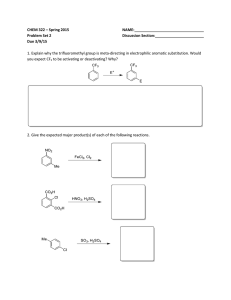

Ethylbenzene E Guy B. Woodle UOP LLC, Des Plaines, Illinois, U.S.A. INTRODUCTION Benzene Alkylation with Ethylene Ethylbenzene (EB) is a single-ring alkylaromatic compound that is used almost exclusively as an intermediate in the production of styrene monomer. On a commercial scale, essentially all EB is produced by alkylating benzene with ethylene. As of April 2004 approximately 30% of the worldwide EB production is carried out by liquid phase alkylation using a homogenous aluminum chloride catalyst in a process that was first commercialized in the 1930s.[1] Ethylbenzene was first produced commercially using a zeolite catalyst in a vapor phase reactor in 1980, which was a significant improvement over the aluminum chloride process. However, it was the development and commercialization of liquid phase and mixed liquid–vapor phase technologies in the 1990s that allowed for efficient production of high-purity EB. In 2003 the annual world EB production capacity was around 28.6 million metric tons, and EB production capacity is forecast to grow at an annual rate of just under 5% from 2004 to 2014.[2] In the production of EB, alkylation is the reaction of ethylene with benzene according to the equation: Successive alkylation reactions occur to a limited extent resulting in the formation of diethylbenzene and other higher ethylated benzenes, commonly called polyethylbenzene (PEB). PHYSICAL AND CHEMICAL PROPERTIES Ethylbenzene is a colorless aromatic liquid. It is only slightly soluble in water, but infinitely soluble in alcohol and ether. Additional properties are listed in Table 1. Ethylbenzene is chemically reactive with the most important reaction being its dehydrogenation to form styrene. Styrene is used to produce polystyrene, which is used in the manufacture of many commonly used products such as toys, household and kitchen appliances, plastic drinking cups, housings for computers and electronics, foam packaging, and insulation. In addition to polystyrene, styrene is used to produce acrylonitrile–butadiene– styrene polymer (ABS), styrene–acrylonitrile polymer (SAN), and styrene–butadiene synthetic rubber (SBR). Ethylbenzene can also be oxidized to form ethylbenzene hydroperoxide, an intermediate in a process to produce propylene oxide. REACTION KINETICS AND THERMODYNAMICS Commercially produced EB is based on alkylating benzene with ethylene. Encyclopedia of Chemical Processing DOI: 10.1081/E-ECHP-120016171 Copyright # 2006 by Taylor & Francis. All rights reserved. Kinetic reaction rate constants increase with the number of ethyl groups alkylated on the benzene ring. For example, the relative rate constant for alkylation of EB is roughly twice that for the alkylation of benzene. Reaction rate constants continue to increase with each successive alkylation reaction until a limitation is reached, such as steric hindrance. The formation of pentaEB and hexa-EB proceeds very slowly for this and other reasons so that only trace quantities are formed. Alkylation reactions are exothermic. The initial alkylation of ethylene to benzene and each successive alkylation reaction generate roughly the same amount of heat (Table 2). In addition to alkylation reactions, transalkylation reactions play a significant role in EB production. 929 930 Ethylbenzene Table 1 Physical properties of EB Molecular weight 106.169 Specific gravitya 0.867 Melting point ( C) –94.975 Boiling point ( C) 136.19 Critical temperature ( C) 346.4 Critical pressure (atm) b 37 Vapor pressure (mmHg at T C) T ( C) Vapor pressure (mmHg) 1 9.8 5 13.9 10 25.9 20 38.6 40 52.8 60 61.8 100 74.1 200 92.7 400 113.8 760 136.2 a From Perry’s Chemical Engineers’ Handbook, 6th Ed.; p. 3–34. Density is at 20 C referred to water at 4 C. b From Perry’s Chemical Engineers’ Handbook, 6th Ed.; p. 3–56. (From Ethylene and Its Industrial Derivatives; S.A. Miller, Ed.; p. 900.) Commercially it is found to be economically attractive to transalkylate all the PEB formed as a result of successive alkylation reactions with benzene in a separate transalkylation reactor to produce additional EB. Transalkylation reaction rates are relatively slow and conversion is generally limited by equilibrium. For transalkylation reaction, the heat of reaction is essentially zero, which leads to a reactor that operates nearly isothermally. The occurrence of both alkylation and transalkylation reactions results in a reaction chemistry that is affected by equilibrium. The equilibrium has been studied and is illustrated in Fig. 1. The horizontal axis is the ratio of ethyl groups to benzene rings and is often referred to as the ethyl-to-phenyl ratio. In