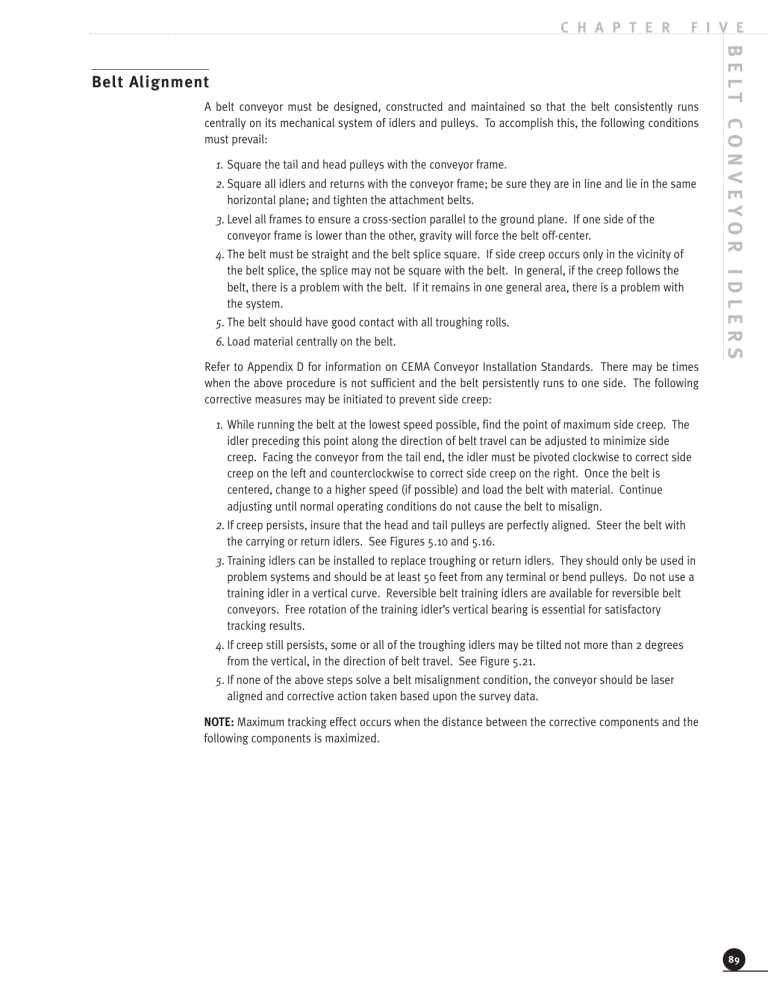

C H A P T E R F I V E A belt conveyor must be designed, constructed and maintained so that the belt consistently runs centrally on its mechanical system of idlers and pulleys. To accomplish this, the following conditions must prevail: 1. Square the tail and head pulleys with the conveyor frame. 2. Square all idlers and returns with the conveyor frame; be sure they are in line and lie in the same horizontal plane; and tighten the attachment belts. 3. Level all frames to ensure a cross-section parallel to the ground plane. If one side of the conveyor frame is lower than the other, gravity will force the belt off-center. 4. The belt must be straight and the belt splice square. If side creep occurs only in the vicinity of the belt splice, the splice may not be square with the belt. In general, if the creep follows the belt, there is a problem with the belt. If it remains in one general area, there is a problem with the system. 5. The belt should have good contact with all troughing rolls. 6. Load material centrally on the belt. B E LT C O N V E Y O R I D L E R S Belt Alignment Refer to Appendix D for information on CEMA Conveyor Installation Standards. There may be times when the above procedure is not sufficient and the belt persistently runs to one side. The following corrective measures may be initiated to prevent side creep: 1. While running the belt at the lowest speed possible, find the point of maximum side creep. The idler preceding this point along the direction of belt travel can be adjusted to minimize side creep. Facing the conveyor from the tail end, the idler must be pivoted clockwise to correct side creep on the left and counterclockwise to correct side creep on the right. Once the belt is centered, change to a higher speed (if possible) and load the belt with material. Continue adjusting until normal operating conditions do not cause the belt to misalign. 2. If creep persists, insure that the head and tail pulleys are perfectly aligned. Steer the belt with the carrying or return idlers. See Figures 5.10 and 5.16. 3. Training idlers can be installed to replace troughing or return idlers. They should only be used in problem systems and should be at least 50 feet from any terminal or bend pulleys. Do not use a training idler in a vertical curve. Reversible belt training idlers are available for reversible belt conveyors. Free rotation of the training idler’s vertical bearing is essential for satisfactory tracking results. 