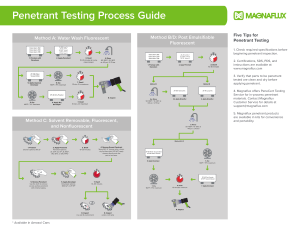

TOTAL NDE SERVICES 1 DYE PENETRANT EXAMINATION PROCEDURE Doc. TNS/PT/01/Rev-1 PROCEDURE DYE PENETRANT EXAMINATION. TNS/PT/04(Q. C. Documents) 1. SCOPE: This work instruction covers Dye Penetrant Examination activities as per the ASME Section V Article 6. The liquid penetrant examination method is an effective means for detecting discontinuities, which are open to the surface of nonporous metals and other materials. Typical discontinuities detectable by this method are cracks, seams, laps, cold shuts, laminations, and porosity. In principle, a liquid penetrant is applied to the surface to be examined and allowed to enter discontinuities. All excess penetrant is then removed, the part is dried, and a developer is applied. The developer functions both as a blotter to absorb penetrant that has been trapped in discontinuities, and as a contrasting background to enhance the visibility of penetrant indications. The following SE Standard provide details, which may be considered in the specific procedure used: (a) SE-165, Standard Practice for Liquid Penetrant Inspection Method 2. Operators Examination: The operators are qualified as per SNT –TC-1A or equivalent standard, the examiner should be qualified from PAEC or ASNT by CUSTOMER based on the technical knowledge and experience of NDT operations. 3.Surface preparation: In general, satisfactory results may be obtained when the surface of the part is in the as-welded, as-rolled, as-cast, or as-forged condition. Surface preparation by grinding, machining, or other methods may be necessary where surface irregularities could mask indications of unacceptable discontinuities. CAUTION: Conditioning of surfaces prior to examination can affect the results. Prior to each liquid penetrant examination the surface to be examined and all adjacent areas within at least in. shall be dry and free of all dirt, grease, lint, scale, welding flux, weld spatter, paint, oil, and other extraneous matter that could obscure surface openings or otherwise interfere with the examination. -4 Drying after Preparation After cleaning, drying of the surfaces to be examined shall be accomplished by normal evaporation or with forced hot or cold air. A minimum period of time shall be established to ensure that the cleaning solution has evaporated prior to application of the penetrant. The surface to be tested, shall be clean dry and free from grease or any other to the correct removal of the excess Penetrant or the right interpretation of the indications. TOTAL NDE SERVICES 2 DYE PENETRANT EXAMINATION PROCEDURE Doc. TNS/PT/01/Rev-1 5. Test Medium System: Standard Practice for Liquid Penetrant Inspection Method Test Medium System Manufacturer Magna Flux Dye Penetrant SKL-SP1 Developer SKD-S2 Cleaner/water wash SKC-S It is not permissible to interchange the test medium system on the same test item. Other test media require prior consent of customer. 6. Execution Methodology: 7.Application of the Dye Penetrant: An adequate quantity of the Dye Penetrant is to be applied to the surface, to be tested by spraying or coating, the surface must be completely wet, during the penetration process the Dye Penetrant should not be allowed to dry on the any part of the surface to be tested. The penetrant may be applied by spraying by using compressed-air-type appara-tus. Processing details for applying the penetrant, the length of time that the penetrant will remain on the surface (dwell time), and the temperature of the surface and penetrant during the examination if outside 60°F to 125°F range. Processing details for removing excess penetrant from the surface, and for drying the surface before applying the developer; 7.1 Penetration Time Penetration time is critical. The minimum penetration time shall be as required in Table Material form Type of discontinuity Penetrant Developer 3 TOTAL NDE SERVICES DYE PENETRANT EXAMINATION PROCEDURE Doc. TNS/PT/01/Rev-1 Steel Casting/Weld Cold shuts, Porosity 5 minutes Lake of fusion, Cracks all forms 7minutes 7.2 Excess Penetrant Removal. After the specified penetration time has elapsed, any penetrant remaining on the surface shall be removed, taking care to minimize removal of penetrant from discontinuities. 7.3 Water Washable Penetrants. Excess water washable penetrant shall be removed with a water spray. The water pressure shall not exceed 50psi (345kPa), and the water temperature shall not exceed 110°F (43°C). 8.Developing The developer shall be applied as soon as possible after penetrant removal; the time interval shall not exceed that established in the procedure. Insufficient coating thickness may not draw the penetrant out of discontinuities; conversely, excessive coating thickness may mask indications. With color contrast penetrants, only a wet developer shall be used. 8.1 Wet Developer Application Prior to applying suspension type wet developer to the surface, the developer must be thoroughly agitated to ensure adequate dispersion of suspended particles. Aqueous Developer Application: Aqueous developer may be applied either a wet or dry surface. It shall be applied by brushing, spraying, or other means, provided a thin coating is obtained over the entire surface being examined. 8.2 Developing time for final interpretation be-gins immediately after the application of a wet developer coating is dry. The minimum developing time shall be as required in the above mentioned Table. 11.Evaluation Time: When the developer has dried After 25 Minutes Also depend upon manufacturer’s instruction in MSDS. 12.Re-Examination: It is not possible to make a clear evaluation of the indications then the Entire examination process must be repeated starting with the initial Cleaning and repeat TOTAL NDE SERVICES DYE PENETRANT EXAMINATION PROCEDURE Doc. TNS/PT/01/Rev-1 examination is to be carried out using the same Test medium system as for the initial test. 13.Evaluation Standards: Cracks and clustered porosity are inadmissible. Linear indications are extending greater than 3 mm are not admissible. In case of chain porosity and linear indications less than/ equal to 3 mm In the heat-effected zones of branches of header/tube, the zone should Be milled and re-examined. If elongated indication occur, the inspector is to be informed and this is Also applies in the case of indications that occur systematically. 14. Examination after Repair: A re-examination of the entire seam is to be carried out if a Cast/weld is Repaired or replaced. 4