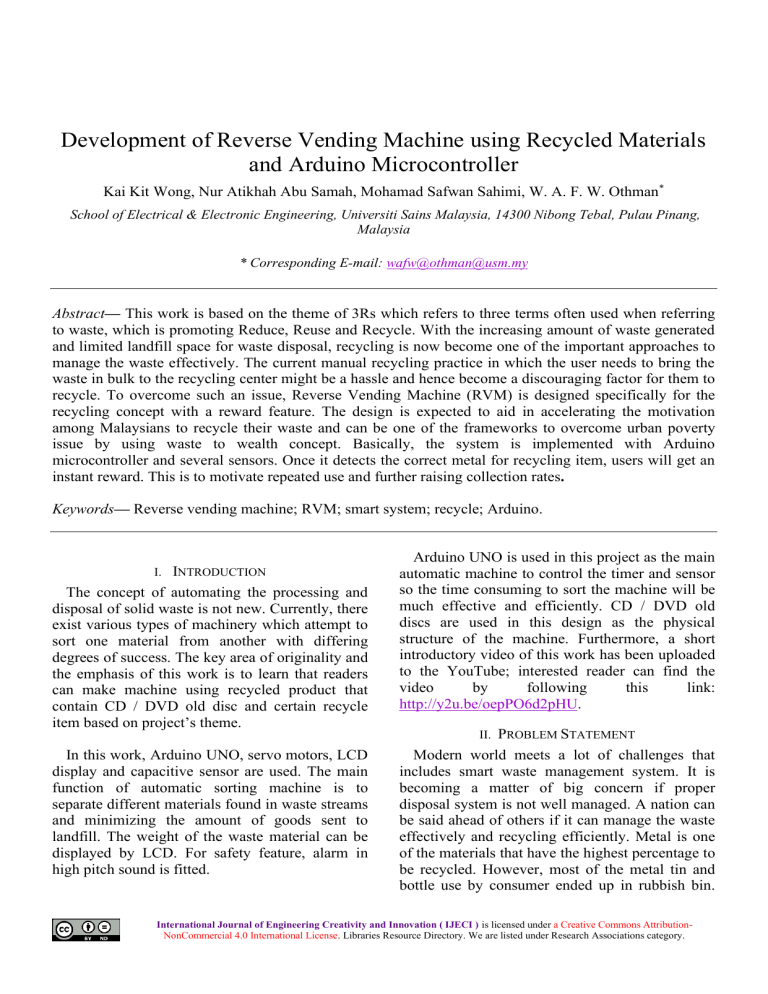

Development of Reverse Vending Machine using Recycled Materials and Arduino Microcontroller Kai Kit Wong, Nur Atikhah Abu Samah, Mohamad Safwan Sahimi, W. A. F. W. Othman* School of Electrical & Electronic Engineering, Universiti Sains Malaysia, 14300 Nibong Tebal, Pulau Pinang, Malaysia * Corresponding E-mail: wafw@othman@usm.my Abstract— This work is based on the theme of 3Rs which refers to three terms often used when referring to waste, which is promoting Reduce, Reuse and Recycle. With the increasing amount of waste generated and limited landfill space for waste disposal, recycling is now become one of the important approaches to manage the waste effectively. The current manual recycling practice in which the user needs to bring the waste in bulk to the recycling center might be a hassle and hence become a discouraging factor for them to recycle. To overcome such an issue, Reverse Vending Machine (RVM) is designed specifically for the recycling concept with a reward feature. The design is expected to aid in accelerating the motivation among Malaysians to recycle their waste and can be one of the frameworks to overcome urban poverty issue by using waste to wealth concept. Basically, the system is implemented with Arduino microcontroller and several sensors. Once it detects the correct metal for recycling item, users will get an instant reward. This is to motivate repeated use and further raising collection rates. Keywords— Reverse vending machine; RVM; smart system; recycle; Arduino. INTRODUCTION The concept of automating the processing and disposal of solid waste is not new. Currently, there exist various types of machinery which attempt to sort one material from another with differing degrees of success. The key area of originality and the emphasis of this work is to learn that readers can make machine using recycled product that contain CD / DVD old disc and certain recycle item based on project’s theme. I. In this work, Arduino UNO, servo motors, LCD display and capacitive sensor are used. The main function of automatic sorting machine is to separate different materials found in waste streams and minimizing the amount of goods sent to landfill. The weight of the waste material can be displayed by LCD. For safety feature, alarm in high pitch sound is fitted. Arduino UNO is used in this project as the main automatic machine to control the timer and sensor so the time consuming to sort the machine will be much effective and efficiently. CD / DVD old discs are used in this design as the physical structure of the machine. Furthermore, a short introductory video of this work has been uploaded to the YouTube; interested reader can find the video by following this link: http://y2u.be/oepPO6d2pHU. PROBLEM STATEMENT Modern world meets a lot of challenges that includes smart waste management system. It is becoming a matter of big concern if proper disposal system is not well managed. A nation can be said ahead of others if it can manage the waste effectively and recycling efficiently. Metal is one of the materials that have the highest percentage to be recycled. However, most of the metal tin and bottle use by consumer ended up in rubbish bin. II. International Journal of Engineering Creativity and Innovation ( IJECI ) is licensed under a Creative Commons AttributionNonCommercial 4.0 International License. Libraries Resource Directory. We are listed under Research Associations category. International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 This is due to consumer awareness and willingness to store metal tin or bottle waste before recycling them. 0.36872 Million ton. Also, 2.7% of the recycle material from household is metal recycle product which is around 1 kiloton [3]. In this work, a reverse vending machine is proposed and developed which can reward the user after the user recycled metal tin or bottle into the machine. The system can encourage more consumers to recycle the metal waste product from a small amount. By using the proper recycling system, the curse of waste will turn into blessings for the civilization. The sorting procedure will make recycling more efficient. IV. ESSENTIAL COMPONENTS DESCRIPTIONS With so much concern recently about being greener and economically friendly, waste management has become a very important topic. Communities and industries are starting to realize that the materials they use and the way they