the case of an alkylation reaction, the ethyl-tophenyl ratio is the moles of ethylene to moles of benzene. Similarly, for a transalkylation reaction, the ethyl-to-phenyl ratio is equivalent to the moles of ethyl groups contributed by PEB to the moles of phenyl groups contributed by PEB plus benzene. At ethyl-to-phenyl ratios above about 0.6, the equilibrium EB concentration is relatively constant at about 48 wt% whereas the PEB concentration continues to increase as the ratio approaches 1.0. Most commercial reactors operate with ethyl-to-phenyl ratios less than 0.6. The equilibrium composition varies only slightly across the temperature range of commercial interest. Table 2 Benzene ethylation thermodynamics Alkylation reaction DH (500 K) (kcal/mol) Ethylene þ benzene ! ethylbenzene (EB) 36.7 Ethylene þ EB ! di-ethylbenzene (DEB) 28.3 Ethylene þ DEB ! tri-ethylbenzene (TEB) 25.9 Ethylene þ TEB ! tetra-ethylbenzene 25.5 Ethylbenzene 931 E Fig. 1 Ethylbenzene composition. Other reactions, such as oligomerization, cracking, and isomerization, can also occur resulting in the formation of compounds such as cumene, butylbenzene, xylene, diphenylethane, and other high-boiling compounds. The formation of these by-products is impacted by the alkylation reaction conditions, in particular whether the reactions occur in the vapor phase or the liquid phase. For example, EB isomerization to xylene typically only occurs under vapor phase reaction conditions where reaction temperatures are relatively high. Isomerization does not occur to a great extent in the liquid phase because of the lower operating temperatures. The formation of by-products is also affected by the type of catalyst. Acid catalysts are used to promote the alkylation of ethylene to benzene. Acid catalysts suitable for benzene alkylation include protonic acids (i.e., H2SO4, HF, and H3PO4), Friedel–Crafts catalysts (i.e., AlCl3 and BF3), and more recently, solid acid catalysts. Solid acid catalysts used for the commercial manufacture of EB are typically zeolitic molecular sieves and materials such as ZSM-5, faujasite, MCM-22, and zeolite beta.[3] Zeolites’ physical and chemical properties can be modified to optimize the activity, selectivity, and stability of the catalysts. This flexibility of zeolites has made them the preferred catalyst of choice. Many zeolites occur naturally as minerals. Some of these are natrolite, chabazite, sodalite, faujasite, and mordenite. Several of these naturally occurring zeolites can be produced synthetically, which makes them suitable for commercial application. In particular, equilibrium faujasite-type structures zeolite X and Y have been broadly used in the petrochemical and chemical industries. A large number of new zeolite materials have been discovered and developed that cannot be found in nature. These specialty synthetic materials include MCM-22 and zeolite beta. The use of these synthetic zeolites has enabled the production of EB to become the highly efficient process it is today.[4] Because the liquid phase process is predominantly used for new EB plants, the critical operating and design parameters for liquid phase benzene alkylation are discussed below. Alkylation Benzene-to-Ethylene Ratio The benzene-to-ethylene molar ratio (B=E) for the alkylation reaction section is the most important parameter for design and operation of an EB plant. A high B=E is beneficial from an equilibrium and catalyst selectivity standpoint, but the large molar excess of benzene relative to ethylene requires substantial energy to recover and recycle. The first liquid phase plants were designed and operated with B=E equal to 6 or greater. Over time, as improved catalysts were developed, the B=E has steadily decreased. In 2004, units are typically designed with B=E in the range of approximately 3.0–3.5. This substantial decrease in B=E has resulted in significantly lower capital costs, because nearly three-fourths of a plant’s equipment cost is associated with recovery and recycle of 932 the excess benzene used in the reactors. Generally, a commercial plant is operated at or very close to the design B=E and is not frequently adjusted. With further improvements in the near future, commercial units will operate at even lower B=E ratios with B=E ratios possibly approaching 1.5 being made possible. Alkylation Reaction Temperature For liquid phase alkylation, the reaction temperature is normally in the range of 170–270 C to achieve an acceptable reaction rate using typical commercial catalysts. Excessive temperatures can increase by-product formation, so reactor design temperatures are often set with this in mind. Temperature also