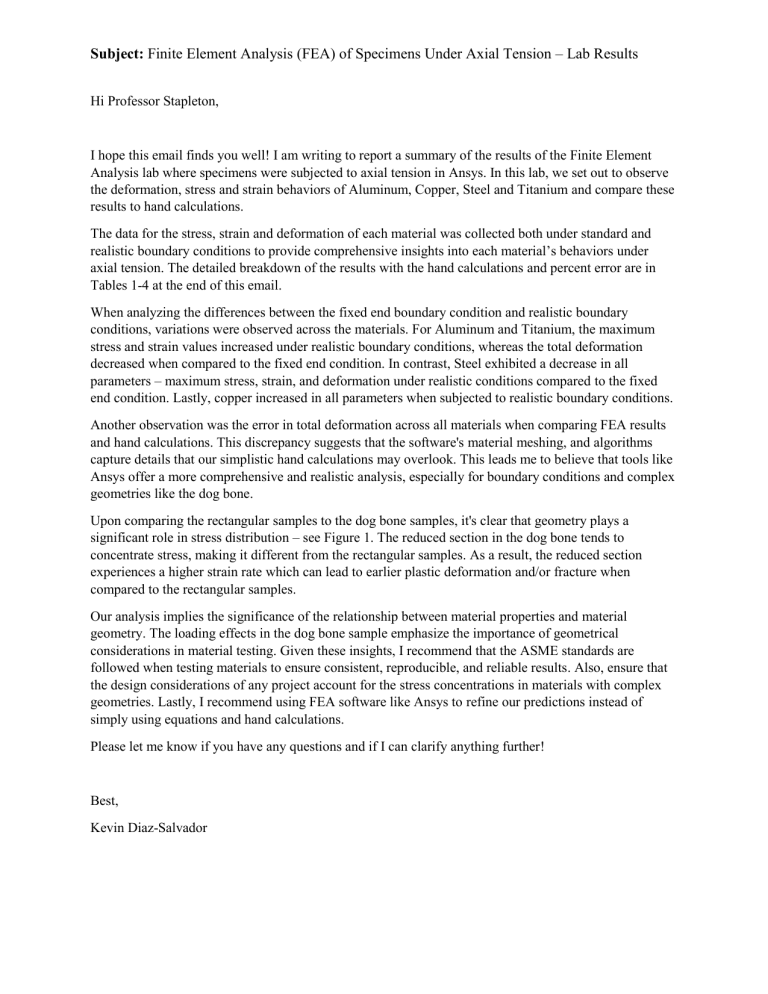

Subject: Finite Element Analysis (FEA) of Specimens Under Axial Tension – Lab Results Hi Professor Stapleton, I hope this email finds you well! I am writing to report a summary of the results of the Finite Element Analysis lab where specimens were subjected to axial tension in Ansys. In this lab, we set out to observe the deformation, stress and strain behaviors of Aluminum, Copper, Steel and Titanium and compare these results to hand calculations. The data for the stress, strain and deformation of each material was collected both under standard and realistic boundary conditions to provide comprehensive insights into each material’s behaviors under axial tension. The detailed breakdown of the results with the hand calculations and percent error are in Tables 1-4 at the end of this email. When analyzing the differences between the fixed end boundary condition and realistic boundary conditions, variations were observed across the materials. For Aluminum and Titanium, the maximum stress and strain values increased under realistic boundary conditions, whereas the total deformation decreased when compared to the fixed end condition. In contrast, Steel exhibited a decrease in all parameters – maximum stress, strain, and deformation under realistic conditions compared to the fixed end condition. Lastly, copper increased in all parameters when subjected to realistic boundary conditions. Another observation was the error in total deformation across all materials when comparing FEA results and hand calculations. This discrepancy suggests that the software's material meshing, and algorithms capture details that our simplistic hand calculations may overlook. This leads me to believe that tools like Ansys offer a more comprehensive and realistic analysis, especially for boundary conditions and complex geometries like the dog bone. Upon comparing the rectangular samples to the dog bone samples, it's clear that geometry plays a significant role in stress distribution – see Figure 1. The reduced section in the dog bone tends to concentrate stress, making it different from the rectangular samples. As a result, the reduced section experiences a higher strain rate which can lead to earlier plastic deformation and/or fracture when compared to the rectangular samples. Our analysis implies the significance of the relationship between material properties and material geometry. The loading effects in the dog bone sample emphasize the importance of geometrical considerations in material testing. Given these insights, I recommend that the ASME standards are followed when testing materials to ensure consistent, reproducible, and reliable results. Also, ensure that the design considerations of any project account for the stress concentrations in materials with complex geometries. Lastly, I recommend using FEA software like Ansys to refine our predictions instead of simply using equations and hand calculations. Please let me know if you have any questions and if I can clarify anything further! Best, Kevin Diaz-Salvador Subject: Finite Element Analysis (FEA) of Specimens Under Axial Tension – Lab Results Aluminum Maximum Deformation (mm) Maximum Strain Experimental Calculation 2.1007 Hand Calculation Error (%) 4.23 101 0.047392 0.0704225 48.6 Maximum Stress 3.3648 5.00 48.6 (GPa) Table 1 – Comparison of Experimental and Hand Calculations for Aluminum under Fixed End Conditions Copper Maximum Deformation (mm) Maximum Strain Experimental Calculation 0.6777 Hand Calculation Error (%) 1.3636 101 0.015421 0.0227273 47.4 Maximum Stress 1.6963 2.5 47.4 (GPa) Table 2 – Comparison of Experimental and Hand Calculations for Copper under Fixed End Conditions Titanium Maximum Deformation (mm) Maximum Strain Experimental Calculation 1.5519 Hand Calculation Error (%) 3.125 101 0.035937 0.0520833 44.9 Maximum Stress 3.4499 5 44.9 (GPa) Table 3 – Comparison of Experimental and Hand Calculations for Titanium under Fixed End Conditions Steel Maximum Deformation (mm) Maximum Strain Experimental Calculation 1.8663 Hand Calculation Error (%) 3.75 101 0.041046 0.0625 52.3 Maximum Stress 8.2092 12.5 52.3 (GPa) Table 4 – Comparison of Experimental and Hand Calculations for Steel under Fixed End Conditions Subject: Finite Element Analysis (FEA) of Specimens Under Axial Tension – Lab Results Figure 1 – Stress Concentration in the Narrowed Section of Dog Bone Sample under Axial Tension