4. If creep still persists, some or all of the troughing idlers may be tilted not more than 2 degrees from the vertical, in the direction of belt travel. See Figure 5.21. 5. If none of the above steps solve a belt misalignment condition, the conveyor should be laser aligned and corrective action taken based upon the survey data. NOTE: Maximum tracking effect occurs when the distance between the corrective components and the following components is maximized. 89 B E LT C O N V E Y O R I D L E R S CHAPTER FIVE Belt Alignment Cont. Table 5.41 Average weight (lbf) of troughing idler rotating parts – steel rolls Table 5.42 Average weight (lbf) of return idler rotating parts – steel rolls Table 5.43 WK2 (lbf-in2) average for three equal-roll troughing idlers Table 5.44 WK2 (lbf-in2) average for single steel return idlers 90 Belt Width CEMA Idler Class (in) B4 B5 C4 C5 C6 18 24 30 36 42 48 54 60 72 84 96 15.0 18.3 21.8 25.3 30.8 32.9 19.2 24.2 28.3 33.0 38.1 41.6 14.5 17.5 20.5 23.5 26.5 29.5 19.1 23.2 26.8 31.3 35.2 39.3 45.9 50.1 26.7 32.6 38.0 43.6 49.2 54.8 62.3 68.3 Belt Width D5 D6 23.2 26.8 31.3 35.2 39.3 45.9 50.1 57.9 32.6 38.0 43.6 49.2 54.8 62.3 68.3 77.8 E6 E7 F6 F7 F8 64.8 73.3 81.9 93.6 102.2 119.4 132.0 145.3 81.8 91.7 101.3 121.8 132.7 154.5 164.0 173.0 143.0 169.0 195.0 221.0 162.0 191.0 219.0 248.0 180.0 211.0 243.0 274.0 E6 E7 F6 F7 F8 59.0 67.4 75.6 83.2 92.2 109.4 114.0 122.0 70.0 80.1 89.9 99.9 109.4 129.0 136.2 149.8 132.0 156.0 181.0 205.0 148.0 175.0 202.0 229.0 163.0 192.0 222.0 252.0 E6 E7 F6 F7 F8 446 502 564 628 689 811 985 1114 801 876 1017 1127 1234 1451 1598 1804 838 967 1095 1224 1278 1481 1695 1921 1901 2208 2532 2870 E6 E7 F6 F7 F8 419 479 539 597 659 779 933 1074 750 857 963 1070 1177 1391 1581 1737 753 884 1014 1145 1171 1376 1582 1790 1760 2071 2382 2693 CEMA Idler Class (in) B4 B5 C4 C5 C6 18 24 30 36 42 48 54 60 72 84 96 13.1 16.3 19.5 22.7 26.0 27.4 16.3 20.9 24.5 28.5 33.0 36.1 12.2 15.2 18.2 21.2 24.6 27.6 16.6 20.1 24.0 28.0 32.1 36.1 21.6 27.1 32.3 37.6 43.3 48.4 Belt Width D5 D6 20.9 25.8 30.1 34.3 38.7 43.4 49.2 55.1 30.1 35.4 40.5 47.2 54.4 60.8 68.1 74.9 CEMA Idler Class (in) B4 B5 C4 C5 C6 18 24 30 36 42 48 54 60 72 84 96 43 53 65 78 90 104 90 116 140 161 185 207 45 56 67 79 91 105 90 116 140 161 185 207 223 245 179 224 269 313 358 400 447 493 Belt Width D5 D6 116 140 161 185 207 223 245 266 224 269 313 358 400 447 493 538 CEMA Idler Class (in) B4 B5 C4 C5 C6 18 24 30 36 42 48 54 60 72 84 96 41 50 61 72 83 94 85 106 128 152 174 196 42 51 61 72 83 94 85 106 128 152 174 196 165 210 254 312 348 385 D5 D6 106 128 152 174 196 218 234 256 210 254 312 248 385 429 473 513