affects the reactor operating pressure and hence the equipment cost. Varying temperature within a relatively small range has little impact on the alkylation reaction overall, so generally, a commercial scale plant is maintained at a constant temperature near the design value throughout its operation cycle. Reactor design plays a significant role in temperature control. Multiple ethylene injection points and heat removal stages are incorporated into the reactor section design to allow reaction temperature to be maintained in the desired range. A common design for reactor sections contains four ethylene injections with one heat removal stage. Another design option uses six ethylene injections with two heat removal stages. Other configurations have been used commercially. Alkylation Reaction Pressure Reaction pressure is sufficiently high so as to prevent any components from vaporizing in the alkylation reactor section. Alkylation reactors are typically operated at about 35–40 bar to maintain the reactor catalyst outlet streams in the liquid phase even at the maximum operating temperature. The ethylene injected into the reactor dissolves into the liquid hydrocarbon mixture such that the alkylation catalyst beds are always in the liquid phase. Reaction pressure is not normally varied during operation. Transalkylation Benzene-toPolyethylbenzene Ratio To obtain an economically viable PEB conversion in the transalkylation reactor, a molar excess of benzene relative to PEB is needed. A high benzene-to-PEB ratio (Bz=PEB) results in high-equilibrium PEB conversion, but at the expense of increased capital cost and Ethylbenzene operating cost associated with the recovery and recycle of the excess benzene. As the Bz=PEB is decreased, these capital and operating costs decrease, but the PEB conversion level declines and formation of heavy by-products increases. Similar to the B=E in the alkylation reactor section, the first liquid phase plants were designed and operated with Bz=PEB close to 10 or higher. Over time, transalkylation catalyst system stability has been improved and the Bz=PEB has steadily decreased and in 2004 plants are typically designed with Bz=PEB in the range of 2.0–4.0. Generally, a commercial plant is operated at or very close to its design Bz=PEB and the operating Bz=PEB is not frequently adjusted. Transalkylation Reaction Temperature The reaction temperature is the key variable for controlling the operation and performance of the transalkylation reactor. Transalkylation reactors are designed to operate across a relatively wide temperature range. During initial operation when catalyst activity is high, relatively low reaction temperatures are sufficient to obtain the desired conversion of polyalkylated compounds. As the catalyst ages and loses activity, the temperature is increased to maintain PEB conversion at or near the desired level. Liquid phase transalkylation reactors typically operate between 170 C and 270 C. Catalyst Poisons Because of the acidic nature of the zeolite catalysts used in the production of EB, a number of materials can interact with the zeolite and negatively impact its performance. These compounds are referred to as catalyst poisons and mostly impact the catalyst activity, although selectivity can also be affected. Any basic or alkaline material can react with a zeolite to effectively neutralize the acidic active sites, which generally results in irreversible loss of catalyst activity. Basic compounds found in the ethylene or benzene feedstocks can include amines, amides, nitriles, and trace metal cations such as sodium and potassium. Of particular concern are nitrogen-containing organic compounds typically present in the benzene feed. There are different types of nitrogen compounds that have been identified as benzene feed contaminants. The most common ones are N-formyl morpholine (NFM), N-methyl pyrolidone (NMP), morpholine, monoethanol amine (MEA), diethanol amine (DEA), and acrylonitrile (ACN). Both NFM and NMP are common aromatic extraction solvents that are used to Ethylbenzene purify benzene. They are used commonly in Europe and less frequently in the rest of the world. Morpholine is a decomposition product of NFM and has also been identified in various benzene feeds. Corrosion inhibitors, including MEA and DEA and other similar compounds, are used in benzene recovery columns and can be found in the feed to an EB plant. Transoceanic shipment containers sometimes alternate loads between benzene and ACN, which can lead to nitrile contamination. In addition to these most common compounds, other basic nitrogen compounds can be present in the feed depending on its