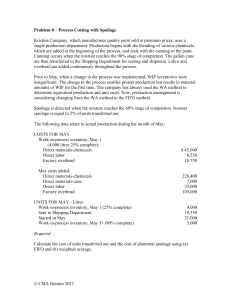

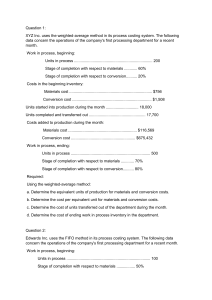

lOMoARcPSD|13494386 07 - CostAcctng Cost Accounting And Cost Management (Far Eastern University) Studocu is not sponsored or endorsed by any college or university Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 Chapter 7 THE COST OF QUALITY AND ACCOUNTING FOR PRODUCTION LOSSES MULTIPLE CHOICE Question Nos. 16, 17, 22, and 23 are AICPA adapted. Question No. 24 is CIA adapted. A 1. The quality costs that are associated with materials and products that fail to meet quality standards and result in manufacturing losses are known as: A. internal failure costs B. external failure costs C. prevention costs D. appraisal costs E. none of the above D 2. The quality costs that are associated with designing, implementing, and maintaining the quality system are known as: A. appraisal costs B. internal failure costs C. external failure costs D. prevention costs E. none of the above C 3. The quality costs that are incurred to ensure that materials and products meet quality standards are known as: A. external failure costs B. prevention costs C. appraisal costs D. internal failure costs E. none of the above B 4. The quality costs that are incurred because inferior quality products are shipped to customers are known as: A. internal failure costs B. external failure costs C. prevention costs D. appraisal costs E. none of the above 82 Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses 83 D 5. All of the following are characteristics of total quality management except: A. the company's objective for all business activity is to serve its customers B. top management provides an active leadership role in quality improvement C. all employees are actively involved in quality improvement D. the company maintains a loosely defined system of identifying quality problems so as not to stifle employee creativity E. the company provides continuous training as well as recognition for achievement A 6. The best approach to quality improvement is to concentrate on: A. prevention B. detection C. appraisal D. increased production E. none of the above C 7. A mathematical technique used to monitor production quality and reduce product variability is: A. the method of least squares B. the statistical scattergraph method C. statistical process control D. linear programming E. none of the above D 8. Appraisal costs include all of the following except: A. inspecting and testing materials B. inspecting products during and after production C. obtaining information from customers about product satisfaction D. designing quality into the product and the production process E. all of the above B 9. Internal failure costs include all of the following except: A. the cost of the scrap B. the cost of warranty repairs and replacements C. rework D. downtime due to machine failures E. all of the above E 10. All of the following accounts would be acceptable ones to credit at the time scrap is sold except: A. Scrap Sales B. Cost of Goods Sold C. Factory Overhead Control D. Work in Process E. all of the above would be acceptable C 11. Scrap includes all of the following except: A. the trimmings remaining after processing materials B. defective materials that cannot be used or returned to the vendor C. partially or fully completed units that are in some way defective D. broken parts resulting from employee or machine failures E. all of the above Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 84 Chapter 7 A 12. When spoilage occurs because of some action taken by the customer, the unrecoverable cost of the spoilage should be charged to: A. Work in Process B. Spoiled Goods Inventory C. Factory Overhead Control D. Applied Factory Overhead E. none of the above C 13. When spoilage occurs because of some internal failure, the unrecoverable cost should be charged to: A. Work in Process B. Spoiled Goods Inventory C. Factory Overhead Control D. Applied Factory Overhead E. none of the above A 14. When rework occurs because of some action taken by the customer, the cost of the rework should be charged to: A. Work in Process B. Spoiled Goods Inventory C. Factory Overhead Control D. Applied Factory Overhead E. none of the above C 15. When rework occurs because of some internal failure, the cost of the rework should be charged to: A. Work in Process B. Spoiled Goods Inventory C. Factory Overhead Control D. Applied Factory Overhead E. none of the above C 16. Newman Company's Job 1865 for the manufacture of 2,200 coats was completed during August at the unit costs presented below. Due to an internal failure in the production process, 200 coats were found to be spoiled during final inspection that were sold to a jobber for $6,000. Direct materials ............................................................................................................... Direct labor ...................................................................................................................... Factory overhead ............................................................................................................ ............................................................................................................................... What would be the unit cost of good coats produced on Job 1865? A. $57.00 B. $55.00 C. $56.00 D. $58.00 E. none of the above SUPPORTING CALCULATION: $20 + $18 + $18 = $56 Downloaded by Christine Eugenio (darkchristine22@gmail.com) $20 18 18 $56 lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses A 17. 