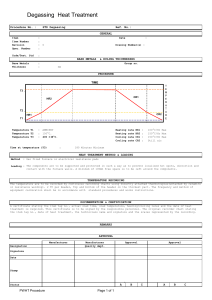

HEAT TREATMENT OF WELDED JOINTS

Heat treatment is an operation that is both time consuming and costly. It can affect the

strength and toughness of a welded joint, its corrosion resistance and the level of residual

stress but is also a mandatory operation specified in many application codes and standards.

In addition it is an essential variable in welding procedure qualification specifications.

Before discussing the range of heat treatments that a metal may be subjected to, there is a

need to clearly define what is meant by the various terms used to describe the range of heat

treatments that may be applied to a welded joint. Such terms are often used incorrectly,

particularly by non-specialists; for a metallurgist they have very precise meanings.

Solution treatment

Carried out at a high temperature and designed to take into a solution elements and

compounds which are then retained in solution by cooling rapidly from the solution

treatment temperature. This may be done to reduce the strength of the joint or to

improve its corrosion resistance. With certain alloys it may be followed by a lower

temperature heat treatment to reform the precipitates in a controlled manner (age or

precipitation hardening).

Annealing

This consists of heating a metal to a high temperature, where recrystallisation and/or

a phase transformation take place, and then cooling slowly, often in the heat treatment

furnace. This is often carried out to soften the metal after it has been hardened, for

example by cold working; a full anneal giving the very softest of microstructures. It also

results in a reduction in both the yield and the tensile strength and, in the case of ferritic

steels, usually a reduction in toughness.

Normalising

This is a heat treatment that is carried out only on ferritic steels. It comprises heating

the steel to some 30-50°C above the upper transformation temperature (for a 0.20%

carbon steel this would be around 910°C) and cooling in still air. This results in a

reduction in grain size and improvements in both strength and toughness.

Quenching

This comprises a rapid cool from a high temperature. A ferritic steel would be heated

to above the upper transformation temperature and quenched in water, oil or air blast

to produce a very high strength, fine grained martensite. Steels are never used in the

quenched condition, they are always tempered following the quenching operation.

Tempering

A heat treatment carried out on ferritic steels at a relatively low temperature, below the

lower transformation temperature; in a conventional structural carbon steel this would

be in the region of 600-650°C. It reduces hardness, lowers the tensile strength and

improves ductility and toughness. Most normalised steels are tempered before

welding, all quenched steels are used in the quenched and tempered condition.

Ageing or Precipitation hardening

A low temperature heat treatment designed to produce the correct size and distribution

of precipitates, thereby increasing the yield and tensile strength. It is generally

preceded by a solution heat treatment. For steel, the temperature may be somewhere

between 450-740 degree C, an aluminium alloy would be aged at between 100-200°C.

Longer times and/or higher temperatures result in an increase in size of the precipitate

and a reduction in both hardness and strength.

Stress relief

As the name suggests, this is a heat treatment designed to reduce the residual

stresses produced by weld shrinkage. It relies upon the fact that, as the temperature

of the metal is raised, the yield strength decreases, allowing the residual stresses to

be redistributed by creep of the weld and parent metal. Cooling from the stress relief

temperature is controlled in order that no harmful thermal gradients can occur.

Post heat

A low temperature heat treatment carried out immediately on completion of welding by

increasing the preheat by some 100°C and maintaining this temperature for 3 or 4

hours. This assists the diffusion of any hydrogen in the weld or heat affected zones

out of the joint and reduces the risk of hydrogen induced cold cracking. It is used only

on ferritic steels, where hydrogen cold cracking is a major concern i.e. very crack

sensitive steels, very thick joints etc.

Post Weld Heat Treatment (PWHT)

So what does the term 'post weld heat treatment' mean? To some engineers it is a

rather vague term that is used to describe any heat treatment that is carried out when

welding is complete. To others however, particularly those working in accordance with

the pressure vessel codes such as BS PD 5500, EN 13445 or ASME VIII, it has a very

precise meaning. When an engineer talks of post weld heat treatment, annealing,

tempering or stress relief it is therefore advisable.

