Hybrid Piezoelectric & Electromagnetic Energy Harvesting Analysis

advertisement

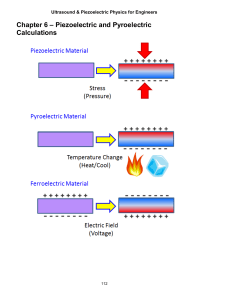

Microsyst Technol (2015) 21:401–414 DOI 10.1007/s00542-013-2030-6 TECHNICAL PAPER Modeling and analysis of hybrid piezoelectric and electromagnetic energy harvesting from random vibrations Ping Li • Shiqiao Gao • Huatong Cai Received: 5 November 2013 / Accepted: 3 December 2013 / Published online: 15 December 2013 Ó Springer-Verlag Berlin Heidelberg 2013 Abstract We illustrate electroelastic modeling, analysis and simulation solutions, and experimental validation of hybrid piezoelectric (PE) and electromagnetic (EM) energy harvesting from broadband random vibration. For a more practically available ambient source, the more compact expressions of mean power and spectral density (SD) involving dimensionless parameters are derived when the harvester is subjected to random excitation. In the study, it is assumed that the base excitation is white noise. Then, the effect of acceleration SD, load resistance, coupling strength on harvester performances are analyzed by numerical calculation and simulation, and the results are validated by the experimental measurements. It is founded that, only if the load resistance of PE and EM element meet the impedance matching can the hybrid energy harvester output the maximal mean power and spectral density at the resonant frequency, which increases with PE load resistance increasing, but hardly affected by load resistance of EM element; the variation extent of mean power with SD of acceleration increasing varies with the load resistance, and it is up to the maximum under the condition of optimal load; moreover, the stronger the coupling strength is, the wider the frequency band becomes, and the greater the mean power and power spectral density are, while the increasing extent decreases with the coupling strength increasing. Besides, the coupling strength can affect the internal resistance of harvester. Furthermore, with coupling strength increasing, the decreasing degree of mean power falls when the load resistance is greater than the optimal load. P. Li (&) S. Gao H. Cai State Key Laboratory of Explosion Science and Technology, School of Mechatronical Engineering, Beijing Institute of Technology, Room.109, Teaching Building 3#, Haidian District, Beijing 100081, China e-mail: gstwliping@126.com 1 Introduction As wireless sensor network and low power devices have been growing remarkably in recent years, it makes possibility to harvest energy of environment to replace chemical batteries that raise maintenance, environment issues and size (Ling et al. 2013; Karami and Inman 2012; Nicholas and Natarajan 2013). Therefore, it is a research focus on converting the vibration energy into electrical energy, and three mechanisms have been proposed: piezoelectric, electromagnetic and electrostatic (Harne and Wang 2013; Mitcheson et al. 2007). Electrostatic energy harvesters need the initial voltage to start harvesting normally, so it can not work independently. Then, piezoelectric energy harvester and electromagnetic energy harvester are got much more attention as they have high electromechanical coupling effect and no external voltage source requirement; furthermore, they can be fabricated by MEMS technology. Shu and Lien (2006) Much of work has been done for piezoelectric and electromagnetic energy harvesters, for example, the structure design (Liua et al. 2011; Liu et al. 2012), fabrication process by MEMS or traditional technique (Hatipoglu and Urey 2010; Wang et al. 2012), mathematics modeling (Williams and Yates 1996; Erturk and Inman 2008; Karami and Inman 2011; Cheng et al. 2007), power optimization methods (Cho et al. 2005; Wu et al. 2009; Guyomar and Lallart 2011), and energy storage and manage circuit (James and Paul 2012; Yogesh and Anantha 2010). However, from the results in the former study, although the voltage of piezoelectric energy harvester can up to several or tens of volts, the output current is only few microamperes. On the contrary, the electromagnetic energy harvest can output hundreds of microamperes, but its voltage is too small to meet the needs of most devices. The 123 402 disadvantages of the two kinds of energy harvesters limit the application ranges seriously. Therefore, researchers proposed the vibration energy harvester that combined piezoelectric and electromagnetic harvesting mechanism, which reaps the benefits of advantages of single harvesting mechanism simultaneously (Torsten and Armaghan 2010; Wu et al. 2008). For hybrid PE and EM energy harvester, the research works mainly focused on the structure design and performance validation at present. Wacharasindhu and Challa tested their designed hybrid piezoelectric-electromagnetic energy harvester respectively and concluded that output power of hybrid energy harvester is more than that of single piezoelectric or electromagnetic energy harvester (Wacharasindhu and Wkwon 2008; Challa et al. 2009). Yang et al. assumed that power of hybrid energy harvester was equivalent to the power consumed by electrical damping in their researches, and they also studied the output characteristics of hybrid energy harvester and proposed several optimization design methods, but they did not consider the electromechanical coupling effect in the analysis (Yang et al. 2010; Tanesse et al. 2009; Robert et al. 2008). The above researches are mostly based on the harmonic excitation, which is a simple and rather idealized representation of real-world ambient vibrations, but the practical application environments of vibration