dispose of them can make a big impact to the world. Proper management of waste plays a vital role in global environment. That is why a reverse vending machine is needed which can be used in houses, offices; industries as a part of smart waste management system and change consumer recycle behavior into a habit. In this work, there are several essential components used to build the whole system. The components include Arduino Uno development board, inductive sensor, servo motors and LCD. Arduino Uno Fig. 1 shows an Arduino Uno development board. Arduino is an open-source electronics platform based on easy-to-use hardware and software. Arduino boards able to read inputs light on a sensor, a finger on a button, or a Twitter message - and turn it into an output - activating a motor, turning on an LED, publishing something online [4]. A. With Arduino, users can tell the board what to do by sending a set of instructions to the microcontroller on the board. To do so you use the Arduino programming language (based on Wiring), and the Arduino Software (IDE), based on Processing. III. RELATED WORKS In 2010, PepsiCo and Waste Management launched a new Dream Machine initiative [1]. The initiative was to test whether the Dream Machine can work as a productive long-term bottle recycling system for Americans. Furthermore, it is also to test whether or not it motivates the consumers to recycle. According to PepsiCo, the recycling rate in America for 2010 was 34% [1]. However, the study done by NAPCOR in 2017 stated that, the recycling rate for America in 2017 was only 29.2% [2]. In Malaysia, only 17.5% of 13.752 Million ton of waste produce have been recycled which equal to 2.4066 million-ton Malaysia government expect 16.76 million of waste produce been generated in 2020 with the growth of 4% per year. Malaysia government aim to increase the percentage of waste produce recycle can increase to 22% which is 3.6872 million ton. Base on Solid Waste and Public Cleansing Management Corporation SWCORP report, there will be 1 percentage of recycle material from household which equal to Figure 1: Arduino Uno development board Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (shields) and other circuits. The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs from personal computers. The microcontrollers are typically programmed using a dialect of features from the programming languages C and C++. In addition to using Available online: http://technical-journals.org/index.php/IJECI/ P a g e |8 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 traditional compiler tool chains, the Arduino project provides an integrated development environment (IDE) based on the Processing language project. Furthermore, Arduino microcontroller is the favorite microcontroller for most designers, hobbyist and researchers. This can be seen by many projects utilizing Arduino microcontroller. These works include the works where Arduino is used for controlling climbing robot [5~12], firefighting robot [13], humanoid robot [14-15], Arduino as the brain for follower robot [16~18], as controller for CNC machine [19~23], as a controller for smart farming system [24]. Inductive sensor Fig. 2 indicates an NPN inductive proximity sensor. Inductive proximity sensor belongs to the category of non-contact electronic proximity sensor. It is used for positioning and detection of metal objects. The sensing range of an inductive switch is dependent on the type of metal being detected. Ferrous metals, such as iron and steel, allow for a longer sensing range, while nonferrous metals, such as aluminum and copper, may reduce the sensing range by up to 60 percent. In this project, this sensor is used to detect metal tin for recycle purpose. [25] B. Figure 3: Servo motor LCD LCD is the acronym for Liquid Crystal Display (Fig. 4). LCD is a thin and flat electronic visual display that uses the light modulating properties of liquid crystal (LC). Since LC does not emit light directly. LCD, therefore, needs a light source and is classified as "passive" display. LCD is utilized in battery-powered electronic devices because it consumes small amount of electric power. LCD is found to replace LED due to the declining price of LCD, the ability to display numbers, characters and graphics with ease of programming. LCD is crucial in the work as it is needed to make the whole system more user-friendly with metal decompose and reward system information. D. Figure 