Heat treatment following welding may be carried out for one or more of three

fundamental reasons:

to achieve dimensional stability in order to maintain tolerances during

machining operations or during shake-down in service

to produce specific metallurgical structures in order to achieve the required

mechanical properties

to reduce the risk of in-service problems such as stress corrosion or brittle

fracture by reducing the residual stress in the welded component

The range of heat treatments to achieve one or more of these three objectives in the

range of ferrous and non-ferrous metals and alloys that may be welded is obviously

far too extensive to cover in great detail within these brief Job Knowledge articles. The

emphasis in the following section will be on the PWHT of carbon and low alloy steels

as required by the application standards although brief mention will be made of other

forms of heat treatment that the welding engineer may encounter in the ferrous alloys.

There are two basic mechanisms that are involved, firstly stress relief and secondly

microstructural modifications or tempering.

Stress Relief

Why is it necessary to perform stress relief? It is an expensive operation requiring part

or all of the welded item to be heated to a high temperature and it may cause

undesirable metallurgical changes in some alloys. As mentioned above there may be

one or more reasons. The high residual stresses locked into a welded joint may cause

deformation outside acceptable dimensions to occur when the item is machined or

when it enters service. High residual stresses in carbon and low alloy steels can

increase the risk of brittle fracture by providing a driving force for crack propagation.

Residual stresses will cause stress corrosion cracking to occur in the correct

environment eg carbon and low alloy steels in caustic service or stainless steel

exposed to chlorides.

What causes these high residual stresses? Welding involves the deposition of molten

metal between two essentially cold parent metal faces. As the joint cools the weld

metal contracts but is restrained by the cold metal on either side; the residual stress

in the joint therefore increases as the temperature falls. When the stress has reached

a sufficiently high value (the yield point or proof strength at that temperature) the metal

plastically deforms by means of a creep mechanism so that the stress in the joint

matches the yield strength. As the temperature continues to fall the yield strength

increases, impeding deformation, so that at ambient temperature the residual stress

is often equal to the proof strength (Fig 1).

To reduce this high level of residual stress, the component is reheated to a sufficiently

high temperature. As the temperature is increased the proof strength falls, allowing

deformation to occur and residual stress to decrease until an acceptable level is

reached. The component would be held at this temperature (soaked) for a period of

time until a stable condition is reached and then cooled back to room temperature.

The residual stress remaining in the joint is equal to the proof strength at the soak

temperature.

Figure 1 shows that residual stress in a carbon manganese steel falls reasonably

steadily from ambient to around 600 degree C but that the high strength creep resistant

steels need to be above 400 degree C before the residual stress begins to fall.

Stainless steel is hardly affected until the temperature exceeds 500 degree C. There

is therefore a range of soak temperatures for the various alloys to achieve an

acceptable reduction in residual stress without adversely affecting the mechanical

properties of the joint. In carbon manganese steels this temperature will be between

550-620 degree C, in creep resistant steels somewhere between 650-750 degree C

and for stainless steels between 800-850 degree C.

Tempering

Tempering is a heat treatment that is only relevant to steels and is carried out to soften

any hard micro-structures that may have formed during previous heat treatments,

improving ductility and toughness. Tempering also enables precipitates to form and

for the size of these to be controlled to provide the required mechanical properties.

This is particularly important for the creep resistant chromium-molybdenum steels.

Tempering comprises heating the steel to a temperature below the lower critical

temperature; this temperature being affected by any alloying elements that have been

added to the steel so that for a carbon-manganese steel, the temperature is around

650°C, for a 2¼CrMo steel, 760°C . Quenched steels are always tempered.

Normalised steels are also usually supplied in the tempered condition although

occasionally low carbon carbon-manganese steel may be welded in the normalised

condition only, the tempering being achieved during PWHT. Annealed steels are not

supplied in the tempered condition.

