Tekla Structures 2018

Create models

March 2018

©2018 Trimble Solutions Corporation

Contents

1

Get to know Tekla Structures basic working methods........... 17

1.1

Set up the workspace..................................................................................... 17

1.2

1.3

Change units and decimals.................................................................................................. 18

Create grids and grid lines....................................................................................................18

Create, modify, or delete a grid...................................................................................... 20

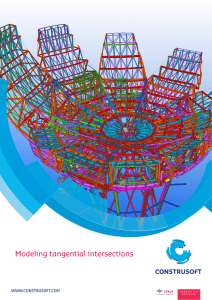

Create a radial grid........................................................................................................... 23

Add a single grid line........................................................................................................24

Modify a single grid line...................................................................................................25

Deleting a single grid line................................................................................................ 27

Create model views............................................................................................................... 28

Move the view plane........................................................................................................ 29

Create views...................................................................................................................... 29

Open a view.......................................................................................................................38

Save a view........................................................................................................................ 39

Modify a view.................................................................................................................... 39

Delete a view..................................................................................................................... 39

Switch between views...................................................................................................... 40

Update and refresh views............................................................................................... 40

Define the work area.............................................................................................................41

Fit work area to entire model..........................................................................................41

Fit work area to selected parts....................................................................................... 42

Fit work area using two points........................................................................................42

Hide the work area box................................................................................................... 42

Coordinate system................................................................................................................43

Show or hide the work plane grid.................................................................................. 44

Shift the work plane......................................................................................................... 44

Base points........................................................................................................................47

Select the work plane.......................................................................................................55

Change the color settings..................................................................................................... 56

Find RGB values for colors.............................................................................................. 56

Change the background color........................................................................................ 58

Change the color of dimensions, part labels, and grids.............................................. 61

Change the rendering of the model.................................................................................... 62

DirectX rendering examples............................................................................................63

Zoom and rotate the model........................................................................... 70

Zoom in and out.................................................................................................................... 70

Rotate the model................................................................................................................... 71

Pan the model........................................................................................................................ 72

Snap to a point or line.................................................................................... 72

Snap to a line..........................................................................................................................73

Snap to extension lines......................................................................................................... 74

Snap to orthogonal points...................................................................................................76

Snap relative to previously picked points........................................................................... 77

Create a temporary reference point...................................................................................78

Lock X, Y, or Z coordinate......................................................................................................79

2

Snapping toolbar.................................................................................................................. 80

Snap zone.......................................................................................................................... 80

Snap priority......................................................................................................................80

Snap depth........................................................................................................................ 80

Snapping in drawings.......................................................................................................81

Snap switches and symbols.................................................................................................81

Snap to a point using exact distance or coordinates........................................................ 83

Enter a distance or coordinates......................................................................................83

Options for coordinates...................................................................................................83

Change the snapping mode............................................................................................ 84

Align objects using a snap grid............................................................................................85

Override the current snap switch........................................................................................ 85

Example: Track along a line towards a snap point............................................................ 86

Snap settings......................................................................................................................... 88

1.4

Create model objects...................................................................................... 89

1.5

Select objects................................................................................................. 117

1.6

Copy and move objects.................................................................................128

Create a model object........................................................................................................... 89

Delete an object..................................................................................................................... 90

Modify model object properties.......................................................................................... 90

Modify model object properties in the property pane................................................ 91

Modify the common properties of different object types in the property pane...... 93

Modify model object properties in a dialog box...........................................................96

Resize and reshape model objects...................................................................................... 97

Copy properties from another object............................................................................... 103

Copy properties using the property pane................................................................... 103

Copy properties using the contextual toolbar............................................................ 104

Save and load object properties........................................................................................ 105

Save and load properties in the property pane......................................................... 105

Save and load properties in a dialog box.................................................................... 107

Remove existing properties.......................................................................................... 108

Customize the property pane layout................................................................................ 108

Add properties to a property pane layout.................................................................. 109

User-defined attributes (UDAs) in the customized property pane.......................... 111

