sieve. • Figure 2 represents the typical sieve analysis curves for distinct classes of aquifer materials, indicating the water bearing characteristics of the formation and the need for artificial gravel pack. • The following terms are used for defining the size characteristics of aquifer materials. Effective Size, d10 The term ‘effective size’ is defined as formation particle size, where 10 per cent of the sand is finer and 90 per cent coarser. For example, the class C curve of Fig. 2 shows that 90 per cent of the sample consists of sand grains larger than 0.25 mm, or that 10 per cent is smaller than this size. Thus, the effective size of the formation material is 0.25 mm. Uniformity coefficient, Cu This is a ratio expressing the variation in grain size of a granular material. It is usually measured by the sieve aperture that passes 60 per cent of the material, divided by the sieve aperture that passes 10 per cent of the material. Thus, in Class C curve (Fig. 2), the uniformity coefficient is 0.75 mm divided by 0.25 mm, i.e. 3. This ratio was proposed by Hazen (1893) as a quantitative expression of the degree of assortment of water bearing sand, as an indicator of porosity. The value of the coefficient for complete assortment (one grain size) is unity, while for fairly even-grained sand it ranges between 2 and 3. For heterogeneous sand, the value will be high. Generally, a material is classified as uniform if the uniformity coefficient Cu is less than 2. Design of the housing pipe and well casing • The design of the housing pipe and well casing will include the selection of a suitable material and diameter and thickness of pipe. Diameter of the housing pipe • The housing pipe is an enlarged section of the well casing at the top of the well, in order to house a deep-well turbine pump or submersible pump. • It should be large enough to accommodate the pump with adequate clearance. • The annular space between the pump and the inner diameter of the housing pipe also permits the installation of an air line to measure the depth to pumping water level. • The housing pipe should be at least 5 cm more in diameter than the nominal diameter of the pump. • The diameter and thickness of the housing pipe (steel pipe) are given in Table 1. Table 1: Diameter and thickness of housing pipes of tube wells for different sizes of submersible pumps Depth of housing pipe • The depth of housing pipe below the ground level is selected such that the pump is always submerged in water. • Since the pump is lowered in the housing pipe, it must be set a few meters below the lowest drawdown level, taking into account the seasonal fluctuations in the spring level or water table, interference from adjoining tube wells and the likely lowering of the water table due to future development of ground water in the area. Diameter of the well casing pipe • The diameter of the pipe of the well section below the pump housing is fixed by the permissible velocity of water through the pipe. • Since the strata suitable for strainers are usually met in layers at different levels, the velocity of water in a pipe of a given size would not be constant, but will increase towards the top. • The velocity may vary between limits of 1.5-4.5 m/s. It is theoretically possible to reduce the size of a pipe from the top to the bottom such that the velocity is more or less constant throughout the pipe length. However, it is not an economical proposition. • The usual practice is to provide a pipe of constant diameter. • A velocity of the order of 2.5-3 m/s is found to be most suitable. • Having fixed the velocity, the diameter of the pipe can be determined for a given discharge. • The relationships Q/v = a and a = d2/4, where Q is the discharge, a the area of crosssection of pipe, and d its diameter, are used to determine the pipe size. Thickness of well casing pipe • The casing pipe must resist substantial stress from compressive, tensile and shear forces. • In addition, it should last for 20-40 years after installation. • Steel has proved to be one of the most practical materials. • Steel pipes are produced in several thicknesses. • Heavier pipes should be used where severe corrosion is expected. • If the soil and water are only mildly corrosive, lighter wall thicknesses may be adequate. • The thickness of well casing pipe is usually recommended as a function of the diameter and depth of the well. • The thickness of the well casing, usually adopted under normal conditions (Ahrens, 1970), is given in Table 2. The values of the thicknesses given apply to plain as well as perforated casings (well screens). Table 2: Suggested thickness of well casing pipe, mm Bore size and well depth • The bore diameter and depth of wells are important parameters influencing the yield of wells. • The size of the well bore should suit the diameter of the well casing. • Gravel pack wells require extra bore size to accommodate the gravel pack in the annular space between the bore hole and the well casing. • The depth and thickness of the water-bearing formations influence the depth of the well. • Shallow tube wells usually tap water only from the top unconfined aquifer, while deep tube wells draw their supplies mainly from the confined aquifers below the unconfined aquifer. Bore size • The bore of a tube well has to be at least 5 cm bigger in diameter than the casing pipe. • This will facilitate the lowering of the pipe. • Thus, for a tube well of size 20 cm, a minimum bore of 25 cm is necessary. • If gravel pack is to be used, the minimum diameter should be twice the thickness of the gravel pack plus the outside diameter of the casing pipe. • However, in case of tube wells drilled with reverse rotary rigs, the diameter of the bore is about 60 cm. • In such a situation, if the tube well diameter at the screen section is 15 cm, the thickness of the gravel pack will be 22.5 cm up to the housing. • If the housing is of 30 cm diameter, the thickness of the gravel pack