energy harvester mostly are broadband random excitation (Cottone et al. 2012; Blystad et al. 2010). Thus, research on performances of energy harvester under random vibration excitation has much more practical significance. Zhao established the model of piezoelectric energy harvest excited by the random vibration for the cantilever beam structure, and tested the output power under white noise excitation (Zhao and Erturk 2013). Adhikari et al. (2009) analyzed mean power of piezoelectric energy harvester in Gaussian white noise excitation through solving two-dimensional stochastic difference equation, and the results showed that in order to get the maximum power, mechanical damping should be reduced and SD of acceleration should be increased. Tang comparatively studied performances of SDOF (singledegree-of-freedom) piezoelectric energy harvester for the double mass and single mass structure. It’s illustrated that their mean power are the same under random excitation when the mass of block is equal to each other for the two harvesters, but their power is different under the sinusoidal excitation (Tang and Zuo 2012). Halvorsen studied amplitude, power and optimal load of the linear piezoelectric energy harvester under random acceleration excitation, and obtained that the optimal load is not equal under the conditions of random and sinusoidal excitation. Compared with sinusoidal excitation, optimal load is unrelated to mechanical damping under the random excitation (Halvorsen 2008). Moreover, Halvorsen simulated output 123 Microsyst Technol (2015) 21:401–414 characteristics of electrostatic energy harvester under the random excitation by Spice software. Jackson studied output performances of piezoelectric energy harvester under random vibration by experimental testing, and illustrated that mean power is linearly proportional to acceleration spectral density, and the smaller resonant frequency, the more output power (Jackson et al. 2013). In addition, Lefeuvre concluded that output power of the piezoelectric energy harvester with the standard rectifier circuit and synchronous charge extraction technology in random acceleration excitation (Lefeuvre et al. 2007). Therefore, it can be seen that piezoelectric energy harvester has been got many researches when it is excited under random vibration. However, for author’s knowledge, there are not any related studies for hybrid piezoelectric-electromagnetic energy harvester under the random vibration excitation. Thus, in this paper, based on the governing electromechanical equations of hybrid piezoelectric-electromagnetic energy harvester, the more compact expressions of mean power and power spectral density involving non-dimension parameters are derived in the random excitation. Moreover, the relationship between mean power, spectral density of power and acceleration spectral density and load resistance are researched by numerical calculation, simulation and experimental validation. Besides, the effect of coupling strength on energy harvesting characteristics is also be analyzed. 2 Theoretical analysis 2.1 Electromechanical coupling model Considering a hybrid energy harvester integrated with piezoelectric and electromagnetic conversion mechanisms, as shown in Fig. 1, magnet is supported by a double-end fixed beam, piezoelectric layers polarized in the beam thickness direction are died on the top surface of beams, and coils are placed under the magnetic. In references (Wang et al. 2012; Tang and Yang 2011),when the harvester structure vibrates around at its resonant frequency, the model of PE or EM energy harvester all can be simplified as a SDOF system. Similarly, designed hybrid energy harvester in Fig. 1 that can be fabricated by MEMS process is modeled as a massspring-damper-PE element-EM element system, as shown in Fig. 2. It consists of the PE harvesting element, EM harvesting element and the mechanical structure, and PE and EM element connect with load resistors respectively. Therefore, when the acceleration is applied to the harvesting system, an effective mass me is bounded on a spring of effective stiffness K, a damper of coefficient cm, a PE element and an E element. Microsyst Technol (2015) 21:401–414 403 coil. These parameters are depended on the material properties and structural parameters of energy harvester, which can be derived by standard model analysis (Spreemann and Manoli 2012; Erturk and Inman 2011). According to literature (Serre et al. 2007), for the low frequency vibration, coil impedance is mainly manifested as the coil resistance, so the effect of coil inductance can be negligible. By means of Fourier transform, load current of EM element and load voltage of PE element in frequency domain are derived from the Eqs. (2) and (3) respectively, and the results are shown in Eqs. (4) and (5). Fig. 1 Designed hybrid PE and EM energy harvester Iem ðxÞ ¼ 1 ge zðxÞix Rc þ Rm ð4Þ Vp ðxÞ ¼ hRp zðxÞix 1 þ ixCp Rp ð5Þ where x response excitation expressed Fig. 2 SDOF model of hybrid PE and EM energy harvester In this case, the coupled PE and EM element alter the vibration response of harvesting system, which affects the power obtained from energy harvesting system in turn. However, the governing equation for the hybrid energy harvester in literatures (Wacharasindhu and Wkwon 2008; Challa et al. 2009) do not consider this electromechanical coupling effect. For the designed hybrid PE and EM energy harvester, let z(t) be the amplitude of the magnet, Vp as output voltage of piezoelectric element, Iem as output current of EM element, and the governing electromechanical