origin, processing, and handling. Feed Treatment to Remove Catalyst Poisons Even trace quantities of catalyst poisons can lead to significant catalyst deactivation and have a large impact on commercial production. There are varieties of adsorbent materials that are capable of removing basic nitrogen compounds from the feed streams. The type of nitrogen species in the feed is an issue that affects the choice of material as well as the guard bed design. Additionally, it is necessary to consider both the equilibrium capacity of these materials and their mass transfer properties when selecting a guard bed material and design. The most common guard bed materials are acidified resin, clay, and zeolite. The choice of optimum guard bed material is generally a function of several variables, including nitrogen adsorption capacity, mass transfer properties, disposal methods, regenerability, and cost. These variables also influence the design of the guard bed. 933 COMMERCIAL PRODUCTION Liquid Phase Aluminum Chloride Catalyst Process The primary means of producing EB from the 1930s to about 1980 was the liquid phase aluminum chloride catalyst process. Although the aluminum chloride catalyst process is still in use at many plants, its share of worldwide EB production is diminishing as all new plants use a solid acid catalyst. A flow diagram of a typical aluminum chloride catalyzed EB plant, based on the widely used Monsanto=Lummus technology, is shown in Fig. 2. The Monsanto=Lummus technology is used in the majority of aluminum chloride catalyst plants because it significantly reduces aluminum chloride catalyst consumption by operating at higher reaction temperatures than competing processes. In the latest version of aluminum chloride plant designs, the alkylation reactions occur in a homogenous liquid phase at 160–180 C. The conditions of the alkylation reactor prohibit the recycle of PEB to the reactor. As a result, these plants have a separate transalkylation reaction zone. The recycle PEB stream is mixed with the alkylation reactor effluent and fed to the transalkylation reaction zone. The aluminum chloride present in the alkylation reactor effluent catalyzes the transalkylation reactions. The effluent stream from the alkylation–transalkylation reaction section is cooled, washed, and neutralized to remove and recover the AlCl3 catalyst. The washed hydrocarbon stream contains unconverted benzene, EB, PEB, and other minor reaction byproducts. It is separated into product and recycle Fig. 2 Monsanto=Lummus aluminum chloride catalyzed EB process. E 934 streams by fractionation in a series of three distillation columns. The first column recovers unconverted benzene in the overhead stream, which is dried in a drying column before being recycled to the alkylation reactor section. The second column separates the product EB as the overhead stream. The last column recovers PEB from the high-boiling, heavy by-product tar components. The PEB is recycled to the transalkylation reaction section. The handling and disposal of the aluminum chloride catalyst and waste has become increasingly more costly and complicated because of environmental considerations. Equipment and piping corrosion and fouling along with the related environmental issues led to the development of EB processes based on solid acid, heterogenous catalysts. These are the main reasons why new plants are not based on the Friedel–Craft-type catalysts. Major equipment pieces needed to be replaced on a regular schedule because of corrosion. This resulted in extensive turnarounds, poor plant onstream efficiency, and thus, are primary contributors to the high operating costs associated with the aluminum chloride process. Vapor Phase Zeolite Catalyst Process The first commercial plant based on the Mobil=Badger vapor phase technology was commissioned in 1980.[5] From 1980 until the early 1990s, use of the vapor phase process gained in popularity because it offered several advantages over the aluminum chloride process. A major benefit of the vapor phase process was the use of a zeolite catalyst that eliminated the issues associated with corrosion and waste disposal of aluminum chloride. The alkylation of benzene is performed in a vapor phase, fixed-bed reactor using a ZSM-5 based catalyst. ZSM-5 is an aluminosilicate zeolite with a high silica and low aluminum content. ZSM-5, a highly porous material, is considered a medium-pore zeolite with two types of pores, both formed by 10-membered oxygen rings. The first type of pore is straight and elliptical in cross section and the second type of pore is circular in cross section and intersects the straight pores at right angles