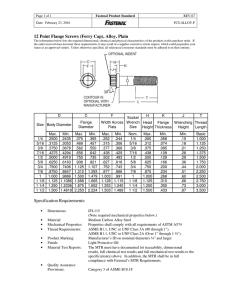

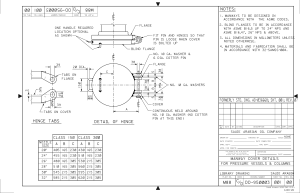

WRC Bulletin 538, Second Edition ISSN 2372-1057 WRC PVRC MPC The Welding Research Council, Inc. Determination of Pressure Boundary Joint Assembly Bolt Loads W. Brown Integrity Engineering Solutions INTENTIONALLY LEFT BLANK ii WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads WRC - The Welding Research Council brings together science and engineering specialists in developing the solutions to problems in welding and pressure vessel technology. They exchange knowledge, share perspectives, and execute R and D activities. As needed, the Council organizes and manages cooperative programs. MPC – A Council of the WRC, the Materials Properties Council is dedicated to providing industry with the best technology and the best data that can be obtained on the properties of materials to help meet today’s most advanced concepts in design and service, life assessment, fitness-forservice, and reliability and safety. PVRC – A Council of the WRC, the goal of the Pressure Vessel Research Council is to encourage, promote, and conduct research in the field of pressure vessels and related pressure equipment technologies, including evaluation of materials, design, fabrication, inspection, and testing. For more information, see www.forengineers.org WRC - The Welding Research Council brings together science and engineering specialists in developing the solutions to problems in welding and pressure vessel technology. They exchange knowledge, share perspectives, and execute R and D activities. As needed, the Council organizes and manages cooperative programs. WRC Bulletins contain final reports fromMPC projects by the Welding Research Council, important – A sponsored Council of the WRC, the Metal Properties Council is papers presented before engineering societies and other reports of current interest. dedicated to providing industry with the best technology and the best data that can be obtained on the properties of materials to help meet today’s most advanced concepts in design and service, life Noassessment, warranty offitness-for-service, any kind expressed implied, respecting and or reliability and safety. of data, analyses, graphs or any other information provided in this publication is made by the Welding Research Council, and the use of any such information is at the user’s sole risk. PVRC – A Council of the WRC, the goal of the Pressure Vessel Research Council is to encourage, promote and conduct research in the field of pressure Allvessels rights are reserved no partequipment of this publication may be reproduced, downloaded, disseminated, and related and pressure technologies, including evaluation of materials, design, or otherwise transferred in any form or by any means, including photocopying, without the express written fabrication, inspection and testing. consent of WRC. For more information, see www.forengineers.org Copyright © 2014 The Welding Research Council. All rights, including translations, are reserved by WRC. ISSN 2372-1057 Library of Congress Catalog Number: 85-647116 Welding Research Council 20600 Chagrin Blvd. Suite 1200 Shaker Heights, OH 44122 www.forengineers.org iii INTENTIONALLY LEFT BLANK iv WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads W. Brown Integrity Engineering Solutions v INTENTIONALLY LEFT BLANK vi WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads DEDICATION WRC Bulletin 538 is dedicated to the memory of Peter Davies. His mentorship and questioning mind helped to lay the foundations upon which the work in WRC 538 was built. The world has lost a great engineer and a wonderful, generous person, but he will not be forgotten. vii WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads FOREWORD Too often leakage and other failure of bolted joints in pressure vessels and piping have been ascribed to improper or inadequate preloading of the bolting. ASME PCC-1-2010 Appendix O “Assembly Bolt Stress Determination” was a major and long overdue step forward in assuring the integrity of bolted joints in pressure equipment. It required several years of dedicated effort on the part of a group of concerned individuals to see to it that the relevant aspects of sealing reliability were documented. To accomplish the goal the Pressure Vessel Research Council of WRC organized an activity capably led by Warren Brown to capture and evaluate the technology needed to support the procedures contained in PCC-1-2010. The purpose of this Bulletin is to assure that the “paper trail”, including the state of the art finite element analysis methods employed, leading to the ASME actions were documented and can be understood and retrieved in the future as a basis for further progress. Dr. Martin Prager Executive Director Welding Research Council viii WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads TABLE OF CONTENTS FOREWORD .....................................................................................................................................................VIII TABLE OF CONTENTS .................................................................................................................................... IX ABSTRACT ....................................................................................................................................................... 10 1 INTRODUCTION........................................................................................................................................ 