Example: How to add IFC related user-defined attributes to the property pane

layout............................................................................................................................................... 112

Select single objects............................................................................................................ 117

Select multiple objects........................................................................................................ 117

Select all objects.................................................................................................................. 118

Select previous objects....................................................................................................... 119

Select handles...................................................................................................................... 119

Modify the selection............................................................................................................ 120

Selecting toolbar................................................................................................................. 121

Select assemblies and cast units....................................................................................... 125

Select nested objects.......................................................................................................... 125

Select reference models, reference model objects and assemblies............................. 126

Select an entire reference model................................................................................. 127

Select a reference model object................................................................................... 127

Select a reference model assembly............................................................................. 127

If you cannot select objects................................................................................................ 127

How to restore missing toolbars....................................................................................... 127

Copy objects......................................................................................................................... 129

Copy by picking two points........................................................................................... 129

Copy linearly................................................................................................................... 131

3

Copy by specifying a distance from origin.................................................................. 131

Copy using drag-and-drop............................................................................................ 132

Copy objects to another object.................................................................................... 133

Copy all content to another object...............................................................................133

Copy to another plane................................................................................................... 134

Copy from another model.............................................................................................134

Copy objects using linear array tool.............................................................................135

Copy objects using radial array tool.............................................................................137

Copy objects using Array of objects (29) component .............................................. 139

Move objects........................................................................................................................ 141

Move by picking two points...........................................................................................141

Move linearly...................................................................................................................142

Move by specifying a distance from origin..................................................................143

Move using drag-and-drop............................................................................................143

Move to another plane.................................................................................................. 145

Move objects to another object....................................................................................146

Rotate objects...................................................................................................................... 146

Rotate around a line...................................................................................................... 146

Rotate around the z axis................................................................................................148

Rotate drawing objects.................................................................................................. 149

Rotation settings............................................................................................................ 150

Mirror objects.......................................................................................................................150

Mirror model objects..................................................................................................... 150

Mirror drawing objects.................................................................................................. 151

1.7

1.8

Filter objects.................................................................................................. 151

Use existing filters............................................................................................................... 152

How to use a view filter................................................................................................. 152

How to use a selection filter..........................................................................................154

Create new filters.................................................................................................................155

Create a view filter..........................................................................................................155

Create a selection filter..................................................................................................157

Create a drawing filter................................................................................................... 157

Create a drawing view filter.......................................................................................... 160

Create a drawing selection filter...................................................................................162

Filtering techniques............................................................................................................. 162

Object properties in filtering............................................................................................. 165

Template attributes in filtering......................................................................................... 181

Wildcards ............................................................................................................................ 182

Examples of filters............................................................................................................... 182

Filter parts based on their name..................................................................................182

Filter main parts............................................................................................................. 183

Filter bolts based on their size......................................................................................184

Filter parts based on their assembly type...................................................................184

Filter sub-assemblies..................................................................................................... 186

Filter reference model objects......................................................................................186

Filter parts within component...................................................................................... 187

Filter reinforcement in pour units based on pour object type................................. 187

Filter all contents of a pour unit................................................................................... 188

Copy and remove filters......................................................................................................189

Copy a filter to another model..................................................................................... 189

Remove a filter................................................................................................................190

Modeling tips................................................................................................. 190

Tips for basic tasks.............................................................................................................. 190

Switch rollover highlight on or off................................................................................ 190

Select values from the model....................................................................................... 191

4

Interrupt object selection..............................................................................................192

Select on right-click........................................................................................................ 192

Copy and move efficiently............................................................................................. 192

Show or hide "Do not show this message again".......................................................193

If you cannot see all objects............................................................................................... 193

Should I model in a 3D or plane view?.............................................................................194

Hide cut lines in a model view........................................................................................... 194

How to cut efficiently.......................................................................................................... 194

Right-hand rule.................................................................................................................... 195

When to use an autosaved model ....................................................................................196

Tips for large models.......................................................................................................... 196

1.9

2

2.1

2.2

Create model templates...............................................................................198

Create a new model template............................................................................................198