4: Pins layout for LCD (Liquid Crystal Display) V. METHODOLOGY System Overview The operating system of the project is depicting in Fig. 5 with block diagram showing the mechanism and flow of the process of this work. The mechanical system representing the physical prototype which have difference chambers to sense the recycle material, to store recycle material and reward system chamber. The NPN inductive sensor is the only sensor that uses to differentiate the material (metal or nonmetal). Arduino Uno development board is the microcontroller that connects the whole system with software. Servo motors that open the valve A. Figure 2: NPN inductive proximity sensor Servo motor Servo motor as shows in Fig. 3 is a selfcontained electric device that rotates or pushes parts of a machine with great precision. It is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback [26]. C. Available online: http://technical-journals.org/index.php/IJECI/ P a g e |9 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 and push the reward and LCD display are the actuator of the whole system. Figure 5: Block diagram of the proposed reverse vending machine Schematic of Circuit Design Fig. 6 shows the schematic circuit connection between Arduino (microcontroller) with inductive sensor, servo motors, and resistors. Several resistors are used to limit the current flowing from and to the microcontroller to prevent the microcontroller from burning. A 16 characters with 2 lines is also connected to the microcontroller to display current status operation to the user. B. Flow Charts of Reverse Vending Machine Fig. 7 shows the flowchart of the system’s behavior. As depicts in Fig. 7, at the beginning the LCD will display “put metal only” to tell user only to insert metal recycle material. When a metal C. recycle material is detected by the inductive sensor, the LCD will display “recycle press D”. Then, user need to press D to trigger the servo-1 which represents the valve that holds the recycle material in the sensing region to open and let the recycle material falls into the recycle region. After the servo-1 move back to its original position where the valve closes, the LCD will display “Reward press R” and “recycle again”. If R button is pressed, reward will be push out. If another metal recycle material is inserted into the sensing region then the system will loop back from LCD display “press D for recycle”. After reward is given, the system is ends. Circuit Implementation on Breadboard Fig. 8 shows the photo of circuit implementation for reverse vending machine prototype with labels depicting its functionality. As can been seen in Fig. 8, the R and D buttons in blue are clearly labeled. The buttons are pushbuttons of normally open tactile type buttons. D. The Arduino Uno Development Board Ports and Pins Connections Table 1 shows the pin connection of Arduino Uno development board to other components used in this work. Digital output pins (2 to 7) of E. Figure 6: Schematic circuit diagram of reverse vending machine Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 10 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 Figure 7: Flow chart of the proposed Reverse Vending Machine (RVM) Arduino board are connected to LCD to show information to the user. Digital input pins (10 & 11) are connected to normally open switches, acting as the input selection of user, either R or D. VI. RESULTS A. Prototype of reverse vending machine Fig. 9 shows the prototype of reverse vending machine, built by using recycled material as a proof of concept working condition. Figure 9(a) depicts the front view; 9(b) shows the back view, 9(c) illustrates the side view; 9(d) portrays the mechanism of rewarding system respectively. Interested readers can follow the following link to watch the video of reverse vending machine in action: http://y2u.be/oepPO6d2pHU. Figure 8: Circuit implementation for reverse vending machine Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 11 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 TABLE 1: PINS CONNECTIONS OF ARDUINO UNO DEVELOPMENT BOARD Input / Output Output from Arduino Uno to LCD Input from button to Arduino uno Input from servo motor to Arduino uno Input from inductive sensor to Arduino uno Arduino Uno Pins Digital Pin 2 Digital Pin 3 Digital Pin 4 Digital Pin 5 Digital Pin 6 Digital Pin 7 Digital Pin 10 Digital Pin 11 Digital Pin 12 Digital Pin 9 Digital Pin 13 Result from