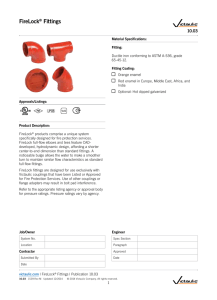

Over 80 years of piping system solutions where innovation and solutions are joined together. Victaulic, the world leader in grooved mechanical pipe joining systems, was founded on innovation. In 1925, the company introduced what was then a radical new concept in the piping industry: a mechanical bolted coupling that joins grooved pipe ends. Developed during World War I as a way to quickly deploy fuel and water lines to Allied forces, this innovative coupling became known as the “victory joint.” After the war, as the company shifted its focus to the commercial piping industry, the name became Victaulic, which is a combination of “victory” and “hydraulics.” Nearly a century later, the ability to create innovative solutions for unique challenges still marks the Victaulic approach. All around the world, Victaulic systems have been proven to dramatically reduce installation time, provide significant savings in total installed cost, and offer complete, start-to-finish solutions to challenging projects. [1] specified for the world’s most demanding projects. Look inside many of the world’s most challenging projects, and you’ll find Victaulic solutions at work: making bold design innovations possible, speeding time to completion, allowing for unpredictable seismic movements and setting the stage for easy scalability. For more than 80 years, Victaulic has been delivering innovative solutions for a demanding world. CANADA CN Tower [2] UNITED STATES EGYPT FRANCE Hoover Dam Alexandria Library La Grande Arche de la Défense UNITED ARAB EMIRATES CHINA SINGAPORE MALAYSIA CANADA UNITED STATES Burj Al Arab Hotel Jin Mao Tower Esplanade Theater Petronas Towers Athabasca Oil Sands Industrial Plant Piping Toronto, Canada Easton, PA United States Nazareth, Belgium Shanghai, China SUPPORTING LOCATIONS WORLDWIDE Victaulic employs more than 3,000 people worldwide with its world headquarters located in Easton, Pennsylvania, USA. Customers are supported through the regional headquarters shown on the map above as well as through manufacturing facilities, distribution centers and sales offices located around the world. Victaulic manufacturing and distribution facilities are located in the United States, Canada, Europe, the Middle East and Asia. Regardless of project location, Victaulic has factory-trained piping specialists available in the field to service customer needs worldwide. [3] [4] 1925 depended on every day since . Founded more than 80 years ago on the landmark idea of machining a groove into pipes and coupling them together, Victaulic has changed the landscape of piping construction. The company’s uncompromising standards have also earned its products a place within many of the structures that the world depends on most. For example, there may be no greater symbol of reliability in the world than the Hoover Dam. From the day it was completed in 1935, it has successfully held back the forces of the mighty Colorado River, and is counted upon as the major source of hydroelectric power and water for the American Southwest. When it was determined that the historic dam needed maintenance of aging parts – with minimal disruption of service – the Bureau of Land Management turned to Victaulic for an innovative piping solution. The Victaulic grooved system provided reliability and speed, enabling the project to be completed effectively and on time. HOOVER DAM Built to withstand 45,000 pounds per square foot (20.412 kg per 929 cm) of water pressure, the Hoover Dam supplies more than 16 million people and numerous industries with a dependable water supply for municipal, industrial and other domestic uses in southern Nevada, Arizona and southern California. It also generates four billion kilowatthours of hydroelectric energy annually. [5] productivity, profitability. Victaulic pipe joining solutions are estimated to reduce average man-hours up to 30% over welding. They have also been shown to reduce calendar days and to accelerate construction to meet today’s compressed schedules. In addition, Victaulic products require no flame which enhances safety and lowers insurance costs. [6] [7] ahead of the curve. Innovation has always been the hallmark of Victaulic. So it’s not surprising that the world’s most innovative designs depend on Victaulic piping solutions. When the time came to turn the breakthrough architectural renderings of the Burj Al Arab Hotel into reality, the engineers turned to Victaulic couplings to make the piping within the world-renowned curved structure functional and dependable. The result is a 7-Star hotel unparalleled for luxury and aesthetic excellence. To enable the piping system of the Burj Al Arab to follow its stunning sail-shaped contour, designers specified flexible Victaulic couplings in a range of sizes. This reduced the number of fittings that otherwise would have been required, and also provided accommodation for seismic and settlement movements that occur in the area. AN ICON OF MODERN ARCHITECTURE Considered the world's most luxurious hotel, the Burj Al Arab was developed by WS Atkins to be an icon for Dubai. According to architect Tom Wills Wright, “The litmus test we used to assess if we had fulfilled the brief was to see if we could draw the building in five seconds and ask everybody to name it.” [8] [9] [ 10 ] elegant solutions. A