Modify an existing model template...................................................................................199

Download model templates............................................................................................... 199

Model template options.................................................................................................... 199

Modeling in Tekla Structures................................................... 201

Parts in Tekla Structures.............................................................................. 202

Part handles......................................................................................................................... 202

Part labels............................................................................................................................. 204

Show part reference lines in a model view.......................................................................205

Part profile types................................................................................................................. 206

Create steel parts.......................................................................................... 206

Create a steel column......................................................................................................... 207

Modify steel column properties................................................................................... 207

Steel column properties................................................................................................ 208

Create a steel beam............................................................................................................ 209

Modify steel beam properties...................................................................................... 210

Steel beam properties................................................................................................... 210

Create a steel polybeam..................................................................................................... 212

Modify steel polybeam properties............................................................................... 213

Steel beam properties................................................................................................... 213

Create a curved beam......................................................................................................... 215

Modify curved beam properties...................................................................................215

Steel beam properties................................................................................................... 216

Create a twin profile............................................................................................................ 217

Modify twin profile properties...................................................................................... 218

Twin profile properties.................................................................................................. 218

Create an orthogonal beam............................................................................................... 220

Modify orthogonal beam properties........................................................................... 220

Orthogonal beam properties........................................................................................221

Create a steel spiral beam.................................................................................................. 222

Basic concepts related to spiral beams....................................................................... 222

Create a spiral beam...................................................................................................... 223

Limitations.......................................................................................................................224

Create a contour plate........................................................................................................ 225

Create a round contour plate....................................................................................... 225

Modify contour plate properties.................................................................................. 226

Contour plate properties...............................................................................................226

Create a bent plate.............................................................................................................. 227

Create a bent plate by selecting parts......................................................................... 228

Create a bent plate by selecting faces......................................................................... 229

Modify the bend radius................................................................................................. 231

5

Modify the shape of a bent plate................................................................................. 232

Remove curved sections................................................................................................235

Examples......................................................................................................................... 236

Limitations.......................................................................................................................237

2.3

Create concrete parts................................................................................... 238

Create a concrete column.................................................................................................. 238

Modify concrete column properties............................................................................ 239

Concrete column properties......................................................................................... 239

Create a concrete beam......................................................................................................240

Modify concrete beam properties................................................................................241

Concrete beam properties............................................................................................ 241

Create a concrete polybeam.............................................................................................. 243

Modify concrete polybeam properties........................................................................ 244

Concrete beam properties............................................................................................ 244

Create a concrete spiral beam........................................................................................... 246

Basic concepts related to spiral beams....................................................................... 246

Create a spiral beam...................................................................................................... 247

Limitations.......................................................................................................................248

Create a concrete panel or wall......................................................................................... 249

Modify concrete panel or wall properties................................................................... 250

Concrete panel or wall properties................................................................................250

Create a concrete slab........................................................................................................ 251

Create a round concrete slab........................................................................................252

Modify concrete slab properties.................................................................................. 253

Concrete slab properties............................................................................................... 253

Create a pad footing............................................................................................................254

Modify pad footing properties......................................................................................255

Pad footing properties...................................................................................................255

Create a strip footing.......................................................................................................... 256

Modify strip footing properties.................................................................................... 257

Strip footing properties................................................................................................. 258

2.4

Create items...................................................................................................259

2.5

Tips for creating and positioning parts...................................................... 264

2.6

Modify parts...................................................................................................270

Limitations to items.............................................................................................................260

Create an item......................................................................................................................260

Create a concrete item........................................................................................................261

Modify item or concrete item properties......................................................................... 261

Change the shape of an item............................................................................................. 262

Item and concrete item properties................................................................................... 262

Create curved parts............................................................................................................. 264

Create horizontal parts....................................................................................................... 266

Create beams close to each other.....................................................................................266

Create closed polybeams.................................................................................................. 266

Alternative way of creating a round plate or slab........................................................... 268

Position columns, pad footings, and orthogonal beams................................................268

Position objects in a radial or circular pattern................................................................. 269

