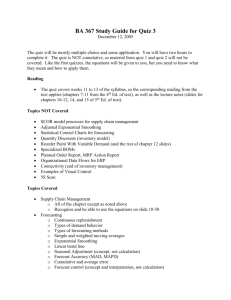

Republic of the Philippines POLYTECHNIC UNIVERSITY OF THE PHILIPPINES Office of the Vice President for Academic Affairs College of Business Administration INSTRUCTIONAL MATERIALS FOR BUMA 20013 / BUMA 20093: OPERATIONS MANAGEMENT (TQM) COMPILED BY: Prof. Reynaldo T. Barrera PUP A. Mabini Campus, Anonas Street, Sta. Mesa, Manila 1016 Direct Line: 335-1730 | Trunk Line: 335-1787 or 335-1777 local 000 Website: www.pup.edu.ph | Email: inquire@pup.edu.ph THE COUNTRY’S 1st POLYTECHNIC Introduction Global competition has caused fundamental changes in the competitive environment of manufacturing industries. Firms must develop strategic objectives which, upon achievement, result in a competitive advantage in the market place. However, for almost all manufacturing industries, an increased productivity and better overall efficiency of the production line are the most important goals. Most industries would like to find the formula for the ultimate productivity improvement strategy. Industries often suffer from the lack of a systematic and consistent methodology. In particular the manufacturing world has faced many changes throughout the years and as a result, the manufacturing industry is constantly evolving in order to stay ahead of competition. Innovation is a necessary process for the continuous changes in order to contribute to the economic growth in the manufacturing industry, especially to compete in the global market. In addition to innovation as a mode for continued growth and change, there are many other vehicles for growth in the manufacturing industry. While operations management has been recognized as an important factor in a country’s economic growth. The traditional view of manufacturing management is the concept of Production Management with the focus on economic efficiency in manufacturing. Later the new name Operations Management was identified, as service sector became more prominent. Rapid changes in technology have posed numerous opportunities and challenges, which have resulted in enhancement of manufacturing capabilities through new materials, facilities, techniques and procedures. Hence, managing a service system has become a major challenge in the global competitive environment. Operations Management has been a key element in the improvement and productivity in business around the world. Operations Management leads the way for the organizations to achieve its goals with minimum effort. Hence, the study of the subject at undergraduate and postgraduate level has more significance. Page 2 of 156 TABLE OF CONTENTS INTRODUCTION..................................................................................................................... 2 COURSE OUTCOMES ........................................................................................................... 7 LESSON 1 – OPERATIONS AND PRODUCTIVITY ............................................................... 8 Introduction to Operations Management ................................................................................. 8 Historical Development........................................................................................................... 9 Goods-Service Continuum.....................................................................................................11 Manufacturing Vs. Service .....................................................................................................11 Supply Chain .........................................................................................................................12 Concept of Production ...........................................................................................................13 Production System ................................................................................................................13 Role of the Operations Manager ............................................................................................16 Systems Approach ................................................................................................................19 Ethical Issues in Operations ..................................................................................................19 LESSON 2 – THE GLOBAL ENVIRONMENT AND OPERATIONS STRATEGY ..................20 Competitiveness ....................................................................................................................20 Marketing’s Influence.............................................................................................................20 Businesses Compete Using Operations ................................................................................20 Why Some Organizations Fail ...............................................................................................20 Hierarchical Planning.............................................................................................................21 Strategy Formulation .............................................................................................................22 Environmental Scanning ........................................................................................................22 Strategic OM Decision Areas.................................................................................................23 The Balanced Scorecard Approach .......................................................................................24 Why Productivity Matters .......................................................................................................25 LESSON 3 – MANAGING PROJECTS..................................................................................27 The Nature of Projects...........................................................................................................27 Project Management Decisions .............................................................................................27 Work Breakdown Structure (WBS) ........................................................................................28 Program Evaluation And Review Technique (PERT) And Critical Path Method (CPM) ..........29 LESSON 4 – FORECASTING DEMAND ...............................................................................31 Forecasting ...........................................................................................................................31 Elements of a Good Forecast ................................................................................................31 Steps in the Forecasting Process ..........................................................................................32 Forecasting Approaches ........................................................................................................32 LESSON 5 - PRODUCT DESIGN ..........................................................................................40 Reasons Design or Re-Design ..............................................................................................40 Legal Considerations .............................................................................................................41 Life Cycle Assessment (LCA) ................................................................................................42 Product or Service Life Stages ..............................................................................................43 Designing for Mass Customization ........................................................................................44 Component Commonality ......................................................................................................48 Reliability ...............................................................................................................................50 LESSON 6 – QUALITY MANAGEMENT ...............................................................................51 Quality Management .............................................................................................................51 Dimensions of Product Quality ..............................................................................................52 Assessing Service Quality .....................................................................................................52 Determinants of Quality .........................................................................................................53 Responsibility for Quality .......................................................................................................53 Costs of Quality .....................................................................................................................53 Ethics and Quality .................................................................................................................54 Baldrige Criteria.....................................................................................................................54 Quality Certification ...............................................................................................................55 Total Quality Management.....................................................................................................55 LESSON 7 - PROCESS DESIGN ..........................................................................................66 Process Selection ..................................................................................................................66 Process Strategy ...................................................................................................................67 Technology for Competitive Advantage .................................................................................67 Product and Service Profiling ................................................................................................69 LESSON 8 – LOCATION DECISIONS ..................................................................................71 The Need For Location Decisions..........................................................................................71 Location Decisions: Objectives ..............................................................................................71 Location Decision: General Procedure ..................................................................................72 Global Location: Facilitating Factors ......................................................................................72 Managing Global Operations .................................................................................................73 Geographic Information System (GIS) ...................................................................................75 Service and Retail Locations .................................................................................................76 Factor Rating .........................................................................................................................77 LESSON 9 – LAYOUT DECISIONS ......................................................................................79 Facilities Layout.....................................................................................................................79 Repetitive Processing ............................................................................................................80 Service Layout.......................................................................................................................83 Designing Process Layouts ...................................................................................................85 LESSON 10 – JOB DESIGN AND WORK MEASUREMENT ................................................86 Quality of Work Life ...............................................................................................................86 Job Design ............................................................................................................................88 Ergonomics ...........................................................................................................................90 Methods Analysis ..................................................................................................................90 Developing Work Methods.....................................................................................................93 Work Sampling ......................................................................................................................94 LESSON 11 – SUPPLY CHAIN MANAGEMENT ..................................................................96 Supply Chain .........................................................................................................................96 Supply Chain Management ...................................................................................................97 Flow Management .................................................................................................................98 Global Supply Chains ............................................................................................................98 Procurement ..........................................................................................................................98 Supplier Management .........................................................................................................101 Inventory Management ........................................................................................................102 Logistics ..............................................................................................................................103 LESSON 12 – MANAGING INVENTORY ............................................................................108 Inventory .............................................................................................................................108 Inventory Counting Systems ................................................................................................109 Abc Classification System ...................................................................................................110 Cycle Counting ....................................................................................................................110 When to Reorder .................................................................................................................114 Fixed-Quantity Vs. Fixed-Interval Ordering ..........................................................................117 LESSON 13 – AGGREGATE PLANNING ...........................................................................119 Sales and Operations Planning ...........................................................................................119 Techniques for Aggregate Planning .....................................................................................123 Aggregate Planning in Services ...........................................................................................124 Disaggregating the Aggregate Plan .....................................................................................125 LESSON 14 – MATERIAL REQUIREMENTS PLANNING (MRP) AND ENTERPRISE RESOURCE PLANNING (ERP) ...........................................................................................129 Dependent Demand ............................................................................................................129 Overview of MRP ................................................................................................................130 MRP Lot Sizing Rules..........................................................................................................134 Using the MRP ....................................................................................................................134 Capacity Requirements Planning.........................................................................................137 Enterprise Resource Planning .............................................................................................138 LESSON 15 – SCHEDULING ..............................................................................................140 Scheduling ..........................................................................................................................140 High Volume Systems .........................................................................................................141 Loading Approaches............................................................................................................143 LESSON 16 – LEAN OPERATIONS ...................................................................................144 Lean Operations: The Beginning .........................................................................................144 Lean: Ultimate Goal .............................................................................................................145 Lean: Supporting Goals .......................................................................................................145 Lean: Building Blocks ..........................................................................................................146 Value Stream Mapping ........................................................................................................152 Transitioning to Lean Systems ............................................................................................152 Lean Services......................................................................................................................153 REFERENCES ....................................................................................................................156 Course Outcomes • • • • • Understand the application of managerial functions to effective and efficient operations management Understand the operative functions involve in operations management Analyze operational problems and apply appropriate techniques to address them Evaluate effective and efficient operational strategy applicable to different business situations Create an effective and efficient operational strategy to different business situations Page 7 of 156 LESSON 1 – OPERATIONS AND PRODUCTIVITY OVERVIEW Effective operations management helps with employee engagement and defines the roles and responsibilities within an organization. No matter what challenges that an organization faces, a strategic operations management plan in place will ensure that employees’ workflow and company production remain unaffected. LEARNING OUTCOMES After this lesson, students will be able to: ✓ Appreciate and learn the concept of operations management and the functions associated with it. ✓ Describe the operations management for goods and services. ✓ Determine the challenges in achieving sustainable production while ensuring the company’s ethical and social responsibilities. COURSE MATERIALS Introduction to Operations Management • • • • What is operations? The part of a business organization that is responsible for producing goods or services How can we define operations management? The management of systems or processes that create goods and/or provide services. Scope of Operations Management The scope of operations management ranges across the organization. The operations function includes many interrelated activities such as: ➢ Forecasting ➢ Capacity planning ➢ Scheduling ➢ Managing inventories ➢ Assuring quality ➢ Motivating employees ➢ Deciding where to locate facilities ➢ And more Basic Functions of the Business Organization Organization Marketing Page 8 of 156 Operations Finance Marketing refers to activities a company undertakes to promote the buying or selling of a product or service. Marketing includes advertising, selling, and delivering products to consumers or other businesses. Some marketing is done by affiliates on behalf of a company. (Source: Investopedia.com) Financial Management means planning, organizing, directing and controlling the financial activities such as procurement and utilization of funds of the enterprise. It means applying general management principles to financial resources of the enterprise. (Source: Managementstudyguide.com) Historical Development Industrial Revolution Pre-Industrial Revolution • • ➢ Craft production - System in which highly skilled workers use simple, flexible tools to produce small quantities of customized goods Some key elements of the industrial revolution ➢ Began in England in the 1770s ➢ Division of labor - Adam Smith, 1776 ➢ Application of the “rotative” steam engine, 1780s ➢ Cotton Gin and Interchangeable parts - Eli Whitney, 1792 Management theory and practice did not advance appreciably during this period Scientific Management • • Movement was led by efficiency engineer, Frederick Winslow Taylor ➢ Believed in a “science of management” based on observation, measurement, analysis and improvement of work methods, and economic incentives ➢ Management is responsible for planning, carefully selecting and training workers, finding the best way to perform each job, achieving cooperate between management and workers, and separating management activities from work activities. ➢ Emphasis was on maximizing output Scientific Management – contributors ➢ Frank Gilbreth - father of motion studies ➢ Henry Gantt - developed the Gantt chart scheduling system and recognized the value of non-monetary rewards for motivating employees ➢ Harrington Emerson - applied Taylor’s ideas to organization structure ➢ Henry Ford - employed scientific management techniques to his factories - Moving assembly line - Mass production Human Relations Movement • The human relations movement emphasized the importance of the human element in job design Page 9 of 156 ➢ ➢ ➢ ➢ ➢ ➢ Lillian Gilbreth Elton Mayo – Hawthorne studies on worker motivation, 1930 Abraham Maslow – motivation theory, 1940s; hierarchy of needs, 1954 Frederick Hertzberg – Two Factor Theory, 1959 Douglas McGregor – Theory X and Theory Y, 1960s William Ouchi – Theory Z, 1981 Decision Models & Management Science • • • • • F.W. Harris – mathematical model for inventory management, 1915 Dodge, Romig, and Shewart – statistical procedures for sampling and quality control, 1930s Tippett – statistical sampling theory, 1935 Operations Research (OR) Groups – OR applications in warfare George Dantzig – linear programming, 1947 Influence of Japanese Manufacturers • Refined and developed management