85 During March, Vaughan Company incurred the following costs on Job 009 for the manufacture of 200 motors: Original cost accumulation: Direct materials ........................................................................................................ Direct labor ............................................................................................................... Factory overhead (150% of direct labor) ............................................................... Direct costs of reworking 10 units: Direct materials ........................................................................................................ Direct labor ............................................................................................................... .................................................................................................................................... $ 660 800 1,200 $ 2,660 $100 160 $260 The rework costs were attributable to the exacting specifications of the customer. What is the cost per finished unit of Job 009? A. $15.80 B. $14.60 C. $14.00 D. $13.30 E. none of the above SUPPORTING CALCULATION: $2,660 + $260 + (150% x $160) = $3,160 200 = $15.80 C 18. Spoilage occurs as a result of an internal failure in a process cost system. Using average costing, the number of equivalent units that production costs should be charged to would be based upon: A. spoiled units B. units transferred out and spoiled units C. units transferred out, spoiled units, and units in ending inventory D. units transferred out and units in ending inventory E. none of the above D 19. Spoilage occurs as a result of normal production shrinkage in a process cost system. Using average costing, the number of equivalent units that production costs should be charged to would be based upon: A. spoiled units B. units transferred out and spoiled units C. units transferred out, spoiled units, and units in ending inventory D. units transferred out and units in ending inventory E. none of the above C 20. In a process cost system, the cost of spoilage due to an internal production failure should be recorded as: A. dr. Work in Process; cr. Finished Goods B. dr. Work in Process; cr. Factory Overhead Control C. dr. Factory Overhead Control; cr. Work in Process D. dr. Materials; cr. Factory Overhead E. dr. Finished Goods; cr. Work in Process Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 86 B Chapter 7 21. Gyro Products transferred 10,000 units to one department. An additional 3,000 units of materials were added in the department. At the end of the month, 7,000 units were transferred to finished goods; while 4,000 units remained in work in process inventory. There was no beginning inventory, and lost units were a result of normal production shrinkage. The production costs for the period in this department would be effectively allocated over: A. 12,000 units B. 11,000 units C. 10,000 units D. 7,000 units E. 13,000 units SUPPORTING CALCULATION: 7,000 + 4,000 = 11,000 B 22. In manufacturing its products for the month of March, Leo Co. incurred normal production shrinkage of $10,000 and spoilage due to internal failure of $12,000. How much spoilage cost should Leo charge to Factory Overhead Control for the month of March? A. $22,000 B. $12,000 C. $10,000 D. $0 E. none of the above C 23. Willis, Inc. instituted a new process in October. During October, 10,000 units were started in Department A. Of the units started, 1,000 were lost in the process due to normal production shrinkage, 7,000 were transferred to Department B, and 2,000 remained in work in process at October 31. The work in process at October 31 was 100% complete as to materials costs and 50% complete as to conversion costs. Materials costs of $27,000 and conversion costs of $40,000 were charged to Department A in October. What were the total costs transferred to Department B? A. $46,900 B. $53,600 C. $56,000 D. $57,120 E. none of the above SUPPORTING CALCULATION: Materials: $27,000 (7,000 + 2,000) = $3 Conversion: $40,000 (7,000 + 1,000) = $5 Transferred costs: 7,000 x $8 = $56,000 Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses D 24. 87 A company that manufactures baseballs begins operations on January 1. Each baseball requires three elements: a hard plastic core, several yards of twine that are wrapped around the plastic core, and a piece of leather to cover the baseball. The plastic core is started down a conveyor belt and is automatically wrapped with the twine to the approximate size of the baseball, at which time the leather cover is sewn to the wrapped twine. Finished baseballs are inspected, and the ones that are defective due to internal production failure are pulled out. Defective baseballs cannot be economically salvaged and are destroyed. Cost and production reports for the first week of operations are: Raw material cost .............................................................................................................. Conversion cost ................................................................................................................. 315 ................................................................................................................................. $ 840 $ 1,155 During the week, 2,100 baseballs were completed; 2,000 passed inspection. There was no ending work in process. The cost of the spoilage charged to Factory Overhead is: A. $33 B. $22 C. $1,100 D. $55 E. none of the above SUPPORTING CALCULATION: Materials: $840 (2,000 + 100) = $.40 Conversion: $315 (2,000 + 100) = $.15 Spoilage: 100 x $.55 = $55 A 25. In a process cost system, the cost of rework usually is debited to: A. Factory Overhead Control B. Applied Factory Overhead C. Spoiled Goods Inventory D. Work in Process E. none of the above The following questions are based on the Appendix to the chapter: D 26. If spoilage occurs as a result of an internal failure in a process cost system, using fifo costing, the number of equivalent units that production costs should be charged to would be based upon: A. spoiled units B. units transferred out and spoiled units C. units transferred out, beginning inventory, and units in ending inventory D. units transferred out, spoiled units, units in ending inventory, and units in beginning inventory E. none of the above Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 88 Chapter 7 C 27. If spoilage occurs as a result of normal production shrinkage in a process cost system, using fifo costing, the number of equivalent units that production costs should be charged to would be based on: A. spoiled units B. units transferred out and spoiled units C. units transferred out, beginning inventory, and units in ending inventory D. units transferred