11 2 HISTORY .................................................................................................................................................... 11 3 ASME PCC-1-2010 APPENDIX O METHOD EXPLANATION.............................................................. 12 4 USING ASME CODE EQUATIONS TO DETERMINE THE FLANGE LIMIT ....................................... 12 5 ELASTIC-PLASTIC FEA METHODS ...................................................................................................... 16 6 CONCLUSION ........................................................................................................................................... 18 7 REFERENCES ........................................................................................................................................... 23 8 APPENDICES ............................................................................................................................................ 24 8.1 8.2 8.3 APPENDIX A – ASME PCC-1-2010 APPENDIX O ERRATA .......................................................................24 APPENDIX B – GRAPHICAL REPRESENTATION OF F AND F2........................................................................25 APPENDIX C – EXAMPLE CALCULATIONS USING WRC 538 ......................................................................27 ix WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads ABSTRACT This WRC Bulletin chronicles the development of the methods detailed in ASME PCC-1-2010 Appendix O “Assembly Bolt Stress Determination”. It includes all the information necessary to enable engineers concerned with sealing reliability to reproduce and build on the work that went into that part of PCC-1. The intent is not to reproduce the method or to include all details of the development of the method. Instead it is to provide references to the documents written during the development of the method and to provide additional details to assist in the understanding and extension of the method in the future. This WRC Bulletin provides references to the historical development articles, an explanation of the basis for the method, a step-by-step guide as to how to apply the ASME code equations to determine flange limits, and a commentary on the Elastic-Plastic Finite Element Analysis (FEA) methods presented therein. The information presented will assist in developing general limits for acceptable bolt stresses that can be applied to flanged joints without damaging them. This is the case for both standard piping flanges and custom pressure vessel and heat exchanger flanges. By incorporating the equations outlined in this document, not only can the correct assembly bolt load be determined, but the joint can be designed such that it is not possible to over-stress the gasket or flanges. This approach vastly improves the practicality and reliability of the joint. By strictly following these procedures it will not be possible to permanently damage the joint during assembly or operation. The method presented also, enables determining which of a joint’s components are limiting. Absent that knowledge it is not possible to correct the root causes of joint leakage. Finally, the document provides important insight into gasket relaxation factors. 10 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 1 INTRODUCTION This WRC bulletin is intended to act as a reference to both chronicle the progression of and also to enable other individuals to reproduce and/or build on the work that went into the development of the method presently detailed in ASME PCC-1-2010 Appendix O “Assembly Bolt Stress Determination”. The intent is not to reproduce the method or to include all details of the development of the method, but to provide reference to the appropriate articles written during the development of the method and also to provide additional details to assist in the reproduction of the method. This WRC bulletin contains an historic reference outlining the development articles, an explanation of the basis for the method, a step-by-step guide as to how to apply code equations to determine the flange limit, and commentary on the Elastic-Plastic Finite Element Analysis (FEA) methods used. 2 HISTORY The development of the current methods outlined in ASME PCC-1-2010 Appendix O for the determination of the assembly bolt load for pressure boundary joints commenced in early 2005 and was a direct result of field experience at Chevron with excessive flange deformation (flange rotation) on piping joints, particularly when assembled to high initial bolt loads. The method built on previous work by Brown on the selection of an appropriate assembly bolt load that involved the consideration of appropriate gasket stress limits [1]. That work considered only the gasket and bolt limits, and neglected the potential for the flange to be the limiting factor. Although this approach worked in most cases, it was found that excessive flange deformation occurred in enough cases to initiate the question as to what an appropriate limit for the joint as a whole (including the flange) should be. This led to the publication of the initial paper on the topic by Brown in 2006 [2], which presented background on the need for inclusion of a flange limit in the calculation of assembly bolt load and outlined an initial method, based on a limit on flange radial stress. However, the paper also indicated that the radial stress limit did