Tempering of tool steels may be performed at temperatures as low as 150 degrees C,

but with the constructional steels that are the concern of the welding engineer the

tempering temperature is generally somewhere between 550- 760°C, depending on

the composition of the steel.

Post Weld Heat Treatment (PWHT)

As mentioned, PWHT is a specific term that encompasses both stress relief and

tempering and is not to be confused with heat treatments after welding. Such

treatments may comprise ageing of aluminium alloys, solution treatment of austenitic

stainless steel, hydrogen release etc. PWHT is a mandatory requirement in many

codes and specifications when certain criteria are met. It reduces the risk of brittle

fracture by reducing the residual stress and improving toughness and reduces the risk

of stress corrosion cracking. It has, however, little beneficial effect on fatigue

performance unless the stresses are mostly compressive.

It is an essential variable in all of the welding procedure qualification specifications such as

ISO 15614 Part 1 and ASME IX. Addition or deletion of PWHT or heat treatment outside the

qualified time and/or temperature ranges require a requalification of the welding procedures.

PWHT temperatures for welds made in accordance with the requirements of EN 13445,

ASME VIII and BS PD 5500 are given below in Table 1.

Table 1: PWHT Temperatures from Pressure Vessel Specifications

Steel

Grade

C Steel

BS EN

13445

ASME

VIII

Temp

range

°C

Normal

holding

temp

°C

Temp range

°C

550600

593

580-620

BS PD 5500

Steel

Grade

BS EN

13445

ASME

VIII

BS PD 5500

C 1/2

Mo

550620

593

630-670

1Cr 1/2

Mo

630680

593

630-700

2 1/4

Cr/Mo

670720

677

630-750

5CrMo

700750

677

710-750

3 1/2

Ni

530580

593

580-620

Note from Table 1 that ASME VIII specifies a minimum holding temperature and not a

temperature range as in the BS and EN specifications.

As mentioned above, PWHT is a mandatory requirement when certain criteria are met,

the main one being the thickness. BS EN 13445 and BSPD 5500 require that joints

over 35mm thick are PWHT’d, ASME VII above 19mm. If, however, the vessel is to

enter service where stress corrosion is a possibility, PWHT is mandatory, irrespective

of thickness. The soak time is also dependant on thickness. As a very general rule this

is one hour per 25mm of thickness; for accuracy, reference must be made to the

relevant specification.

These different requirements within the specifications mean that great care needs to

be taken if a procedure qualification test is to be carried out that is intended to comply

with more than one specification. A further important point is that the PWHT

temperature should not be above that of the original tempering temperature as there

is a risk of reducing the strength below the specified minimum for the steel. It is

possible to PWHT above the tempering temperature only if mechanical testing is

carried out to show that the steel has adequate mechanical properties. The testing

should, obviously, be on the actual material in the new heat treatment condition.

Maximum and minimum heating and cooling rates above 350-400°C are also specified

in the application codes. Too fast a heating or cooling rate can result in unacceptable

distortion due to unequal heating or cooling and, in very highly restrained components,

may cause stress cracks to form during heating.

Application of PWHT

The method of PWHT depends on a number of factors; what equipment is available,

what is the size and configuration of the component, what soaking temperature needs

to be achieved, can the equipment provide uniform heating at the required heating

rate? The best method is by using a furnace. This could be a permanent fixed furnace

or a temporary furnace erected around the component, this latter being particularly

useful for large unwieldy structures or to PWHT a large component on site. Permanent

furnaces may be bogie loaded with a wheeled furnace bed on to which the component

is placed or a top hat furnace that uses a fixed hearth and a removable cover.

Typically, a furnace capable of heat treating a 150tonne pressure vessel would have

dimensions of around 20m long, a door 5x5m and would consume around

900cu/metres of gas per hour.

