Research and Development Priorities to Advance Solar Photovoltaic Lifecycle Costs and Performance

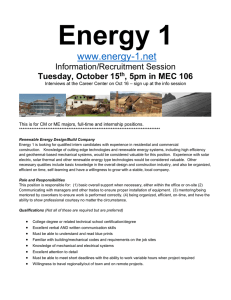

advertisement