not appear to be valid for all cases and that a more comprehensive method would require expansion of the ASME flange design equations [3] to include the tangential (hoop) stress at the shell to hub junction. A follow-up paper by Brown in 2007 [4] presented the method for determining the flange stress at that location, as well as a series of limits on all code flange stress locations that enabled the user to determine the assembly bolt stress where Gross Plastic Deformation (GPD) of the flange would be expected. The developed equation and limits were verified by comparison to Elastic-Plastic Finite Element Analysis (FEA) results for ASME B16.5, SA105, weldneck flanges from NPS 2 to NPS 24 in pressure classes 150, 300, 600, 900, 1500, and 2500. The results were also verified by comparison to Elastic-Plastic FEA on ASME B16.47, SA 105, Series A, weldneck flanges from NPS 26 to NPS 48 in pressure classes 150, 300, 600 and 900. In both cases, standard spiral wound gasket dimensions as per ASME B16.20 were used in the analysis. For piping flanges using similar gaskets and having similar wall thickness to those analyzed in the paper, the Elastic-Plastic FEA results could be used directly for the flange limit in the calculation of the joint assembly bolt stress. For non-standard flanges and flanges having significant difference in gasket or pipe wall thickness, the code equation calculation contained in the paper offered a method of determining the flange limit. However, in developing the limits, incorrect material properties were used in the comparison between the FEA and the code equations, which led to the code equation limits listed in the paper being overly conservative. In a paper presented by Brown the following year [5], the method was further developed to include FEA of other materials (SA182 F304), and the limits for the code calculation method were corrected to reflect comparison against the correct FEA material results. These two updates to the method finalized the work with respect to determining the flange limit for calculation of joint assembly bolt load for weldneck flanges. The information contained in the papers written to that point was sufficient to allow determination of the approximate point of GPD for a weldneck flange. The ASME codes, and others, use the same equations (weldneck flange) to assess a range of configurations, from a true weldneck flange (having an integral butt welded, tapered hub) to slip-on flanges (where the hub is fillet welded to the shell). This method may be used to approximate the behavior of slipon flanges and also integral flanges having only a radius at the hub junction. In the latter case, the approximation will be acceptable. In the case of the slip-on flange, the assessment will be non-conservative in some cases. The case of a loose ring flange can be addressed in the same way as the ASME code, with only the tangential stress (ST) being calculated and by using the same limits as outlined in this document. A more accurate method for determination of slip-on flange strength and confirmation of the method for loose flanges or flanges without hubs 11 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads can be found in Brown [6]. The information and tables contained in the final paper were incorporated directly into ASME PCC-1-2010 Appendix O. Further background and commentary on the method is outlined in Brown [7]. It should be noted that the guidance provided in ASME PCC-1 Appendix O is intended to serve as an example only. By using this WRC bulletin, it is possible to calculate actual specific cases or a general case for all piping joints at a given site. The risk with using the values presented in Table O-8 of Appendix O is that they may not apply to the actual case (for example the wall thickness of the pipe on the joint being considered may be much less than the value used for the Appendix O calculation). Generally, the limits used to generate Table O-8 were higher than might typically be used on piping joints, in order to provide an example that would not be taken as an absolute limit (or rather, would not limit the actual case, if interpreted as an absolute limit). An appendix has been added to this document (Appendix A), which outlines four errata to the current (2010) version of Appendix O that will be corrected in the next revision. 3 ASME PCC-1-2010 APPENDIX O METHOD EXPLANATION The basic premise of the method outlined in ASME PCC-1-2010 Appendix O is that in order to avoid joint leakage, the joint must be assembled to a bolt stress level which provides adequate stress to seat the gasket, adequate stress to provide sufficient residual stress on the gasket during operation and also be sufficiently low such that no damage occurs to any of the joint components during assembly or operation. Using this concept, for most joints, results in a band of acceptable assembly bolt stress values which may be expected to work as shown in Fig. 1, taken from Brown [1]. 