practices that increased productivity ➢ Credited with fueling the “quality revolution ➢ Just-in-Time production Exhibit 1.1 Historical summary of operations management Page 10 of 156 Goods-service Continuum • Products are typically neither purely service- or purely goods-based. Exhibit 1.2 Examples of Goods and Services Manufacturing vs. Service • Manufacturing is characterized by tangible outputs (products). Consumption of outputs at overtime. Jobs useless labor and more equipment, little customer contact, no customer participation in the conversion process (in production). Sophisticated methods for measuring production activities and resource consumption as product are made. • Service is characterized by intangible outputs. In addition, it possesses a potential for high variability in quality of output. Production and consumption occur simultaneously. Jobs use more labor and less equipment, direct consumer contact, frequent customer participation in the conversion process. Elementary methods for measuring conversion activities and resource consumption are used. • Manufacturing and Service Organizations differ chiefly because manufacturing is goodsoriented and service is act-oriented. • The following characteristics can be considered for distinguishing Manufacturing Operations with Service Operations: 1. Tangible/Intangible nature of output 2. Production and consumption 3. Nature of work (job) 4. Degree of customer contact 5. Customer participation in conversion 6. Measurement of performance 7. Quality of output 8. Inventory accumulated. Page 11 of 156 Managing Services is Challenging 1. Jobs in services are often less structured than in manufacturing 2. Customer contact is generally much higher in services compared to manufacturing 3. In many services, worker skill levels are low compared to those of manufacturing employees 4. Services are adding many new workers in low-skill, entry-level positions 5. Employee turnover is high in services, especially in low-skill jobs 6. Input variability tends to be higher in many service environments than in manufacturing 7. Service performance can be adversely affected by many factors outside of the manager’s control (e.g., employee and customer attitudes) Supply Chain • Supply Chain – a sequence of activities and organizations involved in producing and delivering a good or service. Exhibit 1.3 Supply Chain Process Elements of Supply Chain Management • Customers – what products/services do customers want • Forecasting – predicting timing and volume of customer demand • Design – incorporating customer wants, manufacturability, and time to market • Capacity planning – matching supply and demand • Processing – controlling quality, scheduling work • Inventory – meeting demand requirements while managing costs • Purchasing – evaluating potential suppliers, supporting the needs of operations on purchased goods and services • Suppliers – monitoring supplier quality, on-time delivery, and flexibility; maintaining supplier relations • Location – determining the location of facilities • Logistics – deciding how to best move information and materials The Need for Managing the Supply Chain • In the past, organizations did little to manage the supply chain beyond their own operations and immediate suppliers which led to numerous problems: Page 12 of 156 ➢ Oscillating inventory levels ➢ Inventory stockouts ➢ Late deliveries ➢ Quality problems Supply and Demand Concept of Production Production function is ‘the part of an organization, which is concerned with the transformation of a range of inputs into the required outputs (products) having the requisite quality level’. Production is defined as ‘the step-by-step conversion of one form of material into another form through chemical or mechanical process to create or enhance the utility of the product to the user’. Thus, production is a value addition process. At each stage of processing, there will be value addition. Edwood Buffa defines production as ‘a process by which goods and services are created’. Some examples of production are: manufacturing custom-made products like, boilers with a specific capacity, constructing flats, some structural fabrication works for selected customers, etc., and manufacturing standardized products like, car, bus, motor cycle, radio, television, etc. Production System The production system is ‘that part of an organization, which produces products of an organization. It is that activity whereby resources, flowing within a defined system, are combined and transformed in a controlled manner to add value in accordance with the policies communicated by management’. Page 13 of 156 A simplified production system is shown below: Exhibit 1.4 Schematic Production System • • Feedback - measurements taken at various points in the transformation process Control - the comparison of feedback against previously established standards to determine if corrective action is needed. The production system has the following characteristics: 1. 2. 3. 4. Production is an organized activity, so every production system has an objective. The system transforms the various inputs to useful outputs. It does not operate in isolation from the other organization system. There exists a feedback about the activities, which is essential to control and improve system performance. Transformation and Value Adding Activities The objective of combining resources under controlled conditions is to transform them into goods and services having a higher value than the original inputs. The transformation process applied will be in the form of technology to the inputs. The effectiveness of the production factors in the transformation process is known as productivity. The productivity refers to the ratio between values of output per work hour to the cost of inputs. The firm’s overall ratio must be greater than 1, then we can say value is added to the product. Operations manager should concentrate improving the transformation efficiency and to increase the ratio. Exhibit 1.6 Schematic model for operations/production system Operations Management Objectives Page 14 of 156 Objectives of Operations Management can be categorized into Customer Service and Resource Utilization. Customer Service. The first objective of operating systems is to utilize resources for the satisfaction of customer wants. Therefore, customer service is a key objective of operations management. The operating system must provide something to a specification, which can satisfy the customer in terms of cost and timing. Thus, providing the ‘right thing at a right price at the right time’ can satisfy primary objective. These aspects of customer service – specification, cost and timing – are described for four functions in Exhibit 1.7. They are the principal sources of customer satisfaction and must therefore be the principal dimension of the customer service objective for operations managers. Generally, an organization will aim reliably and consistently to achieve certain standards and operations manager will be influential in attempting to achieve these standards. Hence, this objective will influence the operations manager’s decisions to achieve the required customer service. Exhibit 1.7 Aspects of customer service Resource Utilization. Another major objective of operating systems is to utilize resources for the satisfaction of customer wants effectively. Customer service must be provided with the achievement of effective operations through efficient use of resources. Inefficient use of resources or inadequate customer service leads to commercial failure of an operating system. Operations management is concerned essentially with the utilization of resources, i.e. obtaining maximum effect from resources or minimizing their loss, underutilization or waste. The extent of the utilization of the resources’ potential might be expressed in terms of the proportion of available time used or occupied, space utilization, levels of activity, etc. Each measure indicates Page 15 of 156 the extent to which the potential or capacity of such resources is utilized. This is referred as the objective of resource utilization. Operations management is concerned with the achievement of both satisfactory customer service and resource utilization. An improvement in one will often give rise to deterioration in the other. Often both cannot be maximized, and hence a satisfactory performance must be achieved on both objectives. All the activities of operations management must be tackled with these two objectives in mind, and because of this conflict, operations managers will face many of the problems. Hence, operations managers must attempt to balance these basic objectives. The Exhibit 1.8 summarizes the twin objectives of operations management. The type of balance established both between and within these basic objectives will be influenced by market considerations, competitions, the strengths and weaknesses of the organization, etc. Hence, the operations managers should make a contribution when these objectives are set. Exhibit 1.8 The twin objectives of operations management Role of the Operations Manager The Operations Function consists of all activities directly related to producing goods or providing services. A primary function of the operations manager is to guide the system by decision making. • System Design Decisions • System Operation Decisions System Design Decisions • System Design ➢ Capacity ➢ Facility location ➢ Facility layout ➢ Product and service planning ➢ Acquisition and placement of equipment • These are typically strategic decisions that require ➢ long-term commitment of resources ➢ Determine parameters of system operation Key Trends and Issues in Business • E-Business & E-Commerce • Management of Technology • Globalization • Management of Supply Chains • Outsourcing • Agility • Ethical Behavior Page 16 of 156 The Decline in Manufacturing Employment • Productivity - Increasing productivity allows companies to maintain or increase their output using fewer workers • Outsourcing - Some manufacturing work has been outsourced to more productive companies • A Statistical Artifact - Manufacturers are increasingly using contract and temporary labor which no longer show up in the statistics as manufacturing employment Decision Making • Most operations decisions involve many alternatives that can have quite different impacts on costs or profits • Typical operations decisions include: ➢ What: What resources are needed, and in what amounts? ➢ When: When will each resource be needed? When should the work be scheduled? When should materials and other supplies be ordered? ➢ Where: Where will the work be done? ➢ How: How will he product or service be designed? How will the work be done? How will resources be allocated? ➢ Who: Who will do the work? General Approach to Decision Making • Modeling is a key tool used by all decision makers o Model - an abstraction of reality; a simplification of something. o Common features of models: ▪ They are simplifications of real-life phenomena ▪ They omit unimportant details of the real-life systems they mimic so that attention can be focused on the most important aspects of the real-life system Types of Models: o Physical Models ▪ Look like their real-life counterparts o Schematic Models ▪ Look less like their real-life counterparts than physical models o Mathematical Models ▪ Do not look at all like their real-life counterparts Understanding Models Keys to successfully using a model in decision making • What is its purpose? • How is it used to generate results? • How are the results interpreted and used? • What are the model’s assumptions and limitations? Benefits of Models • Models are generally easier to use and less expensive than dealing with the real system • Require users to organize and sometimes quantify information • Increase understanding of the problem Page 17 of 156 • • • Enable managers to analyze “What if?” questions Serve as a consistent tool for evaluation and provide a standardized format for analyzing a problem Enable users to bring the power of mathematics to bear on a problem. Model Limitations • Quantitative information may be emphasized at the expense of qualitative information • Models may be incorrectly applied and the results misinterpreted - This is a real risk with the widespread availability of sophisticated, computerized models are placed in the hands of uninformed users. • The use of models does not guarantee good decisions. Quantitative Methods A decision-making approach that frequently seeks to obtain a mathematically optimal solution • Linear programming • Queuing techniques • Inventory models • Project models • Forecasting techniques • Statistical models Metrics and Trade-Offs Performance Metrics - All managers use metrics to manage and control operations • Profits • Costs • Productivity • Forecast accuracy • Analysis of Trade-Offs - A trade-off is giving up one thing in return for something else • Carrying more inventory (an expense) in order to achieve a greater level of customer service Degree of Customization Relative to other standardized products and services customized products: • Tend to be more labor intensive • Tend to be more time consuming • Tend to require more highly-skilled people • Tend to require more flexible equipment • Have much lower volume of output • Have higher price tags Degree of customization has a significant influence on the entire organization • Process selection • Job design • Affects marketing, sales, accounting, finance, and information systems Page 18 of 156 Establishing Priorities 1. In nearly all cases, certain issues or items are more important than others 2. Recognizing this allows managers to focus their attention to those efforts that will do the most good a. Pareto Phenomenon - a few factors account for a high percentage of occurrence of some event(s) i. The critical few factors should receive the highest priority ii. This is a concept that is appropriately applied to all areas and levels of management Systems Approach System - a set of interrelated parts that must work together The business organization is a system composed of subsystems ▪ marketing subsystem ▪ operations subsystem ▪ finance subsystem The systems approach ▪ Emphasizes interrelationships among subsystems ▪ Main theme is that the whole is greater than the sum of its parts ▪ The output and objectives of the organization take precedence over those of any one subsystem Ethical Issues in Operations Ethical issues arise in many aspects of operations management: ➢ Financial statements ➢ Worker safety ➢ Product safety ➢ Quality ➢ The environment ➢ The community ➢ Hiring and firing workers ➢ Closing facilities ➢ Workers’ rights ACTIVITIES/ASSESSMENT Answer the following: (30 pts.) 1. Define operations management and the functions associated with it. 2. Compare the operations management in a company that produces goods with a company that offers services. 3. In ensuring ethical and social responsibilities in business, what are some challenges in operations that a company may face? Page 19 of 156 LESSON 2 – THE GLOBAL ENVIRONMENT AND OPERATIONS STRATEGY OVERVIEW An organization which formulates long-term strategies will likely succeed in a highly competitive global environment. An organization’s operations strategy must be designed in order to address future needs and challenges of international competition. In order to succeed, the organization. Strategy is the unifying factor in an organization which keeps the organization in the right direction. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Analyze the operations strategy applicable to a global business environment. Competitiveness: How effectively an organization meets the wants and needs of customers relative to others that offer similar goods or services – Organizations compete through some combination of their marketing and operations functions • What do customers want? • How can these customer needs best be satisfied? Marketing’s Influence • Identifying consumer wants and/or needs • Pricing • Advertising and promotion Businesses Compete Using Operations 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Product and service design Cost Location Quality Quick response Flexibility Inventory management Supply chain management Service Managers and workers Why Some Organizations Fail • • • • • Neglecting operations strategy Failing to take advantage of strengths and opportunities Failing to recognize competitive threats Too much emphasis in product and service design and not enough on improvement Neglecting investments in capital and human resources Page 20 of 156 • Failing to establish good internal communications and cooperation • Failing to consider customer wants and needs Hierarchical Planning Vision Mission Goals Organizational Strategies Functional Strategies Tactics Vision- how the company sees itself in the future. - the vision statement describes the company’s future Mission- the reason for an organization’s existence - the mission statement states the purpose of the organization - the mission statement should answer the question of “What business are we in?” - the mission statement serves as the basis for organizational goals Goals – provide detail and the scope of the mission – can be viewed as organizational destinations – goals serve as the basis for organizational strategies Strategy- a plan for achieving organizational goals • Serves as a roadmap for reaching the organizational destinations – Organizations have • Organizational strategies – Overall strategies that relate to the entire organization Page 21 of 156 – Support the achievement of organizational goals and mission • Functional level strategies – Strategies that relate to each of the functional areas and that support achievement of the organizational strategy Tactics and Operations • Tactics – The methods and actions taken to accomplish strategies – The “how to” part of the process • Operations – The actual “doing” part of the process Core Competencies • Core Competencies The special attributes or abilities that give an organization a competitive edge • To be effective core competencies and strategies need to be aligned Strategy Formulation • Effective strategy formulation requires taking into account: – Core competencies – Environmental scanning • SWOT • Successful strategy formulation also requires taking into account: – Order qualifiers – Order winners • Order qualifiers – Characteristics that customers perceive as minimum standards of acceptability to be considered as a potential purchase • Order winners – Characteristics of an organization’s goods or services that cause it to be perceived as better than the competition Environmental Scanning • Environmental Scanning is necessary to identify – Internal Factors • Strengths and Weaknesses – External Factors • Opportunities and Threats Key External Factors • Economic conditions • Political conditions Page 22 of 156 • • • • Legal environment Technology Competition Markets Key Internal Factors • • • • • • • Human Resources Facilities and equipment Financial resources Customers Products and services Technology Suppliers • Operations strategy – The approach, consistent with organization strategy, that is used to guide the operations function. Strategic OM Decision Areas Decision Area What the Decisions Affect Product and service design Costs, quality, liability, and environmental issues Capacity Cost, structure, flexibility Process selection and layout Costs, flexibility, skill level needed, capacity Work design Quality of work life, employee safety, productivity Location Costs, visibility Quality Ability to meet or exceed customer expectations Inventory Costs, shortages Maintenance Costs, equipment reliability, productivity Scheduling Flexibility, efficiency Supply chains Costs, quality, agility, shortages, vendor relations Projects Costs, new products, services, or operating systems Page 23 of 156 Quality-based strategy – Strategy that focuses on quality in all phases of an organization • Pursuit of such a strategy is rooted in a number of factors: – Trying to overcome a poor-quality reputation – Desire to maintain a quality image – A part of a cost reduction strategy Time-based strategies – Strategies that focus on the reduction of time needed to accomplish tasks • It is believed that by reducing time, costs are lower, quality is higher, productivity is higher, time-to-market is faster, and customer service is improved Time-Based Strategies Areas where organizations have achieved time reductions: – Planning time – Product/service design time – Processing time – Changeover time – Delivery time – Response time for complaints Agile operations – A strategic approach for competitive advantage that emphasizes the use of flexibility to adapt and prosper in an environment of change • Involves the blending of several core competencies: – Cost – Quality – Reliability – Flexibility The Balanced Scorecard Approach • A top-down management system that organizations can use to clarify their vision and strategy and transform them into action – Develop objectives – Develop metrics and targets for each objective – Develop initiatives to achieve objectives – Identify links among the various perspectives • Finance • Customer • Internal business processes • Learning and growth – Monitor results Page 24 of 156 The Balanced Scorecard Productivity – A measure of the effective use of resources, usually expressed as the ratio of output to input – • Productivity measures are useful for – Tracking an operating unit’s performance over time – Judging the performance of an entire industry or country Why Productivity Matters • High productivity is linked to higher standards of living – As an economy replaces manufacturing jobs with lower productivity service jobs, it is more difficult to maintain high standards of living • Higher productivity relative to the competition leads to competitive advantage in the marketplace – Pricing and profit effects • For an industry, high relative productivity makes it less likely it will be supplanted by foreign industry Service Sector Productivity • Service sector productivity is difficult to measure and manage because – It involves intellectual activities – It has a high degree of variability • A useful measure related to productivity is process yield Factors Affecting Productivity • • • • • Methods Capital Quality Technology Management Page 25 of 156 Improving Productivity 1. 2. 3. 4. 5. 