Bonded Anchors with Post-Installed Reinforcement Under Tension

advertisement

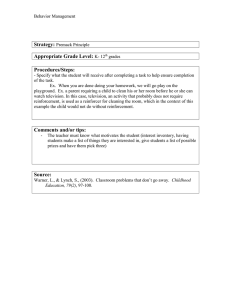

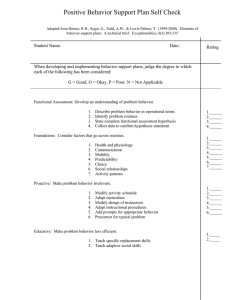

Engineering Structures 252 (2022) 113754 Contents lists available at ScienceDirect Engineering Structures journal homepage: www.elsevier.com/locate/engstruct Bonded anchors with post-installed supplementary reinforcement under tension loading – Experimental investigations Norbert Vita a, *, Akanshu Sharma b, Jan Hofmann c a fischerwerke GmbH & Co. KG, Klaus-Fischer-Straße 1, 72178 Waldachtal, Germany Lyles School of Civil Engineering, Purdue University, 4118 Delon and Elizabeth Hampton Hall, 550 Stadium Mall Drive, West Lafayette, IN 47907-2051, USA c Institute of Construction Materials, Department of Fastening and Strengthening Methods, University of Stuttgart, Pfaffenwaldring 4G, 70569 Stuttgart, Germany b A R T I C L E I N F O A B S T R A C T Keywords: Bonded anchors Anchor groups Post-installed reinforcement Strengthening Tension loading Reinforcement yielding Strut failure This paper presents the results of comprehensive and systematic experimental investigations carried out on anchorages (single anchors and groups) of bonded anchors supplemented with post-installed reinforcement subjected to tension loading. Until now, the use of supplementary reinforcement is allowed in the codes only for anchorages with cast-in headed anchors supplemented with cast-in reinforcement. In this work, tension tests are performed on single anchors and anchor groups with different amounts and arrangements of post-installed reinforcement. Epoxy based mortar was used for installation of both anchors and the reinforcement. It was found that the post-installed supplementary reinforcement can significantly increase the capacity of anchorages undergoing concrete cone breakout failure. Due to high bond strength of the mortar, even relatively short bond lengths within the breakout body were sufficient to activate the reinforcement and contribute significantly to­ wards the resistance. The ultimate load was limited either by reinforcement yielding (for low amounts of rein­ forcement) or strut failure (for moderate to high amounts of reinforcement). Not just the amount but also the placement and arrangement of reinforcement plays an important role in the tension behavior of anchorages with post-installed supplementary reinforcement. At peak load, both the concrete as well as reinforcement contribute significantly to the resistance of the anchorage. 1. Introduction Post-installed fastening systems (anchorages) are often used because of their high flexibility in many applications and because of the improved performance that has been achieved through continuous optimization of these systems in the last decades. In particular, bonded anchors (or adhesive anchors) offer the highest flexibility in design as they can be tailored to a whole range of sizes. The design of anchorages using post-installed anchors is regulated in standards such as ACI 318 [1], EN1992-4 [2] and guidelines such as fib Bulletin 58 [3]. The development of high strength mortar systems for post-installed bonded anchors has led to the fact that often concrete cone failure (under ten­ sion loading) or concrete edge breakout (under shear loading) governs the design. With the new EAD [4] (for bonded fasteners for use in concrete) it is possible to design bonded anchors with a life time of 100 years. In this relatively long service life, the load to be resisted by the anchorage might increase for various reasons. In such cases, the fastening must be recalculated and, if required, replaced with a stronger anchorage. However, it may not be possible to replace the anchorage due to func­ tional requirements and therefore strengthening of an anchorage might be required. The influence of long time loading for bonded anchors has been studied in e.g. [5,6], while differences in the design between cast-in and post-installed are summarized in [7]. Recently, analytical models to predict the capacity of cast-in and bonded anchors under combined tension and shear loads considering dowel action are presented in [8]. Concrete cone resistance of anchorages loaded in tension can be increased at the design stage either by increasing the concrete strength (base material) or by increasing the effective embedment depth of the anchors [9]. By using different base material e.g. steel fiber reinforced concrete, due to the enhanced properties (tensile strength, fracture en­ ergy and steel fiber bridging mechanism) higher failure loads can be obtained [10–12]. Ordinary surface reinforcement may also induce an increased ca­ pacity compared to unreinforced concrete in tension, see e.g. [13,14]. * Corresponding author. E-mail addresses: norbert.vita@fischer.de (N. Vita), akanshu@purdue.edu (A. Sharma), jan.hofmann@iwb.uni-stuttgart.de (J. Hofmann). https://doi.org/10.1016/j.engstruct.2021.113754 Received 2 July 2021; Received in revised form 18 November 2021; Accepted 7 December 2021 Available online 17 December 2021 0141-0296/© 2021 Elsevier Ltd. All rights reserved. N. Vita et al. Engineering Structures 252 (2022) 113754 For anchorages with headed studs, adding supplementary rein­ forcement also known as anchor reinforcement in the form of surface reinforcement and stirrups is a well-known method to enhance the tension resistance of the anchorages and the method is also included in codes and standards [1–3]. In case of anchorages with supplementary reinforcement under tension load, once the concrete cone crack in­ tercepts the stirrups, the reinforcement takes up the tension forces, while the compression is transferred by a network of concrete struts, see Fig. 1. The effectiveness of anchor reinforcement in increasing the resistance of headed-studs have been shown by various researchers in the past [15–17]. Furthermore, Sharma et al. [18–21] studied the load-bearing behavior of anchor groups consisting headed-studs with supplemen­ tary reinforcement in detail. A comprehensive research campaign on headed stud anchorages with supplementary reinforcement under ten­ sion and shear towards the edge was studied and on the basis of the results a new model for predict the load-carrying capacities of anchor­ ages with supplementary reinforcement was developed [22–26]. Furthermore, the beneficial influence of supplementary reinforcement on the behavior and resistance of cast-in anchorages has been demon­ strated by [27–29]. Randl and Kunz [30] investigated the behavior of post-installed bonded and expansion anchors loaded in shear towards the edge rein­ forced with cast-in hairpin reinforcement. The U-shaped hairpin rein­ forcement were cast-in with an inclination of 5–10 degress to the concrete surface. Due to knowing the exact position of the reinforce­ ment, it was possible to install the post-installed anchorages at the right position to the reinforcement. They reported significant increase in the load-carrying capacity (up to 3-times the reference value without rein­ forcement for anchorages with small edge distance) and ductility of anchorages with hairpin reinforcement. On the basis of 76 test results, a model equation is given to predict the load for anchorages under shear loads towards the edge with hairpin reinforcement. So far, most of the research for anchorages with supplementary reinforcement has been carried out with cast-in supplementary rein­ forcement. The studies focusing on the behavior of anchorages with post-installed anchors strengthened using post-installed supplementary reinforcement are absent. However, due to recent advancements in product developments and design methods [31–34] it is possible to use post-installed rebar also as supplementary reinforcement for anchorages. For the first time, in [35] Vita et al. reported the results of tension tests on single post-installed bonded anchors reinforced with different amount and arrangement of post-installed bars as supplementary rein­ forcement. The main objective was to investigate the feasibility and efficacy of using post-installed reinforcement on the load capacity and the load–displacement behavior of post-installed bonded anchors. For both, anchors and reinforcement, high strength epoxy-based injection mortar was used. A significant increase in the ultimate loads and an improved displacement behavior was obtained for the anchors with additional post-installed supplementary reinforcement, provided the failure of anchors without reinforcement occurs due to concrete cone breakout. Moreover, it was shown that a preloading of the anchors up to the characteristic failure load prior to the rebar installation has no negative influence on the load capacity of the anchors. Therefore, it was proposed that this method is suitable also for applications requiring strengthening of existing anchorages. The work reported by Vita et al. [35] served as the pilot project for the work reported in this paper and therefore, some of the results reported in [35] are also included in this paper. Furthermore, Vita el al. [36] investigated the efficacy of postinstalled supplementary reinforcement used for bonded anchors loaded in shear towards to the edge to enhance the concrete edge breakout resistance. Due to the use of high strength mortar, it was shown that even with relatively small anchorage length of the reinforcement in the theoretical concrete edge breakout body, high increase in the ulti­ mate load can be reached. In this work, systematic investigations were performed on anchor­ ages (single anchors and groups) using post-installed (bonded) anchors and strengthened with post-installed supplementary reinforcement under short-term tension loading. This paper provides details of the experimental campaign carried out to investigate the influence of postinstalled supplementary reinforcement on the behavior of anchorages with bonded anchors loaded in tension. The tests were performed on single bonded anchors and 1x2 anchor groups with different amount and arrangement of post-installed supplementary reinforcement. The test program, test setup and results are discussed in detail. The test program is part of a greater test campaign which also includes strengthening of anchorages with bonded anchors under shear loading. The results of the shear tests will be presented in detail in a future paper. 