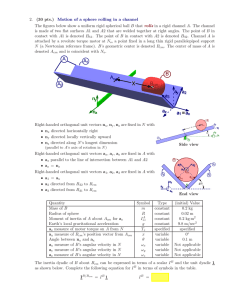

Optimizing and Improving Output of Ballast Cleaning Machine (BCM) - S. K Srivastava, DRM/BKN M. M. Upadhyaya, Sr DEN/C/BKN Synopsis: Ballast is an important constituent of the track structure. During service, ballast loses its resilience owing to various factors. This situation leads to avoidable stress on the track components and under gears of the rolling stock. Therefore, deep screening of ballast is essential at required frequency. Based on ~ 95000 running Track-km length, and at most 10 years frequency, ~9500 km of the track becomes due for deep screening every year. At the rate of current average output per BCM i.e. 5.25 km/month, existing fleet of 118 BCM with IR can deep screen only ~7500 km/ year. Although IR is in the process of buying more BCM, but at the same time, it is the need of the hour to optimize the utilization of available machines by minimizing the avoidable time losses and giving innovative inputs. In the instant paper, the authors have discussed these issues and have suggested the measures to improve the output of the Ballast Cleaning Machines (BCM). *** 1.0 General: Ballast is an important constituent of the track structure, which not only provides strength to the track but also safeguards the formation against the possible damage due to poor drainage conditions. It also helps in reducing wear and tear of the track components as well as rolling stock due to its resilience. This resilience is also necessary for better riding quality, which brings passenger satisfaction. During service, ballast loses its resilience owing to various factors viz. pulverization, inclusion of foreign material like sand, dust, dry leaves, muck, vegetation growth etc. This situation leads to avoidable stresses on the track components and under-gears of the rolling stock. Pre-mature failures of rail/welds do take place in such cases and additional maintenance inputs need to be given to keep the track in safe condition. Moreover, with the growing modernization of the track to achieve better speed potential, mechanized maintenance of track has become inevitable. Availability of minimum 150mm clean ballast cushion is pre-requisite to undertake machine maintenance. As per Para 238 (1) of IRPWM, Deep Screening of ballast needs to be carried out in following circumstances: 1. Prior to complete track renewal. 2. Prior to through sleeper renewal. 3. Where the caking of ballast has resulted in unsatisfactory riding. Page 1 of 10 4. Before converting existing track, fish plated or SWR into LWR or CWR; or before introduction of machine maintenance, unless the ballast was screened in recent past. 5. The entire track must be deep screened at least once in ten years. 2.0 Need for Optimization: As discussed in para 1.0, deep screening has to be carried out at least once in ten years. This is the minimum frequency which can be further increased based on local conditions affecting ballast resilience and drainage property adversely. Assuming an average frequency of once in ten years, 1/10th of ~95000 Track-km, i.e. 9500 km of track becomes due for deep screening every year. On top of that Indian Railways are already having a backlog of deep screening of over 33000 km of plain track and about 15000 main line turnoutsi. At present, Indian Railways have a fleet of 118 nos. of Ballast Cleaning Machines. Average monthly output of BCM over various Railways has been varying from 2.56 track-km to 9.14 track-km with overall average as 5.25 km per machine per month. (Table-1)ii Table-1: Monthly Progress of BCM till November S. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Railway CR ECOR ECR ER NCR NER NFR NR NWR SCR SECR SER SR SWR WCR WR Total No. of M/C Sets 10 5 6 8 9 3 5 10 7 11 5 7 8 6 8 10 118 Actual Progress (km) Actual Progress (T/O) 495 193 325 369 171 143 89 295 215 304 197 199 275 275 290 703 4538 137 18 62 49 46 14 31 32 138 268 0 2 114 29 81 126 1147 Actual Progress (Eq. km) 598 207 372 406 206 154 112 319 319 505 197 201 361 297 351 798 5403 Average progress per machine per month 6.85 4.74 7.10 5.81 2.62 5.88 2.56 3.65 5.22 5.26 4.51 3.29 5.17 5.67 5.02 9.14 5.24 At the present average output @ 5.25 km of deep screening per month per machine, the available capacity for deep screening is only 7434 say 7500 km per year. The existing capacity of deep screening on IR is thus short by about 20% than required. Although IR is in the process of Page 2 of 10 buying more BCM, but unless the utilization of available machines by is improved, existing and accumulating backlog cannot be cleared. 3.0 Design Output vis-à-vis Actual Output: Design output of BCM is 550 m3/hour for the normal machine and 1000 m3/hour for new high output BCM (900 series). Design output is taken for ideal conditions wherein no obstructions are encountered under the track; ballast bed is not very hard; there are no obligatory points like presence of OHE/ Signal masts, which may require adjustment of waste conveyor, etc. The output also depends upon the age of the machine and track features. Fig-1: BCM working in KLYT-PLC Secion Considering average block of 4 hours, in single spell having effective working hours of 2½ hours, ideally one BCM should be able to achieve a progress of about 500 m per day when working alone and progress of 750 m per day when working in convoy of two machines. However in practice due to various losses on Operating, S&T and Engineering account, such as delay in shunting of machines, axle counters not removed in time, bond wires not removed in time, earthing strips not taken out in time, cables/ pipes found at or above formation level, old rails, sleepers, boulders found above formation level etc., affect the output of BCM adversely. Although it may not be feasible to achieve the design output in all cases however by taking certain corrective/ innovative measures it is possible to have near optimum output esp. on those stretches, where deep screening by BCM is being carried out second time or subsequently and much above current average in other locations, as discussed in subsequent paras. Page 3 of 10 4.0 Factors affecting the output and suggested measures: 4.1 Duration of Traffic Block: Ineffective time during deep screening has been assessed to be 60 minutes for plain track and 180 minutes for turnouts.iii as such, longer blocks in single spell shall yield more output than blocks of shorter duration in more than one spell. 