6. Develop productivity measures for all operations Determine critical (bottleneck) operations Develop methods for productivity improvements Establish reasonable goals Make it clear that management supports and encourages productivity improvement Measure and publicize improvements Don’t confuse productivity with efficiency. ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) Discuss the advantages and disadvantages of the different operations strategies. Page 26 of 156 LESSON 3 – MANAGING PROJECTS OVERVIEW Management is concerned with planning, organizing, leading and controlling of resources and activities in order to achieve organizational goals. Project management in particular requires the commitment of people and other to an important activity such as production of goods or delivery of services. In this chapter, the importance of the project, project management and some project management techniques will be illustrated and discussed. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Describe the different project management techniques to guide project managers in the implementation of projects. • Projects – Unique, one-time operations designed to accomplish a specific set of objectives in a limited time frame Examples: • • • • • The Olympic Games Producing a movie Software development Product development ERP implementation The Nature of Projects • Projects go through a series of stages– a life cycle • Projects bring together people with a diversity of knowledge and skills, most of whom remain associated with the project for less than its full life • Organizational structure affects how projects are managed Project Management Decisions • Project success depends upon making key managerial decisions over a sequence of steps: – – – – – – Page 27 of 156 Deciding which projects to implement Selecting the project manager Selecting the project team Planning and designing the project Managing and controlling project resources Deciding if and when a project should be terminated Project Manager • The project manager is ultimately responsible for the success or failure of the project • The project manager must effectively manage: – The work – The human resources – Communications – Quality – Time – Costs Work Breakdown Structure (WBS) - A hierarchical listing of what must be done during a project - Establishes a logical framework for identifying the required activities for the project: - Identify the major elements of the project - Identify the major supporting activities for each of the major elements - Break down each major supporting activity into a list of the activities that will be needed to accomplish it Gantt Chart - a management technique for scheduling and planning small projects. It is a graph or bar chart enumerating the different activities and the time for each activity in the project. Page 28 of 156 Program Evaluation and Review technique (PERT) and Critical Path Method (CPM) PERT and CPM are two techniques used to manage large-scale projects • Managers can obtain: 1. A graphical display of project activities 2. An estimate of how long the project will take 3. An indication of which activities are most critical to timely project completion 4. An indication of how long any activity can be delayed without delaying the project Advantages: • Among the most useful features of PERT-CPM: 1. It forces the manager to organize and quantify available information and to identify where additional information is needed 2. It provides a graphic display of the project and its major activities 3. It identifies a. Activities that should be closely watched b. Activities that have slack time • Potential sources of error: 1. 2. 3. 4. The project network may be incomplete Precedence relationships may not be correctly expressed Time estimates may be inaccurate There may be a tendency to focus on critical path activities to the exclusion of other important project activities 5. Major risk events may not be on the critical path Page 29 of 156 Project Management Software • Technology has benefited project management – CAD • To produce updated prototypes on construction and product-development projects – Communication software • Helps to keep project members in close contact • Facilitates remote viewing of projects – Project management software • Specialized software used to help manage projects – Assign resources – Compare project plan versions – Evaluate changes – Track performance Advantages include: – – – – – – – – Imposes a methodology and common project management terminology Provides a logical planning structure May enhance communication among team members Can flag the occurrence of constraint violations Automatically formats reports Can generate multiple levels of summary and detail reports Enables “what if” scenarios Can generate a variety of chart types ACTIVITIES/ASSESSMENT Answer the following: (20 pts.) Describe the different project management techniques to guide project managers in the implementation of projects. Page 30 of 156 LESSON 4 – FORECASTING DEMAND OVERVIEW Forecasts are important basis for budgetary planning and cost control. Good forecasts are an essential part of efficient service and manufacturing operations. In this chapter, different types and models of forecasts are presented. Production and operations personnel use forecast to make periodic and continual decisions in the organization. Qualitative and quantitative techniques will be presented in this chapter. LEARNING OUTCOMES After the end of this lesson, students will be able to: ✓ Describe forecasting and determine the elements of a good forecast. ✓ Identify the importance of forecasting in making decisions. COURSE MATERIALS Forecasting • Forecast – a statement about the future value of a variable of interest – We make forecasts about such things as weather, demand, and resource availability – Forecasts are an important element in making informed decisions Two Important Aspects of Forecasts • Expected level of demand – The level of demand may be a function of some structural variation such as trend or seasonal variation • Accuracy – Related to the potential size of forecast error Features Common to All Forecasts 1. Techniques assume some underlying causal system that existed in the past will persist into the future 2. Forecasts are not perfect 3. Forecasts for groups of items are more accurate than those for individual items 4. Forecast accuracy decreases as the forecasting horizon increases Elements of a Good Forecast The forecast: • should be timely • should be accurate • should be reliable • should be expressed in meaningful units • should be in writing Page 31 of 156 • technique should be simple to understand and use • should be cost effective Steps in the Forecasting Process 1. Determine the purpose of the forecast 2. Establish a time horizon 3. Select a forecasting technique 4. Obtain, clean, and analyze appropriate data 5. Make the forecast 6. Monitor the forecast Forecast Accuracy and Control • Forecasters want to minimize forecast errors – It is nearly impossible to correctly forecast real-world variable values on a regular basis – So, it is important to provide an indication of the extent to which the forecast might deviate from the value of the variable that actually occurs • Forecast accuracy should be an important forecasting technique selection criterion Forecast Accuracy and Control • Forecasters want to minimize forecast errors – It is nearly impossible to correctly forecast real-world variable values on a regular basis – So, it is important to provide an indication of the extent to which the forecast might deviate from the value of the variable that actually occurs • Forecast accuracy should be an important forecasting technique selection criterion • Forecast errors should be monitored – Error = Actual – Forecast – If errors fall beyond acceptable bounds, corrective action may be necessary Forecasting Approaches • Qualitative Forecasting – Qualitative techniques permit the inclusion of soft information such as: • Human factors • Personal opinions • Hunches – These factors are difficult, or impossible, to quantify • Quantitative Forecasting – Quantitative techniques involve either the projection of historical data or the development of associative methods that attempt to use causal variables to make a forecast – These techniques rely on hard data Page 32 of 156 Judgmental Forecasts • Forecasts that use subjective inputs such as opinions from consumer surveys, sales staff, managers, executives, and experts – Executive opinions – Salesforce opinions – Consumer surveys – Delphi method Time-Series Forecasts • Forecasts that project patterns identified in recent time-series observations – Time-series - a time-ordered sequence of observations taken at regular time intervals • Assume that future values of the time-series can be estimated from past values of the timeseries Time-Series Behaviors • • • • • Trend Seasonality Cycles Irregular variations Random variation Trends and Seasonality • Trend – A long-term upward or downward movement in data • Population shifts • Changing income • Seasonality – Short-term, fairly regular variations related to the calendar or time of day – Restaurants, service call centers, and theaters all experience seasonal demand Cycles and Variations • Cycle – Wavelike variations lasting more than one year • These are often related to a variety of economic, political, or even agricultural conditions • Random Variation – Residual variation that remains after all other behaviors have been accounted for Page 33 of 156 • Irregular variation – Due to unusual circumstances that do not reflect typical behavior • Labor strike • Weather event Time-Series Forecasting - Naïve Forecast • Naïve Forecast – Uses a single previous value of a time series as the basis for a forecast • The forecast for a time period is equal to the previous time period’s value – Can be used when • The time series is stable • There is a trend • There is seasonality Time-Series Forecasting - Averaging • These Techniques work best when a series tends to vary about an average – Averaging techniques smooth variations in the data – They can handle step changes or gradual changes in the level of a series – Techniques • Moving average • Weighted moving average • Exponential smoothing Moving Average • Technique that averages a number of the most recent actual values in generating a forecast Moving Average • As new data become available, the forecast is updated by adding the newest value and dropping the oldest and then recomputing the the average • The number of data points included in the average determines the model’s sensitivity – Fewer data points used-- more responsive – More data points used-- less responsive Page 34 of 156 Weighted Moving Average • The most recent values in a time series are given more weight in computing a forecast – The choice of weights, w, is somewhat arbitrary and involves some trial and error Exponential Smoothing • A weighted averaging method that is based on the previous forecast plus a percentage of the forecast error Other Forecasting Methods - Focus • Focus Forecasting – Some companies use forecasts based on a “best current performance” basis • Apply several forecasting methods to the last several periods of historical data • The method with the highest accuracy is used to make the forecast for the following period • This process is repeated each month Other Forecasting Methods - Diffusion • Diffusion Models – Historical data on which to base a forecast are not available for new products • Predictions are based on rates of product adoption and usage spread from other established products • Take into account facts such as – Market potential – Attention from mass media – Word-of-mouth Techniques for Trend • Linear trend equation • Non-linear trends – Parabolic trend equation – Exponential trend equation – Growth curve trend equation Techniques for Trend • Linear trend equation Page 35 of 156 • Non-linear trends – Parabolic trend equation – Exponential trend equation – Growth curve trend equation Estimating slope and intercept • Slope and intercept can be estimated from historical data Trend-Adjusted Exponential Smoothing • The trend adjusted forecast consists of two components – Smoothed error – Trend factor Trend-Adjusted Exponential Smoothing • Alpha and beta are smoothing constants • Trend-adjusted exponential smoothing has the ability to respond to changes in trend Techniques for Seasonality • Seasonality is expressed in terms of the amount that actual values deviate from the average value of a series • Models of seasonality – Additive • Seasonality is expressed as a quantity that gets added or subtracted from the time-series average in order to incorporate seasonality – Multiplicative • Seasonality is expressed as a percentage of the average (or trend) amount which is then used to multiply the value of a series in order to incorporate seasonality Seasonal relatives – The seasonal percentage used in the multiplicative seasonally adjusted forecasting model • Using seasonal relatives – To deseasonalize data Page 36 of 156 • Done in order to get a clearer picture of the nonseasonal components of the data series • Divide each data point by its seasonal relative – To incorporate seasonality in a forecast • Obtain trend estimates for desired periods using a trend equation • Add seasonality by multiplying these trend estimates by the corresponding seasonal relative Techniques for Cycles • Cycles are similar to seasonal variations but are of longer duration • Explanatory approach – Search for another variable that relates to, and leads, the variable of interest • Housing starts precede demand for products and services directly related to construction of new homes • If a high correlation can be established with a leading variable, it can develop an equation that describes the relationship, enabling forecasts to be made Associative Forecasting Techniques – Home values may be related to such factors as home and property size, location, number of bedrooms, and number of bathrooms • Associative techniques are based on the development of an equation that summarizes the effects of predictor variables – Predictor variables - variables that can be used to predict values of the variable of interest Simple Linear Regression • Regression - a technique for fitting a line to a set of data points – Simple linear regression - the simplest form of regression that involves a linear relationship between two variables • The object of simple linear regression is to obtain an equation of a straight line that minimizes the sum of squared vertical deviations from the line (i.e., the least squares criterion) Least Squares Line Page 37 of 156 Standard Error • Standard error of estimate – A measure of the scatter of points around a regression line – If the standard error is relatively small, the predictions using the linear equation will tend to be more accurate than if the standard error is larger Correlation Coefficient • Correlation – A measure of the strength and direction of relationship between two variables – Ranges between -1.00 and +1.00 • r2, square of the correlation coefficient – A measure of the percentage of variability in the values of y that is “explained” by the independent variable – Ranges between 0 and 1.00 Simple Linear Regression Assumptions 1. Variations around the line are random 2. Deviations around the average value (the line) should be normally distributed 3. Predictions are made only within the range of observed values Issues to consider: • Always plot the line to verify that a linear relationships is appropriate • The data may be time-dependent. – If they are • use analysis of time series • use time as an independent variable in a multiple regression analysis • A small correlation may indicate that other variables are important Using Forecast Information • Reactive approach – View forecasts as probable future demand – React to meet that demand Page 38 of 156 • Proactive approach – Seeks to actively influence demand • • • Advertising Pricing Product/service modifications – Generally requires either and explanatory model or a subjective assessment of the influence on demand ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) 1. 2. 3. Page 39 of 156 What is forecasting? What are the elements of a good forecast? Why is forecasting important in making decisions? LESSON 5 - PRODUCT DESIGN OVERVIEW An effective product strategy links product decision with investment, market share, and product life cycle, and defines the breadth of the production line. The objective of the product decision is to develop and implement a product strategy that meets the demands of the marketplace with a competitive advantage via differentiation, low cost, rapid response, or a combination of these. LEARNING OUTCOME At the end of this lesson, students will be able to: ✓ Determine the interrelatedness of the product design to a successful operations strategy. COURSE MATERIALS Product and Service Design Reasons Design or Re-Design • The driving forces for product and service design or redesign are market opportunities or threats: – Economic – Social and Demographic – Political, Liability, or Legal – Competitive – Cost or Availability – Technological Key Questions • Is there a demand for it? – Market size – Demand profile • Can we do it? – Manufacturability - the capability of an organization to produce an item at an acceptable profit – Serviceability - the capability of an organization to provide a service at an acceptable cost or profit • What level of quality is appropriate? – Customer expectations – Competitor quality – Fit with current offering Page 40 of 156 • Does it make sense from an economic standpoint? – Liability issues, ethical considerations, sustainability issues, costs and profits Legal Considerations – Product liability • The responsibility a manufacturer has for any injuries or damages caused by as faulty product • Some of the concomitant costs – Litigation – Legal and insurance costs – Settlement costs – Costly product recalls – Reputation effects – Uniform Commercial Code • Under the UCC, products carry an implication of merchantability and fitness Normative Behavior • Produce designs that are consistent with the goals of the organization – e.g., Do not compromise on quality, or cut corners, even in areas that are not apparent to the customer • Give customers the value they expect • Make health and safety a concern – Do not place employees, customers, or third parties at risk because of faulty products and services Sustainability – Using resources in ways that do not harm ecological systems that support human existence • Key aspects of designing for sustainability – Life cycle assessment – Reduction of costs and materials used – Re-using parts of returned products – Recycling Page 41 of 156 Life Cycle Assessment (LCA) • LCA – The assessment of the environmental impact of a product or service throughout its useful life • Focuses on such factors as – Global warming – Smog formation – Oxygen depletion – Solid waste generation • LCA procedures are part of the ISO 14000 environmental management procedures Reduce: Costs and Materials • Value analysis – Examination of the function of parts and materials in an effort to reduce the cost and/or improve the performance of a product – Common questions used in value analysis • Could a less expensive part of material be used? • Is the function necessary? • Can the function of two or more parts be performed by a single part? • Can a part be simplified? • Could product specifications be relaxed? • Could standard parts be substituted for non-standard parts? Re-Use: Remanufacturing • Remanufacturing – Refurbishing used products by replacing worn-out or defective components • Can be performed by the original manufacturer or another company – Design for disassembly (DFD) • Designing a product to that used products can be easily taken apart Recycle • Recycling – Recovering materials for future use • Applies to manufactured parts • Also applies to materials used during production – Why recycle? • Cost savings • Environmental concerns Page 42 of 156 • Environmental regulations – Design for recycling (DFR) • Product design that takes into account the ability to disassemble a used product to recover the recyclable parts Other Considerations • Product or service life cycles • Standardization • Product or service reliability • Product or service robustness Product or service life stages Standardization – Extent to which there is an absence of variety in a product, service, or process Advantages of Standardization 1. Fewer parts to deal with in inventory & manufacturing 2. Reduced training costs and time 3. More routine purchasing, handling and inspection procedures 4. Orders fillable from inventory 5. Opportunities for long production runs and automation 6. Need for fewer parts justifies increased expenditures on perfecting designs and improving quality control procedures Page 43 of 156 Disadvantages of Standardization 1. Designs may be frozen with too many imperfections remaining. 