1.1. Failure mechanics of anchorages with supplementary reinforcement Supplementary or anchor reinforcement has a significantly influence on the load-bearing capacity of anchorages loaded in tension or shear failing due to concrete cone or edge breakout. The behavior of anchor­ ages with supplementary reinforcement can be described with a strutand-tie model acc. to [2], given in Fig. 1. When the anchorage is loaded in tension, after the concrete cracks, the stirrups get activated. The applied tension load on the anchorage is transferred from the anchor by a network of concrete struts taking up the compression forces while the stirrups and surface reinforcement resist the tension forces. In principle this strut-and-tie model has three major components, the concrete struts, the tension ties and the nodes [19] which provide the possible mechanisms for the failure of anchorages with supplementary Fig. 1. Fastening with supplementary reinforcement under tension load acc. to EN1992-4 [2], (a) details, (b) corresponding strut and tie model. 2 N. Vita et al. Engineering Structures 252 (2022) 113754 reinforcement. The possible failure mechanisms of the supplementary reinforcement can be the bond failure or yielding of the reinforcement according to [2]. Bond failure of the stirrups occurs, if the anchorage length of the rebars (l1) within the theoretical concrete breakout body is not sufficient to develop the reinforcement. If the stirrups could be activated to the point of yielding, it would lead to significantly enhanced load and deforma­ tion capacity of the anchorage. In principle, the resistance of the anchorage can be increased by increasing the amount of the supplementary reinforcement that can be activated. However, increase in strength of the anchorage is not pro­ portional to the amount of reinforcement only and beyond a certain level of the reinforcement, failure of the concrete struts limit the ca­ pacity of the anchorage [15,19]. A similar behavior can be expected in case of post-installed anchors with post-installed supplementary reinforcement where the anchors without reinforcement fail by concrete cone breakout. However, with post-installed supplementary reinforcement it is relatively easy to realize many different arrangements of reinforcement, which could lead to different patterns of struts from the anchor. This aspect will be shown and discussed in details with the help of test results in later sections. depth or spacing the anchorages) were selected in such a way that in the reference test series without reinforcement, concrete cone breakout governed the failure of the anchorages. Furthermore, in the tension tests with supplementary reinforcement, the aim was to reach yielding of the reinforcement or strut (compression) failure. For the bonded anchor as well as for the post-installed reinforcement, a high-strength epoxy-based injection mortar FIS EM Plus (mean ulti­ mate bond strength of approx. 35 N/mm2) from the company fischer was used. The epoxy mortar is approved for use with bonded anchors [37] as well as with post-installed reinforcement [38]. The test program with detailed test parameters is summarized in Table 1. All tension tests were performed without edge influence with an edge distance higher than the critical edge distance (c > ccr,N = 1,5∙hef). For bonded anchors, diameter, ds = 24 mm threaded rods with steel grade of 12.9 (to avoid steel failure) were used, except the test series TS_1, in which 16 mm threaded rods (steel grade 12.9) were installed. The effective embedment depth of anchors (hef) in all the tests was kept as either 100 mm or 140 mm. In case of test series denoted as T-G (see Table 1) one by two group anchorages (1 × 2) were tested. The anchor spacing was kept constant in all the group tests with s = 140 mm which was smaller than the critical anchor spacing according to [9,37] (s < scrit = 3,0∙hef) in order to have group effect. The first two single test series, T-S_1 and T-S_2 served as the pilot test series in which, different installation conditions for the post-installed reinforcement were investigated as depicted in Fig. 2. The different installation configurations included (compare Fig. 2): 2. Experimental investigations 2.1. Test program Unconfined tension tests on single anchors and anchor groups con­ sisting of bonded anchors without and with post-installed reinforcement were carried out in normal-strength concrete to investigate the influence of post-installed supplementary reinforcement on the behavior of an­ chorages undergoing concrete cone breakout. Therefore, a comprehen­ sive test program was compiled to study the influence of various parameters such as total cross-section area of the reinforcement, arrangement of the reinforcement and or their distance to the anchor. The installation parameters of the anchorages (anchor size, embedment (a) rebars installed vertically without steel plates at the free end on concrete surface (Fig. 2 a). This was the standard configuration of reinforcement used in this work. (b) rebars installed vertically but with steel plate at the free end on the concrete surface (Fig. 2 b), (c) same as case (a) but with specified preloading of the anchor prior to the installation of reinforcement (Fig. 2 c), Table 1 Test Program for bonded anchor with post-installed supplementary reinforcement. Test Series T-S_1.0 T-S_1.1 T-S_1.2 T-S_2.0 T-S_2.1 T-S_2.2 T-S_2.3 T-S_3.0 T-S_3.1 T-S_3.2 T-S_3.3a T-S_3.3b T-S_3.4 T-S_3.5 T-S_3.6a T-S_3.6b T-S_3.7 T-S_3.8 T-S_3.9 T-G_0 T-G_1 T-G_2 T-G_3 T-G_4 T-G_5 T-G_6 T-G_7 ANCHOR REINFORCEMENT Remarks Geometry [-] Size [-] hef [mm] Number [-] Diameter [mm] Area [mm2] Distance (a) [mm] hef,R. [mm] Single Single Single Single Single Single Single Single Single Single Single Single Single Single Single Single Single Single Single 1x2 1x2 1x2 1x2 1x2 1x2 1x2 1x2 M16 M16 M16 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 M24 100 100 100 100 100 100 100 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 – 2 2 – 2 2 2 – 1 2 1 1 1 4 2 2 3 4 6 – 2 4 2 6 4 6 6 – 10 10 – 12 12 12 – 8 8 12 12 16 8 12 12 12 12 12 – 8 8 12 8 12 10 12 – 157 157 – 226 226 226 – 50 101 113 113 201 201 226 226 339 452 679 – 101 201 226 302 452 471 679 – 50 50 – 50 50 70 – 50 50 50 100 50 50 50 100 50 50 50 – 50 50 50 50 50 50 50 – 175 175 – 210 210 210 – 210 210 210 210 210 210 210 210 210 210 210 – 210 210 210 210 210 210 210 Note: By Test Series T-G on 1x2 anchor groups, the spacing was kept constant with s = 140 mm. 3 Reference without steel plate with steel plate Reference without preloading with preloading reinf. diagonal Reference Reference N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 2. Different installation configurations of the post-installed supplementary reinforcement (not scaled); (a) standard, (b) with steel plates, (c) with preloading of the anchor and (d) rebars inclined. (d) rebars installed inclined to the concrete surface at an angle of 55 degrees (perpendicular to the theoretical concrete cone crack) as shown in Fig. 2 d. The concrete mix of the used (three) concrete batches for tests are given in Table 2. From each concrete batch, four concrete slabs were cast. The compressive strength of each concrete mixtures used for testing were measured according to DIN EN 12390–3 [39] on standard 150 mm cubes (3 cubes per concrete mix). The measured compressive strength of the concrete were obtained in the range fcc,150 = 34,0 to 39,4 MPa, with an average strength of fcc,150,m = 36,7 MPa. For the post-installed supplementary reinforcement standard straight, ribbed reinforcing steel bars with a specified characteristic yield stress of fyk = 500 MPa were used. The distance a between the anchors (threaded rods) and the postinstalled rebars was maintained at 50 mm or 100 mm in all cases, which corresponded to 0.36∙hef and 0.71∙hef respectively (for anchors with hef = 140 mm). Note that according to EN 1992–4 [2], the reinforcement may be considered as active if the distance between the anchor and the rebar is smaller than a ≤ 0,75∙hef provided it has sufficient anchorage length within the breakout body. However, according to fib Bulletin 58 [3], only reinforcing bars with distance to the anchorages a ≤ 0,5∙hef are considered to take up the tension load from the anchor. The reinforce­ ment diameter (ds,re = 8, 10, 12, 16 mm) and the number of the rein­ forcement bars (nre = 1, 2, 3, 4, 6) were varied in the different test series which resulted in different total cross-section areas of the post-installed reinforcement (As,re = 50 mm2 up to 679 mm2). The embedment depth of the post-installed supplementary rein­ forcement (hef,re) was primarily kept as 210 mm (1.5 times the embed­ ment depth of the anchor with hef = 140 mm). In this way, the anchorage length of the reinforcement within the concrete breakout body (l1) was almost the same as its anchorage length outside the breakout body (lbd) for the reinforcement bars placed with a distance of a = 50 mm from the anchor (Fig. 2 