4.1.1 Suggestions: Traffic block of minimum 4 hours for plain track and 4½ hours for turnout must be ensured. On single line sections, this can be ensured by regulating a few trains. By deploying two BCM in the convoy with exclusive WST for each BCM, one block section of average 8.0 km length can be handled in 7 to 8 days. On Double Line sections, blocks of longer duration must be planned by introducing single line working. A few trains may be re-scheduled for the purpose. With this method, one block section of average 8.00 km length can be handled in 4 to 5 days. 4.2 Timely Shunting of BCM Convoy: BCM convoy, consisting of BCM, DTS and WST are normally kept in the Track Machine Siding or some Goods Siding. It has been observed that at times, shunting of the convoy is performed during traffic block period, which results into loss of precious working time affecting the output adversely. 4.2.1 Suggestions: (i) It is a good practice to bring the convoy on the main line of the yard, prior to grant of traffic block. For doing so one or two through trains may be required to pass via loop line. Wherever it is not feasible to bring the convoy on the main line of the yard, the convoy must be brought on signaled line and the pilot to exhibit the Hand Signal must be available under the dispatch signal in time so that the block time is not wasted. In Major Yards, where the convoy remains far away from the control tower/ Panel Room, Outdoor Station Master/ Other authorized staff must be there at the leading machine of the convoy to deliver the authority to proceed immediately after the grant of the traffic block. Generally operating staff (ASM/SM) prepares and gives authority/essential papers, to the Machine Operator, after the traffic block is permitted by the Section Controller. This causes unnecessary delay to proceed in the section for working (ii) (iii) (iv) Page 4 of 10 and reduces the effective block hours. At least 5 to 10 minutes can be saved by adopting proper method for paper formalities. 4.3 Proper Planning for working of BCM in Convoy: Generally, blocks of same duration are not granted on regular basis, as such, the output also varies. In case of group working of BCM, at times, there remains less scope of the work for one of the BCM of the convoy. In such cases, the machine needs to be shifted to new location after completing the work in hand and if proper planning is not done in advance, the available block time is wasted. 4.3.1 Suggestions: i) The available scope of work should be assessed on day to day basis and additional cutter bar should be inserted in the track in advance, where the BCM is required to be shifted after completing the work in hand. With this little care, better output can be achieved. (Fig.-2) Fig-2: Planning of BCM working in convoy ii) Generally, in group working, having two BCM, only one WST is given for tamping of deep screened track. It necessitates closure of one BCM, at least 45 minutes before the other one so that the deep screened track may be tamped to restore the traffic at 40 kmph speed. This results into less progress. To achieve better output, either dedicated WST must be provided with each BCM or we may restore the traffic at 20 kmph over the stretch, which could not be tamped after deep screening. Another traffic block of lesser duration say 45 minute to one hour can be taken to tamp this left over stretch to relax the speed to 40 kmph. Page 5 of 10 4.4 Ballasting in advance reduces the output: Output of BCM depends primarily on the advancing speed and height of the excavation chain or excavation depth. Output = (Forwarding speed) X (Cross Sectional area of the cutter bar) Working the BCM at fourth notch gives the best output because the speed of the cutter chain is highest at this notch. However, wear of chain links and wear plates increases proportionately with the speed of the cutter chain. It has been observed that ~10% increase in chain speed, increases ~20% wear in chain links and wear plates. Moreover, in case of higher speed of the cutter chain the ballast is thrown out of the track due the momentum of the chain, which also results into loss of ballast. Due to the fear of loss of ballast, it is a general tendency to train out additional ballast in the track prior to taking up deep screening work. However, this extra ballast on shoulders and crib reduces the output of BCM. Fig-3 4.4.1 Suggestions: Prior to taking up deep screening work, extra ballasting should be avoided unless it is utmost necessary to maintain the track in safe condition immediately after the deep screening. Ballasting prior to deep screening will cause unnecessary pressure on cutter chain, screening unit, main conveyor belt and distributor conveyor belt and machine speed will slow down which will affect the progress of machine adversely. Instead, the ballasting should be done after the deep screening work and initial packing. This will improve the output as well as minimize loss of ballast. Working of BCM at fourth notch improves the output. To take care of increased wear / tear of the chain links, wear plates and tips of the chain made with wear resistant and Page 6 of 10 surface hardened material should be used. Tungsten Carbide tips and surface hardened wear plates have improved the performance of the BCM considerably. Wherever, there is hard ballast bed, working at fourth notch of the BCM gives the best output. Working at lower speed of chain in hard ballast bed stretches reduces the output