equations can be established as follows (Lallart and Inman 2010): me zðtÞ þ cm zðtÞ þ KzðtÞ þ ge Iem ðtÞ þ hVp ðtÞ ¼ l1 me aðtÞ ð1Þ Lc dIem ðtÞ dzðtÞ þ ðRc þ Rm ÞIem ðtÞ þ ge ¼0 dt dt Vp ðtÞ dzðtÞ ¼0 þ Cp Vp ðtÞ h Rp dt ð2Þ ð3Þ where aðtÞ is the excitation acceleration, and l1 is the correction factor of single degree of freedom system compared with the distributed-parameter model (Erturk and Inman 2011). Moreover, h, ge are PE and EM transfer factor respectively (Erturk and Inman 2011; Spreemann and Manoli 2012) (In the reference Spreemann and Manoli 2012, gem is represented by kt), Rp and Rm are load resistor of PE and EM element, Cp is the capacitance of piezoelectric layer, and Rc, Lc are resistance and inductance of is excitation frequency. Similarly, frequency function of amplitude versus acceleration can be obtained by Fourier transform, which is as HðxÞ ¼ ðl1 me ixCp Rp l1 me Þ 8 3 > > C R ðixÞ þ m þ cm þ m > e p p e < = > > > : þ cm þ g2e Rc þ Rm 9 g2e > Cp Rp ðixÞ2 > > = Rc þ Rm > > ; þ KCp Rp þ h2 Rp ix þ K > ð6Þ For a damped linear system of the form zðxÞ ¼ HðxÞaðxÞ, transfer function of output current of EM element and output voltage of PE element are obtained, as illustrated in Eqs. (7) and (8) respectively HIem ðxÞ ¼ Iem ðxÞ ixge ¼ HðxÞ aðxÞ Rc þ Rm ð7Þ HVp ðxÞ ¼ Vp ðxÞ ixhRp ¼ HðxÞ aðxÞ 1 þ ixCp Rp ð8Þ In order to get more compact expressions of transfer function, the dimensionless parameters are assumed that 2 h gp ¼ KC as piezoelectric coupling coefficient; p x g2 n e as electromagnetic coupling coefficient; ge ¼ KR c x k ¼ xn as dimensionless vibration frequency; fm ¼ 2mcemxn as mechanical damping ratio; rp ¼ Rp Cp xn as dimensionless load resistance of PE element; rm ¼ RRmc as dimensionless load resistance of EM element; where xn is the natural frequency of hybrid energy harvesting system. Then, the more compact form of Eqs. (6)–(8) involving the dimensionless parameters can be derived, such that respectively 123 404 Microsyst Technol (2015) 21:401–414 HðkÞ ¼ l1 1 þ rp ðikÞ h i 2 3 g xn rp ðikÞ þ 1 þ 2f þ e rp ðikÞ2 þ 2f þ ge þ rp þ g rp ik þ 1 m m p 1þrm 1þrm HIem ðkÞ ¼ l1 me ge ik þ rp ðikÞ2 h i gem 1 þ rm rp ðikÞ3 þ 1 þ 2f þ ge rp ðikÞ2 þ 2f þ ge þ rp þ g rp ik þ 1 m m p 1þrm 1þrm me HVP ðkÞ ¼ l1 gp ðik þ rp ðikÞ2 Þ= h 9 8 ge 1 2ge 4 3 2 > > > > r ðikÞ þ 2 þ 2f þ þ þ 4f þ þ r þ g r þ r ðikÞ ðikÞ > > p p p m m p p = < rp 1 þ rm 1 þ rm > f ge 1> > > > ; : 2 mþ þ 2 þ gp ik þ > rp rp ð1 þ rm Þrp 2.2 Basic equation of broadband random excitation The more practically available ambient source of energy harvester is random vibration, where is distributed with in a certain range of frequency band and acceleration. According to stochastic theory (Liu 2008), when energy harvesting system is excited by random acceleration with spectral density SA(w), the SD of harvester amplitude, EM output current and PE output voltage are illustrated in Eqs. (12)–(14) respectively SZ ðxÞ ¼ jHðxÞj2 SA ðxÞ ð12Þ SIem ðxÞ ¼ jHIem ðxÞj2 SA ðxÞ 2 SV ðxÞ ¼ HV ðxÞ SA ðxÞ ð13Þ p Based on Wiener–Khinchin theorem (Liu 2008), for stationary random process, its spectral density SðxÞ and autocorrelation function RðsÞ is a Fourier transform pair, as shown in Eq. (15). Moreover, when s ¼ 0, Rð0Þ is mean square value of the random signal. Zþ1 SðxÞeixs dx ð15Þ 1 Thus, substituting Eq. (12) into Eq. (15), mean square value of amplitude is 2 ZM 1 ¼ 2p Zþ1 1 1 SZ ðxÞdx ¼ 2p Zþ1 jHðxÞj2 SA ðxÞdx ð16Þ 1 Similarly, we can also get the mean square value of EM output current and PE output voltage, as shown in Eqs. (17) and (18) respectively. 123 Zþ1 ð10Þ ð11Þ jHIem ðxÞj2 SA ðxÞdx ð17Þ jHVP ðxÞj2 SA ðxÞdx ð18Þ 1 VP2 1 ¼ 2p Zþ1 1 The two expressions in Eqs. (17) and (18) will be used to obtain the average power for the hybrid piezoelectric and electromagnetic energy harvester, and more details are shown in Sect. 2.3. 2.3 White noise excitation ð14Þ p 1 R½ðsÞ ¼ 2p 2 Iem 1 ¼ 2p ð9Þ According to reference (Halvorsen 2007), for linear energy harvesting system, random vibration can be assumed as white noise signal when the excitation frequency bandwidth is much bigger than 3 dB bandwidth of energy harvesting system and the excitation has a flat power spectral density in frequency domain, which indicates that SA (w) is a constant S0. Under white noise excitation with zero mean value, system response will also be stationary random signal with zero mean value. 2.3.1 PE element performances For hybrid PE–EM energy harvester excited by white noise, by substituting SA ðxÞ ¼ S0 into Eq. (18), mean square value of output voltage of PE element is VP2 1 S0 ¼ 2p Zþ1 1 jHVP ðxÞj2 dx ð19Þ Microsyst Technol (2015) 21:401–414 405 In this paper we are interested in the average harvested power given by (Adhikari et al. 2009) 2 V ðtÞ E½V 2 ðtÞ E½PðtÞ ¼ E ð20Þ ¼ Rload Rload so mean power apply on PE load is Vp2 1 S0 Pp ¼ ¼ Rp 2p Rp Zþ1 2 jHVP ðxÞj dx ð21Þ Using the similar analytical method, mean square value of EM element output current under white noise excitation is illustrated in Eq. (27) by substituting SA ðxÞ ¼ S0 into Eq. (17). 