0% Sy Bolt (No Load) Gasket Stress Lost due to Thermal Loading Gasket Stress Lost due to Pressure & Ext. Load ing Z% Sy Bolt (Max. Permissible Load) Y% Sy Bolt 100% Sy Bo lt (Assembly Load) (Max. Possible Load) X% Sy Bolt Operational (Min. Req’d Load) Load Gasket Stress Required to Seal Gasket Buffer against leakage % Sy Bo lt remain ing during operation Gasket Stress lost due to Creep/Relax. % Sy Bo lt lost during operation -ve +ve Buffer against joint damage Bolt Load +/- Assembly Technique and Procedure Accuracy Figure 1 – Bolt Assembly Load Selection Criteria In order to determine the lower limits of assembly bolt stress levels, several gasket properties must be known, such as minimum seating stress, percentage gasket relaxation, and minimum stress during operation. None of these values presently have an industry standard test, and therefore it is not possible to completely codify the method at present. However, as tests are developed to establish the required information, this should be possible. To establish the upper limits on assembly bolt stress (joint component damage), the maximum acceptable gasket stress, and the maximum allowable assembly bolt stress that the flange will withstand must be known. There is not presently an acceptable standard test method for establishing the maximum acceptable gasket stress. Since the gasket values are not well defined, this bulletin will focus more on the establishment of the maximum acceptable bolt stress, based on the flange limit. 4 USING ASME CODE EQUATIONS TO DETERMINE THE FLANGE LIMIT The details outlined in this document assume that the user is familiar with the ASME flange design method outlined in Appendix 2 of ASME [3]. The equations from that document will not be reproduced here, only the additional required equations and the basic structure of the calculation and limits will be presented. The method consists of calculating the flange stress levels at the following combinations of flange geometry 12 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads location and associated stress orientation: a) Longitudinal Hub Stress at Hub/Flange Junction ( S H b) Longitudinal Hub Stress at Hub/Shell Junction ( S H , existing ASME Equation [6]) c) Radial Stress at Hub/Flange Junction ( S R , existing ASME Equation [7]) d) Tangential Stress at Hub/Flange Junction ( ST , existing ASME Equation [8]) e) Tangential Stress at Hub/Shell Junction ( STO , New Equation) f , modified existing ASME Equation [6]) The stress component locations are shown in Fig. 1. The reason for the use of the modification capture the stress at the hub/flange ring junction, versus SH f is to S H , which is at the hub/shell junction for values of f greater than one. The modification mentioned above to the hub longitudinal stress is to divide the calculated value by the hub stress correction factor f . This factor is either equal to or greater than one. When equal to one, the calculated stress is at the hub/flange junction. When greater than one, the calculated stress is at the hub/shell junction. By dividing by f , the value of longitudinal hub stress at the hub/flange junction is always found. The stress at the hub/shell junction will be over-predicted in cases where f equals one. It is not possible to determine the stress at the hub/shell location using values of f less than one, because the equation for f becomes inaccurate below one. However, it was found that the level of conservatism introduced by overestimating the tangential stress at the hub/shell junction, which occurs in some cases, was minimal. The only other modification to the standard Appendix 2 equations is that the moment M O used in the calculations is taken as per the equation below: M O B Ab hG where B (1) = the selected assembly bolt stress (MPa, psi) Ab = the total bolt root area (mm2, in2) per Appendix 2, Notation hG = gasket to bolt moment arm, per Appendix 2, Table 2-6 The method for calculating STO STO is per the equation below: f2 SH f (2) where f = the hub stress correction factor, per Appendix 2, Fig. 2-7.6 or the below equation. The below equation for f is provided as an alternative to the Appendix 2 equation, in order that the expressions for f and f 2 can have the same base equation. The two relationships (below and Appendix 2) agree across the full range within 3%. f 2 = a second hub stress correction factor, determined per the equation below: 13 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 2 2 g1 h g1 h g h a +c +e +g +i +k 1 g0 h 0 g0 h 0 g 0 h 0 fn 2 2 g1 h g1 h g h 1+b +d +f +h +j 1 g0 h 0 g0 h0 g 0 h 0 (3) And f max 1.0, f1 f 2 max 0.25, f 2 for h 0.35 h0 f 2 max 0.25, f3 for h 0.35 h0 where the definition of g1 , g 0 , h and h0 are as per ASME Appendix 2 and the constants a through k , for each of the f variables, are defined per the table below: Graphical representations of f and f 2 are shown in Appendix B of this document. These plots are similar to the existing plots of f in ASME VIII, Div. 1, Appendix 2. f f2 f3 a -0.71375912 -0.01447638 -0.06456312 b -0.12846279 -0.27814745 -0.08232239 c 1.08037907 0.01035395 0.13691677 d 0.99766848 1.37984158 -0.77879888 e 1.21823466 -0.34346764 0.14909019 f 0.01024612 0.02536192 0.00660062 g 0.4262313 -0.00145080 0.06162520 h 1.42049760 2.25543162 0.74639834 i -0.70278181 -0.60889597 -0.07959500 j -0.02483937 -0.15735462 0.09851673 k -1.59460436 1.22516062 -0.11214360 By using the equations below and those contained in ASME Appendix 2, the stress levels at the following locations can be compared with the limits listed following them. Note that the limits are based on material yield at assembly (ambient) temperature S . ya In addition, it should be noted that these limits are selected with the expectation that some localized yielding of the flange is acceptable and does occur in most flange cases when assembled to sufficient bolt stress to ensure joint integrity. The limits are applied using the elastic equations and, 14 