considerably. Therefore, identification of such stretches must be done in advance and works planned accordingly. Based on our experience, for best results, the speed of chain should not be kept more than 3.5 m/s. 4.5 Proper setting of Screening Unit: Proper setting of the screening unit is required to achieve optimum output. Full extent of the screen surface should be able to handle the separation of muck and ballast, so that desired output can be achieved. While working on curves, the screen also gets tilted in the horizontal plane, which affects the quality and output of the screening. Frequency of screen vibrations and average contact time on the screen surface also affects the output. Therefore, these issues must be given due care. 4.5.1 Suggestion: (i) During dry season, when the ballast and muck is absolutely dry, the screen must be set at the steepest angle i.e. 20°, to achieve the best output. However, when the muck is moist, the angle may be kept between 100 and 200. Proper decision as per the site conditions on daily basis shall help in achieving better output. (ii) On curves, the screening unit gets tilted in the horizontal plane due to super elevation and adversely affects the output as well quality of screening. Provision is available there with the operator to keep the screen in horizontal plane and this must be ensured, while working on curves. (iii) Experience suggests that screen vibration frequency of 30 HZ and average contact time on the screen surface of 3 seconds, results into better output and better cleaning quality. 4.6 Obstructions encountered under the track: Lot of obstructions like cables, pipe lines, boulders, rail posts, old signal foundations etc. are encountered under the track, particularly on the gauge converted stretches or in doubling works stretches. These obstructions account for major time loss of effective working hours and badly affect the output of the BCM. Fig-4 Page 7 of 10 4.6.1 Suggestions: i) Locations of pipe line crossings and cable crossings should be identified with the help of cable route diagram/ pipe line network diagram and corrective action must be taken in advance to isolate them. In many cases, this information may not be found in the records or if found, does not match in the field. In such cases, whenever work is done in and around the yards or near mid-section gang quarters or LC duty huts, technical staff of the concerned department viz S&T, Engineering or Electrical should be kept at site so that such pipes/ cables are disconnected immediately and time loss can be minimized. (i) Adequate gas cutting equipment with competent artisan must always accompany the BCM to cut down the rail posts or any other such metallic obstructions to minimize the time loss. (ii) While working in the yard, where old signaling foundations are suspected to be found, JCB and concrete breakers may be kept to minimize the time loss and to improve the output. 4.7 Time consuming process of putting wooden blocks at the end of day’s work: After completing day’s work, the cutter bar is detached and left in the track. In this portion, the track is supported with the help of wooden blocks and wedges and manual packing of four to five sleepers is done before restoring the traffic. This process is time consuming and due to non-availability of good quality of wooden blocks of adequate thickness, two to three blocks of one-foot width are kept one over the other. This Page 8 of 10 arrangement requires constant watch and stability needs to be checked after passage of each train. Fig.5: Supporting arrangement on completion of day’s work Usual Wooden Blocks 4.7.1 Fabricated Steel blocks used in BKN Suggestions: In Bikaner Division of NWR has resorted to an innovative method wherein steel cuboids, similar to CC Crib, having 60 cm X 60 cm X 30 cm size, made of steel angles, are used in place of conventional wooden blocks to support the track near cutter bar. This activity takes merely five minutes and better support can be given to the track. This saves ~15-20 minutes of time which can be utilized to improve the output of the BCM. 4.8 Other points to keep in mind for improved output: Maintenance Schedule of the machine must be strictly adhered to maintain their good health. This, in turn, shall improve the output of the machine as well. Sufficient spares should be kept in the mobile store, so as to use in case of emergency/failure of machine. This will minimize the failure time and improve the output. Connection/ Disconnection of cutter chain before/ after the BCM working should be carried out by trained staff so that effective working time may be saved to the extent possible. This saved time should be utilized to improve the output of the machine. S&T/ TRD staff should be invariably available at site of work in case of working in track circuiting/ electrified area, so that S&T/ Electrical fixtures, if any, may be timely disconnected/ removed and effective block period may be maximized to the possible extent and output of the machine improved. Page 9 of 10 5.0 Track fastenings should be tightened effectively and missing ones should be recouped so as to avoid hanging of sleepers during cleaning process. Muck wagons should be arranged on through ballasted bridges, station yards and cuttings, where disposal is not possible on sides. Level Crossings should be opened in advance to avoid time loss during BCM working. Conclusion: Output of BCM can be significantly improved to a great extent by meticulous planning, proper monitoring, strictly ensuring pre-requisites for ballast cleaning, better co-ordination among various concerned departments, giving innovative inputs and deploying trained and skilled staff to operate the machines. It has been experienced that by adopting these simple measures ~10 km per machine per month can be achieved without much effort, which is almost double the current average. i TMS Data, November 2019 TMS Data, November 2019 iii Para 606 (1) of IRTMM ii Page 10 of 10