2 Iem Zþ1 xn S0 ¼ 2p jHIem ðkÞj2 dk ð27Þ 1 1 Using the non-dimension parameters, it can be derived that Zþ1 2.3.2 EM element performances 2 jHVP ðxÞj dx ¼ xn 1 Zþ1 And mean power of EM load Rm is Pem ¼ 2 jHVP ðkÞj dk 2 Rm Iem ð22Þ 1 The integral in Eq. (22) can be obtained using Eq. (39) in the Appendix. Let ge B2 ¼ rp ; B1 ¼ 1; A4 ¼ rp ; A3 ¼ 2 þ 2fm þ rp ; A 2 1 þ rm 1 2ge ¼ þ 4fm þ þ r p þ g p r p ; A1 rp 1 þ rm f ge 1 ¼2 mþ þ 2 þ g p ; A0 ¼ : rp rp ð1 þ rm Þrp xn Rm S0 ¼ 2p Zþ1 jHIem ðkÞj2 dk The integral of Eqs. (27) and (28) can be calculated by Eq. (40) in the Appendix, then mean square value of EM element output current and mean power can be expressed in Eqs. (29) and (30) respectively involving the dimensionless parameters. me S0 l21 ge 2Rc ð1 þ rm Þ2 ge rp 2fm þ 1þr þ rp þ gp rp þ 1 m h i gem ge þ rp þ gp rp 1 þ 2fm þ 1þr rp rp 2fm þ 1þr m m 2 ¼ Iem The solutions of Eqs. (19) and (21) can be simply expressed as VP2 S0 me A1 B22 A3 B21 ¼ gp l21 2Cp xn A0 A23 þ A21 A4 A1 A2 A3 ð23Þ S0 me gp l21 A1 B22 A3 B21 2 rp A0 A23 þ A21 A4 A1 A2 A3 ð24Þ Pp ¼ On the other hand, by the physical meaning of power spectral density (Liu 2008) the SD of output power of PE element is shown in Eq. (25) when its load resistance is Rp. Spp ðxÞ ¼ 1 S0 jHIem ðxÞj2 SVp ðxÞ ¼ Rp Rp ð25Þ Equation (25) can be expressed in the parameters of the system as SPP ðkÞ ¼ me S0 2 gp ðkrp Þ l xn rp 1 þ ðkrp Þ2 1 2 2 2 2 gp k rp kgp rp kge 2 1 þ 1þk2 r2 k þ 2kfm þ 1þrm þ 1þk2 r2 p ð29Þ l21 ge rm me S 0 2 ð1 þ rm Þ2 ge rp 2fm þ 1þr þ r þ g r þ1 p p p m h i ge ge þ r þ g r þ 1 þ 2f 2fm þ 1þr p p m p 1þrm rp rp m Pem ¼ ð30Þ Moreover, when the load resistance is Rm, the SD of EM element output power is Spem ðxÞ ¼ Rm SIem ðxÞ ¼ Rm S0 jHIem ðxÞj2 m e S0 r m g e l2 k2 xn ð1 þ rm Þ2 1þ gp k2 rp2 1þk2 rp2 1 2 2 kgp rp kge k2 þ 2kfm þ 1þr þ 2 2 m 1þk r Besides, by Eqs. (24) and (26), we can also obtain the normalized power and spectral density by further process, but in this paper we will no longer focus on it. p ð32Þ p ð26Þ ð31Þ Then, Eq. (31) can be expressed as Eq. (32) by using the non-dimension parameters. Spem ðkÞ ¼ 2 ð28Þ 1 2.3.3 Hybrid energy harvesting system According to the results in 2.3.1 and 2.3.2, total output power of hybrid piezoelectric-electromagnetic energy 123 406 Microsyst Technol (2015) 21:401–414 harvester is the sum of power of PE energy harvesting element and EM energy harvesting element, which is shown as density of hybrid piezoelectric-electromagnetic energy harvester are mainly determined by spectral density S0 of excitation acceleration, dimensionless load rp and rm, P ¼ Pem þ Pp 3 2 ge 2 r 2f þ þ r þ g r þ 1 p p p m p 1þr l g r m 7 6 1 e m h i 7 6 ð1 þ rm Þ2 2fm þ ge þ rp þ gp rp 1 þ 2fm þ ge rp rp 7 S0 m e 6 1þrm 1þrm 7 6 ¼ 7 2 6 7 6 2 2 2 5 4 gp l1 A1 B2 A3 B1 þ 2 2 r p A0 A3 þ A1 A4 A1 A2 A3 So, the optimal load resistance of PE and EM element can be derived by Eqs. (34) and (35) respectively. oP ¼ 0 ! rp ¼ rpoptimal orp ð34Þ oP ¼ 0 ! rm ¼ rmoptimal orm ð35Þ Besides, according to the theory of stochastic process (Liu 2008), the SD of hybrid energy harvesting system is SðxÞ ¼ Sem ðxÞ þ Sp ðxÞ þ Sp em ðxÞ þ Sem p ðxÞ ð36Þ where Sem ðxÞ and Sp ðxÞ are auto-SD of EM and PE element respectively, and Sp em ðxÞ, Sem p ðxÞ are the cross SD between EM and PE energy harvesting element. Based on output power of energy harvesting system shown in Eq. (33), we neglect cross power spectral density between EM and PE element to simplify analysis in this paper, so output power spectral density of hybrid piezoelectric-electromagnetic energy harvester is " # g ðkrp Þ2 me S0 rm ge 2 p 2 2 S¼ l þ l k = xn rp 1 þ ðkrp Þ2 ð1 þ rm Þ2 2 !2 !2 3 gp k2 rp2 kg r kg p p e 4 1þ 5 k2 þ 2kfm þ þ 1 þ rm 1 þ k2 rp2 1 þ k2 rp2 ð37Þ Similarly, we can also derive the normalized power and spectral density of hybrid piezoelectric and electromagnetic energy harvester from Eqs. (33) and (37) respectively. Moreover, given specific values of the parameters, the mean power and spectral density of the harvesters can be predicted. ð33Þ dimensionless frequency k, coupling coefficients ge and gp. Thus, in this section, the effects of above factors on output performances of hybrid energy harvester are analyzed by numerical calculation and simulation. Table 1 shows model parameters of designed hybrid PE and EM energy harvester. In the simulation, use matlab software to simulate output characteristics of energy harvester under the random vibration excitation, and compare with the theory results. Let initial value of energy harvesting system be z(0) = 0, Iem(0) = 0, Vp(0) = 0, and t [ 0. A white noise signal that inputs to energy harvesting system is generated by WGN function in matlab software, and the electric output signal of harvester under random excitation can be obtained from the simulation. Then adopting matlab digital signal processing technology to process the signals obtained in the simulation, and mean square value and SD of output signals can be got. Finally, we can have the RMS (Root Mean Square) value of output voltage, current, and power, spectral density of harvester. 3.1 Effect of load and acceleration spectral density on output characteristics Based on analysis results shown in Eqs. (33) and (37), when the excitation frequency is equal to the resonant frequency, performances of harvester are related with load resistance and strength of random excitation when the system parameters of energy harvesting are fixed. Thus, output characteristics of harvester are analyzed at the different SD of acceleration and load resistance in this part. 3.1.1 Mean power 3 Numerical calculation and simulation As the analysis results illustrated in Eqs. (33) and (37), under the white noise excitation, mean power and spectral 123 Supposed spectral density of acceleration S0 = 1 (m/s2)2/ Hz, mean power of hybrid piezoelectric and electromagnetic energy harvester with the different load resistances Microsyst Technol (2015) 21:401–414 407 are shown in Fig. 3. It can be concluded that, when load resistance of PE element and EM element are 170 kX and 24 X respectively, which are equal to 1/Cpwn and Rc, the output power of