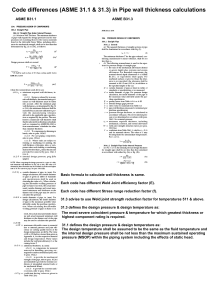

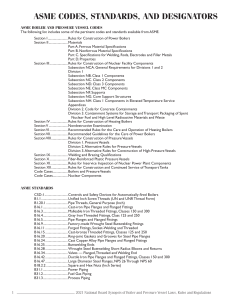

Design of piping systems ASME Pressure classification system When designing the piping system for an industry, pressure integrity is one of the most guiding factors for safe operation of the plant. Process piping code ASME B31.3 refers to ASME B16.5 standard for pressure classification system. This helps piping designers in selecting a proper flange material. The ASME Pressure classification system pre-defines the pressure-temperature limits of components. It defines the allowable pressure a component can withstand without breaching the allowable stress limit at that temperature. This helps piping designers in selecting a proper flange material. For this purpose, let us take ASME B16.5 standard which provides for pressure classification system of pipe flanges and flanged fittings. It tabulates maximum pressure rating with temperature. Flanges made according to ASME B16.5 are categorized into 34 material or material alloy groups. There are 8 carbon and low alloy steel material groups, 10 high-alloy steel material groups, and 16 non-ferrous material groups. Within each group there are sub-groups. ASME B16.5 provides seven pressure classes for flanges. These are 150, 300, 400, 600, 900, 1500, and 2500. In practice ASME B16.5 is used by piping designers to determine flange rating. This is done by the following steps; 1) Determine the maximum operating pressure and temperature required for the flange. 2) Select a flange material according to the service requirement and then a material group out of the 34 listed material groups. 3) Follow the table, start from class 150 and proceed until the desired pressure rating for the temperature is found. Let us understand this with an example; Assume that an ASTM A105 carbon-steel flange is required to satisfy a pressure of 6 MPa at 3000C. Now we need to determine a flange rating with the help of ASME B16.5. So here we have the material, pressure and temperature, now we need to follow the below table and select a particular pressure rating. Note that carbon steel flanges of A105 falls into material group 1.1. Pressure 6MPa = 60 Bar Now we will search for 3000C in the first column, which is our design temperature and the move to right to search for pressure value higher than our design pressure (i.e., 60 Bar). We will stop where we get a pressure value higher than our design pressure. In the case we are getting 79.6Bar in flange class 600. Thus, our flange rating will be 600 for the above design conditions. Tip: - - Carbon steels are not used above 4250C, as prolonged exposure above this temp causes graphitisation, which can result in a substantial loss of the material’s strength and ductility, leading to unexpected failure of the component. Selecting an appropriate metallurgy is very crucial, as one a material meeting the pressure temperature rating might fail due to wrong selection of material. Prepared by Deepak Sharma