out, spoiled units, units in ending inventory, and units in beginning inventory E. none of the above B 28. Primo Products transferred 15,000 units to one department. An additional 5,000 units were in beginning inventory in the department. At the end of the month, 12,000 units were transferred to the next department, 6,000 units remained in work in process, 40% complete as to conversion costs and the remaining units were lost at the 75% stage of conversion. Beginning inventory was 60% complete as to conversion costs and lost units were the result of internal failure. The equivalent units of conversion cost using fifo costing is: A. 14,400 B. 12,900 C. 13,900 D. 13,400 E. none of the above SUPPORTING CALCULATION: Equivalent units in beginning inventory (40% x 5,000) ............................................... Equivalent units started and completed during period (12,000 - 5,000) ........................................................................................................ Equivalent units in ending inventory (40% x 6,000) .................................................... Equivalent units of spoilage (75% x 2,000) ................................................................... Total equivalent units ..................................................................................................... A 29. 2,000 7,000 2,400 1,500 12,900 Primo Products transferred 15,000 units to one department. An additional 5,000 units were added in the department. At the end of the month, 12,000 units were transferred to the next department, 6,000 units remained in work in process, 40% complete as to conversion costs and the remaining units were lost at the 75% stage of conversion. Beginning inventory was 60% complete as to conversion costs, and lost units were the result of normal production shrinkage. The equivalent units of conversion cost using fifo is: A. 11,400 B. 14,400 C. 12,900 D. 13,400 E. none of the above SUPPORTING CALCULATION: Equivalent units in beginning inventory (40% x 5,000) ............................................... Equivalent units started and completed during period (12,000 - 5,000) ........................................................................................................ Equivalent units in ending inventory (40% x 6,000) .................................................... Total equivalent units ..................................................................................................... Downloaded by Christine Eugenio (darkchristine22@gmail.com) 2,000 7,000 2,400 11,400 lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses 89 PROBLEMS PROBLEM 1. Journal Entries for Scrap. Munoz Metal Products accumulates metal shavings from the shop floor and sells them periodically to a nearby scrap dealer. Scrap sales, on account, for the period just ended total $2,300. Required: Indicate the journal entries when: (1)The scrap sales are viewed as additional revenue. (2)The scrap sales are viewed as a reduction of the cost of goods sold during the period. (3)The scrap sales are viewed as a reduction of factory overhead. (4)The scrap sales are traceable to individual jobs and are viewed as a reduction in the cost of materials used on the jobs. SOLUTION (1) (2) (3) (4) Accounts Receivable ................................................................................... Scrap Sales (or Other Income) .......................................................... 2,300 Accounts Receivable ................................................................................... Cost of Goods Sold.............................................................................. 2,300 Accounts Receivable ................................................................................... Factory Overhead Control................................................................. 2,300 Accounts Receivable ................................................................................... Work in Process .................................................................................. 2,300 2,300 2,300 2,300 2,300 PROBLEM 2. Spoilage in a Job Order Cost System. Walker Inc. manufactures custom wood products. During the current period, an order for 2,000 workbenches was begun on Job 1994. After the job was completed, the benches were inspected and 100 units were determined to be defective. The customer has agreed to accept the order with only 1,900 units instead of the quantity originally ordered. The spoiled units can be sold as seconds for $25 each. Spoiled goods are kept in a separate inventory account from finished goods. Total costs charged to Job 1994 follow: Materials ..................................................................................................................................... Labor (200 hours x $15 per hour) .................................................................................................. Factory overhead ($9.50 per labor hour) ...................................................................................... Total cost charged to Job 1994....................................................................................................... Custom jobs are marked up 150 percent on cost. Downloaded by Christine Eugenio (darkchristine22@gmail.com) $ 5,100 3,000 1,900 $ 10,000 lOMoARcPSD|13494386 90 Chapter 7 Required: (1) (2) Assuming that the defective units were the result of an internal failure (i.e., an employee error or a machine failure), prepare the appropriate general journal entries to record the transfer of the defective units to a separate inventory account and the completion and shipment of Job 1994 to the customer. Assuming that the defective units were the result of a change in design specified by the customer after the units were completed, prepare the appropriate general journal entries to record the transfer of the defective units to the separate inventory account and the completion and shipment of Job 1994 to the customer. SOLUTION (1) (2) Spoiled Goods Inventory (10 units x $25 salvage) ................................... Factory Overhead Control ........................................................................ Work in Process (10 units x $50* cost) ............................................. 250 250 Cost of Goods Sold ..................................................................................... Work in Process ($10,000 - 500) ........................................................ 9,500 Accounts Receivable ($9,500 x 150%) ...................................................... Sales ..................................................................................................... 14,250 Spoiled Goods Inventory (10 units x $25 salvage) ................................... Work in Process .................................................................................. 250 Cost of Goods Sold ..................................................................................... Work in Process ($10,000 - $250) ...................................................... 9,750 Accounts Receivable ($9,750 x 150%) ...................................................... Sales ..................................................................................................... 14,625 * $10,000 total job cost = $50 per unit 200 units on job Downloaded by Christine Eugenio (darkchristine22@gmail.com) 500 9,500 14,250 250 9,750 14,625 lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses 91 PROBLEM 3. Entries for Charging Rework Costs Caused by Internal Failure and by Change in Customer Specification. Albany Appliances manufactured 100 microwave ovens in a recent production run and discovered that 10 ovens were defective and required reworking as follows: Rework cost per unit: Materials ......................................................................................................................................... Labor............................................................................................................................................... Factory overhead ........................................................................................................................... Total ......................................................................................................................................... Normal production cost per unit: Materials ......................................................................................................................................... Labor............................................................................................................................................... Factory overhead ........................................................................................................................... Total ......................................................................................................................................... $ $ 10 25 25 60 $ 50 75 75 $ 200 Required: (1) (2) Prepare the journal entries to record (a) the normal production costs, (b) the rework costs, and (c) the transfer of the job costs to Finished Goods assuming that rework costs were caused by an internal failure. Prepare the same journal entries as in (1), assuming that rework costs were caused by a change in customer specifications. SOLUTION (1) (a) (b) (c) (2) Work in Process .............................................................................. Materials ................................................................................... Payroll ....................................................................................... Applied Factory Overhead ...................................................... Debit 20,000 5,000 7,500 7,500 Factory Overhead Control ($60 x 10)............................................ Materials ................................................................................... Payroll ....................................................................................... Applied Factory Overhead ...................................................... 600 Finished Goods ($200 x 100) .......................................................... Work in Process ....................................................................... 20,000 100 250 250 20,000 (a) Same as first entry in (1) (a) above. (b) Work in Process .............................................................................. Materials ................................................................................... Payroll ....................................................................................... Applied Factory Overhead ...................................................... 600 Finished Goods ................................................................................ Work in Process ....................................................................... 20,600 (c) Downloaded by Christine Eugenio (darkchristine22@gmail.com) Credit 100 250 250 20,600 lOMoARcPSD|13494386 92 Chapter 7 PROBLEM 4. Computation of Equivalent Units With Production Losses. Potter Paint Company manufactures paint in three departments using a process cost system with an average cost flow assumption. Selected cost and production data for the Blending Department, the second department in the production process, for the month just ended, are as follows: Units in beginning work in process ..................................................................................................... Units received from Mixing Department ............................................................................................ Units transferred to Finishing Department ........................................................................................ Units in ending work in process ........................................................................................................... Units spoiled due to internal failure .................................................................................................... Work in process, beginning inventory: Cost from preceding department ................................................................................................. Materials ......................................................................................................................................... Labor............................................................................................................................................... Factory overhead ........................................................................................................................... Costs added during the period: From preceding department ......................................................................................................... Materials ......................................................................................................................................... Labor............................................................................................................................................... Factory overhead ........................................................................................................................... 5,000 25,000 20,000 7,000 3,000 $ 4,200 1,960 895 685 $ 15,900 8,775 4,550 3,770 The paint is inspected at the end of the process in the Blending Department to detect any spoiled batches. Ending inventory is 75% complete as to materials and 25% complete as to conversion costs. Required: (1) (2) Compute the equivalent units of production for each cost element in the Blending Department for the month just ended. Determine the average cost per equivalent unit for each cost element. SOLUTION (1)...................................................................... Equivalent units transferred out ...................... Equivalent units in ending inventory ............... Equivalent units of spoilage .............................. Total equivalent units ........................................ From Preceding Department 20,000 7,000 3,000 30,000 Materials 20,000 5,250 3,000 28,250 Downloaded by Christine Eugenio (darkchristine22@gmail.com) Labor 20,000 1,750 3,000 24,750 Overhead 20,000 1,750 3,000 24,750 lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses (2)...................................................................... Cost in beginning inventory .............................. Cost added during the period ........................... Total cost to be accounted for ........................... Divide by equivalent units ................................. Cost per equivalent units ................................... From Preceding Department $ 4,200 15,900 $ 20,100 30,000 $ .67 93 Materials $ 1,960 8,775 $ 10,735 28,250 $ .38 Labor $ 895 4,550 $ 5,445 24,750 $ .22 Overhead $ 685 3,770 $ 4,455 24,750 $ .18 PROBLEM 5. Spoilage With a Salvage Value in a Process Cost System Using an Average Cost Flow Assumption. Carter Company manufactures a single product in two departments, Cutting and Finishing. Units of a product are started in the Cutting Department and then transferred to the Finishing Department where they are completed. Units are inspected at the 80% stage of completion in the Finishing Department. Good units are transferred to finished goods inventory when completed and spoiled units are transferred to a separate inventory account. Spoiled units are inventoried at their salvage value of $3 each, and the unrecoverable cost of spoilage, which was caused by an internal failure, should be charged to the appropriate account. Materials are added at the beginning of the production process. At the end of June, 2,000 units were still in process in the Finishing Department, 100% complete as to materials and 60% complete as to conversion costs. During July, 20,000 units were transferred from the Cutting Department to the Finishing Department and 15,000 were transferred from the Finishing Department to finished goods inventory. At the end of July, the Finishing Department still had 4,000 units in process, 100% complete as to materials and 20% complete as to conversion costs. Cost data related to July operations in the Finishing Department follow: Costs charged to the department: ............................................................................. Cost from preceding department ...................................................................... Materials .............................................................................................................. Labor.................................................................................................................... Factory overhead ................................................................................................ Beginning Inventory $6,050 3,410 1,638 2,184 Added This Period $54,450 30,690 14,742 19,656 Required: Complete the following cost of production report for the Finishing Department based on the data presented for July, assuming the company uses a process cost system with average costing to account for its production. Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 94 Chapter 7 SOLUTION Carter Corporation Finishing Department Cost of Production Report For July, 19-Quantity Schedule Beginning inventory ............................................... Received from Cutting Department ..................... Transferred to finished goods ............................... Ending inventory.................................................... Spoiled in process ................................................... Cost Charged to Department Beginning inventory: Cost from preceding department ................... Materials .......................................................... Labor. .............................................................. Factory overhead ............................................. Total cost in beginning inventory ............ Cost added during period: Cost from preceding department ................... Materials .......................................................... Labor. . ............................................................. Factory overhead ............................................. Total cost added during period ................ Total cost charged to the department................... Materials Labor 100% 100% 20% 80% Total Cost $ $ $ $ $ Overhead 20% 80% Equivalent Units* Quantity 2,000 20,000 22,000 15,000 4,000 3,000 22,000 Unit Cost 6,050 3,410 1,638 2,184 13,282 54,450 30,690 14,742 19,656 119,538 132,820 Downloaded by Christine Eugenio (darkchristine22@gmail.com) 22,000 22,000 18,200 18,200 $2.75 1.55 .90 1.20 $6.40 lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses Cost Accounted for as Follows Transferred to finished goods................................. Transferred to spoiled goods inventory at salvage value ............. Charge to factory overhead for spoilage: Cost from preceding department .............................. Materials ........................................ Labor. . ........................................... Factory overhead ........................... Less salvage value of spoiled units ............................. Work in process, ending inventory: Cost from preceding department .............................. Materials ........................................ Labor. . ........................................... Factory overhead ........................... Total cost accounted for ...................... Units 15,000 95 % Complete 100% Unit Cost $ 3,000 3,000 3,000 3,000 3,000 100% 100% 80% 80% $ 3,000 4,000 4,000 4,000 4,000 100% 100% 20% 20% $ Total Cost 6.40 $96,000 3.00 9,000 2.75 1.55 .90 1.20 $ 8,250 4,650 2,160 2,880 $ 17,940 3.00 9,000 2.75 1.55 .90 1.20 11,000 6,200 720 960 8,940 18,880 $132,820 * Total number of equivalent units required in the cost accounted for section determined as follows: Equivalent units transferred out .......................... Equivalent units in ending inventory ................... Equivalent units of spoilage .................................. Total equivalent units ............................................ Prior Dept. Cost 15,000 4,000 3,000 22,000 Materials 15,000 4,000 3,000 22,000 Downloaded by Christine Eugenio (darkchristine22@gmail.com) Labor 15,000 800 2,400 18,200 Overhead 15,000 800 2,400 18,200 lOMoARcPSD|13494386 96 Chapter 7 PROBLEM 6. Production Shrinkage in a Process Cost System Using an Average Cost Flow Assumption. Carrera Chemical Inc. uses a process cost system with an average cost flow assumption to account for the production of its only product. The product is manufactured in two departments. Units of product are started in the Cooking Department and then transferred to the Blending Department where they are completed. Because of the intense heat applied in the Cooking Department, some of the production volume is lost to evaporation. Labor and overhead are treated as one element of cost in the Cooking Department (i.e., conversion cost). Data related to May operations in the Cooking Department follow: Units in beginning inventory ................................................................................................................. Units started in process this period ...................................................................................................... Units transferred to the Blending Department this period ................................................................ Units in ending inventory (100% materials, 40% conversion cost) ................................................... Costs charged to the department: ............................................................................. Materials .............................................................................................................. Conversion cost .................................................................................................... Required: for May. Beginning Inventory $4,375 2,975 Prepare a cost of production report for the Cooking Department based on the data Downloaded by Christine Eugenio (darkchristine22@gmail.com) 10,000 45,000 40,000 9,000 Added This Period $11,795 6,181 presented lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses 97 SOLUTION Carrera Chemical Inc. Cooking Department Cost of Production Report For May, 19-- Quantity Schedule .................................................................... Beginning inventory ................................................................. Started in process this period .................................................. Materials Transferred to Blending Department..................................... Ending inventory...................................................................... Lost in process .......................................................................... Cost Charged to Department .................................................. Beginning inventory: Materials ............................................................................ Conversion cost .................................................................. Total cost in beginning inventory .............................. Cost added during period: Materials ............................................................................ Conversion cost .................................................................. Total cost added during period .................................. Total cost charged to the department..................................... Cost Accounted for as Follows Transferred to Blending Department .................................... Work in process, ending inventory: Materials ........................................ Conversion cost .............................. Total cost accounted for ...................... Units % Complete 100% Total Cost Quantity 10,000 45,000 55,000 40,000 9,000 6,000 55,000 40% Equivalent Units* $ 4,375 2,975 7,350 $ 11,795 6,181 17,976 25,326 $ $ Conversion Cost Unit Cost 49,000 43,600 $.33 .21 $.54 Unit Cost Total Cost $21,600 40,000 100% $.54 9,000 9,000 100% 40% $.33 .21 $2,970 756 3,726 $25,326 * Total number of equivalent units required in the cost accounted for section determined as follows: Equivalent units transferred out .............................................................................. Equivalent units in ending inventory ....................................................................... Total equivalent units ................................................................................................ Downloaded by Christine Eugenio (darkchristine22@gmail.com) Materials 40,000 9,000 49,000 Conversion Cost 40,000 3,600 43,600 lOMoARcPSD|13494386 98 Chapter 7 This problem is based on material presented in the Appendix to the chapter. PROBLEM 7. Spoilage With a Salvage Value in a Process Cost System With a Fifo Cost Flow Assumption. School Craft Petroleum Company uses a process cost system with a fifo cost flow assumption to account for production, which is manufactured in two departments. Units of product are started in the Cracking Department and then transferred to the Refining Department where they are completed. Units are inspected at the end of the production process in the Refining Department. Good units are transferred to finished goods inventory and spoiled units are transferred to a separate inventory account. Spoiled units are inventoried at their salvage value of $8 each, and the unrecoverable cost of spoilage resulting from an internal production failure is charged to the appropriate account. Data related to September operations in the Refining Department follow: Units in beginning inventory (60% materials, 30% labor, 30% overhead) ...................................... Units received from Cracking Department this period ...................................................................... Units transferred to the finished goods inventory this period ............................................................ Units transferred to special inventory account this period ................................................................ Units in ending inventory (100% materials, 50% labor, 50% overhead) ......................................... Costs charged to the department: ............................................................................. Cost from preceding department ....................................................................... Materials .............................................................................................................. Labor .................................................................................................................... Factory overhead ................................................................................................. Beginning Inventory $17,889 2,733 7,278 12,350 2,800 8,400 7,600 1,100 2,500 Added This Period $68,040 11,900 30,063 51,016 Required: Prepare a cost of production report for the Refining Department based on the data presented for September. Downloaded by Christine Eugenio (darkchristine22@gmail.com) lOMoARcPSD|13494386 The Cost of Quality and Accounting for Production Losses 99 SOLUTION School Craft Petroleum Company Refining Department Cost of Production Report For September, 19-Quantity Schedule Beginning inventory ............................................... Received from Cracking Department .................. Transferred to finished goods ............................... Ending inventory.................................................... Spoiled in process ................................................... Cost Charged to Department Beginning inventory: Cost from preceding department ................... Materials .......................................................... Labor .............................................................. Factory overhead ............................................. Total cost in beginning inventory ............ Cost added during current period: Cost from preceding department ................... Materials .......................................................... Labor .............................................................. Factory overhead ............................................. Total cost added during period ................ Total cost charged to the department................... Materials 60% Labor 30% 100% 100% 50% 100% Total Cost $ $ $ $ $ Overhead 30% Quantity 2,800 8,400 11,200 7,600 2,500 1,100 11,200 50% 100% Equivalent Units* Unit Cost 17,889 2,733 7,278 12,350 40,250 68,040 11,900 30,063 51,016 161,019 201,269 Downloaded by Christine Eugenio (darkchristine22@gmail.com) 8,400 9,520 9,110 9,110 $ 8.10 1.25 3.30 5.60 $ 18.25 lOMoARcPSD|13494386 100 Chapter 7 Cost Accounted for as Follows Transferred to finished goods: From beginning inventory .............. Cost to complete this period: Materials ............................. Labor ................................... Factory overhead ................ Started and completed this period .................................. Total cost transferred to Finishing Department ............... Transferred to spoiled goods inventory at salvage value ............... Charged to factory overhead for spoilage: Cost of completed spoiled units ............................................ Less salvage value of spoiled units ............................................ Work in process, ending inventory: Cost from preceding department ................................ Materials .......................................... Labor. .............................................. Factory overhead ............................. Total cost accounted for ........................ Units % Complete 2,800 2,800 2,800 40% 70% 70% 4,800 100% Unit Cost $ 1.25 3.30 5.60 Total Cost $ 1,400 6,468 10,976 $ 40,250 $ 59,094 $ 18.25 87,600 $ 1,100 1,100 $ 100% 100% 100% 50% 50% 8,800 $ 18.25 $ 20,075 8.00 8,800 8.10 1.25 3.30 5.60 $ 20,250 3,125 4,125 7,000 1,100 2,500 2,500 2,500 2,500 8.00 $ 146,694 11,275 $ 34,500 201,269 * Number of equivalent units of cost added during the current period determined as follows: To complete beginning inventory .................... Started and completed this period ................... Ending inventory............................................... Spoiled units ...................................................... Total equivalent units ....................................... Prior Dept. Cost 0 4,800 2,500 1,100 8,400 Materials 1,120 4,800 2,500 1,100 9,520 Downloaded by Christine Eugenio (darkchristine22@gmail.com) Labor 1,960 4,800 1,250 1,100 9,110 Overhead 1,960 4,800 1,250 1,100 9,110