hybrid energy harvester can be up to the maximum only. Besides, the effect of EM load on voltage and power of PE element is shown in Fig. 4, where the Table 1 Physical characteristics of designed energy harvester Parameters Values PZT layer Length 10 mm Thickness 8 mm Width 2 mm Piezoelectric constant -100e-12 C/N Dielectric constant 3.7899 e-8 F/m Magnet (NdFeB) Diameter 15 mm Thickness 40 mm Beam of one side (stainless steel) Length Width 20 mm 8 mm Thickness 3.8 mm Coil (copper) Number of turns 360 Diameter 15 mm Damping ratio 0.026 voltage and power increase with EM load resistance increasing. It can be explained that with EM load resistance increasing, coupling effect of EM element on amplitude of harvesting system reduces; therefore, output voltage and power of piezoelectric element will be raised. Moreover, it can be predicted that voltage and power of PE element reaches their maximum when the resistance of EM element is infinity. At this case, hybrid piezoelectric-electromagnetic energy harvester becomes piezoelectric energy harvester that based on single energy harvesting mechanism. On the other hand, Fig. 5 displays that PE load almost does not affect the current and power of EM element, which indicates the effect of piezoelectric load variation on vibration characteristics and coupling coefficient of hybrid energy harvester can be neglected. Besides, the PE and EM element reach the maximum power at their optimal load 170 kX, 24 X respectively. In addition, we also analyze the variation regularity of mean power with SD of excitation acceleration at the resonant frequency, and the results are shown in Fig. 6. Mean power of hybrid PE–EM energy harvester linearly increases with the spectral density of acceleration increasing, which has the same conclusion with Jackson for the piezoelectric energy harvester (Jackson et al. 2013). Besides, with the load resistance hiking, the variation of mean power with SD of acceleration rise firstly and fall later, and reach the maximum at the optimal load of energy harvesting element. Furthermore, the similar regularity happens in output voltage of PE element and output current of EM element, as shown in Fig. 7. Therefore, for hybrid piezoelectric and electromagnetic energy harvester, in order to get the maximal power, load resistance of energy harvesting element should be equal to their internal resistance respectively, and acceleration excitation should be as large as possible under the condition of safety structural strength. 3.1.2 Power spectral density Fig. 3 Mean power of hybrid PE and EM energy harvester with the different load resistances Based on the results in Sect. 3.1.1, output power of hybrid PE–EM energy harvester is affected by load resistors of PE and EM energy harvesting element. Thus, power spectral density of hybrid energy harvesting system in different Fig. 4 Effect of EM load on voltage and power of PE element: a power, b voltage 123 408 Microsyst Technol (2015) 21:401–414 Fig. 5 Effect of PE load on current and power of EM element a power, b current Fig. 6 Variation regularity of mean power with SD of excitation acceleration at the resonant frequency a with the different load resistors of EM element, b with the different load resistors of PE element Fig. 7 Output voltage of PE element and output current of EM element with SD of excitation acceleration a output voltage of PE element, b output current of EM element vibration frequencies and load resistors are studied in the several cases. In the analysis, when PE element is in the state of optimal load, it is assumed that load resistance of EM element are 1, 10, 24, 50, 200 X respectively; similarly, when EM element meets impedance matching, it is proposed that the load of PE element are 1, 50, 170, 300 , 800 kX respectively. Besides, supposed spectral density of acceleration S0 = 1 (m/s2)2/Hz, and results are shown in Fig. 8. In Fig. 8, the corresponding frequency of maximal spectral density is the resonant frequency of harvesting system, and the frequency rises from 76 to 78 Hz as piezoelectric load increasing from 1 to 800 kX. Moreover, the SD reaches the maximum at 170 kX. Therefore, piezoelectric load resistance not only affects the value of spectral density of hybrid energy harvester but also the distribution 123 in the frequency domain. On the other hand, when EM load increases from 1 to 200 X, SD maximum is at the 24 X, and variation of the spectral density reaches the maximum at the resonant frequency. However, the resonant frequencies do not vary with the EM load resistance. Thus, it can be concluded that hybrid energy harvester should work at the resonant frequency, and the effect of load resistance on resonant frequency should be taken into consideration when designing the structure of energy harvester. Furthermore, at the optimal load, power spectral density of hybrid energy harvester excited with different acceleration is studied, and the result is illustrated in Fig. 9. It can be concluded that SD of output power increases with spectral density of acceleration increasing, and the corresponding frequencies of spectral density peak are all equal to 77.5 Hz. When spectral density of random acceleration is S0 = Microsyst Technol (2015) 21:401–414 409 Fig. 8 SD of hybrid energy harvesting system at different vibration frequencies and load resistors a with the different load resistors of PE element, b with the different load resistors of EM element 3.2 Effect of coupling strength on performance Fig. 9 Power spectral density of hybrid energy harvester under the acceleration excitation with different