worldwide symbol of luxury, the 30-story Spa Tower of the Bellagio in Las Vegas needed a fire protection system that matched its elegant style. Victaulic not only provided the full line of fire protection products and services, the company also delivered commercial sprinklers concealed in decorative casings to match the Renaissance flair of the hotel. The Bellagio is known for its magnificent accommodations and priceless works of art. To provide maximum protection for the premises, a combination of wet and dry fire protection methods are used, with Victaulic products serving both systems. Victaulic devices continue to revolutionize size and performance standards within the fire protection industry. The flagship line of FireLock NXT ™ devices eliminates the need for complex flow calculations. Regardless of the system size each device is set to a single, consistent rating. The Bellagio Spa Tower is built with three sprinkler systems per floor, for a total of 26,250 sprinklers in the tower alone. Victaulic sprinklers are used to protect everything from luxury hotels to warehouses, libraries to computer rooms and everything in between. [ 11 ] a culture of quality. Standing proudly along the banks of the Nile, a location considered by many to be the cradle of civilization, Egypt’s Alexandria Library, Conference and Cultural Center safeguards some of world’s most treasured artifacts. Halfway around the globe, in another of the world’s great cultural crossroads, the Grand Arche de La Defense rises above Paris as one of architecture’s most stunning achievements. What both of these landmarks have in common is they have entrusted their piping systems to the proven dependability and versatility of Victaulic piping solutions. Protecting the priceless artifacts in the Alexandria Library required a piping system of unparalleled reliability. Victaulic grooved couplings, fittings, valves and accessories were used on the center’s fire protection and HVAC systems. GRANDE ARCHE DE LA DEFENSE, PARIS So large that Notre Dame Cathedral could fit inside its cube, the Grande Arche de La Defense uses Victaulic piping solutions for their unique versatility, including the ability to accommodate expansion, contraction and deflection. [ 12 ] EGYPT Alexandria Library [ 13 ] [ 14 ] faster. safer. easier. In fire protection systems where grooved piping is the accepted standard, there is still a need for faster, easier and safer piping systems. With the introduction of the new installation-ready FireLock EZ™ coupling, Victaulic has set a new standard for speed and ease of installation. With no loose parts, FireLock EZ dramatically reduces the time needed to install grooved systems. As the first manufacturer to receive UL approval for fire protection services, Victaulic has always been at the forefront of product innovation and development for fire protection systems. Based on customer feedback and over 80 years of market experience Victaulic is continually striving to create products that make piping systems faster, easier and safer. [ 15 ] the style of success. When fast-rising fashion retailer Urban Outfitters outgrew its former headquarters, the company needed a new facility that could support its expectations of doubling its business within five years. Having selected an existing structure at the Philadelphia Naval Yard to repurpose, Urban Outfitters began renovating immediately upon signing the deal. Faced with the need to compress schedules and reduce project calendar days, the contractor chose Victaulic piping systems for their speed, reliability and flexibility, and Victaulic Bag and Tag Services to reduce job-site handling. Through this combination of efficient products and services, Victaulic contributed significantly to the meeting of a highly accelerated renovation schedule. The center piece of the new Urban Outfitters headquarters campus is a glass-enclosed heating/ cooling central plant that occupies the lobby area of the main office building. This central plant features many of the most innovative Victaulic products including the Advanced Groove System (AGS) for large diameter piping systems. [ 16 ] [ 17 ] [ 18 ] finishing in record time. A model of international cooperation between architects, engineers and local construction firms, the National Stadium Olympic venue in Beijing, an outstanding landmark of the XXIX Olympiad, is set to achieve its completion in record time. Victaulic provided the piping solutions for this project, which will handle the demands for transport, accommodation and stadia for more than 5,000 athletes, support staff and family members. Victaulic not only secured the contract for the National Stadium in Beijing, but its systems are also used on other related Olympic venues and developments. Victaulic advance project planning services help owners avoid delays due to product availability issues. The company’s specification updates also help minimize costly future change orders. And because of the efficiency during installation, Victaulic piping systems are installed in up to 30% less time, reducing project calendar days. EASE OF INSTALLATION SPEEDS COMPLETION With Victaulic systems, efficiency and ease of installation are guaranteed, as is the flexibility to meet a project’s unique design requirements – a factor particularly in evidence at the ambitious Olympic