2. High cost of design changes increases resistance to improvements 3. Decreased variety results in less consumer appeal. Designing for Mass Customization • Mass customization – A strategy of producing basically standardized goods or services, but incorporating some degree of customization in the final product or service – Facilitating Techniques • Delayed differentiation • Modular design Delayed Differentiation • Delayed Differentiation – The process of producing, but not quite completing, a product or service until customer preferences are known – It is a postponement tactic • Produce a piece of furniture, but do not stain it; the customer chooses the stain Modular Design – A form of standardization in which component parts are grouped into modules that are easily replaced or interchanged • Advantages – easier diagnosis and remedy of failures – easier repair and replacement – simplification of manufacturing and assembly • Disadvantages – Limited number of possible product configurations – Limited ability to repair a faulty module; the entire module must often be scrapped Reliability – The ability of a product, part, or system to perform its intended function under a prescribed set of conditions – Failure • Situation in which a product, part, or system does not perform as intended Page 44 of 156 – Normal operating conditions • The set of conditions under which an item’s reliability is specified Robust design – A design that results in products or services that can function over a broad range of conditions – Pertains to product as well as process design • Consider the following automobiles: – Ferrari 599 – Toyota Avalon » Which is design is more robust? Degree of Newness • Product or service design changes: – Modification of an existing product or service – Expansion of an existing product line or service offering – Clone of a competitor’s product or service – New product or service • The degree of change affects the newness of the product or service to the market and to the organization – Risks and benefits? Phases in Design & Development 1. Idea generation 2. Feasibility analysis 3. Product specifications 4. Process specifications 5. Prototype development 6. Design review 7. Market test 8. Product introduction 9. Follow-up evaluation Idea Generation 1. Supply-chain based 2. Competitor based 3. Research based Page 45 of 156 Supply-Chain Based • Ideas can come from anywhere in the supply chain: – Customers – Suppliers – Distributors – Employees – Maintenance and repair personnel Competitor-Based • By studying how a competitor operates and its products and services, many useful ideas can be generated • Reverse engineering – Dismantling and inspecting a competitor’s product to discover product improvements Research Based • Research and Development (R&D) – Organized efforts to increase scientific knowledge or product innovation – Basic research • Has the objective of advancing the state of knowledge about a subject without any near-term expectation of commercial applications – Applied research • Has the objective of achieving commercial applications – Development • Converts the results of applied research into useful commercial applications. • Research and Development (R&D) – Organized efforts to increase scientific knowledge or product innovation – Basic research • Has the objective of advancing the state of knowledge about a subject without any near-term expectation of commercial applications – Applied research • Has the objective of achieving commercial applications – Development • Converts the results of applied research into useful commercial applications. Page 46 of 156 Concurrent Engineering • Concurrent engineering – Bringing engineering design and manufacturing personnel together early in the design phase • Also may involve marketing and purchasing personnel • Views of suppliers and customers may also be sought Computer-Aided Design (CAD) • CAD – Product design using computer graphics – Advantages • increases productivity of designers, 3 to 10 times • creates a database for manufacturing information on product specifications • provides possibility of engineering and cost analysis on proposed designs – CAD that includes finite element analysis (FEA) can significantly reduce time to market • Enables developers to perform simulations that aid in the design, analysis, and commercialization of new products Production Requirements • Designers must take into account production capabilities – Equipment – Skills – Types of materials – Schedules – Technologies Manufacturability – Ease of fabrication and/or assembly – It has important implications for • Cost • Productivity • Quality DFM and DFA • Design for manufacturing (DFM) – The designing of products that are compatible with an organization’s abilities Page 47 of 156 • Design for assembly (DFA) – Design that focuses on reducing the number of parts in a product and on assembly methods and sequence Component Commonality • When products have a high degree of similarity in features and components, a part can be used in multiple products • Benefits: – Savings in design time – Standard training for assembly and installation – Opportunities to buy in bulk from suppliers – Commonality of parts for repair – Fewer inventory items must be handled The House of Quality The House of Quality Sequence Page 48 of 156 Kano Model • Basic quality – Refers to customer requirements that have only limited effect on customer satisfaction if present, but lead to dissatisfaction if absent • Performance quality – Refers to customer requirements that generate satisfaction or dissatisfaction in proportion to their level of functionality and appeal • Excitement quality – Refers to a feature or attribute that was unexpected by the customer and causes excitement Service Design Definitions • Service – Something that is done to, or for, a customer • Service delivery system – The facilities, processes, and skills needed to provide a service • Product bundle – The combination of goods and services provided to a customer Service Design • Begins with a choice of service strategy, which determines the nature and focus of the service, and the target market – Key issues in service design • Degree of variation in service requirements • Degree of customer contact and involvement Service Blueprint Page 49 of 156 Reliability • Reliability – The ability of a product, part, or system to perform its intended function under a prescribed set of conditions – Reliability is expressed as a probability: • The probability that the product or system will function when activated • The probability that the product or system will function for a given length of time Availability • Availability – The fraction of time a piece of equipment is expected to be available for operation ACTIVITIES/ASSESSMENT Answer the following: (20 pts.) 1. What is the most important driving force for product design or redesign? Why? 2. How often do you think should a company engage in newness of their product? Why? Page 50 of 156 LESSON 6 – QUALITY MANAGEMENT OVERVIEW Quality is an issue that affects an entire organization. To create a quality good or service operations managers need to know what the customer expect. A successful quality strategy begins with an organizational culture that fosters quality, followed by an understanding of the principles of quality, and then engaging employees in the necessary activities to implement quality. When these things are done well, the organization typically satisfies its customers and obtains competitive advantage. LEARNING OUTCOMES At the end of this lesson, students will be able to: ✓ Discuss and appreciate the importance of quality to the whole organization ✓ Identify the benefits of good quality to goods and services. Course materials Quality Management • Quality – The ability of a product or service to consistently meet or exceed customer expectations • Prior to the 1970s and 1980s, quality was not a focal point of U.S. companies • Foreign competition, due in part to a focus on quality, was able to capture significant shares of U.S. markets • Since the 1980s, quality has been increasingly embraced by U.S. executives Quality Contributors • Walter Shewart – “Father of Statistical Quality Control” – Control charts – Variance reduction • W. Edwards Deming – Special vs. common cause variation – The 14 points • Joseph Juran – Quality Control Handbook, 1951 – Viewed quality as fitness-for-use – Quality trilogy– quality planning, quality control, quality improvement • Armand Feigenbaum – Quality is a “total field” – The customer defines quality • Philip B. Crosby – Zero defects Page 51 of 156 – Quality is Free, 1979 • Kaoru Ishikawa – Cause-and-effect diagram – Quality circles – Recognized the internal customer • Genichi Taguchi – Taguchi loss function • Taiichi Ohno and Shigeo Shingo – Developed philosophy and methods of kaizen Reactive vs. Proactive Quality • Quality Assurance – Reactive – Emphasis is on finding and correcting defects before they reach the market • Strategic Approach – Proactive – Focuses on preventing mistakes from occurring – Greater emphasis on customer satisfaction – Involves all manager and workers in a continuing effort to improve quality Dimensions of Product Quality • • • • • • • • • • • • • • • • Performance– main characteristics of the product Aesthetics– appearance, feel, smell, taste Special features– extra characteristics Conformance– how well the product conforms to design specifications Reliability– consistency of performance Durability– the useful life of the product Perceived quality– indirect evaluation of quality Serviceability– handling of complaints or repairs Dimensions of Service Quality Convenience– the availability and accessibility of the service Reliability– ability to perform a service dependably, consistently, and accurately Responsiveness– willingness to help customers in unusual situations and to deal with problems Time– the speed with which the service is delivered Assurance– knowledge exhibited by personnel and their ability to convey trust and confidence Courtesy– the way customers are treated by employees Tangibles– the physical appearance of facilities, equipment, personnel, and communication materials Consistency– the ability to provide the same level of good quality repeatedly Assessing Service Quality • Audit service to identify strengths and weaknesses • In particular, look for discrepancies between: 1. Customer expectations and management perception of those expectations Page 52 of 156 2. Management perceptions customer expectations and service-quality specifications 3. Service quality and service actually delivered 4. Customers’ expectations of the service provider and their perceptions of provider delivery Determinants of Quality • Quality of design – Intention of designers to include or exclude features in a product or service • Quality of conformance – The degree to which goods or services conform to the intent of the designers • Ease-of-Use and user instructions – Increase the likelihood that a product will be used for its intended purpose and in such a way that it will continue to function properly and safely • After-the-sale service – Taking care of issues and problems that arise after the sale • • • • The Consequences of Poor Quality Loss of business Liability Productivity Costs • • • • • • • Benefits of Good Quality Enhanced reputation for quality Ability to command higher prices Increased market share Greater customer loyalty Lower liability costs Fewer production or service problems Higher profits Responsibility for Quality • Everyone in the organization has some responsibility for quality, but certain areas of the organization are involved in activities that make them key areas of responsibility: • Top management • Design • Procurement • Production/operations • Quality assurance • Packaging and shipping • Marketing and sales • Customer service Costs of Quality • Failure Costs - costs incurred by defective parts/products or faulty services. – Internal Failure Costs • Costs incurred to fix problems that are detected before the product/service is delivered to the customer. – External Failure Costs Page 53 of 156 • All costs incurred to fix problems that are detected after the product/service is delivered to the customer • Appraisal Costs – Costs of activities designed to ensure quality or uncover defects • Prevention Costs – All TQ training, TQ planning, customer assessment, process control, and quality improvement costs to prevent defects from occurring Ethics and Quality • Substandard work – Defective products – Substandard service – Poor designs – Shoddy workmanship – Substandard parts and materials ▪ ▪ ▪ Having knowledge of this and failing to correct and report it in a timely manner is unethical. Quality Awards Deming Prize EFQM Excellence Award Baldrige Award Baldrige Criteria I. Leadership (120 points) – Senior leadership – Governance and social responsibilities II. Strategic planning (85 points) – Strategy development – Strategy deployment III. Customer and market focus (85 points) – Customer and market knowledge – Customer relationships and satisfaction IV. Measurement, Analysis, and Knowledge Management (90 points) – Measurement, analysis, and improvement of organizational performance – Management of information, information technology, and knowledge V. Workforce focus (90 points) – Workforce engagement – Workforce environment VI. Process management (85 points) – Work systems design – Work process management and improvement VII. Results (450 points) – Product and service outcomes – Customer-focused outcomes – Financial and market outcomes – Workforce-focused outcomes – Process effectiveness outcomes – Leadership outcomes Page 54 of 156 Quality Certification International Organization for Standardization • ISO 9000 – Set of international standards on quality management and quality assurance, critical to international business • ISO 14000 – A set of international standards for assessing a company’s environmental performance • ISO 24700 – Pertains to the quality and performance of office equipment that contains reused components • ISO 9000: 2000 – Quality Principles: • Principle 1 Customer focus • Principle 2 Leadership • Principle 3 Involvement of people • Principle 4 Process approach • Principle 5 System approach to management • Principle 6 Continual improvement • Principle 7 Factual approach to decision making • Principle 8 Mutually beneficial supplier relationships Total Quality Management • A philosophy that involves everyone in an organization in a continual effort to improve quality and achieve customer satisfaction. 1. 2. 3. 4. 5. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. TQM Approach Find out what the customer wants Design a product or service that meets or exceeds customer wants Design processes that facilitate doing the job right the first time Keep track of results Extend these concepts throughout the supply chain TQM Elements Continuous improvement Competitive benchmarking Employee empowerment Team approach Decision based on fact, not opinion Knowledge of tools Supplier quality Champion Quality at the source Suppliers are partners in the process Continuous Improvement • Continuous Improvement – Philosophy that seeks to make never-ending improvements to the process of converting inputs into outputs Page 55 of 156 – Kaizen • Japanese word for continuous improvement. Quality at the Source • The philosophy of making each worker responsible for the quality of his or her work – “Do it right” and “If it isn’t right, fix it” Six Sigma • Six Sigma – A business process for improving quality, reducing costs, and increasing customer satisfaction – Statistically • Having no more than 3.4 defects per million – Conceptually • Program designed to reduce defects • Requires the use of certain tools and techniques Lean Six Sigma • Lean Six Sigma – A balanced approach to process improvement that integrates principles from lean operation and statistical tools for variation reduction from six sigma to achieve speed and quality – An approach that is equally applicable to products and services • Early application in service support functions of General electric and Caterpillar Finance Obstacles to Implementing TQM • Obstacles include: – Lack of company-wide definition of quality – Lack of strategic plan for change – Lack of customer focus – Poor inter-organizational communication – Lack of employee empowerment – View of quality as a “quick fix” – Emphasis on short-term financial results – Inordinate presence of internal politics and “turf” issues – Lack of strong motivation– – Lack of time to devote to quality initiatives – Lack of leadership Total Quality Management (TQM) in HR: Structure for Freedom THE WHAT Total Quality Management aims at continuous quality improvement of the product or service offered by a business through continuous feedback. Its simple objective is to do the right thing the first time, and every subsequent time so that resources are not wasted fixing mistakes and broken processes. Page 56 of 156 At this point of time you may feel that TQM in HR sets unrealistic expectations and probably is too rigid. Total Quality Management looks at an organization as a collection of processes. To this effect there is a need for stringent recommendations and best practices that must be developed to improve them. But the philosophy piece is prominent too since Total Quality Management relies on the truth that processes repeated for a long enough duration of time have the power to shape culture. The traditional top down approach first sets culture parameters and then trickles this culture down from the C suite to the employees in the form of dos and don’ts. Through Total Quality Management, the tables are turned. The processes and practices which are being constantly tweaked based on data and feedback produce small changes which accrue over time to positively impact culture and business vision. This sets up an effective loop where culture and processes benefit from each other, the nuts and bolts of ensuring customer satisfaction are regularly optimized and the business can boldly prepare for the future. THE WHY Total Quality Management acknowledges the fact that where humans are involved, there is always room for error. But the rules that control processes should step in to compensate. 1. First and foremost, there should be provisions to ensure that mistakes are not made. 2. Second, if they do creep in, there should be a system to detect errors efficiently and swiftly. 3. Third, if an error is somehow propagated down the value chain, there must be authority vested in individuals or processes to shut down the production flow so that more errors aren’t added the mix resulting in faulty units or poor service delivery for future clients. The three-pronged approach springboards off of mundane, well-defined processes. But it also necessitates a culture of honest communication where each employee acts as a sensor gathering feedback and using it to plug the holes in the current process set, without fear of repercussions. There are of course teething pains and implementation struggles. Employees may not have the mindset of “speaking up” and by default look to consensus for action. Managers may not appreciate the new-found employee independence. But once the culture of improvement is in place and the numbers prove that the effort is worth the while, total quality management frees up the company to be progressive, innovative, risk taking and free thinking. THE HOW Total Quality Management stands on 8 key pillars. 1. Focus on Customer – Customers are the true North Star and barometer of a business. In the TQM approach, customer sentiments and feedback are closely monitored through call tracking and surveys. 2. Employee Involvement – Employees must understand why the obsession with improvement ultimately gives them the freedom to innovate on their jobs. TQM not only Page 57 of 156 3. 4. 5. 6. 7. boosts the financial health of a business, it also improves talent connectedness and communication. Process Centeredness – The 8 requirements are met by defining processes. There should be processes to collect and integrate customer and employee feedback. There should be distinct processes to course correct on the TQM journey by adjusting strategy and tactics. And even a set of processes to measure the process centeredness of the implementation. Integrated Structure – Silos stymie Total Quality Management. As discussed, though the concept advocates structure and processes, isolation is not favoured. Different departments in the organization need to learn from each other and refine their processes in collaboration. Strategic Approach – Begin with the company vision and objectives to achieve. Set the processes according to this overarching strategy. Then let the TQM changes manifest as changes in culture, vision and objectives. Clear Communication – Without clear, unhesitant communication between employees and between a business and its customers, gathering authentic feedback and driving improvements is impossible. In any power dynamic, the final say should be in favour of the approach dictated by data and honest feedback. Iterative Improvement – TQM is capable of ushering changes because when an organizational sensor actually “senses” a gap, action is taken according to defined processes and improvements are made to eliminate the errors. The best feedback loop is useless if continuous improvement isn’t prioritized. By now you realize that processes underpin the success of Total Quality Management. The actual definition of these processes is governed by models like the Deming Way and DMAIC process. The Deming Way is also known as the Plan-Do-Check-(Re)Act (PDCA) cycle where scheduled improvements are made, the impact measured and further changes planned accordingly. • • • • • DMAIC stands for Define-Measure-Analyse-Improve-Control. In this approach businesses: Define who they are serving and thus want to improve for Measure KPIs Analyse the gap between the actual results and desired outcomes, as defined by the business objectives Implement data backed improvement suggestions Control or monitor how the improvements impact systems Human Resource Management (HRM) and its Impact on Total Quality Management (TQM): This doesn’t require a lengthy prologue.Empirical studies have shown that HRM practices like training and development, employee career planning, and recruiting and selection have the greatest significant influences on the implementation of Total Quality Management. TQM in HR can be implemented successfully in any part of a business Since a particular sample size can never be large or varied enough to guarantee a positive impact of HRM on TQM, most experts consider these strong positive signals as a good enough reason to invest in Human Resource Management to complement TQM processes. Page 58 of 156 • • • • • • Here’s why. Human Resource management makes the talent in an organization more receptive to the suggestion of continuous improvement. Buy-in is crucial in the early stages of Total Quality Management implementation. If employees feel that their freedom is being curtailed in any way, or if they sense that their feedback may be viewed as being “adversarial” by the management, TQM comes to a screeching halt. Human Resource Management gives employees the skills they need to be great TQM sensors. This includes clear communication, parsing constructive criticism and feedback from interactions with people of different cultures and backgrounds, overall better productivity and strategic planning. The HR department is closely associated with the culture of an organization. It sets boundaries, limits and incentivizes conformance with best practices. Total Quality Management reshapes culture. So, without HRM and HR evangelism, TQM is just a disruption and will never come across as the vehicle of enhanced employee freedom. TQM advocates customer orientation, process management and leadership development. This is the domain of HRM. And HRM in return prepares employees to be better TQM practitioners. The two are intertwined and both contribute to the overall competitiveness and morale building of organizational talent. 