spectral density Fig. 10 Spectral density of harvester at the different excitation frequencies 1 (m/s2)2/Hz, Fig. 10 illustrate the spectral density of energy harvesting element at the different excitation frequencies. In addition, simulation results of displacement, PE output voltage and EM output current are shown in Fig. 11. In Eqs. (33) and (37), it can be got that at the resonant frequency, performances of energy harvester is mainly determined by damping and coupling coefficient when load resistance meets impedance matching, For piezoelectric energy harvester, literature (Shu and Lien 2006) utilizes the ratio of coupling coefficients to damping to characterize the strength of electromechanical coupling effect. Similarly, for hybrid piezoelectric-electromagnetic energy harvester, we also use g/fm (g = gp ? gem) to characterize the value of coupling strength in this paper. Therefore, in this section, we study the influence of coupling effect on power and spectral density of hybrid energy harvester when SD of excitation is fixed. For the designed harvester model in Table 1, ge = 0.0412, gp = 0.0123, fm = 0.026, so g/fm = 2. In the research, spectral density of random acceleration signal is set at 0.2 (m/s2)2/Hz. When the values of g/fm are set at 1, 2, 5 respectively, mean power of hybrid energy harvesters along with EM and PE load resistance at resonant frequency are shown in Fig. 12a and b respectively. It can be concluded that the stronger coupling strength, the larger output mean power. At the both optimal load of EM and PE element both, the maximal mean power rise from 0.85 to 2.6 mW when g/fm increase from 1 to 5. However, the optimal load resistance of EM element increases with coupling strength enhancing. When g/fm is 1, 2, 5, its corresponding optimal load resistance is 20, 24, 35 X respectively, which indicate that coupling effect change the internal resistance of harvester. Moreover, when load resistance is bigger than optimal load, decreasing degree of mean power tends to be more slowly along with coupling strength increasing. On the other hand, the coupling strength does not affect the optimal load resistance of PE element. When g/fm is 1, 2, 5 respectively, its optimal load are all 170 kX. Therefore, for vibration energy harvester, electromechanical coupling strength which can improve output power in practical environments should be enhanced. Under different coupling strength, spectral density of output power in different excitation frequencies are shown 123 410 Microsyst Technol (2015) 21:401–414 Fig. 11 Simulation results of hybrid energy harvester when S0 = 1 (m/s2)2/Hz a input acceleration, b displacement of magnet, c output current of EM element, d output voltage of PE element Fig. 12 Mean power of hybrid energy harvester at the different coupling strength a with the different EM load resistance, b with the different PE load resistance in Fig. 13, which indicates that the stronger coupling effect, the greater output spectral density, and it reaches the maximum at the resonant frequency. When g/fm is 1, 2, 5, power spectral density at resonant frequency is 3 9 10-5, 6.5 9 10-5, 1.8 9 10-4 W/Hz respectively. Besides, the stronger coupling strength, the wider frequency band of energy harvesting, the better energy harvesting efficiency. When the SD of acceleration is 0.2 (m/s2)2/Hz, output current of EM element and output voltage of PE element for the different coupling strength are shown in Figs. 14 and 15 respectively. On the other hand, at the optimal load and resonant frequency, variation law of output mean power and spectral density of hybrid piezoelectric-electromagnetic energy harvester along with the coupling strength are 123 studied. Firstly, the relationship between optimal load resistance of EM element and coupling coefficient is shown in Fig. 16, where the optimal load is proportional to coupling strength. When g/fm increases from 0.35 to 13.38, the optimal load of EM element rises from 20 to 65 X. On this basis, the effect of coupling strength on mean power and spectral density of hybrid energy harvester are shown in Fig. 17. From analysis results in Fig. 17, output mean power and spectral density increase with coupling strength enhancing. However, the bigger coupling strength is, the smaller increasing extent becomes. When g/fm is 0.35, 2.68, 13.38, mean power is 0.44, 1.93, 4.2 mW respectively, and accordingly its power spectral density is 5.45 9 10-6, 8.57 9 10-5, 2.61 9 10-4 W/Hz. Microsyst Technol (2015) 21:401–414 Fig. 13 Spectral density of output power for hybrid energy harvester at the different coupling strength 411 Fig. 16 The relationship between optimal load resistance of EM element and coupling coefficient Then, for hybrid piezoelectric-electromagnetic energy harvester, improving coupling strength can not only increase output power, but also widen frequency band of energy harvesting. 