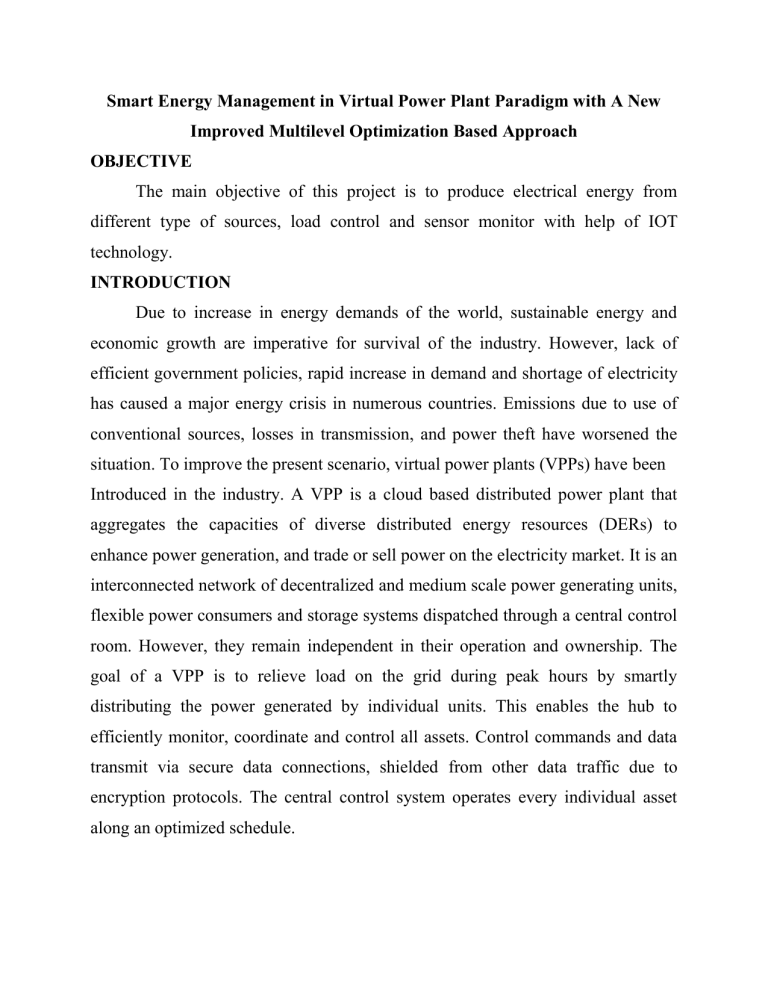

Smart Energy Management in Virtual Power Plant Paradigm with A New Improved Multilevel Optimization Based Approach OBJECTIVE The main objective of this project is to produce electrical energy from different type of sources, load control and sensor monitor with help of IOT technology. INTRODUCTION Due to increase in energy demands of the world, sustainable energy and economic growth are imperative for survival of the industry. However, lack of efficient government policies, rapid increase in demand and shortage of electricity has caused a major energy crisis in numerous countries. Emissions due to use of conventional sources, losses in transmission, and power theft have worsened the situation. To improve the present scenario, virtual power plants (VPPs) have been Introduced in the industry. A VPP is a cloud based distributed power plant that aggregates the capacities of diverse distributed energy resources (DERs) to enhance power generation, and trade or sell power on the electricity market. It is an interconnected network of decentralized and medium scale power generating units, flexible power consumers and storage systems dispatched through a central control room. However, they remain independent in their operation and ownership. The goal of a VPP is to relieve load on the grid during peak hours by smartly distributing the power generated by individual units. This enables the hub to efficiently monitor, coordinate and control all assets. Control commands and data transmit via secure data connections, shielded from other data traffic due to encryption protocols. The central control system operates every individual asset along an optimized schedule. ABSTRACT: A virtual power plant (VPP) is a cloud based distributed power plant that aggregates the capacities of diverse distributed energy resources (DERs) for the purpose of enhancing power generation as well as trading or selling power on the electricity market. The main issue faced while working on VPPs is energy management. Smart energy management of a VPP is a complex problem due to the coordinated operation of diverse energy resources and their associated uncertainties. This research paper proposes a real- time (RT) smart energy management model for a VPP using a multi-objective, multi-level optimizationbased approach. The VPP consists of a solar, wind and thermal power unit, along with an energy storage unit and some flexible demands. The term multi-level refers to three different energy levels depicted as three homes comprising of different amounts of loads. RT operation of a VPP is enabled by exploiting the bidirectional communication infrastructure. Multi-objective RT smart energy management is implemented on a community-based dwelling system using three alternative algorithms i.e., hybrid optimal stopping rule (H-OSR), hybrid particle swarm optimization (H-PSO) and advanced multi-objective grey wolf optimization (AMO-GWO). The proposed technique focuses on achieving the objectives of optimal load scheduling, real-time pricing, efficient energy consumption, emission reduction, cost minimization and maximization of customer comfort altogether. A comparative analysis is performed among the three algorithms in which the calculated real-time prices are compared with each other. It is observed that on average H-PSO performs 7.86 % better than H-OSR whereas AMO-GWO performs 10.49% better than H-OSR and 5.7% better than H-P-SO. This paper concludes that AMO-GWO is the briskest, most economical, and efficient optimization algorithm for RT smart energy management of a VPP. EXISTING SYSTEM In this existing system produce electrical power from solar and dynamo rotation based method only. In this old project is used for Bluetooth, ZIGBEE, RF based communication device and not available IOT based communication method. Distance coverage problem occurred in this model. Poor power management for in this system. PROPOSED SYSTEM In the proposed system, microcontroller is connected with voltage sensor, LCD display, inverter, Driver Circuit with Relay and IOT server. The thermal energy harvester is attributed to the heat applied on two different metals. The temperature difference between them will deliver a potential voltage directly proportional to temperature difference. This is called the See beck effect. The wind model is convert mechanical energy to electrical energy with help of air and dynamo. Solar panel produce electricity from sun light. This power saves in battery backup with help of boosting circuit. Use of embedded technology makes this system efficient and reliable. Micro controller (ARDUINO) allows dynamic and faster control. Liquid crystal display (LCD) makes the system user-friendly to get the voltage. ARDUINO micro controller is the heart of the circuit as it controls all the functions. All sensor value is stored in IOT server. Operate Load depend upon IOT control key. It is easy to understand the pattern using the Dashboard Controller interface is implemented using the MQTT protocol. LITERATURE REVIEW / SURVEY S.NO 1 Author Title of Year A. Internet things Abdelgawa platform for structure health Work done (iot) 2017 Analysis the IOT concept. d and K. monitoring Yelamarthi 2 Yang Bai, Hybrid, multi-source and Heli 2018 Analysis the energy integrated energy harvesters harvester’s concept. Jantunen, and Jari Juuti 3 Manisha R Micro Mhetre, energy 2011 Analysis the energy harvesting for harvester’s concept. Namrata S biomedical applications Nagdeo 4 K. An architectural Yelmarthi, framework A. IOT applications Abdelgawa d, and A. Khattab for 2016 Analysis low-power the power concept low- BLOCK DIAGRAM: Charge controller (SEPIC) Solar Power Voltage Sensor Charge controller (SEPIC) Thermal Source Voltage Sensor LCD Display ARDUINO Micro IOT SERVER ESP8266 Controller Charge controller (SEPIC) Wind Source Relay For IOT Load Switch Battery 12V DC LOAD Voltage Sensor Voltage Sensor Inverter AC Load Power Supply to All Part MONITORING AND CONTROL SECTION ADVANTAGES: No pollution Easy to implement It is very feasible for general facilities that require no large power. The proposed system can be simply extended to the green house environment for Floriculture in office or building sunlight control. APPLICATIONS: It is used in Home and industrial applications. It is used in commercial applications. It is used in Electrical applications. HARDWARE REQUIREMENTS: ARDUINO controller LCD Display Power supply unit ESP8266 WIFI Modem Voltage sensor Battery Wind model PELTIER cell Inverter SEPIC Converter Relay with driver SOFTWARE REQUIREMENTS: EMBEDDED C PROGRAM ARDUINO-1.8.13 IDE BLYNK IOT SERVER CONCLUSION In this paper, an efficient smart energy management frame-work for a community in a VPP paradigm is designed. After identifying some limitations in previous work performed in this domain, an intelligent MAS is developed using JADE platform. Three different algorithms are implemented to improve and overcome those limitations. These algorithms together achieve the main objectives of this research that are RTP, optimal load scheduling, minimum energy consumption, cost minimization, emission reduction and customer comfort. The proposed technique is applied on three different homes in a community, which are presented as three different cases. A comparative analysis is performed between HOSR, H-PSO and AMO-GWO in which calculated RTPs are compared with each other. Energy consumption patterns and device ON/OFF states are also calculated. Based on RTP, it is observed that on average H-PSO performs 7.86 % better than H-OSR whereas AMO-GWO performs 10.49% better than H-OSR and 5.7% better than H-PSO in terms of pricing. Emission rates in kg/kWh are calculated for three most hazardous GHGs i.e., CO2, SO2 and NO2 and it is observed that the emissions calculated using AMO-GWO algorithm are the least as compared to other two algorithms. Hence, it is concluded that on average, the AMO-GWO algorithm performs better than the other two and provides a more efficient and optimal solution to the optimization problem. The simulation results provide an optimum solution to the RT energy management problem of a VPP and validate the claims that a VPP promotes clean and green energy, efficient energy consumption, and customer comfort and control. REFERENCES [1] S. A. A. Kazmi, M. K. Shahzad, A. Z. Khan, and D. R. Shin, ‘‘Smart distribution networks: A review of modern distribution concepts from a planning perspective,’’ Energies, vol. 10, no. 4, p. 501, Apr. 2017. [2] (2020). Next Kraftwerke. How a Virtual Power Plant Works. Accessed: Mar. 2021. [Online]. Available: https://www.next- kraftwerke.com/knowledge [3] S. Babaei, C. Zhao, and L. Fan, ‘‘A data-driven model of virtual power plants in day-ahead unit commitment,’’ IEEE Trans. Power Syst., vol. 34, no. 6, pp. 5125–5135, Nov. 2019. [4] W. Wang, P. Chen, D. Zeng, and J. Liu, ‘‘Electric vehicle fleet integration in a virtual power plant with large-scale wind power,’’ IEEE Trans. Ind. Appl., vol. 56, no. 5, pp. 5924–5931, Sep. 2020. [5] W. Tang and H.-T. Yang, ‘‘Optimal operation and bidding strategy of a virtual power plant integrated with energy storage systems and elasticity demand response,’’ IEEE Access, vol. 7, pp. 79798–79809, 2019.