- National Physical Laboratory

advertisement

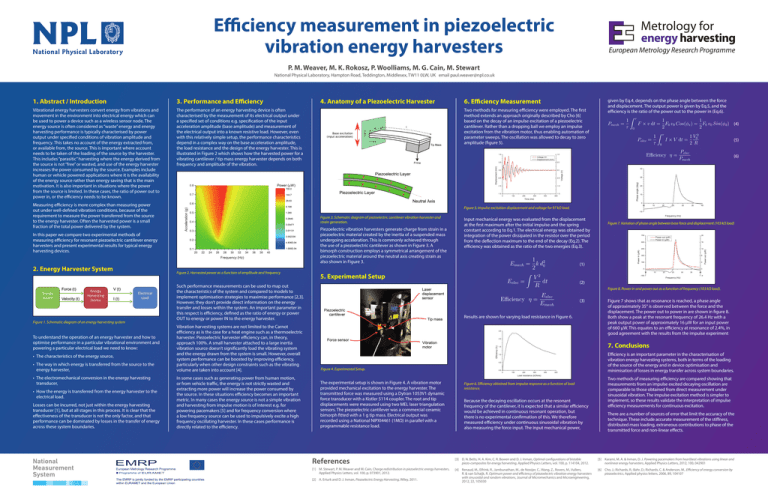

Efficiency measurement in piezoelectric vibration energy harvesters P. M. Weaver, M. K. Rokosz, P. Woolliams, M. G. Cain, M. Stewart National Physical Laboratory, Hampton Road, Teddington, Middlesex, TW11 0LW, UK email paul.weaver@npl.co.uk 1. Abstract / Introduction 3. Performance and Efficiency Vibrational energy harvesters convert energy from vibrations and movement in the environment into electrical energy which can be used to power a device such as a wireless sensor node. The energy source is often considered as “waste” energy and energy harvesting performance is typically characterised by power output under specified conditions of vibration amplitude and frequency. This takes no account of the energy extracted from, or available from, the source. This is important where account needs to be taken of the loading of the source by the harvester. This includes “parasitic” harvesting where the energy derived from the source is not “free” or wasted, and use of the energy harvester increases the power consumed by the source. Examples include human or vehicle powered applications where it is the availability of the energy source rather than energy saving that is the main motivation. It is also important in situations where the power from the source is limited. In these cases, the ratio of power out to power in, or the efficiency needs to be known. The performance of an energy harvesting device is often characterised by the measurement of its electrical output under a specified set of conditions e.g. specification of the input acceleration amplitude (base amplitude) and measurement of the electrical output into a known resistive load. However, even with this relatively simple setup, the performance characteristics depend in a complex way on the base acceleration amplitude, the load resistance and the design of the energy harvester. This is illustrated in Figure 2 which shows how the harvested power for a vibrating cantilever / tip mass energy harvester depends on both frequency and amplitude of the vibration. Measuring efficiency is more complex than measuring power out under well-defined vibration conditions, because of the requirement to measure the power transferred from the source to the energy harvester. Often the harvested power is a small fraction of the total power delivered by the system. Figure 1. Schematic diagram of an energy harvesting system To understand the operation of an energy harvester and how to optimise performance in a particular vibrational environment and powering a particular electrical load we need to know: • The characteristics of the energy source, • The way in which energy is transferred from the source to the energy harvester, • The electromechanical conversion in the energy harvesting transducer, • How the energy is transferred from the energy harvester to the electrical load. Losses can be incurred, not just within the energy harvesting transducer [1], but at all stages in this process. It is clear that the effectiveness of the transducer is not the only factor, and that performance can be dominated by losses in the transfer of energy across these system boundaries. 6. Efficiency Measurement Two methods for measuring efficiency were employed. The first method extends an approach originally described by Cho [6] based on the decay of an impulse excitation of a piezoelectric cantilever. Rather than a dropping ball we employ an impulse excitation from the vibration motor, thus enabling automation of parameter sweeps. The oscillation was allowed to decay to zero amplitude (figure 5). given by Eq.4, depends on the phase angle between the force and displacement. The output power is given by Eq.5, and the efficiency is the ratio of the power out to the power in (Eq.6). (4) (5) (6) Figure 5. Impulse excitation displacement and voltage for 97 kΩ load. Figure 3. Schematic diagram of piezoelectric cantilever vibration harvester and strain generation. Piezoelectric vibration harvesters generate charge from strain in a piezoelectric material created by the inertia of a suspended mass undergoing acceleration. This is commonly achieved through the use of a piezoelectric cantilever as shown in Figure 3. A bimorph construction employs a symmetrical arrangement of the piezoelectric material around the neutral axis creating strain as also shown in Figure 3. In this paper we compare two experimental methods of measuring efficiency for resonant piezoelectric cantilever energy harvesters and present experimental results for typical energy harvesting devices. 