4 Experimental validation Fig. 14 Output current of EM element when the SD of acceleration is 0.2 (m/s2)2/Hz Fig. 15 Output voltage of PE element when the SD of acceleration is 0.2 (m/s2)2/Hz In order to test output characteristics of hybrid piezoelectric-electromagnetic harvester and validate the numerical calculation results, the meso hybrid piezoelectricelectromagnetic harvester is fabricated, and material properties and structure parameters are illustrated in Table 1. Experimental setup is shown in Fig. 18. The whole setup of the device is mounted on the vibrating shaker which is connected to a signal generator through a power amplifier. The signal generator is used to provide the source vibration frequency and amplitude excitation. Lead wires from the piezoelectric cantilever beam are connected across a variable resistor to maximize the piezoelectric power output. Similarly, the current generated in the coil due to electromagnetic power generation is also captured across a different variable resistor. In addition, an accelerometer is used to record vibration acceleration, highspeed camera test the displacement of magnet and dynamic signal analyzer is used to record output voltage of piezoelectric and electromagnetic energy harvesting element. In the experiment, random excitation, which input into the energy harvester, and its power spectral density are shown in Fig. 19a and b respectively. It can be got that spectral density of acceleration is 1.3 9 10-4 (m/s2)2/Hz. At this case, output voltage of piezoelectric and electromagnetic energy harvesting element are tested at the resonant frequency when the load resistors change. Using the matlab algorithm studied in Sect. 3, mean power of energy harvester can be analyzed. 123 412 Microsyst Technol (2015) 21:401–414 Fig. 17 Effect of coupling strength on mean power and spectral density of hybrid energy harvester a power, b spectral density harvester at the different spectral density of acceleration is shown in Fig. 21. It illustrates that output power is linearly proportional to the acceleration spectral density, which is consistent with theoretical analysis results. 5 Conclusion Fig. 18 Experimental setup The experimental results, as shown in Fig. 20, indicate that with load resistance of PE and EM element increasing, their mean power all increase first and decrease later, and the maximum can be output at optimal load respectively, which has the same conclusion with theoretical analysis results in Sect. 3. However, because of uncertainty of random acceleration, there are errors between experimental test results and theoretical analysis results. For random signal process, the appearances of errors are in the expected range (Jackson et al. 2013). At the optimal load resistance, mean power of hybrid piezoelectric-electromagnetic energy Aiming at designed hybrid piezoelectric-electromagnetic energy harvester, electromechanical coupling state equations are set up. Using non-dimension parameters, the more compact expressions of output mean power and spectral density of energy harvester under random excitation are derived. By means of numerical calculation, simulation and experimental test, the effect of acceleration, load and coupling strength on performances of hybrid energy harvester are studied. It can be obtained as follows. 1. Mean power and power spectral density of hybrid piezoelectric-electromagnetic energy harvester are mainly related to vibration frequency k, damping ratio fm, coupling coefficients ge, gp and load resistance rp,rm. Fig. 19 Random acceleration excitation, which input into the energy harvester a measured random acceleration, b its power spectral density 123 Microsyst Technol (2015) 21:401–414 413 to acceleration spectral density, but increasing degree is affected by the value of load resistance. When the load meets the impedance matching, enhancing extent reaches the maximum. Only at the optimal load and resonant frequency can output mean power and spectral density reach the maximum, and the resonant frequency of energy harvesting system rises with the load resistance of PE element increasing, but not influenced by the EM load resistance. Enhancing coupling strength can not only improve output power and power spectral density, but also widen frequency band of energy harvesting. The smaller coupling strength is, the greater increase extent of output power and spectral density will be. In addition, optimal load of EM element varies increases with coupling strength enhancing. 3. 4. Acknowledgments This work is supported by the National High Technology Research and Development Program of China (Grant No. SS2013AA041104). Appendix By using the table in reference (Gradshtenyn and Ryzhik 1994), for the system if the complex frequency response function is of the form Fig. 20 Effect of load resistance on power of harvester a effect of PE load resistance on power of PE element, b effect of EM load resistance on power of EM element HðxÞ ¼ ixB1 þ ðixÞ2 B2 A0 þ ixA1 þ ðixÞ2 A2 þ ðixÞ3 A3 þ ðixÞ4 A4 ð38Þ Their integral of the square of the absolute value of complex frequency response can be computed as respectively Z1 A1 B22 A3 B21 HðxÞ2 dx ¼ p ð39Þ A0 A23 þ A21 A4 A1 A2 A3 1 Also the integral for the transfer function in equation is 2 Zþ1 ixB1 þ ðixÞ2 B2 dx 2 3 A0 þ ixA1 þ ðixÞ A2 þ ðixÞ A3 1 ¼p Fig. 21 Output power of hybrid energy harvester at different spectral density of acceleration 2. Output mean power, voltage, and current of energy harvester increase as SD of acceleration increasing; moreover, mean output power is linearly proportional B22 A1 þ B21 A3 A3 ðA1 A2 A0 A3 Þ ð40Þ References Adhikari S, Friswell MI, Inman DJ (2009) Piezoelectric energy harvesting from broadband random vibrations. Smart Mater Struct 18(11):115005 Blystad LCJ, Halvorsen E, Husa S (2010) Piezoelectric MEMS energy harvesting systems driven by harmonic and random 123 414 vibrations. IEEE Trans Ultrason Ferroelectr Freq Control 57(4):908–919 Challa VR, Prasad MG, Fisher FT (2009) A coupled piezoelectric– electromagnetic energy harvesting technique for achieving increased power output through damping matching. Smart Mater Struct 18:1–11 Cheng S, Wang N, Arnold DP (2007) Modeling of magnetic vibrational energy harvesters using equivalent circuit representations. J Micromech