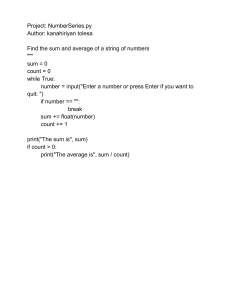

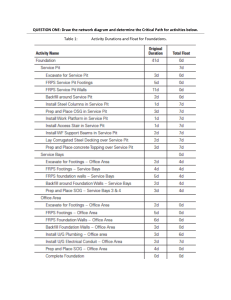

Assignment 1 Table of contents: 1. Introduction……………………………………………………………………………2 2. Czochralski method………………………………………………………………..3 2.1. Introduction to Czochralski method…….………………..…….3 2.2 Steps of Czochralski method………………………………………...4 2.3 Applications of Czochralski method………………………………5 2.4 Advantages and disadvantages of Czochralski method.…6 3. Float zone method………………………………………………………………….7 3.1. Introduction to float zone method……………………………….7 3.2 Steps of Float zone method…………………………………………..8 3.3 Applications of Float zone method………………………………..9 3.4 Advantages and disadvantages of Float zone method….10 4. Comparison between Czochralski and float zone methods…….12 5. Conclusion………………………………………………………………………..…..13 6. Resources……………………………………………………………………………..14 1|Page 1. Introduction Due to its distinct electrical and thermal characteristics, silicon plays a significant role in the semiconductor industry. Silicon is the most abundant solid element on earth, being second only to oxygen and it makes up more than 25% of the earth’s crust. However, it rarely occurs in elemental form, virtually all of it is existing as compounds, like sand as shown in Figure (1). Several growth techniques are used to produce high-quality silicon crystals for electronic devices. Figure 1: Silicon is a fundamental element in earth crust. The goal of silicon growth techniques is to produce uniformly shaped crystals of silicon with a low defect density, as shown in Figure (2). The performance of electronic devices is dependent on the quality of the silicon crystals used in their manufacture, so this is significant in the semiconductor industry. 2|Page The Czochralski (CZ) and Float Zone (FZ) methods, as well as other techniques like Bridgman-Stockbarger (BS) growth, epitaxial growth, and zone melting (ZM) growth, are used to accomplish this. With these methods, high-purity silicon crystals are created by melting a silicon source material and letting it slowly solidify under controlled circumstances. [1] Figure 2: silicon wafers are the final products of these processes. The FZ method involves melting a small portion of a silicon rod and letting it slowly solidify, whereas the CZ method involves slowly removing a silicon seed crystal from a molten silicon melt. Both techniques yield silicon crystals of high quality and with a low defect density, but the method to use depends on the particular application. Other methods, like epitaxial growth, use chemical vapor deposition to grow a thin layer of silicon on top of a silicon wafer (CVD). This method is frequently used to produce thin silicon layers for integrated circuits. In summary, the goal of silicon growth techniques is to use carefully controlled melting and solidification processes to create high-quality silicon crystals with a uniform structure and low defect density. These methods are essential to produce high-performance electronic devices in the semiconductor industry. 2. Czochralski method 2.1. Introduction to Czochralski method The Czochralski method, also known as the Czochralski technique or Czochralski process, is a method of crystal growth used to produce single crystals of metals, such as palladium, platinum, silver, and gold, salts, and artificial gemstones. The technique was developed in 1915 3|Page while a Polish scientist named Jan Czochralski was looking into the rates at which metals crystallised. By mistake, he dipped his pen in molten tin instead of his inkwell and drew a filament of tin, which later turned out to be a single crystal. [2] The growth of large cylindrical ingots – as the one shown in figure (3) - , or boules, of single crystal silicon used in the electronics sector to produce Figure 3: Ingots produced by CZ method. semiconductor products like integrated circuits, may be the most significant application. This technique can also be used to grow other semiconductors, such as gallium arsenide, though in this case lower defect densities can be obtained by modifying the BridgmanStockbarger technique. 2.2 Steps of Czochralski method With this technique, the charge melts and is kept at a temperature just above its melting point. First, a thin layer of melt is reached by lowering the pulling rod. The pulling rod's point tip melts because the rod is at a lower temperature than the rest of the rod. The crystal is then gradually pulled out. The rate of pulling depends on several variables, including thermal conductivity, latent heat of charge fusion, and rate of pulling rod cooling. To maintain the grow crystal's uniformity and cylindrical shape, the seed is rotated. A rod with a seed crystal attached to it is slowly rotated. A melt that is kept at a temperature just above the melting point is used to submerge the seed crystal. By cooling the rod and gradually removing it from the melt (the environment is cooler than the melt), a temperature gradient 4|Page is created. The quality of the crystals improves (fewer flaws), but the growth rate is slowed down, when the crystal is removed from the melt more slowly. A summary of the steps in shown in Figure (4). Figure 4: Summary of the steps of Czochralski method 2.3 Applications of Czochralski method Numerous manufacturing processes use the Czochralski Process, which involves the controlled crystallization of molten materials. The production of large cylindrical ingots, also known as boules and made of single crystal silicon, may be the process' most significant application. The fabrication of a wide variety of semiconductor devices, including integrated circuits, like the shown in figure(5), which are the foundation of contemporary electronics, depends on these boules. Additional semiconductors that can be grown using the Czochralski Process include gallium arsenide, which has special qualities that make it valuable in a