literatures Base on SWCorp report, in year 2020, expected 1 kiloton of metal include aluminum will be recycled from household in Malaysia [3]. B. Connection Connect to pin RS of LCD Connect to pin RW of LCD Connect to pin D7 of LCD Connect to pin D6 of LCD Connect to pin D5 of LCD Connect to pin D4 of LCD Connect to 1 node of always open switch. Connect to 1 node of always open switch. Connect to signal pin of servo motor Connect to signal pin of servo motor Connect to black wire of inductive sensor To produce 1kg of aluminum, 13 KWh of energy is needed. And to produce 1 kiloton of aluminum, 13000 MWh of energy is needed. If new aluminum can be produced from recycled (a) (b) (c) (d) Figure 9: Reverse vending machine prototype, build from recycled material as proof of concept. (a) front view; (b) back view; (c) side view; (d) mechanism of rewarding system Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 12 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 material, it only requires 5% of energy to reproduce compared to raw material. So, in year 2020, total of 1235 MWh of energy can be saved. With the reference of reverse vending machine in UK, more than 95% of aluminum can be recycled back [27]. This recycled figure is much higher compare to traditional recycle method which total of 17.5% of total waste produce been recycle. Thus, 1235 MWh of energy can be saved as more than 95% of metal waste can be recycled from the household. Limitation The current system has some limitation in terms of hardware and software. C. 1) The inductive sensor can differentiate metal and nonmetal, but it is unable to future differentiate the type of the metal like stain steel, iron, aluminum and so on. This is because all metallic object can create the electromagnetic field in close surroundings of the sensing surface. Although the operating distance of the sensor depends on the actuator's shape and size and is strictly linked to the nature of the material (as in Table 2), the operation distance of the sensor is too short (will describe in the next limitation) and the difference between Sn and 0.4Sn is very small [28]. TABLE 2: SENSING DISTANCE BETWEEN INDUCTIVE SENSOR WITH DIFFERENT METALLIC MATERIAL Sensitivity when different metals are present. Sn = operating distance. Fe37 (Iron) 1 x Sn Stainless steel 0.9 x Sn Brass - Bronze 0.5 x Sn Aluminum 0.4 x Sn Copper 0.4 x Sn 2) The inductive sensor model that we use is NBB8-18GM50-E0 NPN normally open inductive sensor which manufacture by Pepperl + Fuchs. The rated operating distance, Sn is 8mm. The assured operating distance, Sa is 0 to 6.48mm. Thus, if distance between the metal object and the inductive sensor is further than 8mm, the sensor won't able to sense the material. 3) The size of the recycle material must be small that 8cm in any dimension. This is because the area of sensing chamber is only 8cm × 8cm. 4) In a mechanism part perspective, maximum number of coins that can be put in reward system is ten coins. This is because mechanism part to hold the coin is (10) and thickness of Malaysia 50sen coin is 2.18mm. the the the the 5) In a software perspective, the maximum number of coin that can be put in that reward system is 2,147,483,647 coins. This is because the integral is assigned for the counting system. The number 2,147,483,647 is the the maximum positive value for a 32-bit signed binary integer in computing. It is equal to equal to 231 − 1. Discussion The prototype built can function based on our objectives. The reverse vending machine constructed is capable to detect the presence of metal object (tin). Then, the metal will be recycled and reward user with instruction. The instruction to recycle metal tin and the reward system will display on the LCD screen. The success of sensor with outputs implies that the interfacing of Arduino Uno development system to NPN inductive sensor, servo motors and LCD are accomplished. D. Besides that, for the connection of the NPN inductive proximity sensor and Arduino is active high. NPN inductive proximity sensor is an always open proximity sensor. Which mean that it will only close when sensor is triggered by metal. When the switch is opened, there is no current flow to the pin. So, the circuit don't have voltage drop and the resistor is short circuit. As, signal back to Arduino pin is same node with ground, Arduino pin receive LOW. When the switch is closed, the circuit is completed and there is