2. Energy Harvester System 4. Anatomy of a Piezoelectric Harvester Figure 2. Harvested power as a function of amplitude and frequency In some cases such as generating power from human motion, or from vehicle traffic, the energy is not strictly wasted and extracting more power will increase the power consumed by the source. In these situations efficiency becomes an important metric. In many cases the energy source is not a simple vibration and harvesting from impulse motion is of interest e.g. for powering pacemakers [5] and for frequency conversion where a low frequency source can be used to impulsively excite a high frequency oscillating harvester. In these cases performance is directly related to the efficiency. Figure 7. Variation of phase angle between base force and displacement (103 kΩ load) (1) 5. Experimental Setup Such performance measurements can be used to map out the characteristics of the system and compared to models to implement optimisation strategies to maximise performance [2,3]. However, they don’t provide direct information on the energy transfer and losses within the system. An important parameter in this respect is efficiency, defined as the ratio of energy or power OUT to energy or power IN to the energy harvester. Vibration harvesting systems are not limited to the Carnot efficiency as is the case for a heat engine such as a thermoelectric harvester. Piezoelectric harvester efficiency can, in theory, approach 100%. A small harvester attached to a large inertia vibration source doesn’t significantly load the vibrating system and the energy drawn from the system is small. However, overall system performance can be boosted by improving efficiency, particularly when other design constraints such as the vibrating volume are taken into account [4]. Input mechanical energy was evaluated from the displacement at the first maximum after the initial impulse and the spring constant according to Eq.1. The electrical energy was obtained by integration of the power dissipated in the resistor over the period from the deflection maximum to the end of the decay (Eq.2). The efficiency was obtained as the ratio of the two energies (Eq.3). (2) Figure 8. Power in and power out as a function of frequency (103 kΩ load). (3) Results are shown for varying load resistance in Figure 6. Figure 7 shows that as resonance is reached, a phase angle of approximately 35° is observed between the force and the displacement. The power out to power in are shown in figure 8. Both show a peak at the resonant frequency of 26.4 Hz with a peak output power of approximately 16 µW for an input power of 660 µW. This equates to an efficiency at resonance of 2.4%, in good agreement with the results from the impulse experiment 7. Conclusions Efficiency is an important parameter in the characterisation of vibration energy harvesting systems, both in terms of the loading of the source of the energy and in device optimisation and minimisation of losses in energy transfer across system boundaries. Figure 4. Experimental Setup. The experimental setup is shown in Figure 4. A vibration motor provided mechanical excitation to the energy harvester. The transmitted force was measured using a Dytran 1053V1 dynamic force transducer with a Kistler 5114 coupler. The root and tip displacements were measured using two MEL laser triangulation sensors. The piezoelectric cantilever was a commercial ceramic bimorph fitted with a 1 g tip mass. Electrical output was recorded using a National NIPXI4461 (1MΩ) in parallel with a programmable resistance load. Figure 6. Efficiency obtained from impulse response as a function of load resistance. Because the decaying oscillation occurs at the resonant frequency of the cantilever, it is expected that a similar efficiency would be achieved in continuous resonant operation, but there is no experimental confirmation of this. We therefore measured efficiency under continuous sinusoidal vibration by also measuring the force input. The input mechanical power, Two methods of measuring efficiency are compared showing that measurements from an impulse excited decaying oscillation are comparable to those obtained from direct measurement under sinusoidal vibration. The impulse excitation method is simpler to implement, so these results validate the interpretation of impulse efficiency measurements for continuous excitation. There are a number of sources of error that limit the accuracy of the technique. These include accurate measurement of the stiffness, distributed mass loading, extraneous contributions to phase of the transmitted force and non-linear effects. References [3] D. N. Betts, H. A. Kim, C. R. Bowen and D. J. Inman, Optimal configurations of bistable piezo-composites for energy harvesting, Applied Physics Letters, vol. 100, p. 114104, 2012. [5] Karami, M. A. & Inman, D. J. Powering pacemakers from heartbeat vibrations using linear and nonlinear energy harvesters, Applied Physics Letters, 2012, 100, 042901 [1] M. Stewart, P. M. Weaver and M. Cain, Charge redistribution in piezoelectric energy harvesters, Applied Physics Letters, vol. 100, p. 073901, 2012. [4] Renaud, M., Elfrink, R., Jambunathan, M., de Nooijer, C., Wang, Z., Rovers, M., Vullers, R. & van Schaijk, R. Optimum power and efficiency of piezoelectric vibration energy harvesters with sinusoidal and random vibrations, Journal of Micromechanics and Microengineering, 2012, 22, 105030 [6] Cho, J.; Richards, R.; Bahr, D.; Richards, C. & Anderson, M., Efficiency of energy conversion by piezoelectrics, Applied physics letters, 2006, 89, 104107 [2] A. Erturk and D. J. Inman, Piezoelectric Energy Harvesting, Wiley, 2011.