a). Given the relatively high bond strength of the epoxy mortar, the length of the bar was sufficient to yield the rebar prior to bond failure. In each test series, three test were planned to perform. However, in some test series only two test could be carried out. 2.3. Anchor and reinforcement installation As mentioned before, an epoxy-based injection mortar, FIS EM Plus from the company fischer was chosen for the installation of the postinstalled bonded anchors for the tensile tests without and with postinstalled supplementary reinforcement. FIS EM Plus is not only approved as bonded anchor use in concrete (ETA-17/0979 [37]) but also suitable and approved for use for post-installed reinforcement (ETA-17/ 1056 [38]). Therefore, it was possible to use the same injection mortar for the post-installed anchorages as well as for the post-installed rein­ forcement. The installation of bonded anchors, as well as the postinstalled reinforcement, was carried out according to the manufac­ turer’s specifications [37,38]. In general, bonded anchor and post-installed reinforcement were installed in single work step, which involves drilling the bore holes for both, anchors and reinforcement, cleaning, injecting the mortar and installing the threaded rods and reinforcing bar. After the minimum specified curing time (10 h at 20 degreesC [38]), the tension test were carried out. This installation procedure was used for saving time during the tests. However, in the test series T-S_2.2, it was first confirmed that simultaneous installation and consecutive installation (rebar installation for a pre-loaded anchor) are equivalent and lead to similar increase in load-bearing capacity of the bonded anchorages. To simulate an existing 2.2. Material properties and test specimens All tension tests were carried out in unreinforced concrete slabs (dimensions: L*W*H = 190*190*40 cm3) made of normal strength concrete of grade C20/25. 4 N. Vita et al. Engineering Structures 252 (2022) 113754 Table 2 Concrete Mix composition. Concrete Batch ID Concrete strength class Mean cube comp.strength fc, Cement type Cement cube,act. [-] [-] [N/mm2] [-] 1 Normal 34.0 2 Normal 38.6 3 Normal 39.4 CEM I 32.5R CEM I 32.5R CEM I 32.5R and loaded anchorage and to investigate the influence of post-installed supplementary reinforcement on the load-bearing behavior of the pre­ loaded anchors, different installation procedure was used in T-S_2.2. In this case, first only the bonded anchor was installed (drilling, cleaning, injection and installing the threaded rods). After curing, it was loaded with 75% of the mean ultimate resistance of the anchor obtained from the reference series. The load of 75% was chosen as it corresponds to the characteristic concrete cone breakout resistance of the anchor assuming 15% coefficient of variation [9]. After unloading, the bonded single anchor was strengthened with the post-installed reinforcing bars, i.e. the reinforcement was installed (drilled, cleaned injected and set). After the required curing time of the reinforcement bonding agent, the tension tests were carried out until failure. A detailed description of the different installation procedures are also given in [35]. The obtained test results without and with preloading (new and existing anchorages) will be discussed in Section 3.1.2. Aggregate Water w/c Superplasticizer [-] [M% of Cem.] 0.68 2.3% 0–2 mm 2–8 mm 8–16 mm [kg/ m3] 252.4 [kg/ m3] 778.0 [kg/ m3] 488.0 [kg/m3] 736.0 [kg/ m3] 172.5 254.0 812.0 485.0 725.0 170.0 0.67 2.0% 256.0 774.0 488.0 726.0 185.0 0.72 1.8% distance from anchor to support ≥ 2hef). The load was applied to the single anchor through a steel fixture with specified clearance hole or by anchor group through a stiff anchor base plate (L*W*H = 200*60*60 mm3). To transfer the load from the hydraulic cylinder into the steel fixture or anchor base plate, a high-strength threaded rod was used. In case of group anchorages, a hinge was placed between anchor base plate and threaded rod to enable rotation free uniform load distribution among the two bonded anchors in the group. The used calibrated load cells had an accuracy class of two and their measuring range was chosen based on the expected ultimate load as 40–200 kN or 100–500 kN. The vertical anchor displacement was measured at the top of the single anchor or on both anchors of the group using a calibrated Linear Variable Displacement Transformer (LVDT). Furthermore, in a few selected tests, strain gauges were installed on the post-installed reinforcing bars to obtain the information about the force taken up by the reinforcement and to separate the concrete and rein­ forcement configuration. The strain gauges were applied on the bars at the position where the theoretical concrete cone crack was expected to intercept the rebar under tension test. The applied load, the anchor displacements and the strains in the post-installed reinforcement (for tests with strain gauges) were recorded at a frequency of 5 Hz by using the commercial data acquisition software DiAdem. All performed unconfined tension tests on single or group an­ chorages without or with post-installed supplementary reinforcement were carried out in oil pressure control using quasi-static loading rate. According to [40] the peak loads were reached within 1 to 3 min. 2.4. Test setup and instrumentation Unconfined tension tests on single bonded anchors and on 1x2 an­ chor groups were carried out in accordance with the ETAG 001, Annex A [40]. Fig. 3 shows the typical test setups. This consisted of a testing rig, a hydraulic cylinder, high strength threaded rod for loading, a calotte, a calibrated load cell, fixture plate and displacement transducers (LVDT) with holder. The testing rig had a suitable wide support with sufficient support distance to enable unrestricted concrete cone breakout (free Fig. 3. Test setups. 5 N. Vita et al. Engineering Structures 252 (2022) 113754 Note: In anchor technology, oil pressure controlled tests are quite common due to their simpler set-up. This is well-accepted since until peak load, the oil-pressure controlled tests are known to provide reliable response. However, the post-peak response is best obtained by per­ forming a displacement controlled test using a hydraulic actuator. In these tests, a standard hydraulic cylinder was used and the measuring frequency was kept as 5 Hz, which provided sufficient data points especially for the tests with supplementary reinforcement. The proced­ ure used for the tests in this work was identical to the procedure used in the previous tests reported by Sharma et al. [19,26]. However, the au­ thors highly recommend that in future, further tests on anchors with post-installed supplementary reinforcement should be carried out in displacement control. Fig. 4. Typical concrete cone breakout bodies obtained in reference tests (T-S_2.0). 3. Test results 3.1. Tests on single anchors third test series (T-S_3.0) different reinforcement areas and arrangement were investigated. In the next sections, typical test results using load–displacement curves will be described and discussed. The results of the tension test performed on single bonded anchors without and with post-installed supplementary reinforcement are sum­ marized in Table 3. This table enlists test results in terms of individual failure loads (Nu,i), mean value of the ultimate (failure) loads (Nu,m), the corresponding coefficient variation of the ultimate loads (CoV), the mean displacements at the ultimate load (δu,m) and the observed failure mode. It may be noted that due to the limited number of tests (2) in some test series, the CoV may not be representative. In all reference tension tests, concrete cone breakout was observed as the failure mode. Typical concrete cone breakout body obtained in the reference tests are showing in Fig. 4. As expected, the concrete cone surface started almost from the bottom of the threaded rods and developed at an angle of approx. 35 degree to the concrete surface which agrees well with the assumption given in [9]. As seen from Table 3, due to the introduction of post-installed sup­ plementary reinforcement a significant increase in the load-bearing capacity of single bonded anchors could be achieved. The highest in­ crease was obtained in case of the test Series T-S_3.9 (6xd12) with more than 100% increase in the peak load corresponding to the mean ultimate load obtained in the reference tests. Moreover, different conditions of the post-installed reinforcement were tested in the first two test series (T-S_1.0 and T-S_2.0) while in the 3.1.1. Influence of end plate (Test series T-S_1) A comparison of the load–displacement curves obtained in test series T-S_1 on single anchor M16, hef = 100 mm without and with postinstalled supplementary reinforcement with two bars of diameter, ds, re = 10 mm installed without and with steel end plate is depicted in Fig. 5. The distance of the rebars to the anchor was 50 mm (0.5∙hef). Although the amount of supplementary reinforcement in these cases is relatively small (As,re = 157 mm2), the failure loads obtained in tests with supplementary reinforcement are significantly higher (approx. 