sites in Beijing. [ 19 ] dynamic design. One of the greatest statements of the ability of Victaulic to make architectural visions possible stands out spectacularly on London’s skyline. Affectionately known as “The Gherkin,” 30 St Mary Axe was commissioned by Swiss Re. The building’s facade, designed to maximize natural ventilation, is cooled by air extracted from the offices to reduce overall heat load. To further reduce energy usage, decentralized on-floor plants allow mechanical ventilation to be controlled on a floor-by-floor basis. Due to its advanced requirements and remarkable shape, this landmark required an innovative and highly flexible piping solution. Victaulic was selected for HVAC and fire protection systems, providing the internal structure for one of the world’s most striking architectural creations. The sound attenuation properties of Victaulic flexible couplings contributed greatly to making the on-floor plants of 30 St Mary Axe a reality. The gasket at the heart of Victaulic couplings significantly reduces sound vibration, keeping the facilities quiet for all building occupants. Despite its distinctive curved shape, the only piece of curved glass in 30 St Mary Axe is the lens at the top of the building. [ 20 ] [ 21 ] unearthing solutions. Since it was founded more than 80 years ago, Victaulic has continuously developed new innovations that change the industry. For example, the Victaulic system for high density polyethylene (HDPE) pipe was developed to allow for bolted mechanical assembly without the need for heat fusing machinery. This resulted in greater safety, faster installation and the productivity benefit of not requiring electrical connections for fusing equipment. [ 22 ] [ 23 ] meeting towering demands. The Taipei Financial Center, also known as Taipei 101, is currently considered the tallest building in the world, rising to 1,676 feet high. Since it is located in the Pacific Rim’s seismic zone and is subject to great weight and wind pressures, Taipei 101 required an innovative piping solution that was flexible enough to handle the unique forces at work while consistently delivering dependable HVAC and fire protection services. Victaulic flexible couplings were used for angular deflection of branches to the air-handling units on every floor. Victaulic expansion joints, used as flexible connectors, were installed at strategic locations on potable water and wet risers. [ 24 ] 550 500 450 400 350 300 250 200 150 100 50 meters The Victaulic system provides many mechanical design features useful in systems subject to earthquake conditions. The inherent flexibility of Victaulic flexible couplings reduces the transmission of stresses throughout the pipe system, and the resilient gasket aids to further reduce the transmission of vibration. End Load End Load The structural standards of the Taipei Financial Center call for the ability to withstand the strongest earthquake in a 2,500 year cycle. The ability to effectively accommodate seismic movement was one key reason the Victaulic grooved system was specified as the center’s pipe joining method of choice. [ 25 ] unique challenges. unique solutions. Throughout Victaulic history, many types of natural resources have moved through the pipelines our products hold together. But at the Rocky Reach Hydroelectric Dam in Wenatchee, Washington, that resource moves under their own power… because they’re fish. The Chelan County Public Utilities Department commissioned a “Juvenile Fish Bypass” for young salmon to swim down after being hatched in the upstream spawning grounds. In a project challenged by underwater construction, difficult conditions and a tight time frame, Victaulic Depend-O-Lok™ couplings and expansion joints eliminated the need to build harnesses, installed faster than sleeve couplings, and helped lower project costs as well. Rocky Reach Dam was constructed in 1956. But every year, up to 6% of the salmon and steelhead runs perished in its turbines during their seasonal migration to the sea. One alternative: spill 40% to 50% of the water by the dam, at a cost of reducing power generation by $25 million a year. The second option: construct a pipe around the turbines so that fish could pass through unharmed. Victaulic Depend-O-Lok type F × F restrained couplings and expansion joints were used to connect pipe joints along the entire length of the dam. [ 26 ] Today, the fish are collected upstream via pumps that conduct water flows of up to 7,000 cubic feet per second to attract the fish into the conduit. They are then transported through the 4,600-foot pipeline, held together by Victaulic couplings, to a discharge point on the downstream side of the dam. [ 27 ] [ 28 ] rugged and reliable. Piping systems used in mining must withstand some of the most abrasive materials on earth. In the Athabasca Oil Sands Project in Alberta, where workers braving temperatures of -40º F/-40º C are helping Syncrude Canada Ltd. extract “heavy oil” from northern Canada’s sludge-filled tar and sand pits, Victaulic couplings are holding the pipes together. In challenging applications around the world, the Victaulic line of piping solutions is helping owners and project managers enhance productivity, meet accelerated schedules and increase profitability. Difficult applications demand creative solutions. Exposed to extreme