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads therefore, indicate stress levels that are well above yield. However, they have been verified against ElasticPlastic FEA to be below the point of GPD for the flange, which is the true limit of flange strength (as opposed to localized yielding, which has no effect on flange strength). a) Longitudinal Hub Stress: SH 2.0S ya b) Tangential Stress at Hub/Flange Junction: ST 1.5S ya c) Tangential Stress at Hub/Shell Junction: STO 1.0S ya d) Combined Stress at Hub/Flange Junction: e) Combined Stress at Hub/Flange Junction: f) Combined Stress at Hub/Shell Junction: SH f ST 3.0S ya SR ST 3.0S ya SH STO 3.0S ya g) Radial Stress at Hub/Flange Junction: SR 2.0S ya In order to determine the flange limit on assembly bolt stress S f max , the assembly bolt stress is increased until one of the above limits is exceeded. The above limits were determined by comparison to Elastic-Plastic FEA results and give, in most cases, a result that is within 10% of the value calculated using Elastic-Plastic FEA. This is considered sufficiently accurate for the intended purpose. When considering these limits by comparison to pressure vessel and piping design practices it is necessary to remember that the flange stresses are predominantly controlled by the bolt load. The bolt load is set at assembly and creates secondary stresses in the joint, since once assembled the joint deformation is displacement controlled. Therefore, the presence of localized portions of the flange at yield should not be a concern. Under repeated assembly and operational cycles the flange will shake-down to a final stress state where no further yielding occurs. The above stress limits are chosen with this in mind and will seem excessive by comparison to present flange design stress limits, due to the different intent of the flange design method (to adequately size the flange) versus this method (to determine the strength of the flange). A more practical measure to use for flange design would be the method contained in this document, with the flange stresses calculated at bolt yield. This would ensure that the flange was never the limiting strength component of the joint. The preceding limits are for the flange assembly case. Typically this is the controlling case, since gasket relaxation will result in a much lower residual bolt stress during subsequent joint operation. However, in cases where the flange yield strength will be reduced by a greater amount than the expected joint relaxation, it is necessary to also consider the flange operating case. In order to do that, (in ASME PCC-1-2010) in all cases analyzed during the development of this method, including piping, pressure vessel, and heat exchanger flanges, the Radial Stress (SR) was never found to control on its own. It is included here as a limit in order to reflect the stress checks currently performed in ASME VIII, Div. 1, Appendix 2. In some cases (e.g., high temperature stainless steel flanges) the yield strength of the flange may reduce significantly during operation. In those cases, the flange limit should be reduced by the ratio of the yield S f max S yo S ya . A useful ratio for determining if this adjustment must be performed is to compare the reduction in yield to the amount of relaxation occurring, and if the reduction ratio exceeds the relaxation, the effect should be included. This check is expressed as follows: the reduction factor should be included if S yo S ya 1.25 g . The additional reduction in gasket relaxation (1.25 term) is included to capture possible variances in actual relaxation versus test or assumed values. The change made between this version and ASME PCC-1-2010 is the use of a “<” rather than a “>” sign, and the change to the remaining relaxation factor (rather than the relaxation loss factor). Practically, the above consideration can be implemented by the following modification to the preceding limits: 15 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads S y = the lesser of S ya or S yo and S yo = the greater of S yo 1.25 g or S yo Where g is the gasket relaxation factor from PCC-1 Appendix O (typically taken as 0.7 unless gasket test data is available), S ya is the assembly (ambient) temperature yield of the flange material and S yo is the operating temperature yield of the flange material. a) Longitudinal Hub Stress: SH 2.0S y b) Tangential Stress at Hub/Flange Junction: ST 1.5S y c) Tangential Stress at Hub/Shell Junction: STO 1.0S y d) Combined Stress at Hub/Flange Junction: e) Combined Stress at Hub/Flange Junction: f) Combined Stress at Hub/Shell Junction: SH f ST 3.0S y SR ST 3.0S y SH STO 3.0S y g) Radial Stress at Hub/Flange Junction : S R 2.0S y 5 ELASTIC-PLASTIC FEA METHODS The FEA that was performed to establish GPD limits for different flange configurations was based on axisymmetric approximation of the flange geometry. The reduction in accuracy by assuming axisymmetric behavior was more than offset by the reduction in assessment time, which was significant given the large number of FEA assessments required. It should be noted at this point that a sensitivity study into such factors as the element order, contact assumptions, and mesh density was performed subsequent to the finalization of the results. It was found that, depending on the assumptions made, the answer for the point of GPD could be made to vary by 2 to 3% between different identical geometry models. However, this variation, while significant from an academic