40% higher) than the failure loads obtained for the corresponding single anchor without reinforcement. Moreover, no significant difference was observed in the load displacement curves obtained for the test without and with steel plate connected to the rebars. This suggests that even with a relatively short bond length within the breakout body (l1 = 6,5∙ds,re) of the reinforcement the reinforcement could be activated without any end anchorage or the hook. This is attributed to the high mean bond strength of the used epoxy-mortar. However, in none of the cases the reinforce­ ment yielding was observed. Since the pullout resistance of the bonded anchor is rather high, the failure mode in both test series was identified as strut failure as shown in Fig. 5. Table 3 Summary of results of tests on single anchors. Test Series Test ID T-S_1.0 T-S_1.1 16-100_0 16-100_2xd10_no steel plat 16-100_2xd10_steel plate 24-100_0 24-100_2xd12_no preload 24-100_2xd12_preload 24-100_2xd12_diagonal 24-140_0 24-140_1xd8 24-140_2xd8 24-140_1xd12 24-140_1xd12_a = 100 24-140_1xd16 24-140_4xd8 24-140_2xd12 24-140_2xd12_a = 100 24-140_3xd12 24-140_4xd12 24-140_6xd12 T-S_1.2 T-S_2.0 T-S_2.1 T-S_2.2 T-S_2.3 T-S_3.0 T-S_3.1 T-S_3.2 T-S_3.3a T-S_3.3b T-S_3.4 T-S_3.5 T-S_3.6a T-S_3.6b T-S_3.7 T-S_3.8 T-S_3.9 1) Ultimate load Nu,i Mean ultimate load Nu,m CoV Mean displ. at Nu,m δu,m Relative increase in load capacity Nu,m/Nu,m,Ref Failure mode1) [kN] – 103.9 [kN] 77.2 111.3 [%] 3.4 7.4 [mm] 1.10 1.38 [-] 1.0 1.44 [-] CC Strut – 83.0 156.8 146.2 115.5 129.3 152.3 191.0 200.6 – 193.9 238.3 233.1 – 259.6 272.9 299.1 107.6 83.4 155.7 150.0 117.9 130.8 148,1 181.5 186.1 164.0 197.9 235.8 230.3 181.4 253.9 249.8 284.5 1.6 2.0 3.4 3.8 3.2 6.4 2.8 5.0 6.9 6.0 2.3 4.4 4.2 0.7 7.3 8.5 4.7 1.54 0.48 1.32 1.30 0.93 0.78 1.25 1.19 1.43 1.10 1.29 1.68 1.63 1.15 2.03 1.82 2.42 1.39 1.0 1.87 1.80 1.41 1.00 1.13 1.39 1.42 1.25 1.51 1.80 1.76 1.39 1.94 1.91 2.18 Strut CC Strut Strut Strut CC Yield Yield Yield/Strut Strut Strut Strut Strut Strut Strut Strut Strut Test No.1 Test No.2 Test No.3 [kN] 79.0 120.2 [kN] 75.3 109.7 108.8 82.0 160.4 156.6 122.3 139.9 144.6 173.1 181.2 171.0 202.9 244.7 219.6 180.4 268.9 245.7 272.8 106.3 85.3 149.9 147.1 115.9 123.3 147.1 180.4 176.5 157.0 196.9 224.4 238.2 182.3 233.3 230.9 281.7 Note: CC = concrete cone breakout failure, Yield = Yielding of the reinforcement, Strut = failure of concrete strut 6 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 5. Left: Load-displacement curves obtained in tension tests on single anchor without (black) and with post-installed rebars, ds,re = 10 mm, without (blue) and with steel plate (orange) and corresponding failure modes. 3.1.2. Influence of pre-loading of the anchor (Test series T-S_2.2) Test series T-S_2 were carried out with M24 bonded anchors with an embedment depth of hef = 100 mm. Two test series with the same condition (2 × ds,re = 12 with distance a = 0,5∙hef) as well as reference test without reinforcement were performed. In the case of the Series TS_2.1, the bonded anchors and the post-installed reinforcing bars were installed in one work step. For the series T-S_2.2 the single anchor were installed first and loaded up to a load of 5%-fractile value of the mean ultimate load obtained from reference tests (=0.75∙Num,ref). The refer­ ence tests were performed by simply installing the anchors according to manufacturer’s instructions and testing them after observing the required curing time. The mean value of the reference test was NRm, c = 83,4 kN which results to a pre-load value of NRk,c = 62,6 kN. Certain fine radial cracks (See Fig. 6) were noticed on the concrete surface initiating from the anchor as a result of the pre-loading. A comparison of the load–displacement curves obtained in these three test series (T-S_2.0, T-S_2.1 and T-S_2.2) is given in Fig. 7. The observed mean failure load was 1,87-times and 1,80-times higher than the corresponding mean failure load in the reference tests for series TS_2.1 (without pre-load) and for T-S_2.2 (with preload), respectively. The initial stiffness obtained for reference test series as well as test series without pre-load is rather similar, which indicates that the presence of reinforcement does not influence the initial stiffness of the anchorage. This can be explained by the fact that the reinforcement gets activated only after the concrete cone crack intercepts the reinforcing bars and therefore until the initiation of concrete crack, the load–displacement curves without and with reinforcement follow the same path. However in the series S1.3, where the tests were performed after the application of a preload and subsequent unloading, the initial stiffness becomes slightly smaller, which can be attributed to the initiation of local damage in the concrete due to the applied pre-load. Nevertheless, there is only an insignificant difference in the load–displacement behavior, failure loads as well as the failure modes (see Fig. 7 b-d) observed for series T-S_2.1 and T-S_2.2. While in the reference test (T-S_2.0) the typical concrete cone breakout can be seen, in the series with reinforcement (T-S_2.1 and T-S_2.2) the concrete breakout was found to be impeded by the rein­ forcement and strut failure were observed. 3.1.3. Influence of angle of the reinforcement (Test series T-S_2.3) In test series T-S_2.3 the influence of inclined supplementary rein­ forcement on the load-bearing behavior of bonded single anchor was also investigated. According to [9], the effectiveness of the reinforce­ ment is greatest when the crack crosses perpendicular the reinforce­ ment. Therefore, based on the assumption of the CCD method [41] that the crack is propagated at an angle of 35 degrees to the concrete surface, the post-installed reinforcements were installed at 55 degrees to the concrete surface according to the schematic shown in Fig. 2 (d). The load–displacement curves obtained from these test carried out with in­ clined supplementary reinforcement as well as from the corresponding reference test are shown in Fig. 8 (a), while the obtained failure mode is showing in Fig. 8 (b). The relative increase in the load capacity was 1,41 which significantly lower than in case of perpendicular installed sup­ plementary reinforcement. The failure mode was identified as strut failure. The lower resistance compared to the vertically installed rebar can be explained due to the fact that although the rebar is perpendicular to the crack, it is inclined to the applied load and therefore, only the vertical component of the force taken up by the reinforcement resists the applied load. 3.1.4. Test series T-S_3 The results of test series T-S_1 and T-S_2 showed that the influence of end plate as well as of the pre-loading on the anchor is negligible. Furthermore, test series T-S_2.3 showed that the vertically installed reinforcement is significantly more efficient compared to the inclined reinforcement. Therefore for simplicity, the tests in test series T-S_3 were performed as follows: i. anchorages and post-installed rebar’s were installed in one work step, without preloading the anchor ii. the rebars were installed without steel end plate iii. the rebars were installed vertically parallel to the load direction Fig. 6. Bonded single anchor after preloading with fine radial cracks (red arrows). In test series 3, the influence of amount and arrangement of post7 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 7. (a) Load-displacement curves obtained from tension tests on single bonded anchor without and with post-installed supplementary reinforcement and (b-d) corresponding failure modes. Fig. 8. (a) Load-displacement curves obtained from tension tests on single anchor without and with post-installed supplementary reinforcement installed inclined and (b) corresponding failure mode. installed supplementary reinforcement on the load carrying capacity of single anchors was investigated. Furthermore, the influence of the dis­ tance between anchors and post-installed supplementary reinforcement was also studied. The results of test series 3 are discussed in the following sub-sections. Fig. 9. Load-displ. curves obtained from tension tests on single anchor without and with post-installed supplementary reinforcement (ds,re = 12 mm) with different distance between anchor and rebars (Left: single rebar, Right: two rebars). 8 N. Vita et al. Engineering Structures 252 (2022) 113754 4. Influence of the distance between anchor and reinforcement were 1,76 and 1,39 for the distance of a = 50 mm and a = 100 mm, respectively. This behavior is understandable by observing the failure pictures of the performed test series given in Fig. 10. In this case, even in the tests series with a = 100 mm distance (TS_3.3b and T-S_3.6b), with a relatively small bond length (~70 mm) in the theoretical concrete cone body, no pull-out of the reinforcement was observed. This is attributed to the high mean bond strength of the epoxy based mortar used to install the reinforcement. The observed failure mode showed truncated concrete cone breakout body indicating strut failure (compare Fig. 21) in all the cases (see Fig. 10). This explains the lower load carrying capacities for reinforcement installed at higher distance due to flatter struts. The distance between anchorage and post-installed supplementary reinforcement was kept constant in all test series at a = 50 mm except for two test series (T-S_3.3b and T-S_3.6b) where the distance was increased to a = 100 mm, to investigate the influence of the load-carrying capacity of the anchorage with supplementary reinforcement. Note that acc. to EN 1994–2 [2], the reinforcement with a maximum distance of a = 0.75∙hef can be considered as active (provided it has sufficient anchorage length) and taken into account in the calculation of the ca­ pacity for the anchorage. Thus, acc. to EN 1994–2 in all performed test series the post-installed reinforcement was sufficient distance to get activated (a = 0.5∙hef for T-S_1 and T-S_2; a = 0.36–0.71∙hef for T-S_3 series). However, the fib guideline Bulletin 58 [3] give smaller value for the distance with a = 0.5∙hef and therefore in the test