5 Steps to Total Quality Management Implementation: Total Quality Management works. But since the process of permeation of improvement consciousness is delicate and time consuming, some organizations are predisposed to be better TQM adopters. Businesses that: Have a track record of quickly identifying external change Crafting a response plan Implementing the action steps Are more likely to taste success with TQM. In siloed and rigid organizations employee buy-in is difficult to build and scepticism impedes progress. Here are the 5 steps that must be taken to institute a culture of Total Quality Management: 1⃣ Management Audit Total Quality Management is a journey of going from where a business and its processes are, to where it would ideally like to be. The very first item on the agenda of TQM implementation is thus a management audit to take full inventory of the processes that do exist, the results they yield and what gaps have already been identified. 2⃣ Defining Critical Success Factors Total Quality Management lives on in a business’ culture. But it is far from being intangible. There are very well-defined processes operating under the hood of a TQM enterprise. This is why it is important to quantify future success too. Critical Success Factors (CSF) are performance-based measures that can reflect the impact of TQM in numbers, charts and graphs. 3⃣ Developing Processes to Meet the 8 Requirements Once an organization is capable of determining whether TQM is working (or not), it is time to develop processes. Processes are governed by rules and can be executed by either tools or talent. For example, one of the 8 requirements is to be customer focused. A business can choose to automate the collection of feedback from users or it can rely on Page 59 of 156 trained employees who understand that every interaction with the brand is a chance to cement customer loyalty and thus follow-up with a review request. Once the feedback is received, it has to be processed. Positive indications are used to strengthen what the brand already does well. Negative inputs open up new areas of improvement. The what, why, who and how of meeting the 8 requirements have to be crystal clear. 4⃣ Being Data-driven Data doesn’t lie. Often the feedback collected from customers and employees shake the status quo. Change isn’t easy and TQM is all about constant change. The discipline to never avoid data advocated shifts – no matter how uncomfortable they are – is the fourth and penultimate step in the process. 5⃣ Being Relentless Last but not the least, an organization has to relentlessly keep “doing”. No change is insignificant and making improvements in small but consistent steps is what brings the real benefits of TQM. Total Quality Management done right is done for the lifetime of the employees who embrace it. Something that has such far reaching effect should be given a great deal of time and thought during and after implementation. Having the HR department and the employees onboard is non-negotiable. (Norberts) PDSA Cycle • Plan-Do-Study-Act (PDSA) Cycle – Plan • Begin by studying and documenting the current process. • Collect data on the process or problem • Analyze the data and develop a plan for improvement • Specify measures for evaluating the plan – Do • Implement the plan, document any changes made, collect data for analysis – Study • Evaluate the data collection during the do phase • Check results against goals formulated during the plan phase – Act • If the results are successful, standardize the new method and communicate it to the relevant personnel • Implement training for the new method • If unsuccessful, revise the plan and repeat the process Page 60 of 156 Problem Solving Process Improvement • Process Improvement – A systematic approach to improving a process Page 61 of 156 Basic Quality Tools Quality Circles • Quality Circles – Groups of workers who meet to discuss ways of improving products or processes • Less structured and more informal than teams involved in continuous improvement • Quality circle teams have historically had relatively little authority to make any but the most minor changes – Work best when decisions are based on consensus • Methods: – List reduction – Balance sheet approach – Paired comparisons Benchmarking Process • Identify a critical process that needs improving Page 62 of 156 • • • • Identify an organization that excels in this process Contact that organization Analyze the data Improve the critical process 5W2H Quality Control Phases of Quality Assurance • Inspection – An appraisal activity that compares goods or services to a standard – Inspection issues: 1. How much to inspect and how often? 2. At what points in the process to inspect? 3. Whether to inspect in a centralized or on-site location? 4. Whether to inspect attributes or variables? Page 63 of 156 How Much to Inspect? Where to Inspect in the Process? • Typical Inspection Points: – Raw materials and purchased parts – Finished products – Before a costly operation – Before an irreversible process – Before a covering process Centralized vs. On-Site Inspection • Effects on cost and level of disruption are a major issue in selecting centralized vs. on-site inspection – Centralized • Specialized tests that may best be completed in a lab – More specialized testing equipment – More favorable testing environment – On-Site • Quicker decisions are rendered • Avoid introduction of extraneous factors • Quality at the source Statistical Process Control (SPC) • identifies special causes of variation and seeks corrective action – Quality of Conformance • A product or service conforms to specifications • A tool used to help in this process: – SPC • Statistical evaluation of the output of a process • Helps us to decide if a process is “in control” or if corrective action is needed Process Variability • Two basic questions: concerning variability: 1. Are the variations random? • Process control 2. Given a stable process, is the inherent variability of the process within a range that conforms to performance criteria • Process capability Page 64 of 156 • Variation – Random (common cause) variation: • Natural variation in the output of a process, created by countless minor factors – Assignable (special cause) variation: • A variation whose cause can be identified Control Process • Sampling and corrective action are only a part of the control process • Steps required for effective control: – Define – Measure – Compare – Evaluate – Correct – Monitor ACTIVITIES/ASSESSMENT Answer the following questions: (20 pts.) 1. What is quality? 2. Why is quality important to an organization? Page 65 of 156 LESSON 7 - PROCESS DESIGN OVERVIEW Layout is one of the key decisions that determines the long-run efficiency of operations. Layout has numerous strategic implications because it establishes an organization’s competitive priorities in regard to capacity, processes, flexibility, and cost, as well as quality of work life, customer contact, and image. An effective layout can help an organization achieve a strategy that supports differentiation, low cost, or response. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Appreciate the importance of process strategies in producing quality goods and services. COURSE MATERIALS Process Selection and Facilities Layout Process Selection • Process selection – Refers to the deciding on the way production of goods or services will be organized – It has major implications for • Capacity planning • Layout of facilities • Equipment • Design of work systems Process Selection and System Design Page 66 of 156 Process Strategy • Key Aspects of Process Strategy: – Capital Intensity • The mix of equipment and labor that will be used by the organization – Process flexibility • The degree to which the system can be adjusted to changes in processing requirements due to such factors as – Product and service design changes – Volume changes – Changes in technology Technology • Technology – The application of scientific discoveries to the development and improvement of products and services and operations processes • Technological Innovation – The discovery and development of new or improved products, services, or processes for producing or providing them Kinds of Technology • Operations Management is concerned with: – Product and service technology • Discovery and development of new products and services – Process technology • Methods, procedures, and equipment used to produce goods and provide services – Information technology • The science and use of computers and other electronic equipment to store, process, and send information Technology for Competitive Advantage • Technological advances can lead to competitive advantage – Product technology • Increased market share and profits – Processing technology • Improved quality • Lower costs • Higher productivity • Expanded processing capabilities Page 67 of 156 Process Selection 1. Variety – 2. How much? Equipment flexibility – 3. To what degree? Volume – Expected output? Types of Processing Page 68 of 156 Product-Process Matrix Process Choice Effects Product and Service Profiling • Process selection involves – Substantial investment in equipment – Has a very specific influence on layout • Product or service profiling – Linking key product or service requirements to process capabilities – Key dimensions relate to • Range of products or services that will be processed • Expected order sizes • Pricing strategies • Expected frequency of schedule changes • Order-winning requirements Page 69 of 156 Automation – Machinery that has sensing and control devices that enable it to operate automatically • Fixed automation • Programmable automation • Flexible automation Automation Questions 1. What level of automation is appropriate? 2. How would automation affect system flexibility? 3. How can automation projects be justified? 4. How should changes be managed? 5. What are the risks of automating? 6. What are the likely effects of automating on: – Market share – Costs – Quality – – Customer satisfaction Labor relations – Ongoing operations ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) Why are process strategies important in producing quality goods and services? Page 70 of 156 LESSON 8 – LOCATION DECISIONS OVERVIEW Firms throughout the world are using concepts and techniques to address the location decision because location greatly affects both fixed and variable costs. Location has a major impact on the overall risk and profit of the company. This chapter illustrates techniques organization use to locate plants, warehouses, store and office. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Appreciate and discuss the importance of strategic location in operations management. COURSE MATERIALS The Need for Location Decisions • Location decisions arise for a variety of reasons: – Addition of new facilities • As part of a marketing strategy to expand markets • Growth in demand that cannot be satisfied by expanding existing facilities • Depletion of basic inputs requires relocation • Shift in markets • Cost of doing business at a particular location makes relocation attractive Location Decisions: Strategically Important • Location decisions: – Are closely tied to an organization’s strategies • Low-cost • Convenience to attract market share – Effect capacity and flexibility – Represent a long-term commitment of resources – Effect investment requirements, operating costs, revenues, and operations – Impact competitive advantage – Importance to supply chains Location Decisions: Objectives • Location decisions are based on: – Profit potential or cost and customer service – Finding a number of acceptable locations from which to choose – Position in the supply chain • End: accessibility, consumer demographics, traffic patterns, and local customs Page 71 of 156 are important • Middle: locate near suppliers or markets • Beginning: locate near the source of raw materials – Web-based retail organizations are effectively location independent – Supply chain management issues such as supply chain configuration • Centralized vs. decentralized distribution Location: Options • Existing companies generally have four options available in location planning: 1. 2. Expand an existing facility Add new locations while retaining existing facilities 3. Shut down one location and move to another 4. Do nothing Location Decision: General Procedure • Steps: 1. Decide on the criteria to use for evaluating location alternatives 2. Identify important factors, such as location of markets or raw materials 3. Develop location alternatives 4. a. Identify the country or countries for location b. Identify the general region for location c. Identify a small number of community alternatives d. Identify the site alternatives among the community alternatives Evaluate the alternatives and make a decision Global Location: Facilitating Factors • Two key factors have contributed to the attractiveness of globalization: – Trade Agreements such as • North American Free Trade Agreement (NAFTA) • General Agreement on Tariffs and Trade (GATT) • U.S.-China Trade Relations Act • EU and WTO efforts to facilitate trade – Technology • Advances in communication and information technology Page 72 of 156 Global Location: Benefits • A wide range of benefits have accrued to organizations that have globalized operations: – Markets – Cost savings – Legal and regulatory – Financial – Other Global Location: Disadvantages • There are a number of disadvantages that may arise when locating globally: – Transportation costs – Security costs – Unskilled labor – Import restrictions – Criticism for locating out-of-country Global Location: Risks • Organizations locating globally should be aware of potential risk factors related to: – Political instability and unrest – Terrorism – Economic instability – Legal regulation – Ethical considerations – Cultural differences Managing Global Operations • Managerial implications for global operations: – Language and cultural differences • Risk of miscommunication • Development of trust • Different management styles • Corruption and bribery – Level of technology and resistance to technological change – Domestic personnel may resist locating, even temporarily Page 73 of 156 Location: Identifying a Country Location: Identifying a Region • Primary regional factors: – Locating near the raw materials • Necessity • Perishability • Transportation costs – Locating near of markets • As part of a profit-oriented company’s competitive strategy • So not-for-profits can meet the needs of their service users • Distribution costs and perishability – Labor factors • Cost of labor • Availability of suitably skilled workers • Wage rates in the area • Labor productivity • Attitudes toward work • Whether unions pose a serious potential problem – Other factors • Climate and taxes may play an important role in location decisions Page 74 of 156 Geographic Information System (GIS) • GIS – A computer-based tool for collecting, storing, retrieving, and displaying demographic data on maps – Aids decision makers in • Targeting market segments • Identifying locations relative to their market potential • Planning distribution networks – Portraying relevant information on a map makes it easier for decision makers to understand Location: Identifying a Community • Many communities actively attempt to attract new businesses they perceive to be a good fit for the community • Businesses also actively seek attractive communities based on such factors such as: – Quality of life – Services – Attitudes – Taxes – Environmental regulations – Utilities – Development support Location: Identifying a Site • Primary site location considerations are – Land – Transportation – Zoning – Other restrictions Multiple Plant Manufacturing Strategies • Organizing operations – Product plant strategy • Entire products or product lines are produced in separate plants, and each plant usually supplies the entire domestic market – Market area plant strategy • Plants are designated to serve a particular geographic segment of the market • Plants produce most, if not all, of a company’s products Page 75 of 156 – Process plant strategy • Different plants focus on different aspects of a process – automobile manufacturers – engine plant, body stamping plant, etc. • Coordination across the system becomes a significant issue – General-purpose plant strategy • Plants are flexible and capable of handling a range of products Service and Retail Locations • Considerations: – Nearness to raw materials is not usually a consideration – Customer access is a • Prime consideration for some: restaurants, hotels, etc. • Not an important consideration for others: service call centers, etc. – Tend to be profit or revenue driven, and so are • Concerned with demographics, competition, traffic/volume patterns, and convenience Evaluating Location Alternatives • Common techniques: – Locational cost-volume-profit analysis – Factor rating – Center of gravity method – Transportation model Locational Cost-Profit-Volume Analysis • Locational Cost-Profit-Volume Analysis – Technique for evaluating location choices in economic terms – Steps: 1. Determine the fixed and variable costs for each alternative 2. Plot the total-cost lines for all alternatives on the same graph 3. Determine the location that will have the lowest total cost (or highest profit) for the expected level of output Locational Cost-Profit-Volume Analysis • Assumptions 1. Fixed costs are constant for the range of probable output 2. Variable costs are linear for the range of probably output 3. The required level of output can be closely estimated 4. Only one product is involved Page 76 of 156 Locational Cost-Profit-Volume Analysis • For a cost analysis, compute the total cost for each alternative location: Factor Rating • Factor Rating – General approach to evaluating locations that includes quantitative and qualitative inputs Procedures: 1. 2. 3. 4. 5. 6. Determine which factors are relevant Assign a weight to each factor that indicates its relative importance compared with all other factors. • Weights typically sum to 1.00 Decide on a common scale for all factors, and set a minimum acceptable score if necessary Score each location alternative Multiply the factor weight by the score for each factor, and sum the results for each location alternative Choose the alternative that has the highest composite score, unless it fails to meet the minimum acceptable score Center of Gravity Method • Center of Gravity Method – Method for locating a distribution center that minimizes distribution costs • Treats distribution costs as a linear function of the distance and the quantity shipped • The quantity to be shipped to each destination is assumed to be fixed • The method includes the use of a map that shows the locations of destinations – The map must be accurate and drawn to scale • A coordinate system is overlaid on the map to determine relative locations Page 77 of 156 ACTIVITIES/ASSESSMENT Answer the following question: (15pts) Discuss the importance of strategic location in operations management. Page 78 of 156 LESSON 9 – LAYOUT DECISIONS OVERVIEW Layout is one of the key decisions that determines the long-run efficiency of operations. Layout has numerous strategic implications because it establishes an organization’s competitive priorities in regard to capacity, processes, flexibility, and cost, as well as quality of work life, customer contact, and image. An effective layout can help an organization achieve a strategy that supports differentiation, low cost, or response. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Demonstrate ability to discuss different lay out decisions and the underlying factors of considering them. COURSE MATERIALS Facilities Layout • Layout – the configuration of departments, work centers, and equipment, with particular emphasis on movement of work (customers or materials) through the system – Facilities layout decisions arise when: • Designing new facilities • Re-designing existing facilities The Need for Layout Planning • Inefficient operations – High cost – Bottlenecks • Accidents or safety hazards • Changes in product or service design • Introduction of new products or services The Need for Layout Planning • Changes in output volume or product mix • Changes in methods or equipment • Changes in environmental or other legal requirements • Morale problems Page 79 of 156 Layout Design Objectives • Basic Objective – Facilitate a smooth flow of work, material, and information through the system • Supporting objectives – Facilitate product or service quality – Use workers and space efficiently – Avoid bottlenecks – Minimize material handling costs – Eliminate unnecessary movement of workers or material – Minimize production time or customer service time – Design for safety Basic Layout Types •Product layouts •Process layouts •Fixed-Position layout •Combination layouts Repetitive Processing Product Layouts • Product layout – Layout that uses standardized processing operations to achieve smooth, rapid, highvolume flow - Used for Repetitive Processing Repetitive or Continuous Product Layout: Advantages • High rate of output • Low unit cost • Labor specialization • Low material handling cost per unit • High utilization of labor and equipment Page 80 of 156 • Established routing and scheduling • Routine accounting, purchasing, and inventory control Product Layout: Disadvantages • Creates dull, repetitive jobs • Poorly skilled workers may not maintain equipment or quality of output • Fairly inflexible to changes in volume or product or process design • Highly susceptible to shutdowns • Preventive maintenance, capacity for quick repair and spare-parts inventories are necessary expenses • Individual incentive plans are impractical Non-repetitive Processing: Process Layouts • Process layouts – Layouts that can handle varied processing requirements Process Layout: Advantages • Can handle a variety of processing requirements • Not particularly vulnerable to equipment failures • General-purpose equipment is often less costly than the specialized equipment used in product layouts • It is possible to use individual incentive plans Process Layout: Disadvantages • In-process inventory costs can be high • Challenging routing and scheduling • Equipment utilization rates are low • Material handling slow and inefficient • Complexities often reduce span of supervision Page 81 of 156 • Special attention for each product or customer • Accounting and purchasing are more involved Fixed Position Layouts • Fixed Position layout – Layout in which the product or project remains stationary, and workers, materials, and equipment are moved as needed Combination Layouts • Some operational environments use a combination of the three basic layout types: – Hospitals – Supermarket – Shipyards • Some organizations are moving away from process layouts in an effort to capture the benefits of product layouts – Cellular manufacturing – Flexible manufacturing systems Flexible Manufacturing System (FMS) • FMS – A group of machines designed to handle intermittent processing requirements and produce a variety of similar products • Includes supervisory computer control, automatic material handling, and robots or other automated processing equipment • It is a more automated version of cellular manufacturing Page 82 of 156 Computer Integrated Manufacturing (CIM) • CIM – A system for linking a broad range of manufacturing activities through an integrated computer system • Activities include – Engineering design – FMS – Purchasing – Order processing – Production planning and control Service Layout • Service layouts can be categorized as: product, process, or fixed position • Service layout requirements are somewhat different due to such factors as: – Degree of customer contact – Degree of customization • Common service layouts: – Warehouse and storage layouts – Retail layouts – Office layouts Line Balancing • Line balancing – The process of assigning tasks to workstations in such a way that the workstations have approximately equal time requirements – Why is line balancing important? 