cold temperatures and highly abrasive media, the piping system for Athabasca needed to be easy to install and maintain. Since non-standard pipe was used, Victaulic created a coupling that was specifically designed to handle the size, temperature and service requirements of the system. ATHABASCA OIL SANDS It is estimated that the Athabasca Oil Sands deposit contains 1.6 trillion barrels (250 km3) of crude. The total product coming through the region’s pipelines is expected to represent 10% of North America's oil production by 2010. [ 29 ] built for speed. The automotive industry is known for its hard-driving schedules. So when Hyundai Motors undertook the project of building a new manufacturing plant in Montgomery, Alabama, they specified Victaulic systems on their compressed air, cooling water, chilled water and condenser water lines. Installation cost savings and fast-track schedule requirements were critical for this construction project, and Victaulic helped the company reach the finish line in world-class time. Welded Peak Man-Power NUMBER OF MEN ON SITE Shift Maximum Manpower Line FEWER MAN-HOURS: FASTER COMPLETION Victaulic Peak Man-Power Meet or Beat Project Schedule Job studies have shown that grooved pipe joining requires up to 30% fewer man-hours than welding. This not only shortens schedule time, it also increases safety by minimizing risk exposure. MECHANICAL CONSTRUCTION WEEKS Fast and easy to install on large-diameter piping systems, Victaulic Advanced Groove System (AGS) couplings dramatically impact installation times, resulting in lower total installed cost, and significantly reduce plant downtime. [ 30 ] [ 31 ] [ 32 ] faster system. better results. For the engineers and contractors charged with building a municipal water pumping station and reservoir to serve the regions of York and Peel in Ontario, Canada, space and time were critical issues. By selecting Victaulic Depend-O-Lok couplings to join the largediameter cement-lined pipe used in the city water lines, the builders were better able to meet the municipalities’ service demands. Depend-O-Lok couplings are designed to meet almost any application or service criteria. The Depend-O-Lok encapsulating coupling is designed to be installed right over the existing pipeline to provide a faster, easier repair solution. It is fast, economical and provides a long-term solution to the problem of leaking or failing joints. YORK PUMPING STATION The pumping station owners required a stainless steel bypass system for an added safety factor. Victaulic Depend-O-Lok couplings specifically designed for stainless steel piping were used in this application. [ 33 ] pure power. The extraordinary demands of the power industry require joining systems that can stand up to highly abrasive materials and provide continuous uninterrupted service. For more than 80 years, Victaulic has been keeping power companies going strong, with a line of products created specifically for the needs of the industry. [ 34 ] [ 35 ] [ 36 ] high adaptability for high technology. Intel Micron Flash Technologies, a joint venture between Intel and Micron, sought to capitalize on the sudden rise in demand for flash memory products. Although the construction of their plant in Lehi, Utah was already considered fast track, it was accelerated to an ultra-fast schedule to maximize the market opportunity. The revised schedule required significant process equipment changes to be made, leading to the relocation of alreadyinstalled piping. Since Victaulic mechanical joints were used across most systems, installers were able to disassemble and reassemble easily and efficiently, helping them meet the project’s highly accelerated schedule. The potable water lines on this project were joined using Victaulic copper connection products. The remaining systems benefited from the application of Victaulic grooved carbon steel products, which include a complete line of check and butterfly valves, suction diffusers, strainers and the Victaulic Advanced Groove System. Victaulic systems are cold-formed and do not require open flames, which can disperse residues into the air. This makes them particularly appropriate for high-tech industries, which make ample use of clean technologies. [ 37 ] time is of the essence. The William Osler Health Centre provides emergency, specialized and general healthcare services to the province of Ontario, Canada, which is growing at the rate of 30,000 new residents per year. To serve the needs of the rapidly-expanding population, Osler Healthcare Group is adding a new hospital to the current Brampton Memorial Hospital Campus. Because of the time pressures of the construction, the need to assure service is not interrupted in the current facility, and the modular nature of the project, Victaulic solutions are the Health Centre’s products of choice for its HVAC, plumbing and fire protection piping systems. PRODUCTIVITY ANSWER Considered the “Productivity Answer” by many contractors, Victaulic recently improved its industry-leading, speed-of-assembly time with the introduction of the FireLock EZ, the first rigid coupling that installs as a single unit. [ 38 ] [ 39 ] [ 40 ] environmentally engineered. National construction leader Alberici built its new headquarters in Overland, Missouri, in a 14-month fast-track design/build schedule that was aggressively