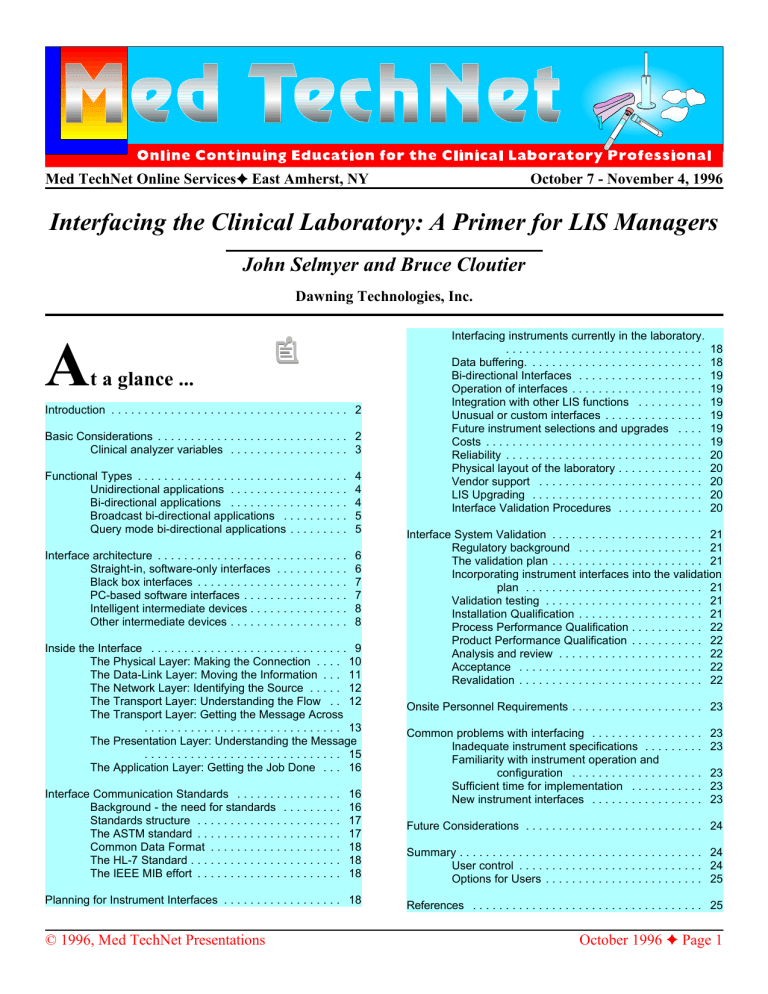

01-Interfacing the Clinical Laboratory A Primer for LIS Managers (1996 LIS History)

advertisement