1. It allows us to use labor and equipment more efficiently. 2. To avoid fairness issues that arise when one workstation must work harder than another. Cycle Time • Cycle time – The maximum time allowed at each workstation to complete its set of tasks on a unit – Cycle time also establishes the output rate of a line Cycle Time and Output Rate Page 83 of 156 How Many Workstations are Needed? • The required number of workstations is a function of – Desired output rate – Our ability to combine tasks into a workstation • Theoretical minimum number of stations Precedence Diagram • Precedence diagram – A diagram that shows elemental tasks and their precedence requirements Assigning Tasks to Workstations • Some Heuristic (Intuitive) Rules: – Assign tasks in order of most following tasks • Count the number of tasks that follow – Assign tasks in order of greatest positional weight. • Positional weight is the sum of each task’s time and the times of all following tasks. Line Balancing Procedure Page 84 of 156 Measuring Effectiveness • Balance delay (percentage of idle time) – Percentage of idle time of a line • Efficiency – Percentage of busy time of a line Designing Process Layouts • The main issue in designing process layouts concerns the relative placement of the departments • Measuring effectiveness – A major objective in designing process layouts is to minimize transportation cost, distance, or time Information Requirements • In designing process layouts, the following information is required: – A list of departments to be arranged and their dimensions – A projection of future workflows between the pairs of work centers – The distance between locations and the cost per unit of distance to move loads between them – The amount of money to be invested in the layout – A list of any special considerations – The location of key utilities, access and exit points, etc. ACTIVITIES/ASSESSMENT Answer the following: (20 pts.) 1. Why is there a need for layout planning? 2. What are the differences between a product layout and a service layout? Page 85 of 156 LESSON 10 – JOB DESIGN AND WORK MEASUREMENT OVERVIEW By reasonable quality of work life, we mean a job that is not only reasonably safe and for which the pay is equitable but that also achieves an appropriate level of both physical and psychological requirements. Mutual commitment means that both management and employee strive to meet common objectives. Mutual trust is reflected in reasonable, documented employment policies that are honestly and equitably implemented to the satisfaction of both management and employee. When management has a genuine respect for its employees and their contributions to the firm, establishing a reasonable quality of work life and mutual trust is not difficult. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Discuss the importance of the role of human resources in delivering effective and efficient operations through job design and work measurement. COURSE MATERIALS Quality of Work Life • Quality of work life affects workers’ overall sense of well-being and contentment, but also their productivity • Important aspects of quality of work life: – How a worker gets along with co-workers – Quality of management – Working conditions – Compensation • Quality of work life affects workers’ overall sense of well-being and contentment, but also their productivity • Important aspects of quality of work life: – How a worker gets along with co-workers – Quality of management – Working conditions – compensation Working Conditions Page 86 of 156 Compensation • It is important for organizations to develop suitable compensation plans for their employees • Compensation approaches – Time-based systems – Output-based systems – Incentive systems – Knowledge-based systems Compensation Systems • Time-based system – Compensation based on time an employee has worked during the pay period • Output-based (incentive) system – Compensation based on amount of output an employee produced during the pay period Incentive Plan Success • To obtain maximum benefit from an incentive plan, it should be 1. Accurate 2. Easy to apply 3. Consistent 4. Easy to understand 5. Fair • There should also be an obvious relationship between effort and reward, and no limit on earnings Individual and Group Incentive Plans • Individual incentive plans – Straight piecework • Worker’s pay is a direct linear function of his or her output • Minimum wage legislation has reduced their popularity – Base rate + bonus • Worker is guaranteed a base rate, tied to an output standard, that serves as a minimum • A bonus is paid for output above the standard • Group incentive plans – Tend to stress sharing of productivity gains with employees Page 87 of 156 Knowledge-Based Pay Systems • Knowledge-based pay – A pay system used by organizations to reward workers who undergo training that increases their skills – Three dimensions: • Horizontal skills – Reflect the variety of tasks the worker is capable of performing • Vertical skills – Reflect the managerial skills the worker is capable of • Depth skills – Reflect quality and productivity results Management Compensation • Many organizations used to reward managers based on output • New emphasis is being placed on other factors of performance – Customer service – Quality • Executive pay is increasingly being tied to the company or division for which the executive is responsible Job Design • Job design – The act of specifying the contents and methods of jobs • What will be done in a job? • Who will do the job? • How the job will be done? • Where the job will be done? – Objectives • Productivity • Safety • Quality of work life Job Design Success • Job design success factors: – Carried out by personnel with appropriate training and background – Consistent with the goals of the organization – In written form – Understood and agreed to by both management and employees Page 88 of 156 Designing Work Systems • Efficiency vs. Behavioral approaches to job design – Specialization • Motivation • Teams • Ergonomics • Methods analysis • Motion studies • Working conditions Efficiency vs. Behavioral Job Design • Efficiency School – Emphasizes a systematic, logical approach to job design – A refinement of Frederick Winslow Taylor’s scientific management concepts • Behavioral School – Emphasizes satisfaction of needs and wants of employees Specialization • Specialization – Work that concentrates on some aspect of a product or service Motivation • Motivation is a key factor in many aspects of work life – Influences quality and productivity – Contributes to the work environment • Trust is an important factor that affects motivation Page 89 of 156 Teams • Teams take a variety of forms: – Short-term team • Formed to collaborate on a topic or solve a problem – Long-term teams • Self-directed teams – Groups empowered to make certain changes in their work processes • Benefits of teams – Higher quality – Higher productivity – Greater worker satisfaction • Team problems – Some managers feel threatened – Conflicts between team members Ergonomics • Ergonomics (human factors) – The scientific discipline concerned with the understanding of interactions among human and other elements of a system • Three domains of ergonomics – Physical (repetitive movements, layout, health, safety) – Cognitive (mental workload, decision making, HCI, and work stress) – Organizational (communication, teamwork, work design, and telework) Methods Analysis • Methods Analysis – Analyzing how a job gets done – It begins with an analysis of the overall operation – It then moves from general to specific details of the job concentrating on • Workplace arrangement • Movement of workers and/or materials The Need for Methods Analysis • The need for methods analysis can arise from a variety of sources – Changes in tools and equipment – Changes in product design or introduction of new products Page 90 of 156 – Changes in materials and procedures – Government regulations or contractual agreements – Accidents or quality problems Methods Analysis Procedure 1. Identify the operation to be studied, and gather relevant data 2. Discuss the job with the operator and supervisor to get their input 3. Study and document the present methods 4. Analyze the job 5. Install the new methods 6. Follow up implementation to assure improvements have been achieved Guidelines for Selecting a Job to Study • Consider jobs that: – Have a high labor content – Are done frequently – Are unsafe, tiring, unpleasant, and/or noisy – Are designated as problems • • Quality problems Processing bottlenecks Analyzing the Job: Flow Process Charts • Flow process chart – Chart used to examine the overall sequence of an operation by focusing on movements of the operator or flow of materials Page 91 of 156 Analyzing the Job: Worker-Machine Chart • Worker machine chart – Chart used to determine portions of a work cycle during which an operator and equipment are busy or idle Motion Study • Motion study – Systematic study of the human motions used to perform an operation • Motion Study Techniques – Motion study principles– guidelines for designing motion-efficient work procedures – Analysis of therbligs– basic elemental motions into which a job can be broken down Page 92 of 156 – Micromotion study– use of motion pictures and slow motion to study motions that otherwise would be too rapid to analyze – Charts– activity or process charts, simo charts (simultaneous motions) Developing Work Methods • In developing work methods that are motion efficient, the analyst attempts to – Eliminate unnecessary motions – Combine activities – Reduce fatigue – Improve the arrangement of the workplace – Improve the design of tools and equipment Work Measurement • Work measurement is concerned with how long it should take to complete a job. • It is not concerned with either job content or how the job is to be completed since these are considered a given when considering work measurement. • Commonly used work measurement techniques – Stopwatch time study – Historical times – Predetermined data – Work sampling Standard Time • Standard time – The amount of time it should take a qualified worker to complete a specified task, working at a sustainable rate, using given methods, tools and equipment, raw material inputs, and workplace arrangement. Stopwatch Time Study • Used to develop a time standard based on observations of one worker taken over a number of cycles. • Basic steps in a time study: 1. Define the task to be studied and inform the worker who will be studied 2. 3. Determine the number of cycles to observe Time the job, and rate the worker’s performance 4. Compute the standard time Page 93 of 156 Historical Times • Standard Elemental Times are derived from a firm’s own historical time study data. – Over time, a file of accumulated elemental times that are common to many jobs will be collected. – In time, these standard elemental times can be retrieved from the file, eliminating the need to go through a new time study to acquire them. Procedure: 1. Analyze the job to identify the standard elements. 2. Check the file for elements that have historical times and record them. Use time studies to obtain others, if necessary. 3. Modify the file times if necessary. 4. Sum the elemental times to obtain the normal time, and factor in allowances to obtain the standard time. Predetermined Time Standards • Predetermined time standards involve the use of published data on standard elemental times. • Developed in the 1940s by the Methods Engineering Council. • The MTM tables are based on extensive research of basic elemental motions and times. • To use this approach, the analyst must divide the job into its basic elements (reach, move, turn, etc.) measure the distances involved, and rate the difficulty of the element, and then refer to the appropriate table of data to obtain the time for that element Work Sampling • Work sampling is a technique for estimating the proportion of time that a worker or machine spends on various activities and idle time. – work sampling does not require timing an activity or involve continuous observation of the activity – Uses: 1. ratio-delay studies which concern the percentage of a worker’s time that involves unavoidable delays or the proportion of time a machine is idle. 2. analysis of non-repetitive jobs. Page 94 of 156 ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) Discuss the importance of the role of human resources in delivering effective and efficient operations through job design and work measurement. Page 95 of 156 LESSON 11 – SUPPLY CHAIN MANAGEMENT OVERVIEW A supply chain consists of all parties involved, directly or indirectly in fulfilling a customer request. The supply chain not only includes the manufacturer and the supplier but also transporters, warehouses, retailers, and customers themselves. Within each organization, such as a manufacturer, the supply chain includes all the functions involved in receiving and filling a customer request. A typical supply chain may involve a variety of stages. LEARNING OUTCOMES After this lesson, students will be able to: ✓ Discuss the importance of supply chain in operations management. ✓ Demonstrate ability to relate logistics and supply chain to operations management. COURSE MATERIALS Supply Chain • Supply Chain: – the sequence of organizations - their facilities, functions, and activities - that are involved in producing and delivering a product or service – Sometimes referred to as value chains Facilities • The sequence of the supply chain begins with basic suppliers and extends all the way to the final customer – Warehouses – Factories – Processing centers – Distribution centers – Retail outlets – Offices Functions and Activities • Supply chain functions and activities – Forecasting – Purchasing – Inventory management – Information management – Quality assurance – Scheduling Page 96 of 156 – Production and delivery – Customer service Typical Supply Chains Supply Chain Management • Supply Chain Management (SCM) – The strategic coordination of business functions within a business organization and throughout its supply chain for the purpose of integrating supply and demand management • SCM Managers – People at various levels of the organization who are responsible for managing supply and demand both within and across business organizations. – Involved with planning and coordinating activities • Sourcing and procurement of materials and services • Transformation activities • Logistics Page 97 of 156 Key SCM Issues • The goal of SCM is to match supply to demand as effectively and efficiently as possible • Key issues: – Determining appropriate levels of outsourcing – Managing procurement – Managing suppliers – Managing customer relationships – Being able to quickly identify problems and respond to them – Managing risk Flow Management • Three types of flow management – Product and service flow • Involves movement of goods and services from suppliers to customers as well as handling customer service needs and product returns – Information flow • Involves sharing forecasts and sales data, transmitting orders, tracking shipments, and updating order status – Financial flow • involves credit terms, payments, and consignment and title ownership arrangements Global Supply Chains • Global supply chains – Product design often uses inputs from around the world – Some manufacturing and service activities are outsourced to countries where labor and/or materials costs are lower – Products are sold globally • Complexities – Language and cultural differences – Currency fluctuations – Political instability – Increasing transportation costs and lead times – Increased need for trust amongst supply chain partners Procurement • The purchasing department is responsible for obtaining the materials, parts, and supplies and services needed to produce a product or provide a service. • The goal of procurement Page 98 of 156 – Develop and implement purchasing plans for products and services that support operations strategies Duties of purchasing • Identifying sources of supply • Negotiating contracts • Maintaining a database of suppliers • Obtaining goods and services • Managing supplies Purchasing Interfaces The Purchasing Cycle The main steps: 1. Purchasing receives the requisition 2. Purchasing selects a supplier 3. Purchasing places, the order with a vendor 4. Monitoring orders 5. Receiving orders Page 99 of 156 Ethics in Purchasing • E-business – the use of electronic technology to facilitate business transactions – Applications include • Internet buying and selling • E-mail • Order and shipment tracking • Electronic data interchange • Product and service promotion • Provide information about products and services Advantages of E-Business • Companies can: – Have a global presence – Improve competitiveness and quality – Analyze customer interests – Collect detailed information – Shorten supply chain response times – Realize substantial cost savings • Also allows the: – Creation of virtual companies – Leveling of the playing field for small companies Page 100 of 156 E-Business Order Fulfillment Problems • Customer expectations – Order quickly 🡪 Quick delivery • Demand variability creates order fulfillment problems • Sometimes Internet demand exceeds an organization’s ability to fulfill orders • Inventory – Outsourcing order fulfillment • Loss of control – Build large warehouses • Internal holding costs Supplier Management • Choosing suppliers – Supplier audits – Supplier certification • Supplier relationship management • Supplier partnerships – CPFR – Strategic partnering Choosing Suppliers • Vendor analysis – Evaluating the sources of supply in terms of price, quality, reputation, and service Supplier Audits and Certification • Supplier audit – A means of keeping current on suppliers’ production (or service) capabilities, quality and delivery problems and resolutions, and performance on other criteria • Supplier certification – Involves a detailed examination of a supplier’s policies and capabilities – The process verifies the supplier meets or exceeds the requirements of a buyer Supplier Relationship Management • Type of relationship is often governed by the duration of the trading relationship Short-term- oftentimes involves competitive bidding; minimal interaction Medium-term- often involves an ongoing relationship Long-term- often involves greater cooperation that evolves into a partnership Page 101 of 156 Contrasting Supplier Relationships CFPR • Collaborative Forecasting, Planning, and Replenishment (CFPR) – A supply chain initiative that focuses on information sharing among supply chain trading partners in planning, forecasting, and inventory Inventory Management • Inventory issues in SCM – Inventory location • Centralized inventories • Decentralized inventories – Inventory velocity • The speed at which goods move through a supply chain – The bullwhip effect • Inventory oscillations that become increasingly larger looking backward through the supply chain The Bullwhip Effect • Variations in demand cause inventory fluctuations to fluctuate and get out of control – Inventory fluctuation can be magnified by • Periodic ordering • Reactions to shortages • Forecast inaccuracies • Order batching • Sales incentives and promotions • Liberal product return policies – Results in • Higher costs • Lower customer satisfaction Page 102 of 156 Mitigating the Bullwhip Effect • Good supply chain management can overcome the bullwhip effect – Strategic buffering • Holding inventory at a distribution center rather than at retail outlets – Replenishment based on need • Vendor-managed inventory – Vendors monitor goods and replenish retail inventories when supplies are low Order Fulfillment • Order fulfillment – The process involved in responding to customer orders – Often a function of the degree of customization required • Common approaches – Engineer-to-order (ETO) – Make-to-order (MTO) – Assemble-to-order (ATO) – Make-to-stock (MTS) Logistics • Logistics – Refers to the movement of materials and information within a facility and to incoming and outgoing shipments of goods and materials in a supply chain Page 103 of 156 Movement Within a Facility Incoming and Outgoing Shipments • Traffic management – Overseeing the shipment of incoming and outgoing goods • Handles schedules and decisions on shipping method and times, taking into account: – Costs of shipping alternatives – Government regulations – Needs of the organization – Shipping delays or disruptions RFID • Radio frequency identification (RFID) – A technology that uses radio waves to identify objects, such as goods in supply chains – Similar to barcodes but • Are able to convey much more information • Do not require line-of-sight for reading • Do not need to be read one at a time – Types: • Active • Passive Page 104 of 156 3-PL • Third-party logistics (3-PL) – The outsourcing of logistics management – Includes • Warehousing and distribution Managing Returns • Reverse Logistics – The process of transporting returned items • Products are returned to companies or third-party handlers for a variety of reasons and in a variety of conditions – Elements of return management • Gatekeeping – Screening returned goods to prevent incorrect acceptance of goods • Avoidance – Finding ways to minimize the number of items that are returned Creating an Effective Supply Chain • It begins with strategic sourcing – Analyzing the procurement process to lower costs by reducing waste and non-valueadded activities, increase profits, reduce risks, and improve supplier performance – There must be • Trust • Effective communication – Information velocity • Event management capability • Performance metrics Challenges • Barriers to integration of organizations • Getting top management on board • Dealing with trade-offs • Small businesses • Variability and uncertainty • Response time Page 105 of 156 Trade-Offs • Lot-size-inventory trade-off – Large lot sizes yield benefits in terms of quantity discounts and lower annual setup costs, but it increases the amount of safety stock (and inventory carrying costs) carried by suppliers • Inventory-transportation costs – Suppliers prefer to ship full truckloads instead of partial loads to spread shipping costs over as many units as possible. This leads to greater holding costs for customers – Cross-docking • A technique whereby goods arriving at a warehouse from a supplier are unloaded from the supplier’s truck and loaded onto outbound truck, thereby avoiding warehouse storage • Lead time-transportation costs – Suppliers like to ship in full loads, but waiting for sufficient orders and/or production to achieve a full load may increase lead time • Product variety-inventory – Greater product variety usually means smaller lot sizes and higher setup costs, as well as higher transportation and inventory management costs – Delayed differentiation • Production of standard components and subassemblies which are held until late in the process to add differentiating features • Cost-customer service – Producing and shipping in large lots reduces costs, but increases lead time – Disintermediation • Reducing one or more steps in a supply chain by cutting out one or more intermediaries Page 106 of 156 ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) What is the relationship between supply chain and logistics management? Page 107 of 156 LESSON 12 – MANAGING INVENTORY OVERVIEW Organizations from small to large businesses can make use of inventory management to manage their flow of goods. There are numerous inventory management techniques and using the correct one can lead to providing the correct goods at the correct amount, place and time. Inventory control is a separate area of inventory management that is concerned with minimizing the total cost of inventory while maximizing the ability to provide customers with products in a timely manner. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Appreciate and discuss the importance of managing inventory. COURSE MATERIALS Inventory – A stock or store of goods • Independent demand items – Items that are ready to be sold or used Types of Inventory • Raw materials and purchased parts • Work-in-process • Finished goods inventories or merchandise • Maintenance and repairs (MRO) inventory, tools and supplies • Goods-in-transit to warehouses or customers (pipeline inventory) Inventory Functions • Inventories serve a number of functions such as: 1. To meet anticipated customer demand 2. To smooth production requirements 3. To decouple operations 4. To protect against stockouts 5. To take advantage of order cycles 6. 7. To hedge against price increases To permit operations 8. To take advantage of quantity discounts Page 108 of 156 Inventory Management • Management has two basic functions concerning inventory: 1. Establish a system for tracking items in inventory 2. Make decisions about • When to order • How much to order Effective Inventory Management • Requires: 1. A system keeps track of inventory 2. A reliable forecast of demand 3. Knowledge of lead time and lead time variability 4. Reasonable estimates of 5. • • holding costs ordering costs • shortage costs A classification system for inventory items Inventory Counting Systems • Periodic System – Physical count of items in inventory made at periodic intervals • Perpetual Inventory System – System that keeps track of removals from inventory continuously, thus monitoring current levels of each item • Two-bin system – Two containers of inventory; reorder when the first is empty Inventory Counting Technologies • Universal product code (UPC) – Bar code printed on a label that has information about the item to which it is attached • Radio frequency identification (RFID) tags – A technology that uses radio waves to identify objects, such as goods in supply chains Page 109 of 156 Demand Forecasts and Lead Time • Forecasts – Inventories are necessary to satisfy customer demands, so it is important to have a reliable estimate of the amount and timing of demand • Lead time – Time interval between ordering and receiving the order • Point-of-sale (POS) systems – A system that electronically records actual sales – Such demand information is very useful for enhancing forecasting and inventory management ABC Classification System • A-B-C approach – Classifying inventory according to some measure of importance, and allocating control efforts accordingly – A items (very important) • 10 to 20 percent of the number of items in inventory and about 60 to 70 percent of the annual dollar value – B items (moderately important) – C items (least important) • 50 to 60 percent of the number of items in inventory but only about 10 to 15 percent of the annual dollar value Cycle Counting • Cycle counting – A physical count of items in inventory • Cycle counting management – How much accuracy is needed? • A item: ± 0.2 percent Page 110 of 156 • B items: ± 1 percent • C items: ± 5 percent – When should cycle counting be performed? – Who should do it? How Much to Order: EOQ Models • The basic economic order quantity model • The economic production quantity model • The quantity discount model Basic EOQ Model • The basic EOQ model is used to find a fixed order quantity that will minimize total annual inventory costs • Assumptions – Only one product is involved – Annual demand requirements are known – Demand is even throughout the year – Lead time does not vary – Each order is received in a single delivery – There are no quantity discounts Page 111 of 156 Total Annual Cost Goal: Total Cost Minimization Deriving EOQ • Using calculus, we take the derivative of the total cost function and set the derivative (slope) equal to zero and solve for Q. • The total cost curve reaches its minimum where the carrying and ordering costs are equal. Page 112 of 156 Economic Production Quantity (EPQ) • Assumptions – Only one product is involved – Annual demand requirements are known – Usage rate is constant – Usage occurs continually, but production occurs periodically – The production rate is constant – Lead time does not vary – There are no quantity discounts EPQ: Inventory Profile EPQ – Total Cost EPQ Page 113 of 156 Quantity Discount Model • Quantity discount – Price reduction offered to customers for placing large orders Quantity Discounts When to Reorder • Reorder point – When the quantity on hand of an item drops to this amount, the item is reordered. – Determinants of the reorder point 1. 2. Page 114 of 156 The rate of demand The lead time 3. The extent of demand and/or lead time variability 4. The degree of stockout risk acceptable to management Reorder Point: Under Certainty Safety Stock • As the amount of safety stock carried increases, the risk of stockout decreases. – This improves customer service level • Service level – The probability that demand will not exceed supply during lead time – Service level = 100% - Stockout risk How Much Safety Stock? • The amount of safety stock that is appropriate for a given situation depends upon: 1. The average demand rate and average lead time 2. Demand and lead time variability 3. The desired service level Page 115 of 156 Reorder Point Reorder Point: Demand Uncertainty Reorder Point: Lead Time Uncertainty How Much to Order: FOI • Fixed-order-interval (FOI) model – Orders are placed at fixed time intervals • Reasons for using the FOI model – Supplier’s policy may encourage its use – Grouping orders from the same supplier can produce savings in shipping costs – Some circumstances do not lend themselves to continuously monitoring inventory position Page 116 of 156 Fixed-Quantity vs. Fixed-Interval Ordering FOI Model OI* represents the optimal time between orders. Time-frame of interest is an appropriate period (e.g., days or weeks). This is usually based on the time-frame expressed by the average demand rate, d-bar. Single-Period Model • Single-Period Model – Model for ordering perishables and other items with limited useful lives Page 117 of 156 – Shortage cost • Generally, the unrealized profit per unit • Cshortage = Cs = Revenue per unit – Cost per unit – Excess cost • Different between purchase cost and salvage value of items left over at the end of the period • Cexcess = Ce = Cost per unit – Salvage value per unit Single-Period Model • The goal of the single-period model is to identify the order quantity that will minimize the long-run excess and shortage costs • Two categories of problem: – Demand can be characterized by a continuous distribution – Demand can be characterized by a discrete distribution Stocking Levels ACTIVITIES/ASSESSMENT Answer the following questions: (20 pts.) 1. What is the relationship between inventory management and the supply chain? 2. Why is there a need to balance the inventory needs with customers’ needs? Page 118 of 156 LESSON 13 – AGGREGATE PLANNING OVERVIEW The aggregate plan generally contains targeted sales forecasts, production levels, inventory levels, and customer backlogs. This schedule is intended to satisfy the demand forecast at a minimum cost. Properly done, aggregate planning should minimize the effects of shortsighted, day-to-day scheduling. Longer-term perspective on resource-use can help minimize short-term requirement changes with a resulting cost savings. LEARNING OUTCOME After the end of this lesson, students will be able to: ➢ Discuss aggregate planning and the planning levels. COURSE MATERIALS Aggregate planning – Intermediate-range capacity planning that typically covers a time horizon of 2 to 18 months – Useful for organizations that experience seasonal, or other variations in demand – Goal: • Achieve a production plan that will effectively utilize the organizations’ resources to satisfy demand Sales and Operations Planning • Some organizations use the term sales operations and planning rather than aggregate planning – Sales and operation planning • Intermediate-range planning decisions to balance supply and demand, integrating financial and operations planning • Since the plan affects functions throughout the organization, it is typically prepared with inputs from sales, finance, and operations Planning Levels Page 119 of 156 The Planning Sequence Aggregation • The plan must be in units of measurement that can be understood by the firm’s nonoperations personnel • Aggregate units of output per month • Dollar value of total monthly output • Total output by factory • Measures that relate to capacity such as labor hours Dealing with Variation • Most organizations use rolling 3, 6, 9- and 12-month forecasts – Forecasts are updated periodically, rather than relying on a once-a-year forecast • Strategies to counter variation: – Maintain a certain amount of excess capacity to handle increases in demand – Maintain a degree of flexibility in dealing with changes • Hiring temporary workers • Using overtime – Wait as long as possible before committing to a certain level of supply capacity • Schedule products or services with known demands first • Wait to schedule other products until their demands become less uncertain Page 120 of 156 Overview of Aggregate Planning Demand and Supply • Aggregate planners are concerned with the – Demand quantity • If demand exceeds capacity, attempt to achieve balance by altering capacity, demand, or both – Timing of demand • Even if demand and capacity are approximately equal, planners still often have to deal with uneven demand within the planning period Aggregate Planning Inputs • Resources – Workforce/production rates – Facilities and equipment • Demand forecast • Policies – Workforce changes – Subcontracting – Overtime – Inventory levels/changes – Back orders • Costs – Inventory carrying – Back orders – Hiring/firing – Overtime – Inventory changes – subcontracting Page 121 of 156 Aggregate Planning Outputs • Total cost of a plan • Projected levels of – Inventory – Output – Employment – Subcontracting – Backordering Aggregate Planning Strategies • Proactive – Alter demand to match capacity • Reactive – Alter capacity to match demand • Mixed – Some of each Demand Options • Pricing – Used to shift demand from peak to off-peak periods – Price elasticity is important • Promotion – Advertising and other forms of promotion • Back orders – Orders are taken in one period and deliveries promised for a later period • New demand Supply Options • Hire and lay off workers • Overtime/slack time • Part-time workers • Inventories • Subcontracting Page 122 of 156 Aggregate Planning Pure Strategies • Level capacity strategy: – Maintaining a steady rate of regular-time output while meeting variations in demand by a combination of options: • inventories, overtime, part-time workers, subcontracting, and back orders • Chase demand strategy: – Matching capacity to demand; the planned output for a period is set at the expected demand for that period. Chase Approach • Capacities are adjusted to match demand requirements over the planning horizon – Advantages • Investment in inventory is low • Labor utilization in high – Disadvantages • The cost of adjusting output rates and/or workforce levels Level Approach • Capacities are kept constant over the planning horizon • Advantages – Stable output rates and workforce • Disadvantages – Greater inventory costs – Increased overtime and idle time – Resource utilizations vary over time Techniques for Aggregate Planning • General procedure: 1. Determine demand for each period 2. Determine capacities for each period 3. Identify company or departmental policies that are pertinent 4. Determine unit costs 5. Develop alternative plans and costs 6. Select the plan that best satisfies objectives. Otherwise return to step 5. Page 123 of 156 Trial-and-Error Techniques • Trial-and-error approaches consist of developing simple table or graphs that enable planners to visually compare projected demand requirements with existing capacity • Alternatives are compared based on their total costs • Disadvantage of such an approach is that it does not necessarily result in an optimal aggregate plan Trial-and-Error Technique Assumptions • The regular output capacity is the same in all periods • Cost is a linear function composed of unit cost and number of units • Plans are feasible • All costs are associated with a decision option can be represented by a lump sum • Cost figures can be reasonably estimated and are constant for the planning period • Inventories are built up and drawn down at a uniform rate throughout each period • Backlogs are treated as if they exist the entire period Cumulative Graph Mathematical Techniques • Linear programming models • Simulation models – Computerized models that can be tested under different scenarios to identify acceptable solutions to problems Aggregate Planning in Services • Hospitals: – Aggregate planning used to allocate funds, staff, and supplies to meet the demands of patients for their medical services Page 124 of 156 • Airlines: – Aggregate planning in this environment is complex due to the number of factors involved – Capacity decisions must take into account the percentage of seats to be allocated to various fare classes in order to maximize profit or yield • Restaurants: – Aggregate planning in high-volume businesses is directed toward smoothing the service rate, determining workforce size, and managing demand to match a fixed capacity – Can use inventory; however, it is perishable • The resulting plan in services is a time-phased projection of service staff requirements • Aggregate planning in manufacturing and services is similar, but there are some key differences related to: 1. Demand for service can be difficult to predict 2. Capacity availability can be difficult to predict 3. Labor flexibility can be an advantage in services 4. Services occur when they are rendered Yield Management • Yield management – An approach to maximizing revenue by using a strategy of variable pricing; prices are set relative to capacity availability • During periods of low demand, price discounts are offered • During periods of peak demand, higher prices are charged • Users of yield management include – Airlines, restaurants, hotels, restaurants Disaggregation Aggregate Plan → Disaggregation → Master Schedule Disaggregating the Aggregate Plan • Master schedule: – The result of disaggregating an aggregate plan – Shows quantity and timing of specific end items for a scheduled horizon The heart of production planning and control – It determines the quantity needed to meet demand from all sources – It interfaces with • Marketing Page 125 of 156 • Capacity planning • Production planning • Distribution planning – Provides senior management with the ability to determine whether the business plan and its strategic objectives will be achieved The Master Scheduler • The master scheduler’s duties: – Evaluating the impact of new orders – Providing delivery dates for orders – Deals with problems • Evaluating the impact of production or delivery delays • Revising master schedule when necessary because of insufficient supplies or capacity • Bring instances of insufficient capacity to the attention of relevant personnel so they can participate in resolving conflicts The Master Scheduling Process Master Scheduling Process • The master production schedule (MPS) is one of the primary outputs of the master scheduling process – Once a tentative MPS has been developed, it must be validated • Rough cut capacity planning (RCCP) is a tool used in the validation process – Approximate balancing of capacity and demand to test the feasibility of a master schedule – Involves checking the capacities of production and warehouse facilities, labor, and vendors to ensure no gross deficiencies exist that will render the MPS unworkable Page 126 of 156 MPS – Forecasts and Customer Orders MPS – Projected On Hand Determining MPS and Projected On Hand Adding MPS and Projected On Hand to the MPS Page 127 of 156 Available to Promise Time Fences Period 1 2 3 “Frozen” (firm or fixed) 4 5 6 “slushy” (somewhat firm ) ACTIVITIES/ASSESSMENT Answer the following: (20 pts.) Discuss aggregate planning and the different planning levels. Page 128 of 156 7 8 “liquid” (open) 9 LESSON 14 – MATERIAL REQUIREMENTS PLANNING (MRP) AND ENTERPRISE RESOURCE PLANNING (ERP) OVERVIEW Most manufacturers use an organizational system called material requirements planning (MRP). Others use an enterprise resource planning (ERP) system instead. In addition to meeting material requirements, ERP systems integrate organizational needs such as accounting, marketing, human resources, and supply chain management. In this chapter, differences between MRP versus ERP will be explored. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Discuss the elements of Material Requirements Planning and Enterprise Resource Planning. COURSE MATERIALS MRP and ERP Dependent Demand • Dependent demand – Demand for items that are subassemblies or component parts to be used in the production of finished goods. – Dependent demand tends to be sporadic or “lumpy” • Large quantities are used at specific points in time with little or no usage at other times Page 129 of 156 Dependent vs Independent Demand •Material requirements planning (MRP): – A computer-based information system that translates master schedule requirements for end items into time-phased requirements for subassemblies, components, and raw materials. – The MRP is designed to answer three questions: 1. What is needed? 2. How much is needed? 