Furnaces can be heated using electricity, either resistance or induction heating,

natural gas or oil. If using fossil fuels care should be taken to ensure that the fuel does

not contain elements such as sulphur that may cause cracking problems with some

alloys, particularly if these are austenitic steels or are nickel based – corrosion

resistant cladding for example. Whichever fuel is used the furnace atmosphere should

be closely controlled such that there is not excessive oxidation and scaling or

carburisation due to unburnt carbon in the furnace atmosphere. If the furnace is gas

or oil fired the flame must not be allowed to touch the component or the temperature

monitoring thermocouples; this will result in either local overheating or a failure to

reach PWHT temperature.

Monitoring the temperature of the component during PWHT is essential. Most modern

furnaces use zone control with thermocouples measuring and controlling the

temperature of regions within the furnace, control being exercised automatically via

computer software. Zone control is particularly useful to control the heating rates when

PWHT’ing a component with different thicknesses of steel. It is not, however,

recommended to use monitoring of the furnace temperature as proving the correct

temperatures have been achieved in the component. Thermocouples are therefore

generally attached to the surface of the component at specified intervals and it is these

that are used to control the heating and cooling rates and the soak temperature

automatically so that a uniform temperature is reached. There are no hard and fast

rules concerning the number and disposition of thermocouples, each item needs to be

separately assessed.

As mentioned earlier, the yield strength reduces as the temperature rises and the

component may be unable to support its own weight at the PWHT temperature.

Excessive distortion is therefore a real possibility. It is essential that the component

is adequately supported during heat treatment and trestles shaped to fit the

component should be placed at regular intervals. The spacing of these will depend on

the shape, diameter and thickness of the item. Internal supports may be required

inside a cylinder such as a pressure vessel; if so, the supports should be of a similar

material so that the coefficients of thermal expansion are matched.

Whilst heat treating a pressure vessel in one operation in a furnace large enough to

accommodate the entire vessel is the preferred method this is not always possible. In

this case the pressure vessel application codes permit a completed vessel to be heat

treated in sections in the furnace. It is necessary to overlap the heated regions – the

width of the overlap is generally related to the vessel thickness. BS EN 13445 for

instance specifies an overlap of 5√Re where R = inside diameter and e = thickness;

ASME VIII specifies an overlap of 1.5 metres. It should be remembered that if this is

done there will be a region in the vessel (which may contain welds) that will have

experienced two cycles of PWHT and this needs to be taken into account in welding

procedure qualification testing. There is also an area of concern, this being the region

between the heated area within the furnace and the cold section outside the furnace.

The temperature gradient must be controlled by adequately lagging the vessel with

thermally insulating blankets and the requirements are given in the application codes.

It is, of course, possible to assemble and PWHT a vessel in sections and then to carry

out a local PWHT on the final closure seam. Local PWHT will be discussed in the next

part of this series on heat treatment.

When it is not possible to place the entire component in a furnace for heat treatment

(because of the size of the fabrication, circumferential welds in a pipework system or

when installing equipment on site, for example), then a local PWHT may be the only

option. Local PWHT needs careful planning to ensure that heating and cooling rates

are controlled and that an even and correct temperature is achieved. Uneven and/or

rapid heating can give rise to harmful temperature gradients producing thermally

induced stresses that exceed the yield stress. This may result in the development of

new residual stresses when the component is cooled.

Local PWHT may be carried out using high velocity gas burners, infra red burners,

induction heating and high or low resistance heating elements. Electrical equipment is

more easily installed and controlled than heating using natural gas or propane,

particularly on site. High voltage resistance heating is rarely used on site due to the

need for the radiant heaters to be positioned a set distance from the surface and, more

significantly perhaps, the health and safety risks involved with the use of high voltage

current. Low voltage electrical resistance heating and induction heating are the two

most commonly used methods.

High velocity gas burners are more advantageous when large areas need to be heat

treated, particularly if, for example, firing can take place within a pressure vessel which

then becomes its own furnace. For local PWHT of vessel circumferential seams

internal insulating barriers can be used to localise the heat source. Motorised valves

and micro-processor control of the combustion conditions enabled precise

management of the heating cycle to be achieved.