range of electronic applications. It is possible to create 5|Page semiconductors with specific properties, such as electrical conductivity and optical properties, that are tailored to meet the needs of various industries by carefully controlling the growth conditions during the Czochralski Process. Overall, the Czochralski Process is essential to the creation of modern society's indispensable Figure 5: Example of integrated electronic devices. This process has revolutionized circuits that can be produced using the electronics industry and paved the way for CZ method. countless technological advancements by enabling the growth of high-quality, large-scale single crystals. [3] Monocrystalline Czochralski silicon is a common name for monocrystalline silicon (mono-Si) grown using this technique (Cz-Si). It serves as the building block for the production of integrated circuits, which are used in a variety of electronic devices like semiconductors, televisions, computers, and mobile phones. The photovoltaic industry also makes extensive use of monocrystalline silicon to create traditional mono Si solar cells. For silicon, the highest light-to-electricity conversion efficiency is produced by the nearly ideal crystal structure. 2.4 Advantages and disadvantages of Czochralski method There are several advantages in using Czochralski method including: 1. High purity: The Czochralski method yields crystals with a low impurity content that are of high purity. This is due to the process' use of an inert gas or vacuum to melt the raw material, which minimises contamination. 2. Large crystal size: The Czochralski method can yield large single crystals with a diameter of up to several inches. This is helpful for 6|Page applications like those in the electronics sector that call for large single crystals. 3. Precisely control : Reproducible and uniform crystal growth are made possible by the Czochralski method's ability to precisely control crystal growth parameters like temperature, pressure, and pulling rate. 3. Float zone method 3.1. Introduction to float zone method Very pure silicon is produced by vertical zone melting and is known as float-zone silicon. The method was modified from one created by William Gardner Pfann for germanium and created at Bell Labs by Henry Theuerer in 1955. Molten silicon in the vertical configuration has enough surface tension to prevent the charge from separating. The main benefit of crucibleless growth is that it shields silicon from contamination from the vessel itself, making it a naturally highpurity substitute for boule crystals grown using the Czochralski method. Light impurities like carbon (C) and oxygen (O2) are present in very small amounts. Nitrogen (N2), another light impurity, is now purposefully added during the Figure 6: wafers produced by float zone method. growth stages because it helps to control microdefects and improves the mechanical strength of the wafers. [4] Due to surface tension restrictions during growth, the diameters of float-zone wafers are typically no larger than 200 mm. An RF heating coil is used to produce a localized molten zone from which a polycrystalline rod of ultrapure silicon of electronic grade grows. The 7|Page growth is initiated at one end by a seed crystal. The entire procedure is carried out in an inert gas purge or an evacuated chamber. The impurities are carried away by the molten zone, which lowers the concentration of impurities (most impurities are more soluble in the melt than the crystal). To incorporate a uniform concentration of desired impurity, specialised doping techniques like core doping, pill doping, gas doping, and neutron transmutation doping are used. 3.2 Steps of Float zone method High-quality single-crystal materials are purified and grown using a method called the Float Zone Method. In this process, a tiny piece of the polycrystalline rod is melted, and the molten zone is then recrystallized as a single crystal. The Float Zone Method involves the following steps: Choosing the initial material: A polycrystalline rod that has first been grown using another method is typically the starting material for the Float Zone Method. The initial substance must have the desired crystal structure and a sufficient level of purity. Adding the content: The required heating and cooling components are loaded into a vacuum-sealed chamber along with the polycrystalline rod. After that, the chamber is vacuumed to produce a high vacuum. Melting of the rod: Using a focused heating source, such as a laser or radiofrequency Figure 7: The melting steps in the FZ method. 8|Page coil, a small portion of the polycrystalline rod is melted. With exact movements, the molten zone is precisely controlled and moved down the length of the rod. Crystal growth: The material behind the molten zone solidifies to form a single crystal as it travels along the rod. The temperature gradient, pulling speed, and dopant concentration are just a few of the methods used to carefully monitor and manage the crystal growth. Repeat the procedure on the newly formed crystal to further boost its purity and perfection after the crystal growth is finished. Finishing and annealing: The crystal is typically annealed to reduce internal stresses and enhance its mechanical and electrical properties after it has been grown. To correct any surface flaws and prepare the crystal for additional processing and use, it may also be polished or finished in another way. Overall, the Float Zone Method is a sophisticated and tightly controlled process that can create single crystals of exceptionally high quality with a variety of uses in optics, electronics, and other fields. 3.3 Applications of Float zone method Power devices use these particular silicon crystals that are produced. This is due to the fact that they are semiconductor materials, which shield people from electric shock. Additionally, it has detector applications. Float zone wafers are frequently used in high efficiency solar products, including chips, as the one shown in figure (8). 