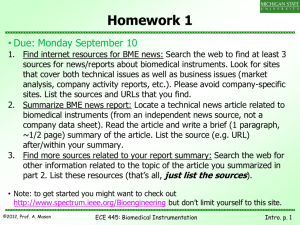

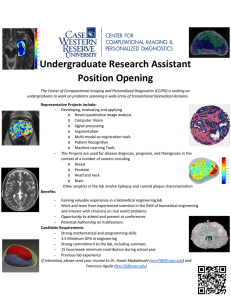

Biomedical Engineering overview Awada Ali Ph.D. OUTLINES • INTRODUCTION • DEFINITION • ACTIVITIES • ROLE PLAYED BY BIOMEDICAL ENGINEER • APPLICATIONS INTRODUCTION Many of the problems facing health care professionals are extremely important to the engineer because they involve: 1. The fundamental aspects of device and systems analysis. 2. Design. 3. Practical application. All of which lie at the heart of processes that are fundamental to engineering practice. These medically relevant design problems can range: • From small and "simple" devices: Recording electrodes and transducers used to monitor activity of specific physiological processes in either a research or a clinical setting. • To very complex large-scale constructs: Design and implementation of automated clinical labs, and Hospital information systems. DEFINITION • Biomedical engineering is an interdisciplinary branch based on both engineering and life sciences. • Biomedical engineers apply electrical, chemical, optical, mechanical, and other engineering principles to understand, modify, or control biological systems. • It ranges from theoretical, non-experimental undertakings to state-of-the-art applications. • It can includes research, development, implementation, and operation. BIOMEDICAL ENGINEERING ACTIVITIES The field has moved significantly from being concerned primarily with the development of medical devices to includes many new career areas. These areas include: • Detection, measurement, and monitoring of physiologic signals. • Diagnostic interpretation via signal-processing techniques of bioelectric data. • Therapeutic and rehabilitation procedures and devices. • Devices for replacement of bodily functions (artificial organs). ROLE PLAYED BY BIOMEDICAL ENGINEER Biomedical engineering involves training three types of individuals: 1. Clinical engineer in health care • The clinical engineer maintains the traditional service relationship with the life scientists who originate a problem that can be solved by applying the specific expertise of the engineer. • They must understand the biological situation to apply their judgment and contribute their knowledge toward the solution of the given problem as well as to defend their methods in terms that the life scientist can understand. 2. Biomedical Design Engineer • These individuals assume the gap between the technological education of the physician and current technological capability. • They examine some portion of the medical front and identify areas in which advanced technology might be advantageous. • They pose their own problem and then proceed to provide the solution conceptually in the form of hardware or software. • They must convince the medical community that they can provide a useful tool. • They should have a great deal of engineering and medical knowledge as well as experience in numerous medical systems. 3. Research Scientist • They are interested in applying engineering concepts and techniques to the investigation and exploration of biological processes. • The most powerful tool is the construction of an appropriate mathematical model of the specific biological system under study. • Through simulation techniques, they can use this model to understand features that are too complex for analytical computation. • The process of simulation facilitates the design of experiments that can be performed on the actual biological system. • This mathematical model can predict the effect of changes on a biological system where actual experiments may be very difficult. • The experiments results can be used to increase understanding of a biological mechanism results from this iterative process. CONCLUSIONS Each of these roles envisioned for the biomedical engineer requires a different attitude and a degree of knowledge about the biological environment. Rising social and economic expectations, and a need for the development of more adequate techniques for: • Prevention • Diagnosis • Treatment of disease Development and employment of biomedical engineers have become a necessity. Introduction to bioinstrumentation Awada Ali Ph.D. Introduction • Bioinstrumentation • Sensor or actuator (or both) used in medicine or biological research • Usually directly connected to a living system • Process, display or transmits biological data • Areas of biomedical engineering that use these instruments • • • • • • Bioelectronics (cardiac monitoring) Biomechanics (tissue testing) Biooptics (screening for biomarkers, radiation therapy) Biomaterials (biocompatibility testing) Biosystems (properties of cells) Medical imaging (MRI, PET) • Key to successful of biomedical engineering: • Understand the physiology of a system • Know the variables to be measured • Know the function and limitations of the components Generalized Medical Instrumentation System Sensor Signal conditioning Medical and Physiological Parameters BI Operational Modes • Direct vs. Indirect • Direct mode: measure desired measurand directly • if the sensor is invasive, direct contact with the measurand is possible but expensive, risky and least acceptable • Indirect mode: measure a quantity that is accessible and related to the desired measurand • • assumption: the relationship between the measurands is already known often chosen when