in a zigzag pattern. Therefore, throughout its crystalline structure, ZSM-5 has an intersecting two-dimensional pore structure. The original vapor phase design accomplished the alkylation and transalkylation reactions in a single reactor. Subsequent designs performed the transalkylation reactions in a vapor phase, secondary reactor that was separate from the alkylation reactor. Fig. 3 shows a flow diagram for the latest publicly disclosed version of the process, sometimes referred to as the third-generation EB process. The alkylation and Ethylbenzene transalkylation reaction section consists of a fired reactor feed heater, a multibed alkylation reactor, a transalkylation reactor, and various heat exchange equipment. Both the alkylation and the transalkylation reactors are vapor phase, operating at temperatures in the range of 370–420 C and pressure in the range of 0.69–2.76 MPa. The third-generation process is capable of achieving an EB yield greater than 99%. However, the hightemperature vapor phase operation of the reactors is not trouble free. The significant extent of the isomerization reactions and the catalyst deactivation by deposition of carbonaceous material are the most important problems associated with the high temperature. Any xylene formed because of isomerization cannot be separated and therefore ends up contaminating the EB product. While the xylene impurity is not a significant problem in the vapor phase EB plant, it is not desired because it results in higher operating cost in the downstream styrene plant. Catalyst deactivation occurs at a rate that requires periodic catalyst regeneration. The length of time between regeneration can vary from as little as 2 mo to slightly more than 1 yr depending on the specific plant design and operating conditions. Because the reactors must be taken off-line for regeneration, the onstream efficiency can be low, resulting in high operating costs for a vapor phase plant. Additional equipment may be required for the regeneration procedure, depending on the specific plant design, which adds capital cost to the plant. The Mobil=Badger vapor phase process includes four distillation columns. The first major separation is in a benzene recovery column where unconverted benzene is recovered as an overhead product for recycle to the alkylation and transalkylation reactors. The bottom stream is fed to an EB recovery column where EB product is separated from cumene, the PEB, and other heavy components. The cumene, PEB, and other heavy by-products are further separated in the PEB recovery column. The heavy residue is typically used as fuel in the reactor feed heater. The PEB fraction is recovered in the overhead stream and recycled to the transalkylation reactor where it reacts to form additional EB. A fourth column is used as a stabilizer column to vent any light components and to remove water from the system. Liquid Phase Zeolite Catalyst Processes EBOneTM process offered by Lummus=UOP One of the shortcomings of the vapor phase zeolitic EB process is the occurrence of side reactions that can lead to high levels of contaminants in the EB product. Ethylbenzene 935 E Fig. 3 Mobil=Badger EB process. The commercialization of liquid phase processes, which operate at substantially lower temperatures, decreased the side reactions dramatically, resulting in ultrahigh-purity EB product. This improvement alleviated problems previously encountered in the downstream styrene plant. The first liquid phase commercial plant based on the Lummus=UOP process was commissioned in 1990. Since then, more than 25 projects have been licensed with more than 17 plants in commercial operation as of 2004. The liquid phase plants typically achieve high onstream efficiency, often greater than 99%, which results in low turnaround and maintenance costs. This technology is now licensed by UOP LLC and ABB Lummus Global. The first liquid phase plants used a zeolite Y based catalyst for both the alkylation and the transalkylation reactions. A significant improvement in the process occurred in the mid-1990s when EBZ-500TM catalyst was developed and put into commercial operation.