sense, was well within the accuracy of other factors that commonly occur in bolted joint practice. Three such factors are: a) b) c) The effect of assembly method inaccuracy on achieved bolt load. This factor is well documented and commonly the achieved accuracy for controlled joint assembly is within the ±10% to ±30% range. The as-delivered material yield strength versus the minimum specified strength is often around 70 MPa (10ksi) higher. For common flange materials, this means that the actual GPD is likely to be around 30% higher than the GPD calculated using the minimum specified yield strength. For standard piping flanges, the exact shape of the hub is not well defined in the B16.5 and B16.47 standards. The hub height, h, can be varied from the full height of the flange to a minimum 45° angle hub. The difference in strength between a full height hub and a 45° hub can be significant. For an NPS 20, cl.150 flange, Elastic-Plastic FEA demonstrated that the 45° hub had a maximum allowable assembly bolt load of less than 30% of the full height hub geometry flange. Most suppliers tend to deliver flanges with hubs closer to the full height condition. For this reason, it was assumed in the analysis conducted that the hub height corresponded to the full possible height. It should be noted that this may not be conservative in all cases, depending on the flange supplier. As can be seen from the above factors, it would be very easy to over think this problem and end up with so many variations of flange limits, for every different possible combination, that the end result would not be practical or usable. The intent of the FEA work was, therefore, to provide a basis upon which an approximate code equation method could be verified such that, if desired, other variables could be incorporated into the assessment on an as-needs basis using the code equation method. The goal was to achieve agreement between the methods of 16 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads around ±10% in order to be satisfied that both methods resulted in an answer that would be sufficiently accurate for the purposes of selecting an assembly bolt load. The following FEA modeling simplifications/assumptions were made in order to facilitate the assessment and/or to achieve as accurate as possible a result: 1) The flange geometry was taken from the appropriate ASME standard, with the assumption that the hub height was a full height hub. One half of the flange pair was modeled, with symmetry being assumed through the central plane of the gasket. 2) The gasket sealing element geometry was taken as a spiral wound gasket in accordance with ASME B16.20. The inner and outer rings were not modeled, so any possible contact between the flange and those components was neglected. 3) The FEA models were constructed using first-order axisymmetric elements for the flange, first-order plane stress elements for the bolts/nuts, and Abaqus gasket elements with normal direction behavior only (GKAX4N) (See Fig. 3). 4) The gasket element elastic behavior was taken from flat-platen room temperature testing of a spiral wound gasket (see Fig. 4). 5) The gasket element surfaces were tied to the flange raised face. Since the gasket elements used do not allow tension or shear to be generated this has no effect in terms of overly restraining the joint, as would be the case with other methods of modeling the gasket. 6) The nut width was taken as the across flats dimension of the appropriate size standard heavy hex nut. 7) In general, the contact between the flange and the nut was modeled as rough friction with no lateral movement and the ability to separate after contact. This means that the reaction point between the nut and the flange will move inward as the flange is loaded and rotates. In a very few cases, however, it was necessary to tie the nut to the flange in order to achieve convergence. Those cases will slightly under-estimate the point of GPD due to the additional restraint in movement. 8) The width of the bolt, as modeled with Plane Stress elements, was taken as ¾ of the actual bolt diameter in order that the bending moment of inertia for the plane stress representation was identical to the actual multiple cylindrical bolt cross-section. This bending is due to flange rotation and is significant in that it controls the amount of movement of the nut reaction point inward as the flange rotates. 9) The depth of the plane stress elements was calculated in order that the overall total area of the elements matched the total tensile area of the flange bolts. Note that root area was not used (as is required in code calculations) as the tensile area is considered to be more appropriate in terms of actual joint elastic interaction behavior. However, particularly in the larger size flanges, the two areas could be interchanged without significant effect on the end result. 10) The bolt load was applied using the “*Pretension” command in Abaqus. This command reduces the length of the elements across a plane on the bolt until the desired preload is established. The load was applied in 35 MPa (5ksi) increments until GPD was found. 11) The point of GPD was determined from the FEA results as the FEA step where the slope of the change in flange rotation versus applied bolt load was greater than two times the initial elastic portion of the slope (See Fig. 5). 