will be reduced to 15 cm. • In case of a well drilled with a direct rotary-drilling rig, different diameters of the bore could be obtained by under reaming, with a view to use lesser thicknesses of the gravel pack. • However, the thickness of the gravel pack should not ordinarily be less than 7.5 cm. Well depth • The depth of a tube well depends upon the locations of water-bearing formations, desired yield of the well and economic considerations. • Generally, a well log showing the locations of water-bearing formations is prepared and the strata to be tapped selected. • The depth of the well is decided on the basis of the hydraulic conductivity of the aquifer material and the desired yield of the well. • Often, if the desired yield is not possible at a reasonable depth, it will be necessary to limit the depth without achieving the desired discharge. • Sometimes the depth of the well will have to be curtailed if poor quality ground water is encountered in lower aquifers. Selection of strata to be screened • After the particle size distribution of the formation samples are obtained from various depths, the average size, effective size and uniformity coefficient of the aquifer material are marked on the strata chart. • This would help to determine the thickness and relative permeability of each aquifer. • The permeability of the aquifer is proportional to the square of the effective grain size d10, for the same uniformity coefficient, Cu. • In case two samples have the same effective size, the sample with a lower value of uniformity coefficient is more permeable. • In case of an unconfined aquifer which is too thick and homogeneous, it is desirable to provide the screen in the lower 1/3rd thickness. • In case of confined aquifers with thick and nearly homogeneous strata, about 75-90 per cent of the central part of the aquifer should be screened. • Where the aquifers are too thick and heterogeneous, it is common practice to place screens opposite the more permeable beds, leaving about 30 cm depth both at the top and bottom of the aquifer, so that the finer material in the transition zone does not move into the well. • The top of the screen should be set below the lowest pumping level allowed, keeping in view possible fluctuations of the water table. Design of well screen • The well screen is the most important component of a well. The life of a well is governed mainly by the life of the screen, which should, therefore, be carefully designed. The basic requirements of a well screen are: (i) It should be resistant to corrosion and deterioration. (ii) It should be strong enough to prevent collapse. (iii) It should offer minimum resistance to the flow of water, and (iv) It should prevent excessive movement of sand into the well. • A screen in actual practice may represent a compromise of these desirable characteristics. • The design of a well screen will include the determination of the diameter of the screen, its length, percentage of open area, size and shape of each slot, and thickness and material of the screen. • The length of the screen and its placement are governed by the thickness and location of the aquifers. • In case an adequate thickness of water-bearing formations is available, the length of the screen, its diameter, and per cent open area, are governed by the head loss through the screen and its effect on the losses in the aquifer, in addition to the initial cost of the screen. • The size of the slot opening is governed by the size of the gravel or aquifer material which it has to retain. The design principles for different elements of well screen are discussed below: Slot opening • Choosing the right width of the slot of a well screen is one of the important steps in well design. • Over-sized slots will pump finer materials (sand, silt and clay) indefinitely and clear water will be difficult to obtain. • Under-sized slots will provide more resistance to the flow of ground water, resulting in more head loss and corrosion. • Fine slots are also blocked by small sand and silt particles which are carried up to the well screen as suspensions. • The problem of clogging is reduced as the size of well screen openings are increased. Therefore, well screen slot openings should be as wide as possible. • It is determined by matching the size of the opening with the grain-size distribution of the material surrounding the screen. • In practice, the slot size varies from values as low as 0.2 mm to as large as 5 mm. The logical steps for the design of slot openings are as follows: Non gravel-pack wells • The design of the slot opening of a non-gravel-packed or naturally developed well is based on the sieve analysis data of the samples representing the water-bearing formation. • A grain size distribution curve is plotted for each sample. • For a homogeneous formation, the size of screen opening taken is one that will retain 40 per cent of sand if the ground water is not corrosive. • However, if the ground water is corrosive, the screen slot size should be one that will retain 50 per cent of the sand. • The optimum size of the slot opening is determined by selecting a point on the particle size distribution curve of the aquifer, where the 40 per cent (or 50 per cent, as the case may be) line intersects the sample-analysis curve and then determining the screen opening from the horizontal scale. Gravel-pack wells • Size of openings of the slots of well screens for a gravel-packed well are determined on the basis of the particle size distribution curve of the gravel. • On this curve, a point is located indicating the 90 per cent size of the gravel to be retained. • Through this point, a line is drawn parallel to the y-axis, meeting the x-axis at another point which indicates the slot size of the well screen. • The actual size of the slot is fixed at ± 8 per cent of the above size, depending on the size of the tool used in making the slots of the well screen. Percent open area • Water flows