[6] EBZ-500 catalyst is based on zeolite beta, which has unique characteristics that make it highly suitable for benzene alkylation. Zeolite beta has a tetragonal crystal structure with straight 12-membered ring channels with crossed 10-membered ring channels. This crystal arrangement gives zeolite beta a unique threedimensional structure that results in high catalyst activity, an important feature in the relatively lowtemperature liquid phase process. Furthermore, benzene alkylation in the liquid phase is typically limited by diffusion, so zeolite beta with its relatively large pore dimensions is well suited for the application. vapor phase A typical EBOne plant flow diagram is shown in Fig. 4. The alkylation reactor is maintained in the liquid phase and uses multiple catalyst beds and ethylene injections to improve the reaction selectivity. Dividing the ethylene into multiple feed streams keeps the alkylation catalyst deactivation rate very low. In some plants using EBZ-500 catalyst, operating lengths of more than 8 yr have been obtained without catalyst regeneration. The ethylene conversion is essentially 100% in the alkylation reactors, and the reactors operate nearly adiabatically. The exothermic heat of reaction is recovered and used within the process to heat internal process streams or to generate steam. In the few instances when EBZ-500 catalyst has been regenerated, it has been restored to essentially the same activity and selectivity as fresh catalyst. The regeneration is a mild carbon burn procedure that is relatively inexpensive. If required, in situ regeneration equipment can be incorporated into the design. This is not common and is usually considered only for locations were ex situ regeneration facilities are not readily accessible. The transalkylation reactor is also maintained in the liquid phase but uses EBZ-100TM catalyst, which is made using zeolite Y. Transalkylation reaction is nearly thermo-neutral, so it operates essentially isothermally. The reactor temperature is generally adjusted to provide the desired level of PEB conversion. While a high temperature results in high PEB conversion that closely approaches equilibrium composition, these conditions can result in undesired side reactions. 936 Ethylbenzene Fig. 4 Lummus=UOP’s EBOneTM process. Deactivation of EBZ-100 catalyst is rare, usually only occurring because of unusual upsets or operation of the transalkylation reactor. Plants have operated for approximately 10 yr without regenerating the transalkylation catalyst. If EBZ-100 catalyst requires regeneration, an inexpensive, mild carbon burn procedure is used. The alkylation and transalkylation reactor effluent streams are sent to the distillation section, which consists primarily of three fractionation columns. The first column is the benzene column. It separates unconverted benzene into the overhead stream for recycle to the reactors. The benzene column bottom stream is the feed to the EB column. The EB column recovers the EB product in an overhead stream at purities as high as 99.98 wt%. The bottom stream of the EB column feeds a relatively small PEB column where PEB is fractionated overhead and recycled to the transalkylation reactor. The bottom stream of the PEB column, referred to as flux oil, is generally used as fuel in an integrated styrene complex. Ethylbenzene yields greater than 99.5% can be achieved by the Lummus=UOP technology. EBMaxTM process offered by Mobil=Badger The EBMax process offered by Mobil=Badger is a liquid phase alkylation reaction using a catalyst based Fig. 5 Mobil=Badger’s EBMaxTM process. Ethylbenzene on MCM-22. A commercial plant based on the EBMax technology was commissioned in 1995 at Chiba Styrene Monomer Company.[7] MCM-22 is classified as a medium-pore zeolite consisting of two independent, nonintersecting, 10-membered ring channels. One of the channels contains ‘‘super cages’’ that have a diameter defined by 12-membered rings. The MCM-22 crystal surface is covered with 12-membered ring pockets with each pocket being half of a ‘‘super cage.’’ It is within these surface pockets that the alkylation reactions are thought to occur. A typical EBMax plant flow diagram is shown in Fig. 5. The alkylation reactor is maintained in the liquid phase and uses multiple catalyst beds and ethylene injections. The ethylene conversion is essentially 100% in the alkylation reactors, and the reactors operate nearly adiabatically. The exothermic heat of reaction is recovered and used to generate steam, heat reactor feed streams, or as heat duty in the distillation columns. The transalkylation reactor in an EBMax plant can be either vapor phase or liquid phase. More recently, the transalkylation reactor has been designed as liquid phase because of its improved energy efficiency. The transalkylation reaction is conducted in the liquid phase using Mobil TRANS-4TM catalyst. The alkylation and transalkylation reactor effluent streams are sent to the distillation section, which consists primarily of three fractionation columns. The first column is a benzene column and it separates unconverted benzene into the overhead stream for recycle to the reactors. The benzene column