series T-S_3.3b and T-S_3.6b with a = 100 mm = 0.71∙hef the reinforcement would not be considered active. In Fig. 9 the load–displacement curves obtained for test series with same amount of reinforcement (left: 1xd12, right: 2xd12) and different distance from the anchor (a = 50 or 100 mm) are compared. Further­ more, in Fig. 9 corresponding reference test results are also shown. As expected, the peak load decreases with increasing distance between the anchor and the reinforcement independent of the amount of the rebars in both cases. This is attributed to the fact that with increasing distance, the bond length within the breakout body reduces and the strut becomes flatter. The relative increase in the load carrying capacity compared to the corresponding mean reference load were obtained in case of single rebar (1xd12) as 1,42 for a = 50 mm and 1,25 for a = 100 mm. The corresponding relative increase in the capacity for two rebars (2xd12) 5. Influence of amount and placement of supplementary reinforcement (Test series T-S_3) Fig. 11 shows the load displacement curves obtained for the test series with 1xd8 (T-S_3.1), 2xd8 (T-S_3.2) and 4xd8 (T-S_3.5) postinstalled rebars, as well as the curves from reference test series (TS_3.0). The pictorial legends in Fig. 11 indicate the respective configu­ ration of the reinforcement used for the single anchors. The relative increase in the load carrying capacity with respect to the reference test series were 1.11, 1.39 and 1,80-times for tests with 1x, 2x and 4x d8 rebars, respectively. This shows that even a relatively small amount of supplementary reinforcement (2xd8, As = 101 mm2) can significantly enhance the load carrying capacity of the anchorage. Addition of only one 8 mm bar resulted in only a marginal increase in the failure load. This is attributed to the fact that the presence of only one reinforcement Fig. 10. Typical failure modes obtained from tension tests on anchor with post-installed supplementary rebars (ds,re = 12 mm), with small distance (a + c) and with greater distance (b + d). 9 N. Vita et al. Engineering Structures 252 (2022) 113754 positively, if the amount of reinforcement is increased. The initial stiffness of the load–displacement curves is quite similar for the series with and without reinforcement. As can be seen, even a relatively small amount of reinforcement leads to a significant increase in the failure load of the anchors. Even with a single 12 mm diameter reinforcement, the capacity of the anchor increased by more than 40%. In general, the peak load increased with increasing amount of reinforcement but this increase in the peak loads is not proportional to the cross-sectional area of the supplementary rein­ forcement. Except in the case of test with single 12 mm reinforcement, the failure was governed by strut failure in all the tests. Note that in all the cases, the reinforcement was placed in a symmetric pattern (in plan) around the anchor so that a stable strut mechanism is possible. It can be seen that beyond a certain amount of reinforcement, the increase in failure load with the amount of reinforcement is relatively low, since the strut failure limits the maximum achievable increase in the load carrying capacity of the anchorage. Similar behavior was shown valid for cast-in anchorages with cast-in supplementary reinforcement [15,24]. With the highest amount of reinforcement of 6x12 (As,re = 678 mm2), the mean failure load reached was 2.18 times the mean failure load of the refer­ ence test without reinforcement. Typical failure pictures of these series are given in Fig. 13. While in reference test (Fig. 13 (a)) ordinary concrete cone breakout was dis­ played, in cases with supplementary reinforcement of 12 mm diameter bars 1x, 2x, 3x, 4x and 6x (Fig. 13 b, c, d, e and f respectively) concrete cone was restricted by the reinforcement. With one bar (Fig. 13 b), the failure cone is truncated only on the side of the bar, while for the 2x reinforcement configuration (Fig. 13 c), a dog bone shaped breakout body is visible. For the cases with 3x, 4x and 6x reinforcement, see Fig. 13 (d, e, f), due to steep and more than two struts, the failure of the anchors is similar to the pull-out failure with confined test setup. Fig. 11. Load-displacement curves from tension tests on single bonded anchors without and with post-installed supplementary reinforcement, ds,re = 8 mm. results in unsymmetric strut formation, which does not result in a stable strut mechanism. However, two symmetrically placed reinforcing bars result in stable strut mechanism resulting in higher capacity of the anchorage. In the test with 1x and 2x d8 rebars, yielding of the reinforcement was reached which is confirmed by the fact that in both cases, unre­ stricted concrete cone breakout bodies were formed. On contrary, for the tests with 4 × d8 rebar’s, strut failure was observed with only a small cloverleaf shaped concrete breakout area. Fig. 12 summarizes the load–displacement curves obtained from the tension tests on single anchors reinforced with ds,re = 12 mm rebars placed at a distance of a = 50 mm from the anchor with different number (n = 1, 2, 4, 3, 6) of the bars. To enable a direct comparison the results, the reference curves obtained in unreinforced tests (Series T-S_3.0) are also plotted in each case in Fig. 12. Depending on the number of 12 mm bars (1x, 2x, 3x, 4x, 6x) following values of mean peak loads were measured: 186,1 kN; 197,9 kN; 230,3 kN; 253,9 kN; 249,8 kN; 284,5 kN respectively. The results of the tests on anchors reinforced with ds,re = 12 mm diameter reinforcing bars shows, in general, similar behaviour to the results with 8 mm diameter rebars, but as expected, the effect of 12 mm bars is stronger than of 8 mm bars. Not only the failure load, but the displacement at the failure load of the anchorages are influenced 6. Influence of geometric arrangement of the reinforcement (Test series T-S_3.4 þ 3.5) According to current standards [1–3], the maximum diameter that can be used for supplementary reinforcement is limited to ds,re = 16 mm. This is partly due to indirectly avoiding strut failure and partly due to the fact that the mandrel diameter of bars bigger than 16 mm diameter becomes rather large according to EN1992-1–1. However, it has been shown by the previous works by Sharma et al. [19,24] as well as in this work that the strut failure may be reached even with smaller bar di­ ameters depending on the configuration (placement) and amount of supplementary reinforcement. In test Series T-S_3.4, only one ds,re = 16 Fig. 12. Load-displacement curves from tension tests on single bonded anchor without and with post-installed supplementary reinforcement, ds,re = 12 mm. 10 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 13. Typical failure mode obtained from tension test on anchor without and with post-installed supplementary rebars, ds,re = 12 mm. mm (As,re = 201 mm2) rebar was used as supplementary reinforcement. The aim was to investigate the influence of the asymmetric arrangement of the reinforcement. In Fig. 14, a comparison the load–displacement curves obtained for the anchor reinforced with one 16 mm rebar (T-S_3.4) and obtained with four 8 mm rebars placed symmetric around the anchor (T-S_3.5) along with the reference test results without reinforcement are given. In both reinforced test series the total cross-section area of the reinforcement is the same (As,re = 200 mm2). It can be clearly seen that the anchor reinforced with 4–8 mm rebars results in a higher increase in the load carrying capacity. The relative increase in the load capacity was 1,51-, and 1.80-times the mean reference failure obtained for the tests with 1x16 and 4xd8 rebar’s, respectively. This can be explained with the fact that in case of 1x16, only one strut can be formed which is relatively unstable. However, in case of 4x8 rebars, the symmetric and stable struts form which leads to higher load increase. It may be argued that the higher increase in 4x8 bar case might be due to higher bond area compared to 1x16 bar. However, as seen in Fig. 14, comparing the failure pictures for ds,re = 16 mm and ds,re = 8 mm, in both test series strut failure was the decisive failure mode due to strong bond resistance of the epoxy mortar. Whereas with 1x16 bar case, the concrete failure was only slightly restricted on one side, with 4x8 bars, a rather small concrete break-out body formed. 