more freely through a screen with large open area than through one with limited open area. • When the open area of the screen is large, the entrance velocity is low and head loss at the screen is minimum. • Ahrens (1970) stated that little or no increase in well efficiency results from open areas greater than about 25 per cent, whereas efficiency falls rapidly as the open area becomes less than 15 per cent. • When a screen is placed in an aquifer, sediment will settle down around it and partially block the slot openings. • Walton (1962), observed that, on an average, about one-half of the open area of a well screen is blocked by aquifer materials. • Based on these studies, it may be concluded that it is desirable to provide an open area of about 20 per cent for well screens other than slotted pipes. Diameter of screen • The considerations which govern the diameter and length of the well screen are the per cent open area of the screen, characteristics of the aquifer, cost of the screen, discharge to be pumped from the well, and head loss through the aquifer and the screen. • The diameter should ensure that the area of the opening available in the screen for flow of water, after giving allowance for possible clogging of the screen, should produce a screen entrance velocity of not more than 3 cm/s. • However, in areas where sufficient sand thickness is not available, a maximum entrance velocity of 5 cm/s may be permitted. • It should also be ensured that the percentage of slot area to screen surface area is about 20 per cent. • Generally, the screen diameter is kept the same as that of the casing. • Table 3 gives the recommendations for casing and screen diameters for various discharges to be pumped from the well. Table 3: Recommended diameter of casing pipe and well screen Screen length • The optimum length of the well screen depends upon the thickness and stratification of the aquifer and the available drawdown. • The following guidelines may be followed under various aquifer conditions. i) water table aquifers • In case of homogeneous water table aquifers, the bottom one-third of the aquifer may be screened. • However, in order to obtain higher specific capacity, sometimes the bottom half of the aquifer is screened. ii) Artesian aquifers • In case of homogeneous aquifers, 75 – 90 per cent of the thickness of the water-bearing sand should be screened. • The percentage of the aquifer to be screened increases with the increase in its thickness. • For an aquifer of thickness less than 8 m, screening of 75 per cent is satisfactory. • At least 30 cm of the aquifer depth at the top and bottom of the screen should be left unscreened to safeguard against an error in the placement of screen during installation. • The pumping water level should never fall below the top of the aquifer. • The screen is usually located at the centre of the aquifer. • In case of non-homogeneous aquifers, it is obviously best to screen the most permeable strata. • When the aquifer comprises of various layers of good water bearing strata, each strata is tapped separately by dividing the screen into sections of lengths based on the thickness of the aquifer layer and interspacing with sections of blind pipes. Minimum length of screen • The length of screen to be provided in a well depends on the thickness of the aquifer available, as discussed above. • However, the condition of minimum length required to keep the entrance velocity through the opening less than the permissible value must be satisfied. • An entrance velocity more than the permissible value, will result in excessive pumping of sand. • Sometimes, to satisfy the above condition, the design discharge of the well will have to be reduced. • The values of optimum screen entrance velocities recommended by Walton (1970), on the basis of studies made for several actual case histories of well failures due to clogging of screen openings, is given in Table 4. • To prevent rapid clogging, the minimum length of the well screen for a non-gravel pack well is designed on the basis of the following equation (Walton, 1962): • The equation above is also used to determine the length of the screen in a gravel-pack well. • In this case, the average value of the hydraulic conductivity of the aquifer and the gravel pack is used to determine the entrance velocity of the screen. • To determine the minimum length of the well screen, the optimum entrance velocity, based on the hydraulic conductivity of the aquifer, is determined (The practice being followed in the design of tube wells in unconsolidated formations is to allow a permissible entrance velocity of 3 cm/s through the effective open area of the screen). • From the aquifer test, the expected capacity of the well is estimated. • From the information on the open area of well screen per meter, the effective open area is determined. • The screen length is then estimated using Eq. above. • It is recommended that a screen length greater than this value should be provided wherever possible to keep the entrance velocity lower than 3 cm/s, in order to ensure a longer life of the well. EXAMPLE 1 • A fully penetrating tube well in a confined aquifer has a maximum discharge capacity of 3000 l/min. • The aquifer is overlain and underlain by impervious layers. • The thickness of the aquifer is 22 m. • Design the length of the well screen, assuming the effective open area of the available strainer to be 15 per cent and the diameter of the well 20 cm. Solution • Effective open area per meter length of the well screen is • Assuming the safe entrance velocity to be 3 cm/s or 1.8 m/min, the minimum length of well screen is given by • The aquifer thickness is 22 m. Hence, it will be safe to provide a 20 m length of screen, which is more than the essential length of 18 m and about 90 per cent of the aquifer depth. • The screen may be provided in the central portion of the aquifer, leaving one meter depth of aquifer unscreened at both ends.