bottom stream feeds the EB column. The EB column recovers 937 the EB product in the overhead stream, and the bottom stream of the EB column feeds the PEB column where PEB is fractionated overhead and recycled to the transalkylation reactor. The bottom stream of the PEB column is removed as a residue stream and is generally used as fuel in an integrated styrene complex. Mixed Liquid–Vapor Phase Zeolite Catalyst Process The CDTECH EBTM process is based on a mixed liquid–vapor phase alkylation reactor section. The design of a commercial plant is similar to the liquid phase technologies except for the design of the alkylation reactor, which combines catalytic reaction with distillation into a single operation.[8] Theoretically, catalytic distillation can overcome limitations in a typical two-step process consisting of reaction followed by distillation or separation. Often, a two-step process is limited by chemical equilibrium, heat transfer, mass transfer, or some combination of these. Catalytic distillation can overcome many of these constraints by simultaneously separating products from reactants, maintaining nearly isothermal operation and lowering the external ratio of reaction diluents. The CDTECH alkylation reactor consists of two main sections—a catalytic distillation section and a standard distillation section—as shown in Fig. 6. Benzene is fed to the top of the alkylation reactor and ethylene is fed as a vapor below the catalytic distillation section, creating a countercurrent flow of Fig. 6 CDTECH EBTM process. E 938 Ethylbenzene the alkylation reactants through the catalytic distillation section. Throughout the catalytic distillation section, a vapor–liquid equilibrium is established with ethylene largely concentrated in the vapor phase. The ethylene that dissolves into the liquid phase rapidly alkylates benzene on the catalyst active sites to produce EB. The rapid reaction of ethylene in the liquid phase creates a driving force for additional ethylene to dissolve into the liquid phase where the alkylation reaction occurs on the catalyst active sites. The exothermic heat of reaction creates the vaporization necessary to effect the distillation. The alkylation reaction products, mainly EB, diethylbenzene, and smaller amounts of other by-products, are continuously fractionated and removed from the catalytic distillation section. In the lower section of the alkylation reactor, standard distillation occurs and the reactor bottom stream contains primarily EB, PEB, and other high-boiling by-products. The catalytic distillation section uses a zeolite catalyst that is packaged into specially engineered bales. The catalyst bales function similarly as typical column structured packing and are designed to optimize both the distillation and the chemical reaction processes that occur in this portion of the alkylator.[9] The alkylator typically does not achieve 100% conversion of the ethylene, so the overhead stream from the alkylation reactor contains some unconverted ethylene and benzene. This overhead stream is fed to a finishing reactor were the unconverted ethylene is fully reacted. The finishing reactor is a fixed-bed reactor that operates in the liquid phase. One particular advantage of the CDTECH process is the ability of the alkylation reactor to accept a dilute ethylene feed. Because the alkylator operates in a mixed vapor–liquid phase, it is capable of utilizing dilute ethylene feeds, for example, offgas from a fluid catalytic cracking plant or dilute ethylene from a steam cracker plant. In general, ethylene feed streams containing significant amounts of hydrogen, methane, or ethane do require some pretreatment and cannot be used directly in the straight liquid phase technologies. ECONOMICS Although there are several different commercial technologies in use; the economic information described below relates only to the liquid phase technology. The cost of EB production consists of three main components: raw materials, utilities, and the fixed cost associated with the plant. The cost of utilities includes fuel, electricity, steam, cooling water, catalyst, and chemical costs required to operate the plant. Ethylbenzene plants typically have a small net negative utilities cost because the credit value of steam generated usually exceeds the cost of other utilities used throughout the plant. The major cost components for EB production using the liquid phase process are listed in Table 3. The major cost of production is the cost of ethylene and benzene raw materials, which accounts for more than 95% of the total cost of production because of the extremely high product yield of the commercial processes. As