the measurand requires invasive procedures to measure directly • Example indirect mode • Cardiac output (volume of blood pumped per minute by the heart) • can be determined from measurement of respiration, blood gas concentration & dye dilution • Organ morphology can be determined from x-ray shadows BI Operational Modes • Sampling vs. Continuous mode • Most sensors are analog, then signal is converted to digital for processing or transmission • Sampling: for slow varying measurands that are sensed infrequently like body temperature & ion concentrations • Continuous: for critical measurements requiring constant monitoring like electro-cardiogram and respiratory gas flow • Generating vs. Modulating • Generating: also known as self-powered mode • • derive their operational energy from the measurand itself Example: piezoelectric sensors, solar cells • Modulating: measurand modulates the electrical signal which is supplied externally • modulation affects output of the sensor • Example: photoconductive or piezoresistive sensor BI Operational Modes • Analog vs. digital modes • most sensors are inherently analog (some optical sensors are exceptions) • require analog-to-digital converters before any DSP techniques could be applied for filtering • Nyquist criterion: any continuous signal of frequency bandwidth f can be fully reconstructed from its discrete time sample at sampling rate 2f • Real-time vs. Delayed-time mode • Real-time: real time processing is essential for bioinstrumentations with feedback • Example: ECG signals need to measured in real-time to determine an impending cardiac arrest • Delayed-time: some delay is acceptable for output display/transmission systems • Example: cell cultures which requires several days before any output is acquired Measurement Constraints • The signal to be measured imposes constraints on how it should be acquired and processed • Signal/frequency ranges • Most medical measurands parameters are typically much lower than conventional sensing parameters (microvolts, mm Hg, low frequency) • Interference and cross-talk • Noise from environment, instruments, etc. • Other measurands affect measurement (and can’t be isolated) • e.g., Cannot measure EEG without interference from EMG Require filtering and/or compensation Placement of sensor(s) in/on/near the body plays a key role in any bio-instrumentation design Measurement Constraints • Measurement variability is inherent at molecular, organ and body level Primary cause • interaction between different physiological systems • existence of numerous feedback loops whose properties are poorly understood • SAFETY • Due to interaction of sensor with living tissue, safety is a primary consideration in all phases of the design & testing process • the damage caused could be irreversible • In many cases, safe levels of energy is difficult to establish • Safety of medical personnel also must be considered • Operator constraints • Reliable, easy to operate, rugged and durable Classification of biomedical instruments • Quantity being sensed • pressure, flow or temperature • makes comparison of different technologies easy • Principle of transduction • resistive, inductive, capacitive, ultrasonic or electrochemical • makes development of new applications easy • Organ systems • cardiovascular, pulmonary, nervous, endocrine • isolates all important measurements for specialists who need to know about a specific area • Clinical specialties • pediatrics, obstetrics, cardiology or radiology • easy for medical personnel interested in specialized equipment. Instrument Characterization • Enable comparison of available instruments • Permit evaluation of new instrument designs Generalized static characteristics • Static characteristics: • performance of instruments for dc or very low frequency inputs • some sensors respond only to time-varying inputs and have no static characteristics • Dynamic characteristics: • require temporal relationships to describe the quality of measurements Performance characteristics Performance characteristics quantifying the quality of the measurement or the signal processing Static instrument characteristics: • Accuracy: Difference between the true value and the measured value normalized by the magnitude of the true value • Several ways to express accuracy: most popular is in terms of percentage of full-scale measurement • Precision: Expresses number of distinguishable alternatives from which a given result is selected • High-precision does not mean high accuracy. • Resolution: Smallest incremental quantity that can be measured with certainty • Reproducibility: Ability of an instrument to give the same output for equal inputs applied over some period of time Regulation of Medical Devices Regulatory division of medical devices: class I, II and III • more regulation for devices that pose greater risk • Class I (General controls) • Manufacturers are required to perform registration, premarketing notification, record keeping, labeling, reporting of adverse experiences and good manufacturing practices • Class II (Performance standards) 800 standards needed to be met • Class III (Premarketing approval ) • Manufacturers have to prove the safety of these devices prior to market release • Implanted devices (pacemakers etc.) are typically designated class III • Investigational devices are typically exempt