met by the mechanical contractor on the job. To meet this schedule, Alberici sought an innovative grooved piping solution for the building’s unique under-floor HVAC system and selected Victaulic to efficiently support the chilled and hot water systems for the building’s air distribution. After the project’s completion in early 2005, the US Green Building Council (USGBC) designated the building as the greenest building in the world because Alberici was able to accumulate more points under the Leadership for Energy and Environmental Design (LEED) rating system than any other building in history. The Victaulic grooved system fit Alberici’s intent for indoor air quality during construction helping to contribute to LEED certification. In addition, the Victaulic grooved piping system reduced on-site material waste and handling due to pre-planned pipe lengths. Victaulic piping systems can contribute to the LEED new construction rating system. For more information about LEED in North America, visit www.usgbc.org or www.cagbc.ca. [ 41 ] innovation is a part of the process. Some companies start their research and development in a laboratory. At Victaulic, our process begins in the field. The first step in our product development methodology is simple: listen to the customer. In fact, customer interaction shapes the entire product development process at Victaulic. This ongoing “voice of the customer” can only be offered because Victaulic is completely vertically-integrated: all research, development, manufacturing and quality control is performed and managed by Victaulic people at Victaulic locations. As a result, Victaulic has produced a constant stream of innovations for more than 80 years, including many breakthrough solutions that created pioneering changes in the way piping is installed. As the industry’s only single source manufacturer, Victaulic employs the latest molding technologies to ensure the highest performance and quality in its gaskets. In fact, Victaulic gaskets are subjected to stringent quality control standards and exhaustive testing, from air and water aging, to thermal cycling and compression set and tensile strength. These results, along with advanced analysis techniques, allow Victaulic product engineers the ability to predict and understand the performance of its products in real-world conditions. The ground-breaking Advanced Groove System (AGS) features a two-piece coupling housing in all sizes for enhanced strength, easier installation and single groove profile that all add up to the strongest Victaulic mechanical coupling assembly ever produced in its size range. [ 42 ] The industry-changing FireLock NXT device is the most compact and efficient device on the market. The lighter, simpler design includes fewer moving parts and simplified trim configurations for an outof-the-box installation that requires less time and labor to install and ultimately reduces project costs. [ 43 ] [ 44 ] the complete assurance of total quality control. Businesses that work with Victaulic not only have the confidence of knowing they are working with the leader in the industry, they also have the assurance that comes with working directly with the manufacturer. At Victaulic, quality is a pervasive corporate philosophy which directs the entire process of meeting customers’ requirements on time, every time. In fact, all Victaulic foundries have achieved ISO certification. Quality testing is performed at each step of the process to ensure our products meet the high demands of the marketplace. This includes metallurgical testing for every pour, and pressure testing and flow-testing for every valve. VPDS The Victaulic Product Delivery System, or VPDS, assures quality continues after manufacturing, with on-site and off-site support and a company-wide focus on just-in-time delivery. [ 45 ] [ 46 ] continuing to advance solutions. With the introduction of the patent-pending Advanced Groove System (AGS), Victaulic delivers a comprehensive solution for handling higher end loads, withstanding higher pressure ratings, and providing greater safety. The system also provides superior seismic-shock performance and a union at every joint for easy adjustment, maintenance or expansion. [ 47 ] 930s EARLIEST APPLICATIONS a history of continuous innovation. Due to their easy assembly, Victaulic systems first found their niche in services such as large water supply lines, oil field piping and mining piping systems. What began simply as a faster, easier and more economical way to join pipe now has evolved into a whole new approach to providing piping solutions. As the world leader in mechanical piping systems, Victaulic has set the global standard for piping efficiency, engineering expertise and performance reliability – not only for the typical project, but also for the world’s most demanding piping projects. 920s 1919 1920 1921 1922 1923 1924 1925 1926 1927 A STRONG FOUNDATION FOR INNOVATION [ 48 ] As the inventor of the grooved piping method, Victaulic designed its couplings using four basic components which remains unchanged even today. Comprised of a housing, gasket and bolts and nuts, Victaulic couplings have joined pipe simply and reliably for more than 80 years. 