3. When is it needed? Overview of MRP MRP Inputs: Master Schedule Page 130 of 156 • Master schedule: – One of three primary inputs in MRP; states which end items are to be produced, when these are needed, and in what quantities. – Managers like to plan far enough into the future so they have reasonable estimates of upcoming demands – The master schedule should cover a period that is at least equivalent to the cumulative lead time – Cumulative lead time » The sum of the lead times that sequential phases of a process require, from ordering of parts or raw materials to completion of final assembly. MRP Inputs: Bill of Materials • Bill of Materials (BOM) – A listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce one unit of a product – Product structure tree • A visual depiction of the requirements in a bill of materials, where all components are listed by levels Product Structure Tree Page 131 of 156 Low-level coding – Restructuring the bill of material so that multiple occurrences of a component all coincide with the lowest level at which the component occurs MRP Inputs: Inventory Records • Inventory records – Includes information on the status of each item by time period, called time buckets • Information about – Gross requirements – Scheduled receipts – Expected amount on hand • Other details for each item such as – Supplier – Lead time – Lot size – Changes due to stock receipts and withdrawals – Canceled orders and similar events Assembly Time Chart Page 132 of 156 MRP Record Gross requirements • Total expected demand Scheduled receipts • Open orders scheduled to arrive Projected Available • Expected inventory on hand at the beginning of each time period Net requirements • Actual amount needed in each time period Planned-order receipts • Quantity expected to receive at the beginning of the period offset by lead time Planned-order releases • Planned amount to order in each time period MRP: Development • The MRP is based on the product structure tree diagram • Requirements are determined level by level, beginning with the end item and working down the tree – The timing and quantity of each “parent” becomes the basis for determining the timing and quantity of the children items directly below it. – The “children” items then become the “parent” items for the next level, and so on MRP Considerations • Safety Stock – Theoretically, MRP systems should not require safety stock – Variability may necessitate the strategic use of safety stock • A bottleneck process or one with varying scrap rates may cause shortages in downstream operations Page 133 of 156 • Shortages may occur if orders are late or fabrication or assembly times are longer than expected • When lead times are variable, the concept of safety time is often used – Safety time » Scheduling orders for arrival or completions sufficiently ahead of their need that the probability of shortage is eliminated or significantly reduced MRP Lot Sizing Rules – Lot-for-Lot (L4L) ordering • The order or run size is set equal to the demand for that period • Minimizes investment in inventory • It results in variable order quantities • A new setup is required for each run – Economic Order Quantity (EOQ) • Can lead to minimum costs if usage of item is fairly uniform – This may be the case for some lower-level items that are common to different ‘parents’ – Less appropriate for ‘lumpy demand’ items because inventory remnants often result – Fixed Period Ordering • Provides coverage for some predetermined number of periods Using the MRP • Pegging – The process of identifying the parent items that have generated a given set of material requirements for an item • Backflushing – Exploding an end item’s BOM to determine the quantities of the components that were used to make the item Updating the System • An MRP is not a static document – As time passes • Some orders get completed • Other orders are nearing completion • New orders will have been entered • Existing orders will have been altered – Quantity changes – Delays – Missed deliveries Page 134 of 156 MRP Outputs: Primary • Primary Outputs – Planned orders • A schedule indicating the amount and timing of future orders – Order releases • Authorizing the execution of planned orders – Changes • Revisions of the dates or quantities, or the cancellation of orders MRP Outputs: Secondary • Secondary Outputs – Performance-control reports • Evaluation of system operation, including deviations from plans and cost information – Planning reports • Data useful for assessing future material requirements – Exception reports • Data on any major discrepancies encountered MRP in Services • Food catering service – End item 🡪 catered food – Dependent demand 🡪 ingredients for each recipe, i.e., bill of materials • Hotel renovation – Activities and materials “exploded” into component parts for cost estimation and scheduling MRP Benefits • Enables managers to easily – determine the quantities of each component for a given order size – To know when to release orders for each component – To be alerted when items need attention • Additional benefits – Low levels of in-process inventories – The ability to track material requirements – The ability to evaluate capacity requirements – A means of allocating production time – The ability to easily determine inventory usage via backflushing Page 135 of 156 MRP Requirements • To implement an effective MRP system requires: – A computer and the necessary software to handle computations and maintain records – Accurate and up-to-date • Master schedules • Bills of materials • Inventory records – Integrity of data files MRP II • Manufacturing resources planning (MRP II) – Expanded approach to production resource planning, involving other areas of the firm in the planning process and enabling capacity requirements planning • Most MRP II systems have the capability of performing simulation to answer a variety of “what if” questions so they can gain a better appreciation of available options and their consequences MRP II: Overview Closed Loop MRP • When MRP II systems began to include feedback loops, they were referred to as closed loop MRP • Closed Loop MRP – Systems evaluate a proposed material plan relative to available capacity Page 136 of 156 – If a proposed plan is not feasible, it must be revised • This evaluation is referred to as capacity requirements planning Capacity Requirements Planning • Capacity requirements planning (CRP) – The process of determining short-range capacity requirements. – Inputs to capacity requirement planning • Planned-order releases for the MPR • Current shop loading • Routing information • Job time – Key outputs • Load reports for each work center System Stability • Stability in short-term plans is very important – Without stability, changes in order quantity and/or timing can render material requirements plans virtually useless – System nervousness refers to how a system might react to changes • Sometimes the reaction can be greater than the original change Time Fences • Time fences – Series of time intervals during which order changes are allowed or restricted • The nearest fence is most restrictive • The farthest fence is least restrictive Page 137 of 156 Using MRP to Assist in CRP Load Reports • Load reports – Department or work center reports that compare known and expected future capacity requirements with projected capacity availability. Enterprise Resource Planning • Enterprise resource planning (ERP) – ERP was the next step in an evolution that began with MRP and evolved into MRPII – ERP, like MRP II, typically has an MRP core – Represents an expanded effort to integration financial, manufacturing, and human resources on a single computer system – ERP systems are composed of a collection of integrated modules Page 138 of 156 Overview of ERP Software Modules ERP Considerations • How can ERP improve a company’s business performance? • How long will an ERP implementation project take? • How will ERP affect current business processes? • What is the ERP total cost of ownership? • What are the hidden costs of ERP ownership? ACTIVITIES/ASSESSMENT Answer the following: (20 pts.) Compare and contrast MRT from ERP. Page 139 of 156 LESSON 15 – SCHEDULING OVERVIEW Scheduling is the last stage of planning before production. It specifies when labor, equipment and facilities are needed to produce a product or provide a service. Scheduling techniques vary by type of production process. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Discuss the importance of scheduling in the planning process. COURSE MATERIALS Scheduling: • • Establishing the timing of the use of equipment, facilities and human activities in an organization Effective scheduling can yield • Cost savings • Increases in productivity Scheduling is constrained by multiple system design decisions: – System capacity – Product and/or service design – Equipment selection – Worker selection and training – Aggregate planning and master scheduling Objectives of scheduling: • • • • • • • • • meeting customer due dates minimizing job lateness minimizing response time minimizing completion time minimizing time in the system minimizing overtime minimizing machine or labor utilizations minimizing idle time minimizing work-in-process inventory Page 140 of 156 High Volume Systems • Flow System – High-volume system with standardized equipment and activities – Flow system scheduling • Scheduling for flow systems • The goal is to achieve a smooth rate of flow of goods or customers through the system in order to get high utilization of labor and equipment High-Volume: Scheduling Difficulties • Few flow systems are entirely dedicated to a single product or service – Each product change requires • Slightly different inputs of parts • Slightly different materials • Slightly different processing requirements that must be scheduled into the line – Need to avoid excessive inventory buildup – Disruptions may result in less-than-desired output Page 141 of 156 High-Volume Success Factors • The following factors often dictate the success of high-volume systems: • Process and product design • Preventive maintenance • Rapid repair when breakdowns occur • Optimal product mixes • Minimization of quality problems • Reliability and timing of supplies Intermediate-Volume Systems • • Output fall between the standardized-type output of high-volume systems and the maketo-order output of job shops Output rates are insufficient to warrant continuous production – Rather, it is more economical to produce intermittently • Work centers periodically shift from one product to another Intermediate-Volume Systems • Three basic issues: – Run size of jobs – The timing of jobs – The sequence in which jobs will be produced • • Important considerations – Setup cost – Usage is not always as smooth as assumed in the economic lot size model Alternative scheduling approach – Base production on a master schedule developed from customer orders and forecasted demand Low-Volume Systems • Job shop scheduling – Page 142 of 156 Scheduling for low-volume systems with many variations in requirements • Make-to-order products • Processing requirements • Material requirements – • Processing time • Processing sequence and steps A complex scheduling environment • It is impossible to establish firm schedules until actual job orders are received Low-Volume Systems: Loading • Loading – the assignment of jobs to processing center – the process of assigning work to limited resources Gantt chart • Used as a visual aid for loading and scheduling purposes • Purpose of the Gantt chart is to organize and visually display the actual or intended use of resources in a time framework • Managers may use the charts for trial-and-error schedule development to get an idea of what different arrangements would involve Loading Approaches • Infinite loading – • Jobs are assigned to workstations without regard to the capacity of the work center. Finite loading – Jobs are assigned to work centers taking into account the work center capacity and job processing times. Activities/Assessment Answer the following: (15 pts.) Why is scheduling important in planning and production? Page 143 of 156 LESSON 16 – LEAN OPERATIONS OVERVIEW Lean operations is a means of running an organization by focusing on providing greater customer satisfaction while using as few resources as possible. Lean management is an approach to managing an organization that supports the concept of continuous improvement, a long-term approach to work that systematically seeks to achieve small, incremental changes in processes in order to improve efficiency and quality. LEARNING OUTCOME After the end of this lesson, students will be able to: ✓ Discuss how lean management maximizes customer value. COURSE MATERIALS • Lean operation – A flexible system of operation that uses considerably less resources than a traditional system • Tend to achieve – Greater productivity – Lower costs – Shorter cycle times – Higher quality Lean Operations: The Beginning • Lean operations began as lean manufacturing, also known as JIT in the mid-1900s • Developed by Taiichi Ohno and Shigeo Ohno of Toyota – Focus was on eliminating all waste from every aspect of the process • Waste is viewed as anything that interfered with, or did not add value to, the process of producing automobiles Lean Systems: Basic Elements • Lean systems have three basic elements: – A system that is 1. 2. 3. Page 144 of 156 Demand driven Focused on waste reduction Has a culture dedicated to excellence and continuous improvement Lean: Ultimate Goal • The ultimate goal: – A balanced system • One that achieves a smooth, rapid flow of materials through the system to match supply to customer demand Goals and building blocks of lean systems Lean: Supporting Goals • The degree to which lean’s ultimate goal is achieved depends upon how well its supporting goals are achieved: 1. Eliminate disruptions 2. Make the system flexible 3. Eliminate waste, especially excess inventory Waste – Represents unproductive resources – Seven sources of waste in lean systems: 1. Inventory 2. Overproduction 3. Waiting time 4. Unnecessary transporting 5. Processing waste 6. Inefficient work methods 7. Product defects Page 145 of 156 Kaizen • The kaizen philosophy for attacking waste is based upon these ideas: 1. Waste is the enemy and to eliminate waste it is necessary to get the hands dirty 2. Improvement should be done gradually and continuously; the goal is not big improvements done intermittently 3. Everyone should be involved 4. Kaizen is built on a cheap strategy, and it does not require spending great sums on technology or consultants 5. It can be applied everywhere 6. It is supported by a visual system 7. It focuses attention where value is created 8. It is process oriented 9. It stresses that the main effort for improvement should come from new thinking and a new work style 10. The essence of organizational learning is to learn while doing Lean: Building Blocks • Product design • Process design • Personnel/organizational elements • Manufacturing planning and control Building Blocks: Product Design • Four elements of product design important for lean systems: 1. Standard parts 2. Modular design 3. Highly capable systems with quality built in 4. Concurrent engineering • Eight aspects of process design that are important for lean systems: 1. Small lot sizes 2. Setup time reduction 3. Manufacturing cells 4. Quality improvement 5. Production flexibility 6. A balanced system 7. Little inventory storage 8. Fail-safe methods Page 146 of 156 Process Design: Small Lot Sizes • In the lean philosophy, the ideal lot size is one • Benefits of small lot size – Reduced in-process inventory • Lower carrying costs • Less storage space is necessary – Inspection and rework costs are less when problems with quality do occur – Less inventory to ‘work off’ before implementing product improvements – Increased visibility of problems – Permits greater flexibility in scheduling – Increased ease of balancing operations Process Design: Setup Time Reduction • Small lot sizes and changing product mixes require frequent setups • Unless these are quick and relatively inexpensive, they can be prohibitive • Setup time reduction requires deliberate improvement efforts – Single-minute exchange of die (SMED) • A system for reducing changeover time – Group technology may be used to reduce setup time by capitalizing on similarities in recurring operations Process Design: Manufacturing Cells • One characteristic of lean production systems is multiple manufacturing cells • Benefits include – Reduced changeover times – High equipment utilization – Ease of cross-training workers Process Design: Quality Improvement • Quality defects during the process can disrupt operations • Autonomation (jidoka) – Automatic detection of defects during production • Two mechanisms are employed – One for detecting defects when they occur – Another for stopping production to correct the cause of the defects Page 147 of 156 Process Design: Work Flexibility • Guidelines for increasing flexibility – Reduce downtime due to changeovers by reducing changeover time – Use preventive maintenance on key equipment to reduce breakdowns and downtime – Cross-train workers so they can help when bottlenecks occur or other workers are absent – Use many small units of capacity; many small cells make it easier to shift capacity temporarily and to add or subtract capacity – Use off-line buffers. Store infrequently used safety stock away from the production area – Reserve capacity for important customers Process Design: Balanced System • Takt time – The cycle time needed to match customer demand for final product – Sometimes referred to as the heartbeat of a lean system • Takt time is often set for a work shift • Procedure: 1. 2. 3. Determine the net time available per shift If there is more than one shift per day, multiply the net time by the number of shifts Compute the takt time by dividing the net available time by demand Process Design: Inventory Storage • Lean systems are designed to minimize inventory storage – Inventories are buffers that tend to cover up recurring problems that are never resolved • partly because they are not obvious • partly because the presence of inventory makes them seem less serious Process Design: Fail-Safe Methods • Poka-yoke (Fail safing) – Building safeguards into a process to reduce or eliminate the potential for errors during a process Page 148 of 156 Building Blocks: Personnel/Organizational • Five personnel/organizational elements that are important for lean systems: – Workers as assets – Cross-trained workers – Continuous improvement – Cost accounting – Leadership/project management Personnel/Organizational: Workers as Assets • Workers as assets – Well-trained and motivated workers are the heart of the lean system • They are given greater authority to make decisions, but more is expected of them Personnel/Organizational: Cross-Trained Workers • Cross-trained workers – Workers are trained to perform several parts of a process and operate a variety of machines • Facilitates flexibility • Helps in line balancing Personnel/Organizational: Continuous Improvement • Continuous improvement – Workers in lean systems have greater responsibility for quality, and they are expected to be involved in problem solving and continuous improvement – Lean workers receive training in • Statistical process control • Quality improvement • Problem solving Personnel/Organizational: Cost Accounting • Cost accounting – Activity-based costing • Allocation of overhead to specific jobs based on their percentage of activities Personnel/Organizational: Leadership • Leadership/project management – Managers are expected to be leaders and facilitators, not order givers – Lean systems encourage two-way communication between workers and managers Page 149 of 156 Building Blocks: MPC • Seven elements of manufacturing planning and control (MPC) are particularly important for lean system: 1. Level loading 2. Pull systems 3. Visual systems 4. Limited work-in-process (WIP) 5. Close vendor relationships 6. Reduced transaction processing 7. Preventive maintenance and housekeeping • Lean systems place a strong emphasis on achieving stable, level daily mix schedules 1. MPS – developed to provide level capacity loading 2. Mixed model scheduling • Three issues need to be resolved – – – What is the appropriate product sequence to use? How many times should the sequence be repeated daily? How many units of each model should be produced in each cycle? MPC: Communication • Communication moves backward through the system from station to station – Each workstation (customer) communicates its need for more work to the preceding workstation (supplier) • Assures that supply equals demand – Work moves “just in time” for the next operation • Flow of work is coordinated • Accumulation of excessive inventories is avoided MPC: Pull Systems • Push system – Work is pushed to the next station as it is completed • Pull system – A workstation pulls output from the preceding workstation as it is needed – Output of the final operation is pulled by customer demand or the master schedule – Pull systems are not appropriate for all operations Page 150 of 156 • Large variations in volume, product mix, or product design will undermine the system MPC: Visual Systems • Kanban – Card or other device that communicates demand for work or materials from the preceding station • Kanban is the Japanese word meaning “signal” or “visible record” – Paperless production control system – Authority to pull, or produce, comes from a downstream process. Ideal number of kanban cards MPC: Limited WIP • Benefits of lower WIP – Lower carrying costs – Increased flexibility – Aids scheduling – Saves costs of scrap and rework if there are design changes – Lower cycle-time variability MPC: Close Vendor Relationships • Lean systems typically have close relationships with vendors – They are expected to provide frequent, small deliveries of high-quality goods • A key feature of many lean systems is the relatively small number of suppliers used Page 151 of 156 MPC: Reduced Transaction Processing • Lean systems seek to reduce costs associated with the ‘hidden factory’: – Logistical transactions – Balancing transactions – Quality transactions – Change transactions Value Stream Mapping • Value stream mapping – A visual tool to systematically examine the flows of materials and information • Its purpose is to help identify waste and opportunities for improvement • Data collected: – Times – Distances traveled – Mistakes – Inefficient work methods – Waiting times – Information flows Transitioning to Lean Systems • Make sure top management is committed and that they know what will be required • Decide which parts will need the most effort to convert • Obtain support and cooperation of workers • Begin by trying to reduce setup times while maintaining the current system • Gradually convert operations, begin at the end and work backwards • Convert suppliers to JIT • Prepare for obstacles Obstacles to Conversion • Management may not be fully committed or willing to devote the necessary resources to conversion • Workers/management may not be cooperative • It can be difficult to change the organizational culture to one consistent with the lean philosophy • Suppliers may resist Page 152 of 156 Lean Services • In service the focus is often on the time needed to perform the service because speed is often the order winner • Lean benefits can be achieved in the following ways: – Eliminate disruptions – Make system flexible – Reduce setup and lead times – Eliminate waste – Minimize WIP – Simplify the process JIT II • A supplier representative works right in the company’s plant, making sure there is an appropriate supply on hand • It is often referred to as vendor managed inventory (VMI) ACTIVITIES/ASSESSMENT Answer the following: (15 pts.) How does lean operations lead to improved goods and services based on what customers want and value? Page 153 of 156 Final Examination Essay (50pts.) Why is Total Quality Management (TQM) important in operations management? Page 154 of 156 Course Grading System Class Standing • Quizzes • Attendance • Recitation • Projects/Assignments/Seatwork/Special Report Midterm / Final Examinations Midterm Grade + Final Term Grade 2 Page 155 of 156 = FINAL GRADE 70% 30% 100% References: • • • • Operations Management by S. Anil Kumar & N. Suresh, 2009 Operations Management, Roberta Russel and Bernard Taylor, 2003 (4th ed.) Principles of Operations Management, by Jay Heizer and Barry Render, 2001 (9th ed.) Sage HR Blog/Easy to implement HR tips/Norberts Erts/ Page 156 of 156