Low voltage electrical resistance heating uses flexible ceramic heating elements,

colloquially known as corsets, an appropriate number being assembled to cover the

area to be heat treated. Induction heating uses insulated cables that can be wrapped

around the joint or shaped to fit the area to be heated or specially designed fitting for

repetitive PWHT operations as illustrated in Fig 1. To perform the PWHT, temperature

control thermocouples are firstly attached, often by capacitor discharge welding, the

elements placed in position and the area then lagged with thermal insulating blankets

to reduce heat loss and to maintain an acceptable temperature gradient.

There are no standard terms used to describe the various regions within the locally

PWHT'd area. In this article the terms 'soak band', 'heated band', 'gradient control

band', 'temperature gradient', which may be axial and through thickness, and 'control

zone' as suggested by the ASME will be used (see Fig 2).

The soak band is the area that is heated to, within the specified PWHT temperature

and time range. It comprises the weld, the two HAZs and part of the surrounding parent

metal. The heated band is the area covered by the heating elements, the temperature

at the edge of the heated band generally being required to be at least half that of the

soak temperature. The temperature gradient control band is the region where thermal

insulation, perhaps supplemented by additional heating elements, is applied to ensure

that an acceptable axial temperature gradient is achieved from PWHT temperature to

ambient. A control zone is the region where a number of heating elements are grouped

together and controlled by a single thermocouple, enabling different regions to be

heated independently; particularly useful with large diameter items or where there are

variations in thickness.

Temperature gradients may be axial (along the length of a pipe or vessel) and through

thickness. The through thickness temperature gradient is caused by heat losses from

the internal surface and is a function of both thickness and internal diameter, the larger

the diameter, the greater the effect of radiation and convection losses. Both the width

of the soak band and the temperature achieved can be substantially less than that on

the outside of the pipe or tube. Insulation on the inner surface will reduce the

temperature/width differential but may not be possible on small diameter tubes or

pipework systems. This through thickness gradient is one of the reasons that

specifications and codes require the soak or heated band to be a minimum width,

generally related in some way to the thickness of the component.

As mentioned above, there are rules in the application codes concerning the size of

the heated area, normally related to the thickness. In a circular component such as a

pipe butt weld or a pressure vessel circumferential seam the width of the band is easy

to calculate. ASME VIII for instance requires the soak band width to be twice the

thickness of the weld or 50.8mm either side of the weld, whichever is the lesser.

ASME B31.3 requires the soak band width to be the weld width plus 25.4mm either

side of the weld. BS EN 13445 does not specify a soak band width but instead

specifies a heated band width of 5√Rt centred on the weld and where R = component

inside radius and t = component thickness. There are no requirements in the ASME

codes regarding heated band width. A very approximate rule of thumb for flat plate is

that the heated band should be a minimum of twice the length of the weld although

practical considerations may prevent achieving this ideal.

There are no requirements, in any code or specification, on the width of the thermally

insulated band although BS EN 13445 recommends 10√Re. It is essential that the

relevant specification is referred to for specific guidance on what is required and it is

worth remembering that the specification requirements on soak or heated band widths

are minima and very little is lost by ensuring the specified dimensions are comfortably

exceeded.

What is an acceptable axial temperature gradient? Again, there is little advice in the

codes and specifications. It is generally assumed that if the temperature at the edge

of the heated band is above half that of the soak temperature then the temperature

gradient will not be harmful. During heating and cooling BS EN 13445 specifies a

maximum temperature difference of 150°C in 4500mm below 450°C (1°C in 3mm) and

1000C in 4500mm above 4500C (1°C in 4.5mm).

To ensure that gradients and temperatures are controlled within acceptable limits

sufficient thermocouples need to be attached to provide both temperature control and

recording. For small diameter tubes, eg less than 100mm diameter, one control zone

and one recording thermocouple are regarded as sufficient; between 100-200mm one

control zone and one recording thermocouple at each of the 12 o’clock and 6 o’clock

positions; above 250mm diameter one control zone and one recording thermocouple

at each 900 quadrant, 12, 3, 6 and 9 o’clock, are suggested.