1928 1929 1930 1931 1932 1933 1934 1935 1936 1937 1938 1939 1940 19 0 950s PIONEERING ROLL GROOVING FOR EASE AND SAFETY Victaulic introduced roll grooving to the piping industry, making it far easier to prepare pipe to accept Victaulic grooved piping components. Pressing a groove into the pipe as it is rotated, roll groovers create a cold-formed groove without removing any metal or pipe material, thus enabling the pipe to retain its full pipe wall. 1941 1942 940s 1943 1944 1945 1946 1947 1948 1949 1950 1951 1952 INTRODUCTION OF WRENCH-ONLY ASSEMBLY 1953 1954 1955 1956 1957 1958 960s 1959 1960 1961 1962 1963 1964 1965 1966 1967 1968 1969 GLOBAL EXPANSION AND VERTICAL INTEGRATION ® With the introduction of the Roust-A-Bout coupling, Victaulic ushers in a new era of productivity by permitting wrench-only assembly of pipe. This innovative method does not require any pipe-end preparation such as threading or welding. Over the years, Victaulic expanded its market from North and South America to Asia and Europe, setting the stage for a global enterprise serving projects around the world. During this time, Victaulic also began a program of vertical integration that continues to this day. This program allows Victaulic to control every phase of product development, from design and testing, [ 49 ] through production and delivery to the marketplace. 970s CREATING BRANCH CONNECTIONS WITHOUT WELDING Victaulic pioneers a fast and easy way to insert a mid-pipe outlet without welding, known as the bolted mechanical branch connection. After a hole is drilled or cut into the pipe to receive a preformed outlet, positioning and sealing is assured using a pressure-responsive gasket molded to conform to the pipe’s outside diameter. 1970 1971 1972 1973 1974 1975 1976 1977 1978 1979 1975 Victaulic products are used in the mechanical shark in the film “JAWS.” [ 50 ] 1980 1981 980s 1982 1983 1984 1985 1986 1987 1988 1989 1990 IMPROVING AN INNOVATION: RIGID GROOVED COUPLINGS Having already designed the first rigid coupling, Victaulic takes the next step by introducing Zero-Flex®, a rigid coupling with a unique, angle bolt-pad design. The patented design eliminates the torque requirements of earlier rigid couplings, allows the coupling to resist flexural and torsional loads, and provides visual verification of proper installation. 1991 1992 2 990s CUSTOM SOLUTIONS By introducing the revolutionary Depend-O-Lok coupling system, Victaulic extended the life of existing large-diameter pipelines while making it easier to join new ones. Custom designed to meet the service challenges of large diameter piping systems, Depend-O-Lok couplings are ideal for industrial, wastewater, water or mine piping systems. Moving forward, the Victaulic charter of continuous product innovation will grow even stronger. In fact, today Victaulic leads the industry in the amount of resources it devotes to ongoing product research and development. Our focus is, and will remain, making piping installations faster, easier, safer, and more cost-effective. From concept to commissioning, Victaulic provides all the tools and services necessary to simplify your next piping project. 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2000 2003 2004 2005 2006 2007 2008 2009 the innovations continue... and beyond... THE FIRST COMPLETELY PRE-ASSEMBLED RIGID COUPLING The fastest fire protection coupling ever, the FireLock EZ rigid coupling provides users with increased efficiency. A lightweight, installation-ready coupling, the FireLock EZ has the added safety advantage of no loose parts. [ 51 ] HOUSING GROOVE BOLT/NUT GASKET GROOVE [ 52 ] the Victaulic difference. value-added services. At the root of all the benefits that Victaulic solutions bring to a project – such as productivity, safety, design flexibility and quality – are the unique features of its products. Victaulic offers Construction Piping Services (CPS) to assist customers in all aspects of a project, from pre-planning and concepts to the construction and post-construction phases. The only mechanical piping systems manufacturer with factory-trained piping specialists in the field worldwide, Victaulic offers such services as: VICTAULIC GROOVED END PIPING SYSTEMS PROVIDE: Contraction Deflection Flexibility – with the inherent expansion/contraction/ deflection properties of flexible couplings in grooved systems Rigidity – with an angled pad design that provides positive clamping of the pipe to resist torsional and flexural loads Noise and vibration attenuation – by isolating the transference of vibration at each joint Seismic stress absorption – by providing significant pressure restraint and end load capability to withstand pipe movement from internal and external sources The Victaulic service and support team is comprised of experienced sales representatives, on-site training personnel and engineering professionals, all prepared to help in facilitating the evaluation, planning and fulfillment of your piping system needs. End Load End Load Exaggerated for clarity Easy system maintenance and expansion – through simple coupling disassembly that allows for easy access For additional information about Victaulic products and services, visit www.victaulic.com. Value analysis Project management Field service Engineered products Alignment ease – through a design that allows for full rotation of the pipe and system components before tightening CB-100 © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. 01/2007