6.1. Tests on 1x2 anchor groups Additional to the tension tests on single anchors, unconfined tension tests were performed on 1 × 2 group anchorages consisting of bonded anchors with 24 mm threaded rods without and with post-installed supplementary reinforcement. In Table 4 the results of tests on anchor groups are summarized. Individual test results in terms of failure loads (Nu,i), mean value of the ultimate failure loads (Nu,m), the corresponding coefficient variation of the ultimate loads (CoV), the mean displace­ ments at the ultimate load (δu,m) are reported. Furthermore Table 4 Fig. 14. (a) Load-displacement curves from tension tests on single bonded anchor without (black) and with post-installed supplementary reinforcement, one rebar ds, re = 16 mm (blue) and four rebars ds,re = 8 mm (orange and (b) typical failure mode obtained from tension test on single anchor with post-installed supplementary rebars ds,re = 16 mm and (c) with ds,re = 8 mm. 11 N. Vita et al. Engineering Structures 252 (2022) 113754 Table 4 Test Results by 1x2 anchor groups. Test Series T-G_0 T-G_1 T-G_2 T-G_3 T-G_4 T-G_5 T-G_6 T-G_7 1) Test ID M24-140-140_0 M24-140-140_2xd8 M24-140-140_4xd8 M24-140140_2xd12 M24-140-140_6xd8 M24-140140_4xd12 M24-140140_6xd10 M24-140140_6xd12 Ultimate load Nu,i Mean ultimate load Nu,m CoV Mean displ. at Nu, Test No.1 Test No.2 Test No.3 δu,m Rel. increase in load capacitiy Nu,m/Nu,m,Ref [kN] 180.9 248.2 300.4 298.6 [kN] 167.3 264.6 269.3 278.1 [kN] 195.7 234.1 271.0 265.2 [kN] 181.3 249.0 280.2 280.6 [%] 7.9 6.1 6.2 6.0 [mm] 0.55 0.93 1.28 1.51 [-] 1.0 1.37 1.55 1.55 [-] CC Yield Yield Yield 341.8 325.9 318.2 326.6 358.2 298.2 339.4 316.9 5.9 5.1 1.59 1.45 1.87 1.75 Strut Strut 321.6 322.1 380.8 341.5 10.0 1.23 1.88 Strut 315.5 346.3 379.9 347.2 9.3 1.51 1.92 Strut m Failure mode1) Note: CC = concrete cone breakout failure, Yield = Yielding of the reinforcement, Strut = failure of concrete strut includes the obtained failure mode as well as the relative increase in the mean load carrying capacity with respect to the mean ultimate load obtained in the reference tests without reinforcement In the reference tests series T-G_0, ordinary concrete cone breakout for the anchor group was observed. The obtained mean ultimate breakout load of 181.3 kN corresponds well to the calculated load 187,7 kN according to the CCD method. The behavior of anchor groups of bonded anchors loaded with postinstalled supplementary reinforcement loaded under tension is similar to that observed in case of single anchors. Even with a relatively small amount of reinforcement in case of test Series T-G_1 (2xd8 = As,re = 101 mm2), a significant increase of 37% in the ultimate load was obtained. With increasing amount of supplementary reinforcement, the capacity of anchorage increases but not directly proportional to the amount of reinforcement. Beyond a certain amount of supplementary reinforce­ ment, the capacity of anchorage seems to saturate, at around twice the failure load of the anchorage without reinforcement, due to attainment of strut failure. as 1.37, 1.55 and 1.87-times for the test Series with 2x (T-G_1), 4x (TG_2), and 6x (T-G_4) reinforcement, respectively. Nevertheless, the stiffness of the anchor groups without or with supplementary rein­ forcement is similar to as observed in case of tests on single anchors. Fig. 16 shows typical failure pictures of these anchor groups tests with ds,re = 8 mm supplementary reinforcement. To investigate the influence of the amount of supplementary rein­ forcement, test series with ds,re = 12 mm rebars were performed with different number (n = 2, 4, 6) of the bars while the distance to the an­ chor was kept constant at 50 mm (0.36∙hef). The rebars were installed symmetric around the anchor group. The load–displacement curves obtained from the tension tests on anchor groups with supplementary reinforcement (ds,re = 12 mm) along with the corresponding reference curves are summarized in Fig. 15 on the right. The ultimate breakout loads as well as the displacement at the ultimate loads increase with increasing amount of the reinforcement while the initial stiffness of the anchor groups are not affected by the amount of reinforcement. While the mean failure load for the reference tests was 181.3 kN, the mean failure loads obtained for tests with 2x, 4x and 6xd12 rebars were 280.6, 316.9 and 347.2 kN respectively, which leads to 1.51, 1.75 and 1.92times increase in the failure load relative to the reference test series. Whilst in case of 2xd12 rebars (T-G_3) yielding of the reinforcement was achieved, with 4xd12 and 6xd12 rebars strut failure governed the failure load. 6.1.1. Influence of amount of supplementary reinforcement Fig. 15 summarizes the load–displacement curves obtained on 1x2 anchor groups loaded in tension with different number (n = 0, 2x, 4x, 6x) of ds,re = 8 mm rebars (left) as supplementary reinforce­ ment. The relative increase in the ultimate breakout load was obtained Fig. 15. Load-displacement curves from tension tests on 1x2 anchor groups without and with post-installed supplementary reinforcement with ds,re = 8 mm (left) and with ds,re = 12 mm (right). 12 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 16. Typical failure mode obtained from tension test on 1x2 anchor groups with post-installed supplementary reinforcement, ds,re = 8 mm. 6.1.2. Influence of the arrangement of reinforcement To investigate the arrangement of supplementary reinforcement in case of 1x2 anchor groups, tension tests were performed on the groups with 4xd12 (T-G_5) and with 6xd10 (T-G_6) rebars resulting in almost equal cross-section area of As,re = 452 and 471 mm2, respectively. Typical load–displacement curves obtained from both test series and corresponding reference test series without reinforcement are plotted in Fig. 17. In both test series the anchor groups failed by strut failure with a typical small concrete breakout body within the reinforcement. The mean load capacities were obtained as 1.75-, and 1.88-times of the corresponding reference mean load for T-G_5 (4xd12) and T-G_6 (6xd10), respectively. Due to the almost same amount of the rein­ forcement, the difference can be only explained that with six rebars more struts can form resulting in slightly higher capacity. This behavior highlights two aspects: (i) not only the amount of the reinforcement, but also their arrangement have an influence of the load-carrying capacity of the anchorages failing due to strut failure, and (ii) the strut failure de­ pends not only on the geometry of the anchorage and reinforcement but also on the possible number of struts that can be activated to transfer the applied load from the anchorage. analyzed on the basis of the test results with constant distance between anchor and post-installed supplementary reinforcement. The normal­ ized increase factors in the load carrying capacity for the anchor groups tested are plotted in Fig. 18 as a function of the cross-section area (As,re) of the post-installed reinforcement for single anchor tests (left) and for anchor groups (right). The data plotted includes only the tests with 24 mm threaded rods with hef = 140 mm the distance between anchor and reinforcement as a = 50 mm. In both the diagrams it can be clearly seen that initially (for low amount of reinforcement), the rate of increase of the failure load is stronger than for higher amounts of reinforcement. Until a certain amount of reinforcement, the failure is governed by yielding of the postinstalled reinforcement and therefore with increasing reinforcement, a strong increase in the capacity of the anchorage is obtained. However, beyond this certain amount of reinforcement, further increase in the capacity is rather low because from this point onward, the failure is governed by the strut failure. As shown earlier, the strut failure depends not on the amount of the reinforcement, but rather on the position of the reinforcement to the anchor (a, hef), which define the angle of the strut. It is interesting to note that in the single anchor tests (Fig. 18 left side), even after reaching the strut failure (As,re ~ 200 mm2), the ca­ pacity of the anchorage further increased with increasing amount of reinforcement. This increase is attributed to not the cross-sectional area of the reinforcement, but to the larger number of bars that result in more struts being formed. In case of anchor groups, the limit of the change in the failure mode from yielding of the reinforcement to strut failure was 7. Discussion 7.1. Influence of the amount of supplementary reinforcement The influence of the amount of supplementary reinforcement is Fig. 17. Load-displacement curves from tension tests on 1x2 anchor groups without and with post-installed supplementary reinforcement, ds,re = 10 mm T-G_6 (1x2M24 + 6xd10)and typical failure picture. 13 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 18. Load increase factor depending on the cross-section area of the reinforcement for constant distance between anchor and reinforcement. reached at approx. As,re = 300 mm2 with 6xd8 reinforcing bars where the increase in the load capacity 1.76-times the peak load obtained in the reference test series on anchor groups. On further increasing the amount of reinforcement with 4xd12, 6xd10 and 6xd12 bars (As, 2 re = 452, 471 and 679 mm respectively), led to 1.70, 1.79 and 1.80times higher capacity than the corresponding reference load. This in­ dicates that if the failure mode is governed by strut failure, the increase in capacity does not depend directly on the amount of the reinforcement but on the number of possible struts and the angle of the strut. This will be further discussed with more examples in the next section. As mentioned earlier, the presence of the post-installed supplemen­ tary reinforcement results in an increase of not only the ultimate load but also the displacement at the ultimate load. This can be clearly seen from Fig. 19, where the relatively increase of the mean displacements at the ultimate load obtained for the tests with reinforcement is given with respect to the mean displacement at ultimate load obtained from the reference tests, as a function of the amount of the reinforcement are given. With a relatively moderate amount of reinforcement (2xd12) it is possible to achieve 2,5-times higher displacements than without reinforcement. 