These thermocouples should be placed on the centre line of the weld. Thermocouples

will also be needed at the edge of the soak band and the edge of the heated band.

Ideally, thermocouples should also be placed on the opposite surface to the heating

elements to ensure that the correct through thickness temperature has been achieved

although this is rarely possible on pipe systems. It is advisable to double up on the

thermocouples to cope with the possibility of a thermocouple failure.

Thermocouples use a hot and a cold junction to measure the temperature, the hot

junction being attached to the component, the cold junction within the temperature

recorder. For accurate temperature measurement the hot junction must obviously be

at the temperature of the component. Errors can be introduced if the junction is not

firmly attached, either by capacitor discharge (CD) welding, by mechanically fixing the

wires to the component or by overheating of the thermocouple junction.

CD welding of the thermocouple wires gives the most accurate results, particularly if

the two wires are separated by 3-4mm. Mechanically attached wires will probably need

to be insulated by covering the junction with heat resistant putty to prevent overheating

of the thermocouple by the overlying heater. If the wire covering is stripped back then

the bare wires also need to be insulated. It is advisable to specify the positions of the

thermocouples on a drawing and to include these within a formal written heat treatment

procedure document that covers both the specification and best practice requirements.

Fig 1. Induction PWHT of Pipework

Fig 2 Schematic of Temperature bands within a local PWHT (Reproduced with

permission of the American Welding Society (AWS), Miami, Florida, USA)

ABOUT POSTWELD HEAT

TREATMENT/STRESS RELIEF HEAT

TREATMENT

Post Weld Heat Treatment (PWHT), or stress relief as it is sometimes known, is

a method for reducing and redistributing the residual stresses in the material

that have been introduced by welding.

The extent of relaxation of the residual stresses depends on the material type and

composition, the temperature of PWHT and the soaking time at that temperature. A

commonly used guideline for PWHT is that the joint should be soaked at peak

temperature for 1 hour for each 25mm (1 inch) of thickness, although for certain

cases a minimum soak time will be specified.

In addition to reduction and redistribution of residual stresses during the welding

process, PWHT at higher temperatures permits some tempering, precipitation or

ageing effects to occur. These metallurgical changes can reduce the hardness of the

as-welded structure, improving ductility and reducing the risks of brittle fracture. In

some steels, however, ageing/precipitation processes can cause deterioration in the

mechanical properties of the steel, in which case, specialist advice should be taken

on the appropriate times and temperatures to use.

The necessity for PWHT depends on the material and the service requirements.

Other factors that influence the need for PWHT are the welding parameters and the

likely mechanism of failure. In some standards, PWHT is mandatory for certain

grades or thicknesses, but where there is an option, cost and potential adverse

effects need to be balanced against possible benefits.

The energy costs are generally significant due to the high temperatures and long

times involved, but costs associated with time delays may be more important.

Detrimental effects include distortion, temper embrittlement, over-softening and

reheat cracking, which means that control of heating and cooling rates, holding

temperature tolerances and the times at temperature are extremely important, and

must be carefully controlled in order to realise the full benefit of the process.

Quenched and tempered (Q&T) steels have the PWHT temperature limited to below

the original tempering temperature of the steel, as higher temperatures can change

the microstructure of the base material from what was expected or required.

AVOIDING PWHT - CAN IT BE JUSTIFIED?

(MAY 2005)

Current BSI and ASME codes for the construction of pressure vessels, boilers and

piping specify that post-weld heat treatment is required if the thickness of the

components being welded exceeds a specified value. This value depends on the

type of material being used, and varies from code to code. An alternative procedure

is available for deciding whether or not PWHT is necessary to avoid the risk of failure

by fracture. This involves conducting a fracture mechanics assessment using

procedures such as those in BSI 7910 (or API 579). The use of these procedures is

permitted in the British pressure vessel standard BS PD 5500:2003.