current flow. So, the circuit have voltage drop between the resistor. As this movement, signal back to Arduino pin is same node with 5V, Arduino pin receive HIGH (Fig. 10). Other than that, for the connection of button and Arduino is active low. The button is a always open Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 13 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 button. When the switch is opened, there is no current flow to the pin. So, the circuit don't have voltage drop and the resistor is short circuit. As, signal back to Arduino pin is same node with 5V, Arduino pin receive HIGH. When the switch is closed, the circuit is completed and there is current flow. So, the circuit have voltage drop between the resistors. As this movement, signal back to Arduino pin is same node with ground, Arduino pin receive LOW (Fig. 11). measure the weight of recycle product, but we failed to build a proper mechanism in our prototype to get a accurate value. 2) In this piece of work, we faced problems in detecting different kind of recycle material. Solution: We decided to detect metal recycle product only. So, the system will only detect metal with inductive proximity sensor. We tried to use capacitive proximity sensor to detect plastic bottle as well with the concept of detect the density of plastic material. However, the density range of plastic material is too wide, and it may detect other material as well. 3) In this project, we faced problems in designing the mechanism part of the prototype. Figure 10: Active high circuit of inductive sensor Solution: We analyzed the motion that we need. Then, we checked the components that we had. With the engineering knowledge that we have (dynamics and mechanism), we are able to design the mechanism system of the reverse vending machine. CONCLUSION In a nutshell, the aim and objectives of our mini project are accomplished. We successfully build a reverse vending machine to encourage more people to recycle metal tin. The prototype of reverse vending machine is constructed successfully and is working normally. A step-bystep approach in designing the microcontrollerbased system for metal detection and reward system has been followed. The results obtained from the number of metals detected and recycled is reliable and accurate to give users reward fairly. VII. Figure 11: Active low circuit of normally open button. Problem Analysis Throughout the period of project, we have encountered problems during completing the task. The problems that we encountered are listed below: 1) In this work, we faced problem in measuring the reward given when certain amount of waste product recycled. E. Solution: We decided to use counting system to count the number of metal bottle or tin that user want to recycle and give out equivalent reward from them. We tried to use weight sensor to Throughout the project, the knowledge learnt from the mechatronics system lectures are applied. The troubleshooting skill is also enhanced. Understanding about microcontroller (Arduino Uno), sensors and actuators are very important as well to make sure all components able to interface with each other in a right and efficient way. Also, knowledge about mechanical design also very important in this project to ensure every mechanical parts function smoothly. Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 14 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 Finally, we hope that our system can motivate more consumers to recycle their used metal tin and bottle and make it as a habit. ACKNOWLEDGMENT All authors have disclosed no conflicts of interest, and authors would like to thank the Universiti Sains Malaysia for supported the work by Research University Grant Scheme (Grant number: 1001/PELECT/8014113). [1] [2] [3] [4] [5] [6] [7] REFERENCES NAPCOR, 2018. Report on Postconsumer PET Container Recycling Activity in 2017: Available at: https://napcor.com/wpcontent/uploads/2018/11/NAPCOR_2017Rate Report_FINAL.pdf. [Accessed on 28/April/2019]. WM, 2011. Waste Management: Available at: http://www.wm.com/about/pressU room/pr2010/20100628_Dream_Machine_rec ycling_kiosks_rolling_out_a cross_the_country.pdf. Accessed on [28/April/2019]. SWCorp Malaysia, 2014. SWCorp Strategic Plan (Pelan Strategik SWCorp) 2014-2020. Retrieved from http://goo.gl/J52vMN [Accessed on 21/April/2019]. b_e_n, "Sparkfun," [Online]. Available: https://learn.sparkfun.com/tutorials/what--is-an--arduino. [Accessed