12) The bolt-hole region of the flange was modeled using anisotropic elastic material properties. Since the stress levels in that region did not typically approach yield, the use of elastic properties should not have affected the obtained GPD value. The material properties (subscripts indicate direction, as per the code equations) used were: Tangential Young’s Modulus = Very Small Value (Negligible) Radial and Longitudinal Young’s Modulus = E f Radial/Longitudinal Shear Modulus = Radial and Longitudinal Young’s Modulus / 2.6 Other Shear Moduli = Very Small Value (Negligible) where E f = Young’s Modulus, nb = number of bolts, d bh = diameter of bolt hole, C = bolt pitch circle diameter This results in the following values for each of the materials used in this study: 17 1 0.25 n b dbh C WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads Material Young’s Modulus Young’s Modulus (Tangential) ET ER and EH Shear Modulus GRH GRT and GTH SA-105 SA-182 F304 202,500 MPa 193,500 MPa 1 MPa 1 MPa 151,875 MPa 145,125 MPa 58,413 MPa 55,817 MPa 0.5 MPa 0.5 MPa 13) The Elastic-Plastic stress-strain behavior was taken from ASME II-D material properties for SA-105 and SA-182 F304 materials using the MPC method outlined in ASME Section VIII Div. 2 (see Fig. 6). Further examples of FEA plots are shown in Fig. 7 to Fig. 9. The plots are chosen to highlight different categories of stress component limits and are provided for information only, since the actual GPD point was determined purely from flange rotation results. The first plot is of a standard NPS 20, cl.150 flange, which has GPD occurring at the hub to shell junction STO . The second plot is of a 24 inch heat exchanger joint, which has two different flanges. One of them has GPD occurring at the hub to shell junction direction SH . combination of STO and the other at the hub in the axial The final example is a B16.47 Series A, NPS 46, cl. 300 flange, which shows failure due to the SH and ST . Examples of the calculations outlined in this WRC bulletin for some standard flanges are shown in Appendix C, for information. 6 CONCLUSION The information presented in this WRC bulletin will assist in developing general limits to the acceptable bolt stress that can be applied to flanged joints without damaging them. This is the case for both standard piping flanges and custom pressure vessel and heat exchanger flanges. By incorporating the equations outlined in this document, not only can the correct assembly bolt load be determined, but in fact at the design stage, the joint can be designed such that it is not possible to over-stress the gasket or flanges. This vastly improves the practicality of the joint, in that it will therefore not be possible to overstress and permanently damage the joint during assembly or operation. In addition, the method outlined is essential for determining the root cause of joint leakage, since without knowledge as to which of the joint components, if any, are limiting, it is not possible to categorically identify the root cause of joint leakage. 18 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads Figure 2 – Flange Stress Component Locations First-order Axisymmetric Radial Stress Hoop Stress Axial Stress Gasket Elements Plane Stress Elements Figure 3 – FEA Model Plot (NPS 12, cl.300 flange) 19 First-order Axisymmetric Anisotropic Properties WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads Gasket Stress (MPa) LOADING mm MPa 0.000 0.0 0.024 9.6 0.102 21.8 0.479 34.1 0.774 46.8 1.000 64.6 1.250 99.9 UNLOADING 1 0.708 0.0 0.749 10.0 0.762 22.5 0.770 35.3 0.774 46.8 UNLOADING 2 1.202 0.0 1.233 19.8 1.239 39.9 1.244 59.8 1.247 80.2 1.250 99.9 Figure 4 – Gasket Mechanical Behavior Flange Rotation (degrees) 0 -0.5 -1 -1.5 -2 Rotation (deg) Normalised on Load -2.5 -3 0 0.2 0.4 0.6 0.8 Bolt Stress / Yield 1 1.2 Figure 5 – Example Flange Rotation vs. Bolt Load Plot (NPS 16, cl.300) 20 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 500 450 400 Stress (MPa) 350 300 250 SA182 F304 200 SA105 150 100 50 0 0.00E+00 2.00E-02 4.00E-02 6.00E-02 8.00E-02 1.00E-01 Strain Figure 6 – Flange Material Elastic-Plastic Properties Strength Limited by ST0 Sh ST SR Sh ST SR Figure 7 – 20in., cl.150, SA182-F304 FEA Results (MPa) 21 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads Strength Limited by ST0 ST Sh ST Sh ST Strength Limited by ST0 ST Strength Limited By SH Strength Limited By SH Sh Sh Figure 8 – 24in. Heat Exchanger FEA GPD Results (psi) von Mises Sh Sh Strength Limited By (SH + ST) Figure 9 – 46in., Cll.300, SA182-F304 FEA Results (MPa) 22 ST ST WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 7 REFERENCES 1. Brown, W., 2004, “Efficient Assembly of Pressure Vessel Bolted Joints” Proceedings of the ASME PVP 2004, ASME, San Diego, USA 2. Brown, W., Reeves, D., 2006, “Considerations for Selecting the Optimum Bolt Assembly Stress For Piping Flanges”, Proceedings of the ASME PVP 2006, ASME, Vancouver, Canada, PVP2006-ICPVT11-93094 3. ASME. 2007, ASME Section VIII, Division 1, Boiler and Pressure Vessel Code, American Society of Mechanical Engineers, NY, USA 4. Brown, W., Reeves, D.., 2007, “An Update on Selecting the Optimum Bolt Assembly Stress For Piping Flanges”, Proceedings of the ASME PVP 2007, ASME, San Antonio, Texas, PVP2007-26649 5. Brown, W., 2008, “Selecting the Optimum Bolt Assembly Stress: Influence of Flange Material on Flange Load Limit”, ASME PVP Conference, Chicago, IL, PVP2008-61709 6. Brown, W., 2008, “Selecting the Optimum Bolt Assembly Stress: Influence of Flange Type on Flange Load Limit”, ASME PVP Conference, Chicago, IL, PVP2008-61708 