7.2. Influence of the number and arrangement of rebar The influence of the number of the rebars or struts on the increase in the load carrying capacity of the anchors can be clearly seen in Fig. 20 where the relative increase factor is plotted as a function of the number of reinforcing bars. To compare, the results of the test Series T-S_3.4, TS_3.5 and T-S_3.6a where the amount of the reinforcement used was 1xd16, 4xd8 and 2xd12 rebars, respectively are plotted. Note that in all these three test series, the total cross-section area of the reinforcement can be considered as practically equal. However, as the number of bars (and hence the number of struts) increase, the strut failure load also increased. As shown in Fig. 21, if the anchor is reinforced with one reinforcing bar each on both sides arranged symmetrically outside the anchorage (Type 1), the struts will be active only in the plane of the reinforcing bars (two struts). These struts impede the spread of the concrete cone breakout body and in such case, the possible failure mode in Section A-A (with supplementary reinforcement) and in Section B-B (rectangular without suppl. reinforcement) would be different resulting on the con­ crete surface in a dog bone shape breakout body, see Top View in Fig. 21, Type 1. If additional post-installed rebars are installed in the B-B section, (see Fig. 21, Type 2), a symmetric and more stable strut mechanism can be mobilized compared to that for Type 1. In this case, the struts are active Fig. 19. Relative increase in the mean displacement at peak load for tests with reinforcement in respect to the mean displacement at peak load for reference tests depending on the cross-section area of the reinforcement for constant distance between anchor and reinforcement. Fig. 20. Increase factors as a function of the number of rebars. 14 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 21. Consideration of strut formation in case of anchors with supplementary reinforcement. in both orthogonal planes Section A-A and B-B, resulting in four struts (two in each orthogonal direction). In this case, the struts will restrict the formation of the concrete cone breakout body in both the directions and no unrestricted concrete cone breakout is possible. In this case, a smaller, circular concrete breakout can form on the concrete surface only inside from the reinforcements (as shown in Fig. 21, Type 2, top view). In general, if the number of post installed reinforcing bars is increased, more struts can form. Since the angle of the strut depends on the ratio of the distance of the rebar from the anchor and the embedment depth of the anchor, the bars placed closer to the anchor would result in higher resistance to the applied load by the strut action. In principle, a symmetric strut formation (symmetric arrangement of rebars) is considered to provide higher resistance compared to unsymmetric strut formation for otherwise same number of struts. contribution of concrete against the applied tension force was obtained by deducting the total tension force taken up by all the rebars from the total applied load. Fig. 22 shows the evaluated results of tension tests on single anchors with 2xd8 and 2xd12 rebars (Series T-S_3.2 Test No.3 and T-S_3.6a Test No.3) to show the separate contribution of concrete and reinforcement towards tension resistance. The figure plots the total applied load on the anchor, the tensile forces in the two rebars, the total force taken up by the reinforcement and the calculated contribution for concrete, as a function of the anchor displacement. In both the tests, at the beginning, the curve of the applied load and the curve of the force carried by concrete are identical, because the reinforcing bars are not activated and therefore the total load is taken up by concrete. With increasing the applied load, once the applied load reaches almost the value of the reference failure load (without reinforcement), the concrete cracks cross the rebars, which starts to take up the load significantly while the contribution of concrete gradually drops down. In case of 2xd8 rebars (Fig. 22, left), the reinforcing bars reached the yield at the peak of applied load, while for with higher amount of reinforcement (2xd12) (Fig. 22, right), at the peak load, the reinforcing bars did not yield and the failure was governed by strut failure. Nevertheless, in both the cases it can be seen that at peak load, both the reinforcement as well as concrete contribute significantly towards the tension resistance of the anchor. This observation is similar to the behavior observed and reported by Sharma et al. [23–25] for anchorages with cast-in headed studs reinforced with cast-in supplementary rein­ forcement. This aspect will be discussed and used for the development of an analytical model to calculate the tension resistance of post-installed anchors with post-installed supplementary reinforcement, which will be presented in another paper. 7.3. Individual contribution of concrete and reinforcement towards tension resistance of the anchorage To separate the contribution of the concrete and reinforcement in the load-bearing behavior and load transfer mechanism for post-installed anchorages with post-installed supplementary reinforcement, in certain tests strain gauges were installed on the post-installed supple­ mentary reinforcement to measure the strains developing in the rebars. Two strain gauges were attached (glued) on the reinforcement, where the theoretical crack should intersect the rebars during the tension tests. The strain measured in the reinforcement were converted into the cor­ responding stress in the rebar assuming an elastic-perfectly plastic behavior with modulus of elasticity of steel as 200 GPa and mean yield stress as 550 MPa (1.1 times the specified characteristic yield stress). The stress was converted into tensile force taken up by the rebar by multiplying the stress with the cross-section area of the rebars. The 15 N. Vita et al. Engineering Structures 252 (2022) 113754 Fig. 22. Separated contribution of reinforcement and concrete to tension resistance for tests on single anchors with 2xd8 (left) and 2xd12 (right). 8. Conclusions and further work well as the concrete contribute significantly towards the resistance of the anchorage with reinforcement. 7) Based on the detailed evaluation of the test results, an analytical model is developed by the authors for the calculation of resistance of post-installed bonded anchors with post-installed supplementary reinforcement. This model will be presented later in another paper. In this work, the influence of post-installed supplementary rein­ forcement on the behavior of anchorages with bonded anchors under tension loads was investigated. The test program included unconfined tension tests on single anchors and on 1x2 anchor groups without (as reference) and with post-installed reinforcement as a supplementary reinforcement. Based on the test results, the following conclusions can be summarized: Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. 1) The test results on bonded anchorages (single and group) shows clearly the positive influence of the post-installed reinforcing bars installed relatively close to the anchors. Even with a relatively small amount of reinforcement, a strong enhancement in the load-bearing behavior of anchorages is obtained both in terms of failure load as well as a relatively ductile behavior. 2) The pilot tests showed that the influence of pre-loading, if any, up to 75% of the ultimate capacity of the anchorage without reinforcement is negligible on the performance of the anchorage strengthened with supplementary reinforcement. Therefore, post-installed supplemen­ tary reinforcement can be used also for strengthening of existing anchorages in the same way as in the design of a new anchorage. 3) By increasing the amount of the supplementary reinforcement, the relative increase in the ultimate load increases proportionally with the amount of the reinforcement up to a certain amount of rein­ forcement that results in yielding of reinforcement. Once the failure mode starts being governed by the strut failure, the increase in the failure load with increasing amount of reinforcement is not so sig­ nificant and only a moderate increase with increasing number of struts is observed. 4) Tests with supplementary reinforcement placed at a relatively large distance to the anchor (a = 0.75∙hef) have shown that even with a relatively small bond length of the post-installed reinforcing bars in the concrete cone breakout body, strut failure can be reached instead of pull-out of the reinforcement. This is due to the high bond strength of the epoxy mortar used for post-installed rebar. Due to this, even smaller bond lengths can be used for post-installed rebar compared to the cast-in rebar. 5) In case of strut failure, besides the influence of the relative position of the reinforcement to the anchorages (a / hef) that define the angle of the strut, the number of rebars and thus the number of possible compression struts have an influence on the capacity of anchorages with supplementary reinforcement. 