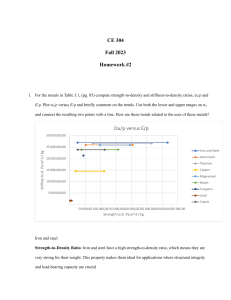

CE 304 Fall 2023 Homework #2 1. For the metals in Table 3.1, (pg. 85) compute strength-to-density and stiffness-to-density ratios, σu/ρ and E/ρ. Plot σu/ρ versus E/ρ and briefly comment on the trends. Use both the lower and upper ranges on σu and connect the resulting two points with a line. How are these trends related to the uses of these metals? Ou/p versus E/p 30 000 000,00 Stiffnes to D. Pa.m^3 / kg 25 000 000,00 Iron and Steel Aluminium 20 000 000,00 Titanium Copper 15 000 000,00 Magnesium 10 000 000,00 Nickel Tungsten 5 000 000,00 Lead Cobalt - 50 000 100 000 150 000 200 000 250 000 300 000 350 000 Strength to D. Pa.m^3 / kg Iron and steel Strength-to-Density Ratio: Iron and steel have a high strength-to-density ratio, which means they are very strong for their weight. This property makes them ideal for applications where structural integrity and load-bearing capacity are crucial Stiffness-to-Density Ratio: Iron and steel also have a relatively high stiffness-to-density ratio. This means they are stiff and can maintain their shape under heavy loads. This property is advantageous in applications where minimal deformation is required Aluminum Strength-to-Density Ratio: Aluminum has a good strength-to-density ratio, although it's not as strong as iron and steel. However, its lower density makes it particularly suitable for applications where weight reduction is critical. Stiffness-to-Density Ratio: Aluminum has a moderate stiffness-to-density ratio, which means it can provide adequate stiffness while keeping the overall weight of a structure or component relatively low. Titanium Strength-to-Density Ratio: Titanium has an excellent strength-to-density ratio, which is one of the highest among metals. This makes it highly desirable for applications where a combination of high strength and low weight is essential. Stiffness-to-Density Ratio: Titanium also has a good stiffness-to-density ratio, which means it can maintain its shape under load Copper Strength-to-Density Ratio: Copper has a relatively low strength-to-density ratio compared to metals like steel and titanium. It is not as strong for its weight. As a result, copper is often used in applications where electrical and thermal conductivity are more important than high strength Stiffness-to-Density Ratio: Copper also has a moderate stiffness-to-density ratio. This property is useful in applications where some rigidity is required Magnesium Strength-to-Density Ratio: Magnesium has a reasonably good strength-to-density ratio, making it one of the lightest structural metals available. It is used in applications where weight reduction is critical Stiffness-to-Density Ratio: Magnesium has a relatively low stiffness-to-density ratio compared to other structural metals like steel or aluminum. This means it is not as stiff and may deform more under load, which can limit its use in some high-stress applications. Nickel Strength-to-Density Ratio: Nickel has a moderate strength-to-density ratio. It is often alloyed with other metals to improve its properties. Stiffness-to-Density Ratio: Nickel has a reasonable stiffness-to-density ratio, making it suitable for applications where a combination of strength, corrosion resistance, and stiffness is required. Tungsten Strength-to-Density Ratio: Tungsten has an exceptional strength-to-density ratio, making it one of the densest and strongest naturally occurring elements. It is primarily used in applications that require extremely high-density materials. Stiffness-to-Density Ratio: Tungsten also has a good stiffness-to-density ratio, which is essential in applications where high-temperature stability and mechanical strength are crucial. Lead Strength-to-Density Ratio: Lead has a relatively low strength-to-density ratio, which means it is not a particularly strong material for its weight. However, lead is known for its high density, which makes it useful for radiation shielding applications Stiffness-to-Density Ratio: Lead also has a low stiffness-to-density ratio, meaning it is not very stiff. This property is not well-suited for structural applications but is valuable for damping vibrations and noise Cobalt Strength-to-Density Ratio: Cobalt has a moderate strength-to-density ratio. It is often used as an alloying element in materials like superalloys, which are used in high-temperature applications Stiffness-to-Density Ratio: Cobalt has a reasonable stiffness-to-density ratio, which contributes to its suitability for high-temperature and high-stress applications. It can maintain its shape and structural integrity under demanding conditions.