7. Brown, W., 2010, “Background on the New ASME PCC-1-2010 Appendices D & O Guidelines for Allowable Gasket Contact Surface Flatness and Defect Depth &Assembly Bolt Load Selection”, ASME PVP Conference, Bellevue, WA, PVP2010-25766 8. ASME PCC-1-2010 “Guidelines for Assembly of Pressure Boundary Bolted Joints”, ASME, NY, 2010 23 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 8 APPENDICES 8.1 Appendix A – ASME PCC-1-2010 Appendix O Errata Errata #1 – Usage of the flange rotation limit (gmax) is not consistent throughout the appendix. The definition implies that the limit is associated with the sum of the mating flange rotations, but the limits listed in O-4.1(a) are for single flanges and the flange rotation levels listed in the Tables (O-3, O-5, and O-7) are for single flanges. The limit definition and references throughout the Appendix should be changed to ensure it is clear that the limit applies to single flange rotation. Therefore, for a flange pair, the gasket will see the combined rotation of both flanges, but each flange will be checked independently against the flange rotation limit. Errata #2 – The incorrect WRC bulletin (WRC 528) was referenced in Appendix O, it should be this bulletin (WRC 538). Errata #3 – The incorrect method was used to determine if the reduction in flange material yield should be accounted for in an assessment. The correct method is as per outlined in this WRC bulletin. Errata #4 – The incorrect limits were used to create Tables O-4M and O-4. The corrected tables, using the flange stress limits defined in this document, are as follows: Table O-4M Replacement 150 300 2 450 310 2.5 576 284 3 724 394 4 445 561 5 402 724 6 541 593 8 724 614 10 503 639 12 712 607 14 583 454 16 563 398 18 614 472 20 568 451 24 479 365 26 218 242 28 193 264 30 228 290 32 173 272 34 160 296 36 207 261 38 211 557 40 199 536 42 218 581 44 221 676 46 238 724 48 222 524 600 515 388 545 633 663 630 657 566 563 513 508 594 482 450 359 354 447 396 463 404 623 634 626 638 687 605 900 332 377 517 417 468 543 463 444 494 526 532 534 545 546 448 399 465 460 418 436 551 532 585 570 563 625 1500 413 441 432 492 528 605 576 627 554 485 487 521 501 481 Table O-4 Replacement 150 2 65 2.5 83 3 105 4 65 5 58 6 78 8 105 10 73 12 103 14 84 16 82 18 89 20 82 24 69 26 32 28 28 30 33 32 25 34 23 36 30 38 31 40 29 42 32 44 32 46 35 48 32 2500 447 496 531 454 501 535 557 543 594 24 300 45 41 57 81 105 86 89 93 88 66 58 69 65 53 35 38 42 40 43 38 81 78 84 98 105 76 600 75 56 79 92 96 91 95 82 82 74 74 86 70 65 52 51 65 58 67 59 90 92 91 93 100 88 900 48 55 75 61 68 79 67 64 72 76 77 77 79 79 65 58 67 67 61 63 80 77 85 83 82 91 1500 60 64 63 71 77 88 83 91 80 70 71 76 73 70 2500 65 72 77 66 73 78 81 79 86 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 8.2 Appendix B – Graphical Representation of f and f2 h/(sqrt(B.g 0) 0.05 0.1 f (longitudinal stress factor) 0.2 0.3 10 0.35 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 1 1 2 3 g1/g0 25 4 5 h/(B*g0) 0.5 h/(B*g0) 0.5 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 2.5 h/(sqrt(B.g 0) 0.05 0.1 0.2 0.3 0.35 0.4 f2 (hoop factor) 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 0.25 1 2 3 g1/g0 26 4 5 h/(B*g0) 0.5 h/(B*g0) 0.5 WRC Bulletin 538 Determination of Pressure Boundary Joint Assembly Bolt Loads 8.3 Appendix C – Example Calculations Using WRC 538 The below examples are presented for comparison purposes, dimensions are in mm and results in MPa. They are calculated using a flange yield stress of 345 MPa. Flange Size Flange Class Flange Spec Pipe Outside Diameter (mm) Pipe Wall Thickness (mm) Flange Bore (mm) Flange Outside Diameter (mm) Hub Outside Diameter (mm) Hub Thickness at Flange Ring (mm) Flange Thickness (mm) Hub Height (mm) Bolt Circle Diameter (mm) Bolt Diameter (mm) Bolt Area (mm²) Number of Bolts Gasket Inner Diameter (mm) Gasket Outer Diameter (mm) Flange Young's Modulus (MPa) Poisson’s Ratio Hub Thickness Ratio Hub Length Ratio Axial Stress Hub Factor Hoop Stress Hub Factor Basic Gasket Width (mm) Effective Gasket Width (mm) Gasket Reaction Diameter (mm) Gasket Moment Arm (mm) Bolt Stress (MPa) Bolt Load (N) Axial Stress (MPa) Radial Stress (MPa) Tangential Stress at hub/flange (MPa) Tangential Stress at hub/shell (MPa) Flange Rotation @ W NPS Class ASME Pipe OD g0 B A X g1 t h C b Ab nb Gask ID Gask OD E Poisson’s g1/g0 h/ho f f2 b0 b G hG Sb W SH SR ST STO f 27 44 150 B16.47A 1117.6 9.5 1098.5 1405.0 1145.0 23.2 100.4 76.0 1314.0 38.1 906.5 40 1124.0 1165.2 202500 0.3 2.4 0.7 1.00 0.59 10.3 8.1 1149.0 82.5 221 8025408 418 45 295 245 0.9 16 300 B16.5 406.4 7.9 390.6 647.7 483.0 46.2 55.6 88.8 571.5 31.8 599.3 20 422.4 463.6 202500 0.3 5.8 1.6 1.00 0.79 10.3 8.1 447.4 62.0 399 4785057 312 370 194 245 0.4 24 300 B16.5 609.6 14.3 581.1 914.4 701.0 60.0 68.3 98.1 812.8 38.1 906.5 24 628.7 685.8 202500 0.3 4.2 1.1 1.42 0.93 14.3 9.5 666.8 73.0 365 7950404 374 335 165 245 0.4 12 900 B16.5 323.9 17.5 288.9 609.6 419.0 65.0 79.2 120.8 533.4 34.9 745.2 20 323.9 368.3 202500 0.3 3.7 1.7 1.00 0.27 11.1 8.4 351.5 90.9 494 7368113 393 490 246 107 0.2 INTENTIONALLY LEFT BLANK 28 WRC PVRC MPC The Welding Research Council, Inc. The Welding Research Council brings together science and engineering specialists in developing the solutions to problems in welding and pressure vessel technology. They exchange knowledge, share perspectives, and execute R & D activities. As needed, the Council organizes and manages cooperative programs.