seen in Table 3, more than 95% of the total cost of production comes from the raw material costs of the ethylene and benzene feedstocks. The remaining cost, less than 5%, comes from fixed and utilities costs. The utilities costs are zero or slightly negative because all heat input and the heat of the alkylation reaction is recovered as low-pressure steam, which is valuable for a downstream styrene plant. The efficiency of this liquid phase process delivers extremely high commercial yields. The benzene cost is the largest cost component, so the economics of EB production is highly dependent on benzene price. Table 3 Typical economics for an EB liquid phase processa Unit Quantity Unit/MT Price $/Unit Cost $/MTb Product Ethylbenzene MT 1.0000 530 530.0 Raw materials Ethylene Benzene MT MT 0.2653 0.7387 629 453 166.9 334.6 By-product credits Flux Oil MT 0.0030 125 Net feedstock cost (0.4) 501.1 Utilities cost (0.6) Fixed cost 12 Total cost of production a North America, 2003. b MT, metric ton. 512.5 Ethylbenzene 939 production of polystyrene, has become an important feedstock for products that are used in everyday life. Most people come in contact with numerous products produced from styrene throughout the course of a normal day. Because of its close link with styrene production, the demand for EB is expected to continue growing at a rate comparable to the demand growth rate of styrene, which is nearly equal to the gross domestic product (GDP) growth rate. The chemical processing technologies that have been developed are sophisticated and produce EB to meet that demand at the lowest possible cost. Research and development aimed at discovering further improvements in existing technologies and identifying new technologies for EB production remains an area of great focus with strong potential for application in the marketplace. REFERENCES Fig. 7 Distribution of EB cost components. The raw material cost has two components—one dictated by the stoichiometry and one caused by yield losses occurring as a result of the process technology. If the unalterable stoichiometric raw material consumption is removed from the cost of production, the resultant distribution of cost components appears very different, as illustrated in Fig. 7. From this perspective, the raw material cost is only about 10% of the incremental cost of production and the fixed costs become dominant. Recent catalyst and process design improvements have reduced the variable costs of EB production, while ever-increasing plant complexity and more stringent environmental regulations have greatly increased the fixed costs. Other recent trends, such as globalization of the EB–styrene market, have also resulted in higher fixed costs. The result of the shift in focus from variable costs to fixed costs is that plants are being designed for larger capacities. For example, in 2003, typical new EB plants in the Asia Pacific Region produced an average of 368 KMTA EB per year, nearly double the capacity of typical plants started up just 5 yr earlier. CONCLUSIONS Since its first commercial production in the 1930s, EB, mainly through its role as an intermediate in the 1. Lentz, R.; Gami, A. Recent EB capacity expansion; creative approaches to revamp projects. Styrene Conference General Session; Prague, Czech Republic, Jun 22–25, 2003. 2. CMAI Capacity Database Report for World Ethylbenzene Capacity; http://www.cmaiglobal.com (accessed May 2004). 3. Sherman, J. Synthetic zeolites and other microporous oxide molecular sieves. National Academy of Sciences Colloquium ‘‘Geology, Mineralogy, and Human Welfare,’’ Irvine, CA, Nov 8–9, 1998; Proc. Natl. Acad. Sci. USA 1999, 96, 3471–3478. 4. Schmidt, R.J.; Zarchy, A.S.; Peterson, G.A. New developments in cumene and ethylbenzene alkylation. AIChE Spring Meeting; New Orleans, LA, Mar 10–14, 2002. 5. Degnan, T.F. Jr.; Smith, C.M.; Venkay, C.R. Alkylation of aromatics with ethylene and propylene: recent developments in commercial processes. Appl. Catal. 2001, 221, 283–294. 6. Woodle, G.B.; Zarchy, A.S.; Morita, M.; Shinohara, K. Leading-edge ethylbenzene production, Lummus= UOP liquid phase EB process. 1998 International Styrene Symposium; Sappora, Japan, Jun 14–18,1998. 7. Bhandarkar, M.; Lewis, P.J.; Dandekar, A.B.; Venkat, C.R.; Degnan, T.F. EBMax: liquid phase alkylation of benzene with ethylene over zeolite MCM-22. In European Petrochemicals Technology Conference; London, U.K. Jun 21–22, 1999. 8. Phanse, G. Catalytic distillation: the next step in aromatic alkylation. AIChE Spring Meeting; New Orleans, LA, Mar 10–14, 2002. 9. Smith L.A., Jr. Alkylation of Organic Aromatic Compounds, US. Patent 5,446,223, Aug 29, 1995. E