9|Page There are numerous optical applications for float zone wafers. This is because it is employed in the production of lenses and windows, which are typically employed in terahertz applications. The number of impurities, such as oxygen and carbon, is incredibly low in float zone silicon. For this reason, float zone silicon is utilized instead of czochalski grown silicon. It can go through a lighter doping process Figure 8: Example of solar products produced by Float zone method thanks to the purity of the silicon in the float zone. In some cases, silicon from the float zone results in measurements of high resistivity. The most common material used in the production of high efficiency solar panels and discrete power devices is FZ silicon. Based on scientific research, silicon is a semiconductor. As a result, it is ideal for electric equipment because it lessens the hazards related to electricity. [5] 3.4 Advantages and disadvantages of Float zone method There are several benefits and drawbacks to the Float Zone Technique. Some of the main benefits are as follows: High purity: Crystals made using the Float Zone Technique can have impurity levels as low as 1 part per million (ppm). High perfection: The Float Zone Technique can produce crystals with very low defect densities, which makes them appropriate for uses where good crystal quality is crucial. Customized doping: The Float Zone Technique enables fine control over dopant concentrations, enabling the crystal's characteristics to be tailored to applications. 10 | P a g e Huge crystals: Using traditional techniques, it can be challenging to develop crystals as large as several centimeters in diameter. The Float Zone Technique makes this possible. Continuous growth: Continuous crystal growth is achievable using the Float Zone Technique, resulting in the production of long, homogeneous crystals. Also, there are several disadvantages of Float zone method including: Time-consuming: Crystal growth rates for the Float Zone Technique are typically only a few millimeters per hour. This implies that the growth of a single crystal may need several days or even weeks. Expensive: The Float Zone Technique is an expensive approach when compared to other crystal growth techniques since the equipment required is complicated and expensive. Restricted accessibility: The Float Zone Technique is a highly specialized procedure that can only be used by people with a high level of skill. It might not be publicly accessible or available to researchers outside of specialist facilities as a result. Restricted scalability: The Float Zone Technique is more suited for laboratory-scale research than industrial-scale manufacture because it is not readily scalable to large-scale production. Restricted crystal shapes: Cylindrical crystals are commonly grown using the Float Zone Technique, which may not be appropriate for all applications. Overall, the Float Zone Technique is an effective method for producing single crystals of high quality, but it necessitates a high level of knowledge and specialized equipment, and it may not be appropriate for many applications. 11 | P a g e 4. Comparison between Czochralski and float zone methods Method Principle Crystal purity Crystal quality Control Dopant concentration Equipment complexity Crystal shape Growth rate Applications Float Zone Melting and solidification of a small portion of a rod, which is progressively moved along its length Extremely high Excellent Precise control over the zone of melting and solidification Can be precisely controlled High Czochralski Growth of a single crystal by pulling it out of a melt Cylindrical Conical or cylindrical Moderate to fast Production of large single crystals for use in semiconductor and optical applications Slow Research, production of highpurity crystals for semiconductor and solar cell applications High Good to excellent Control over the melt composition and temperature Can be difficult to control Moderate Table 1: Comparison between FZ and CZ 12 | P a g e 5. Conclusion In conclusion, the growth of high-quality single crystals for a variety of applications is largely carried out using the Float Zone and Czochralski processes, particularly in the semiconductor and solar cell sectors. While Czochralski can make larger crystals at a faster rate and is known for producing exceptionally pure and high-quality crystals with fine dopant control, Float Zone is a more complicated and time-consuming procedure. In the end, the decision between these strategies is based on the particular needs of the application, as well as the tools and resources accessible. 13 | P a g e 6. Resources [1] Hu, X. (2021). Research on silicon wafer manufacturing process and physical properties testing using high-purity polysilicon. Journal of Physics: Conference Series, 2083(2), 022050. https://doi.org/10.1088/1742-6596/2083/2/022050 [2] Silicon Wafer Manufacturing: The process of growing silicon ingots. Wafer Manufacturing. (n.d.). https://www.waferworld.com/post/silicon-wafer-manufacturingthe-process-of-growing-silicon-ingots [3] Crystal growth in the process of modified Czochralski. (2006). Magnetohydrodynamics, 42(4), 451–468. https://doi.org/10.22364/mhd.42.4.12 [4] Lüdge, A., Riemann, H., Wünscher, M., Behr, G., Löser, W., Muiznieks, A., & Cröll, A. (2010). Floating zone crystal growth. Crystal Growth Processes Based on Capillarity, 203–275. https://doi.org/10.1002/9781444320237.ch4 [5] Basics of Solar Cell. Basics of solar cell, solar photovoltaic modules. (n.d.). https://www.leonics.com/support/article2_13j/articles2_13j_en.p hp#:~:text=Solar%20Cell%20or%20Photovoltaic%20(PV,created%2 0at%20positive%2Fnegative%20junctions. 14 | P a g e