on 21/April/2019]. Mustapa MA, Othman WAFW, Abu Bakar E et al. (2018). "Development of Pole-Like Tree Spiral Climbing Robot". In: Hassan M. (eds) Intelligent Manufacturing & Mechatronics. Lecture Notes in Mechanical Engineering. Springer, Singapore, pp. 285-293. Bisht, R. S., Pathak, P. M., & Panigrahi, S. K. (2018, September). Development of Magnetic Adhesion Based Wheel-Driven Climbing Machine for Ferrous Surface Applications. In ASME 2018 Dynamic Systems and Control Conference (pp. V001T04A016V001T04A016). American Society of Mechanical Engineers. Lau, S. C., Othman, W. A. F. W., & Bakar, E. A. (2013, November). Development of slidercrank based pole climbing robot. In 2013 IEEE International Conference on Control System, Computing and Engineering (pp. 471-476). IEEE. [8] Rajasekhar, T. M. K., & Sugadev, M. (2018). Arduino Controlled Special Stair Climbing Wheel- chair Bot. International Journal of Pure and Applied Mathematics, 118(24). [9] Koo, Y. C., Elmi, A. B., & Wajdi, W. A. F. (2012). Piston mechanism based rope climbing robot. Procedia Engineering, 41, 547-553. [10] Faisal, R. H., & Chisty, N. A. (2018). Design and Implementation of a Wall Climbing Robot. International Journal of Computer Applications, 179(13), 1-5. [11] Faizal MIN, Othman WAFW, Syed Hassan SSNA (2015). "Development of pole-like tree climbing robot", In. Proc. 2015 IEEE International Conference on Control System, Computing and Engineering (ICCSCE), IEEE, pp. 224-229. [12] Sivakumar, B. G., & Sudhagar, K. (2018). An independent situating &navigation system for stair climbing robotic wheelchair. Mental, 5(5.8), 5-4. [13] Singh, D., Das, S. K., Das, E., Agrawal, M., & Patel, V. (2018). Arduino And Sensors Based Fire Fighting Robot. i-Manager's Journal on Instrumentation & Control Engineering, 6(2), 37. [14] Vital, J. P., Ferreira, N. F., & Valente, A. (2018, September). Educational Humanoid Robot Using A Sensoring Fusion Through Arduino. In Memorias de Congresos UTP (pp. 235-242). [15] Basyal, L., Kaushal, S., & Singh, G. (2018). Voice Recognition Robot with Real Time Surveillance and Automation. International Journal of Creative Research Thoughts, 6(1), 2320-2882. [16] Ahmad MF, Alhady SSN, Kaharuddin S, et al (2015). "Visual based sensor cart follower for wheelchair by using microcontroller". In. Proc. 2015 IEEE International Conference on Control System, Computing and Engineering (ICCSCE), IEEE, pp. 123-128. [17] Saad, W. H. M., Karim, S. A. A., Azhar, N., Manap, Z., Soon, Y. Y., & Ibrahim, M. M. (2018). Line Follower Mobile Robot for Surveillance Camera Monitoring System. Journal of Telecommunication, Electronic and Computer Engineering (JTEC), 10(2-7), 1-5. [18] Sani NA, Syed SSNA, Othman WAFW, et al. (2012). "Cordless Cart Follower for Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 15 International Journal of Engineering Creativity and Innovation, 2019, 1 (1), 7-16 Wheelchair User", Trends in intelligent robotics, automation, and manufacturing, Springer, Berlin, Heidelberg, pp. 252-262. [19] Hirani, A. (2019). Design of mini CNC using arduino uno. [20] Hirani, A. (2018). Design of cost effective CNC using Arduino Uno. [21] Ahmed, B. J. S. A. A. (2018). Design and Analysis Mini CNC Plotter Machine. [22] Khan, M., Ahmed, M. K., Ulay, N. A. A., Sarwar, M., & Islam, N. (2018). Custom CNC milling machine (Doctoral dissertation, BRAC University). [23] Sathyakumar, N., Balaji, K. P., Ganapathi, R., & Pandian, S. R. (2018). A Build-Your-Own Three Axis CNC PCB Milling Machine. Materials Today: Proceedings, 5(11), 2440424413. [24] Cheong, C. K., Iskandar, A. M. K., Azhar, A. S., & Othman, W. A. F. W. (2018). Smart Aquaponics System: Design and Implementation using Arduino Microcontroller. [25] SS Intelligence. "SICK sensor intelligent", [Online]. Available: https://www.sick.com/us/en/proximity-sensors/inductive--proximity-sensors/c/g190731. [14/April/2019]. [26] Eglowstein, H. (2012). "Introduction to servo motors". Science Buddies, [Online]. [27] Cost of a Deposit Return Reverse Vending Machine., December 2017, [online] Available: http://www.zerowastescotland.org.uk/sites/def ault/files/reverse%20v%20%20CFE%20response.pdf. [Last accessed 14/April/2019] [28] Operating Principles for Inductive Proximity Sensors, March 2017, [online] Available: http://www.fargocontrols.com/sensorslinducti ve_op.html. [Last accessed 18/April/2019]. Available online: http://technical-journals.org/index.php/IJECI/ P a g e | 16