Microeng 17:2328–2335 Cho J, Anderson M, Richards R (2005) Optimization of electromechanical coupling for a thin-film PZT membrane: I. Modeling. J Micromech Microeng 15:1797–1803 Cottone F, Gammaitoni L, Vocca H et al (2012) Piezoelectric buckled beams for random vibration energy harvesting[J]. Smart Mater Struct 21(3):035021 Erturk A, Inman DJ (2008) A distributed parameter electromechanical model for cantilevered piezoelectric energy harvesters. J Vib Acoust 130:1–15 Erturk A, Inman DJ (2011) Piezoelecric energy harvesting. Wiley, UK Gradshtenyn IS, Ryzhik IM (1994) Table of Integrals Series, and Products. Academic, New York Guyomar D, Lallart M (2011) Recent progress in piezoelectric conversion and energy harvesting using nonlinear electronic interfaces and issues in small scale implementation. Micromachines 2:274–294 Halvorsen E (2007) Broadband excitation of resonant energy harvesters. PowerMEMS, pp 319–322 Halvorsen E (2008) Energy harvesters driven by broadband random vibrations. J Microelectromech Syst 17(5):1061–1071 Harne RL, Wang KW (2013) A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater Struct 22:1–12 Hatipoglu G, Urey H (2010) FR4-based electromagnetic energy harvester for wireless sensor nodes. Smart Mater Struct 19:1–11 Jackson WC, Brian KH, Emiliano SR (2013) Experimental analysis of a piezoelectric energy harvesting system for harmonic, random, and sine on random vibration. Adv Acoust Vib. doi:10.1155/ 2013/241025 James D, Paul DM (2012) Power-extraction circuits for piezoelectric energy harvesters in miniature and low-power applications. IEEE Trans Power Electron 11:4514–4530 Karami MA, Inman DJ (2011) Electromechanical modeling of the low-frequency Zigzag micro-energy harvester. J Intell Mater Syst Struct 22:271–282 Karami MA, Inman DJ (2012) Powering pacemakers from heartbeat vibrations using linear and nonlinear energy harvesters. Appl Phys Lett 100:042901–042904 Lallart M, Inman DJ (2010) Mechanical effect of combined piezoelectric and electromagnetic energy harvesting. Proc IMAC XXVIII:2.1–4 Lefeuvre E, Badel A, Richard C et al (2007) Energy harvesting using piezoelectric materials: case of random vibrations. J Electroceram 19(4):349–355 Ling CS, Dan H, Steve GB (2013) Technological challenges of developing wireless health and usage monitoring systems. In: Proc SPIE 8695, 86950 K-1 Liu CH (2008) Stochastic Process, 4th edn. Huazhong University of Science and Technology Press, China 123 Microsyst Technol (2015) 21:401–414 Liu H, Lee C, Kobayashi T (2012) A new S-shaped MEMS PZT cantilever for energy harvesting from low frequency vibrations below 30 Hz. Microsyst Technol 18:497–506 Liua H, Quana C, Taya CJ (2011) A MEMS-based piezoelectric cantilever patterned with PZT thin film array for harvesting energy from low frequency vibrations. Phys Proc 19:129–133 Mitcheson PD, Green TC, Yeatman EM (2007) Power processing circuits for electromagnetic, electrostatic and piezoelectric inertial energy scavengers. Microsyst Technol 13:1629–1635 Nicholas R, Natarajan B (2013) A structured approach to optimization of energy harvesting wireless sensor networks. In: The 10th annual IEEE CCNC, pp 420–425 Robert D, Wu WJ, Chen YY (2008) A hybrid piezoelectric and electromagnetic energy harvesting device. In: 19th international conference on AST 10, pp 6–9 Serre C, Rodrı́guez AP, Fondevilla N (2007) Vibrational energy scavenging with Si technology electromagnetic inertial microgenerators. Microsyst Technol 13:1655–1661 Shu YC, Lien IC (2006) Analysis of power output for piezoelectric energy harvesting systems. Smart Mater Struct 15:1499–1512 Spreemann D, Manoli Y (2012) Electromagnetic vibration energy harvesting devices. Springer, Germany Tanesse Y, Zhang S, Priya S (2009) Multimodal energy harvesting system: piezoelectric and electromagnetic. J Intell Mater Syst Struct 20:625–633 Tang L, Yang Y (2011) Analysis of synchronized charge extraction for piezoelectric energy harvesting. Smart Mater Struct 20:1–13 Tang X, Zuo L (2012) Vibration energy harvesting from random force and motion excitations. Smart Mater Struct 21(7):075025 Torsten R, Armaghan S (2010) Analysis and modelling towards hybrid piezo-electromagnetic vibrating energy harvesting devices. In: AIP conference proceedings, vol 81, pp 81–85 Wacharasindhu T, Wkwon J (2008) A micromachined energy harvester from a keyboard using combined electromagnetic and piezoelectric conversion. J Micromech Microeng 18:1–8 Wang P, Li W, Che L (2012) Design and fabrication of a micro electromagnetic vibration energy harvester. J Semicond 10:1–4 Williams CB, Yates RB (1996) Analysis of a micro-electric generator for Microsystems. Sens Actuators, A 52:8–11 Wu X, Khaligh A, Xu Y (2008) Modeling, design and optimization of hybrid electromagnetic and piezoelectric MEMS energy scavengers. In: IEEE 2008 custom integrated circuits conference, pp 177–181 Wu WJ, WickenheiserA M, Reissman T (2009) Modeling and experimental verification of synchronized discharging techniques for boosting power harvesting from piezoelectric transducers. Smart Mater Struct 18:1–14 Yang B, Lee C, Kee WL (2010) Hybrid energy harvester based on piezoelectric and electromagnetic mechanisms. J Micro Nanolith MEMS MOEMS 9:1–10 Yogesh KR, Anantha PC (2010) An efficient piezoelectric energy harvesting interface circuit using a bias-flip rectifier and shared inductor. IEEE J Solid State Circuits 1:189–206 Zhao S, Erturk A (2013) Electroelastic modeling and experimental validations of piezoelectric energy harvesting from broadband random vibrations of cantilevered bimorphs. Smart Mater Struct 22(1):015002