Alternative to code rules

Welding thick walled components generates residual stresses that can be the cause

of failure mechanisms such as brittle fracture and stress corrosion cracking. A

criterion for PWHT based on a fracture mechanics assessment is more complicated

than the code criterion of thickness alone. It may at first seem unlikely that

designers, owners or certifying authorities would abandon the thickness-based

criteria in favour of a more complicated approach. However, there are cases when

PWHT is a code requirement but it may be considered unnecessary, excessively

expensive, or practically impossible. In these cases, a fracture mechanics

assessment may be used, subject to the agreement of the concerned parties. A

fracture mechanics approach is based entirely on avoidance of failure by fracture or

plastic collapse, Fig.1. Inspection engineers should also give consideration to the

influence of heat treatment on avoiding other mechanisms such as fatigue and stress

corrosion cracking, before adopting this approach.

Fig. 1. Fracture mechanics assesses the combined effects of flaw size, material properties

and stresses acting on the flaw

Another Option: 'Patch' PWHT

When a component is too large to be furnace heat treated, local heat treatment of a

circumferential band is allowed. Both API 570 and AWS D10.10 allow for the

possibility of local heat treatment band on components, subject to various

precautions. (British codes specify the size of local 'heated band' and American

codes specify the size of the 'soak band'). The ASME B&PV Code will allow the

width of the patch to vary provided the resulting temperature gradients are not

harmful.

The severity of the resulting residual stresses due to temperature gradients from

varying patches can be investigated using finite element analysis (FEA). The

acceptability of any proposed variation in a soak band (eg. variable width, band

shape, etc), can then be easily determined by evaluating the magnitude of the

calculated residual stresses. That is (for a particular joint geometry), the magnitude

of residual stress calculated by FEA, after modelling the code rules, versus the

calculated stresses after modelling the proposed variation, Fig.2.

Fig. 2. Residual stress after PWHT: full circumferential band (left) versus triangular patch (right)

An FEA approach can be used at the time of original fabrication or in-service repair.

The FEA should model the material properties in an elastic-plastic manner and allow

stress relaxation during PWHT, as well as account for the initial stresses caused by

welding. Experimental measurement of the residual stresses after patch PWHT will

also be required to validate the results obtained from 'patch' PWHT.

A fracture mechanics case study

Fracture mechanics analysis is based on a consideration of the stresses acting at

critical locations in a structure, the local geometry, the mechanical properties, the

size of flaws (which may have escaped detection or been detected but left unrepaired after NDE), and the fracture toughness of the parent metal, weld metal and

HAZ.

A boiler operator wished to waive PWHT of a stub-to-header weld repair. The parent

material was 2¼Cr½Mo steel. The header collects steam from the boiler superheater

via several hundred separate boiler tubes, Fig.3. The tubes emerge vertically from

the furnace and each tube is welded to a shorter length of tubing ('the antler'), which

is welded to a short stub tube, which is welded directly to the header. The stub tubes

are welded to the header in the fabrication works.

Fig. 3. Boiler header and tube assembly

PWHT of the stub-to-header welds (along with the header welds) in the fabrication

works is not excessively difficult or expensive. The stub-to-antler welds can be made

on site (or in the fabrication works) and do not normally require PWHT (even for

2¼Cr½Mo) because they are thin sections.

However, PWHT of a single stub to header replacement (repair) during service is

cumbersome. Such PWHT requires uniform heating of a cylindrical band around the

header circumference. This is complicated by the many tubes protruding from the

header, and the operation may cause an expensive delay to a repair outage.

Assumed flaws

To justify the boiler repair without PWHT, hypothetical flaws were assessed, Fig.4:

Surface and embedded longitudinal flaws in the header at the weld toe;

Surface and embedded longitudinal flaws in the stub at the weld toe; and

Embedded transverse flaws around the stub-to-header weld.

For each flaw location, the primary stresses (from pressure loading) were estimated

in the stub at the weld toe, in the weld itself and in the header at the weld toe. The

header and stub were 52mm (2in) and 10mm (0.4in) thick, respectively.

