Managerial Accounting Textbook: Tools for Business Decisions

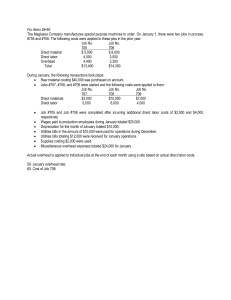

advertisement