Meyers et al. - Technical Graphics-Schroff Development Corp. (2008)

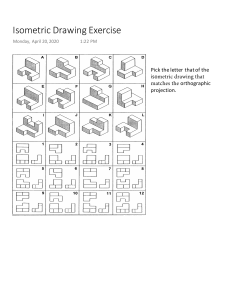

advertisement