Fig. 4. Locations of assumed flaws in boiler stub-to-header welds

More than pressure stress

Thermal stresses resulting from thermal expansion were also estimated. Thermal

stresses arise during shutdown and a worst case temperature change of 100°C in

one minute was assumed at the inside surface. The thermal stresses acting on the

postulated flaws were actually found to be compressive. Their presence reduces the

magnitude of the total stresses driving failure by fracture (results in a lower total

crack driving force than that associated with applied and welding residual stresses

alone). Since these stresses occur only as a result of a thermal shock, the

assessment was performed assuming no thermal stresses.

In accordance with the recommendations of BS7910, residual stresses in the aswelded condition (ie. after repair, without PWHT) were assumed to be uniform

across the thickness as follows:

For longitudinal flaws at the weld toe in the header or stub, the welding residual

stress was assumed to be the lesser of the room temperature yield strengths of the

weld or parent metal, ie. 275MPa (399ksi).

For transverse flaws in the weld, the welding residual stress was assumed to be

equal to the room temperature yield strength of the weld, ie. 370MPa (537ksi).

NDE rationale and toughness assumptions

Based on a review the boiler manufacturer's available data relevant to the parent

metal, weld metal and HAZ, the fracture toughness expressed in terms of K Ic was

assumed to be 3162N/mm3/2 (92ksi/in½ ) at the operating temperature.

A full volumetric inspection of the stub-to-header weld repair was considered

practically difficult in-situ, by both ultrasonic testing and radiography. The repair weld

was only subject to visual inspection and magnetic particle examination which would

readily discover surface-breaking flaws but not embedded flaws, Table 1.

Table 1. Summary of NDE detection capabilities

Flaw Type

Versus NDE Method

Surface

Embedded

Type

Diagnosis

Length

Measurement

Height

Measurement

Visual

✔

x

Good

✔

x

Radiography

✔

✔

Good

✔

x

Ultrasonics

✔

✔

Poor

✔

✔

Magnetic Particle

✔

x

Good

✔

x

Dye Penetrant

✔

x

Good

✔

x

Eddy Current

✔

✔

Poor

✔

✔

Potential Drop

✔

x

Poor

✔

✔

The boiler operator argued that a plausible embedded flaw height might be up to

12.5mm (½in). (This would be the height of a root flaw which could have extended as

a hydrogen crack in the weld metal and HAZ, mainly below the header outer

surface). Such a flaw may be either longitudinal or transverse with regard to the

welding direction. Longitudinal flaws were considered to have a maximum length

equal to the weld circumference, and transverse flaws would be limited to the width

of the weld.

Assessment results

The results of the fracture mechanics assessment demonstrated that the assumed

embedded flaws in the as-welded condition were acceptable, i.e. are non-critical in

terms of fracture and plastic collapse. The 12mm (~½in) deep surface flaws

assumed to exist in the header were also acceptable. The critical height of a surface

flaw in the stub, with a length equal to the weld toe circumference, was found to be

only 5.3mm (0.2in). If the minimum surface flaw height that can be reliably detected

using visual or magnetic particle NDE is less than the tolerable height, say 3mm

(~1/8in), then larger unacceptable flaws (height >5.3mm) can be detected by NDE

and dealt with. Therefore, it maybe concluded that non-detectable surface flaws do

not threaten the integrity of the stub repair in the as-welded condition. Based on the

above and assuming that no other mechanisms (eg. creep-fatigue) may lead to

extension of the original flaws, it was concluded that the weld repair was fit-forservice under operating loading in the as-welded condition.

Financial justification

It was shown that avoiding PWHT was technically justified. The cost of this fracture

mechanics analysis was negligible in comparison with the total cost associated with

carrying out PWHT on site which was cumbersome and expensive. The main

advantage of the codes' thickness criterion is its simplicity. Unfortunately, it is not

possible to use fracture mechanics to justify a general relaxation or rationalisation of

the thickness criteria in the codes. The chances of making a successful case for

avoidance of PWHT are best with a good knowledge of the fracture mechanics input

parameters. Assumptions regarding fracture toughness, flaw sizes and applied

stresses can be crucial to the outcome of the analysis.