6) The evaluation of tension tests performed with strain gauges showed that when the ultimate load is reached, both the reinforcement as Acknowledgement The experimental investigations presented in this paper were financially supported by fischerwerke GmbH & Co. KG. The support received from fischerwerke is greatly acknowledged. The opinions, findings, and conclusions or recommendations expressed in this publi­ cation are those of the authors and do not necessarily correspond with those of the sponsoring organization. References [1] ACI Committee and International Organization for Standardization, Building code requirements for structural concrete (ACI 318M-11) and commentary: Appendix DANCHORING TO CONCRETE. Farmington Hills, Mich.: American Concrete Institute, 2011, ISBN 9780870312649. [2] EN 1992-4: Eurocode 2: Design of concrete structures - Part 4: Design of fastenings for use in concrete, EN 1992-4:2018, 2018, European Committe for Standardization (CEN). Brussels, 2018. [3] fédération internationale du béton/International Federation for Concrete (fib), Bulletin 58, Design of anchorages in concrete - Guide to good practice. Lausanne, Switzerland: Internat. Federation for Structural Concrete (fib), 2011, ISBN 978-288394-098-7. [4] EAD 330499-01-0601 - Bonded fasteners for use in concrete, EAD 330499-01-0601, 2018, European Organisation for Technical Approvals (EOTA), 2018. [5] K. Ninčević, I. Boumakis, S. Meissl, and R. Wan-Wendner, “Consistent Time-toFailure Tests and Analyses of Adhesive Anchor Systems,” Applied Sciences, 2020, vol. 10, no. 4, 1527, 27 p., doi:10.3390/app10041527. [6] Nilforoush R, Nilsson M, Söderlind G, Elfgren L. Long-Term Performance of Adhesive Bonded Anchors. ACI Struct J 2016;113(2):251–61. https://doi.or g/10.14359/51688060. [7] Mahrenholtz P, Wood RL. Design of post-installed and cast-in-place anchors according to the new EN 1992–4 and ACI 318–19. Structural Concrete 2021;22(2): 650–65. https://doi.org/10.1002/suco.202000118. [8] Matsunaga K, Takase Y, Abe T. Modeling of dowel action for cast-in and postinstalled anchors considering bond property. Eng Struct 2021;245:112773. https:// doi.org/10.1016/j.engstruct.2021.112773. [9] R. Eligehausen, R. Mallée, and J. F. Silva, Anchorage in Concrete Construction, 1st ed. s.l.: Ernst Sohn, 2006, ISBN 978-3-433-01143-0. [10] Tóth M, Bokor B, Sharma A. Anchorage in steel fiber reinforced concrete – concept, experimental evidence and design recommendations for concrete cone and 16 N. Vita et al. [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] Engineering Structures 252 (2022) 113754 concrete edge breakout failure modes. Eng Struct 2019;181:60–75. https://doi. org/10.1016/j.engstruct.2018.12.007. Bokor B, Tóth M, Sharma A. Fasteners in Steel Fiber Reinforced Concrete Subjected to Increased Loading Rates. Fibers 2018;6. https://doi.org/10.3390/fib6040093. Vita N, Sharma A. Behaviour of single bonded anchors in non-cracked and cracked steel fiber reinforced concrete under short-time tensile loading. Engineering Structures 2021;(245). https://doi.org/10.1016/j.engstruct.2021.112900. M. Nilsson, U. Ohlsson, and L. Elfgren, “Effects of surface reinforcement on bearing capacity of concrete with anchor bolts,” Nordic Concrete Research, No 44, pp. 161–174, 2011. [Online]: http://ltu.diva-portal.org/smash/get/diva2:980534/ FULLTEXT01.pdf. Nilforoush R, Nilsson M, Elfgren L, Ožbolt J, Hofmann J, Eligehausen R. Influence of Surface Reinforcement, Member Thickness, and Cracked Concrete on Tensile Capacity of Anchor Bolts. ACI Structural Journal 2017;114. https://doi.org/ 10.14359/51689505. W. Berger, “Trag- und Verschiebungsverhalten sowie Bemessung von Kopfbolzenverankerungen mit und ohne Rückhängebewehrung unter Zuglast,” PhD Thesis, Institute of Construction Materials, University of Stuttgart, Stuttgart, Germany, 2015. [Online]. Available: http://elib.uni-stuttgart.de/opus/volltexte/ 2015/10302. K. Schmid, “Tragverhalten und Bemessung von Befestigungen am Bauteilrand mit Rückhängebewehrung unter Querlasten rechtwinklig zum Rand: Behaviour and Design of Fastenings at the Edge with Anchor Reinforcement unde Shear Loads towards the Edge,” PhD Thesis, Institute of Construction Materials, University of Stuttgart, Stuttgart, Germany, 2010. [Online]. Available: http://elib.uni-stuttgart. de/opus/volltexte/2010/5796. Infaso, Handbuch. I, Entwurf von Anschlüssen zwischen Stahl und Beton. Stuttgart: Universitätsbibliothek der Universität Stuttgart, 2015. [Online]. Available: http:// elib.uni-stuttgart.de/opus/volltexte/2015/9947. Sharma A, Eligehausen R, Asmus J. Experimental investigation of concrete edge failure of multiple-row anchorages with supplementary reinforcement. Structural Concrete 2016;18. https://doi.org/10.1002/suco.201600015. A. Sharma, R. Eligehausen, and J. Asmus, “Comprehensive experimental investigations on anchorages with supplementary reinforcement,” in 3rd International Symposium on Connections between Steel and Concrete: Stuttgart, Germany, 27th - 29th September 2017 : book of abstracts, A. Sharma and J. Hoffmann, Eds., Stuttgart: IWB, 2017, pp. 242–252, ISBN 978-3-945773-06-2. A. Sharma, R. Eligehausen, and J. Asmus, “Experimental investigations on concrete edge failure of headed studs groups in reinforced concrete,” in 23rd International Conference on Structural Mechanics in Reactor Technology 2015 (SMiRT 23): Manchester, United Kingdom, 10-14 August 2015, 2017, ISBN 9781510843448. R. Eligehausen, J. Asmus, and A. Sharma, “Bemessung von Befestigungen mit Kopfbolzen am Bauteilrand ohne und mit Rückhängebewehrung unter Querlasten senkrecht zum Rand - Experimentelle Untersuchungen und Vergleich der gemessenen Bruchlasten mit EN 1992-4,” Der Prüfingenieur, 2016. Eligehausen R, Sharma A, Asmus J. Behaviour and design of fastenings with headed studs with supplementary reinforcemen close to an edge under shear loads perpendicular to the edge 2019;18:65. A. Sharma, R. Eligehausen, and J. Asmus, Analytical model for concrete edge failure of multiple row anchorages with supplementary reinforcement, 2016. A. Sharma, R. Eligehausen, and J. Asmus, “Comprehensive analytical model for anchorages with supplementary reinforcement,” in 3rd International Symposium on Connections between Steel and Concrete: Stuttgart, Germany, 27th - 29th September 2017 : book of abstracts, A. Sharma and J. Hoffmann, Eds., Stuttgart: IWB, 2017, pp. 253–265, ISBN 978-3-945773-06-2. A. Sharma, R. Eligehausen, J. Asmus, J. Bujnak, and K. Schmid, “Analytical Model for Anchorages with Supplementary Reinforcement Under Tension or Shear Forces,” in High tech concrete: Where technology and engineering meet : proceedings of [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] [39] [40] [41] 17 the 2017 Fib Symposium, held in Maastricht, the Netherlands, June 12-14, 2017, D. A. Hordijk and M. Luković, Eds., 2018, pp. 974–982, ISBN 978-3-319-59470-5. A. Sharma, R. Eligehausen, J. Asmus, and J. Bujnak, “Behavior of Anchorages with Supplementary Reinforcement Under Tension or Shear Forces,” in High tech concrete: Where technology and engineering meet : proceedings of the 2017 Fib Symposium, held in Maastricht, the Netherlands, June 12-14, 2017, D. A. Hordijk and M. Luković, Eds., 2018, pp. 965–973, ISBN 978-3-319-59470-5. G. Di Nunzio and G. Muciaccia, “Effect of Supplementary Reinforcement on the Pull-out of Cast-in-Place Anchors,” in The New Boundaries of Structural Concrete 2019: 5th Workshop on, ACI Italy Chapter, Politecnico Milano, Department of Civil Environmental Engineering, Ed., 2019. Bui T, Limam A, Nana WSA, Arrieta B, Roure T. Cast-in-place Headed Anchor Groups Under Shear: Experimental and Numerical Modelling. Structures 2018;14: 178–96. https://doi.org/10.1016/j.istruc.2018.03.008. Di Nunzio G. Pull-out of cast-in-place fasteners: Influence of the bearing pressure and structural interaction with the concrete member, PhD-Thesis. Department of Civil and Environmental Engineering, Politecnico di Milano, Milano, Italy; 2020. N. Randl and J. Kunz, “Post-Installed Fastenings for Bridge Equipment,” IABSE Congress Report, 2000, vol. 16, doi: 10.2749/222137900796299101. European Organisation for Technical Approvals (EOTA), “Assessment of postinstalled rebar connections,” TR 023. [Online]. Available: https://www.eota.eu/ en-GB/content/technical-reports/28/. European Organisation for Technical Approvals (EOTA), “Desing method for anchorage of post-installed reinforcing bars (rebars) with improved bond-splitting behavior as compared to EN 1992-1-1,” TR 069, Oct. 2019. [Online]. Available: https://www.eota.eu/en-GB/content/technical-reports/28/. EAD 330087-00-0601 - System for post-installed rebar connections with mortar, EAD 330087-00-0601, 2018, European Organisation for Technical Approvals (EOTA), 2018. Looi D-T-W, Lee A, Su R, Zhang Y. Design and installation of post-installed reinforcements: A state-of-the-art review. Transactions Hong Kong Institution of Engineers 2020;27. https://doi.org/10.33430/V27N2THIE-2019-0033. Vita N, Sharma A, Hofmann J. Local strengthening of anchorages with postinstalled (supplementary) reinforcement. IOP Conference Series: Materials Science and Engineering 2019;615:12093. https://doi.org/10.1088/1757-899X/615/1/ 012093. N. Vita, A. Sharma, J. Hofmann, “Strengthening of anchorages with post-installed supplementary reinforcement under shear loading,” in vol. 18, Otto-Graf-Journal: Journal on Research and Testing of Materials, MPA University of Stuttgart and the Institute for Materials in Construction, Ed., 2019, pp. 357–368. [Online]. Available: https://www.mpa.uni-stuttgart.de/institut/publikationen/otto-grafjournal/new_downloadgallery/30_Vita.pdf. DIBt-Deutsche Institut for Bautechnik, “Europäische Technische Bewertung - ETA17/0979: fischer Injektionssystem FIS EM PLUS; Verbunddübel zur Verankerung in Beton,” DIBt-Deutsche Institut for Bautechnik, 17.Juni.2020. DIBt-Deutsche Institut for Bautechnik, “Europäische Technische Bewertung - ETA17/1056: Bewehrungsanschluss mit fischer injektionssystem FIS EM Plus; Injektionssystem für nachträglich eingemörtelte Bewehrungsanschlüsse,” DIBtDeutsche Institut for Bautechnik, Jan. 2021. DIN EN 12390-3:2019-10, Testing hardened concrete - Part 3: Compressive strength of test specimens; German version EN 12390-3:2019, 12390-3, 2019, DIN Deutsches Institut für Normung e. V.: Beuth Verlag GmbH. 10772 Berlin, Germany, 2019. ETAG 001-Guideline for European technical approval of metal anchors for use in concrete, Annex-A: Details of tests, 1997, European Organisation for Technical Approvals (EOTA). Brussels, 1997. Fuchs W, Eligehausen R, Breen JE. Concrete Capacity Design (CCD) Approach for Fastening to Concrete. ACI Struct J 1995;92(1):73–94. https://doi.org/10.14359/1 533.