Optional ways of placing objects in a model....................................................................269

How to model identical areas........................................................................................... 270

Modify the part properties................................................................................................. 270

User-defined attributes................................................................................................ 271

Change the profile of a part.......................................................................................... 272

Change the material of a part.......................................................................................274

Modify the length of a part........................................................................................... 275

6

Modify the position of a part........................................................................................ 275

Modify the adaptivity of reinforcement or surface treatment in parts................... 277

Split parts..............................................................................................................................277

Split a straight or curved part or polybeam................................................................ 277

Split a plate or slab using a polygon............................................................................ 278

Combine parts..................................................................................................................... 278

Attach parts to each other..................................................................................................279

Attach a part to another part........................................................................................280

Detach an attached part................................................................................................280

Explode attached parts..................................................................................................280

Warp a part...........................................................................................................................281

Warp a beam or a column using deformation angles............................................... 281

Warp a concrete slab by moving chamfers................................................................. 281

Warp a Floor Bay (66) slab.............................................................................................282

Camber a part...................................................................................................................... 283

2.7

Add details to parts.......................................................................................283

Create bolts.......................................................................................................................... 283

Create a bolt group........................................................................................................ 284

Create a single bolt........................................................................................................ 285

Create bolts using the Auto bolt component............................................................. 285

Create a bolt group by exploding a component.........................................................288

Change or add bolted parts.......................................................................................... 288

Bolt group shape............................................................................................................ 289

Bolt properties................................................................................................................290

Create studs......................................................................................................................... 294

Create holes......................................................................................................................... 295

Create round holes........................................................................................................ 295

Create oversized holes.................................................................................................. 296

Create slotted holes....................................................................................................... 296

Create welds.........................................................................................................................298

Set the visibility and appearance of welds.................................................................. 298

Create a weld between parts........................................................................................ 300

Create a polygon weld................................................................................................... 300

Create a weld to a part.................................................................................................. 301

Welds in components.................................................................................................... 302

Weld preparation............................................................................................................302

Change a weld to a polygon weld................................................................................ 304

Create user-defined cross sections for welds.............................................................304

Create fittings.......................................................................................................................306

Create cuts............................................................................................................................306

Cut parts with a line....................................................................................................... 307

Cut parts with a polygon............................................................................................... 307

Cut parts with another part.......................................................................................... 308

Create part chamfers.......................................................................................................... 309

Chamfer part corners.................................................................................................... 310

Chamfer part edges....................................................................................................... 310

Status of polybeam chamfers.......................................................................................311

Corner chamfer properties........................................................................................... 312

Edge chamfer properties...............................................................................................313

Add surface treatment........................................................................................................ 314

Modify surface treatment properties.......................................................................... 315

Add surface treatment to parts.................................................................................... 316

Create new surface treatment options........................................................................319

Tiled surface treatment................................................................................................. 320

Create an unpainted area using the No paint area component.............................. 325

7

Add a surface to a face....................................................................................................... 327

2.8

2.9

2.10

Create assemblies......................................................................................... 328

Create an assembly............................................................................................................. 328

Create a sub-assembly.................................................................................................. 329

Use bolts to create assemblies..................................................................................... 329

Bolt sub-assemblies to an existing assembly............................................................. 330

Use welds to create assemblies................................................................................... 330

Weld sub-assemblies to an existing assembly........................................................... 331

Add objects to assemblies..................................................................................................331

Assembly hierarchy........................................................................................................ 332

Add parts to an assembly..............................................................................................333

Create a nested assembly............................................................................................. 333

Join assemblies............................................................................................................... 333

Change the assembly main part........................................................................................ 334

Change the main assembly................................................................................................ 334

Remove objects from an assembly................................................................................... 334

Check and highlight objects in an assembly.................................................................... 335

Explode an assembly.......................................................................................................... 335

Assembly examples.............................................................................................................336

Create cast units........................................................................................... 337

Define the cast unit type of a part.....................................................................................337

Create a cast unit................................................................................................................. 338

Add objects to a cast unit................................................................................................... 338

Change the cast unit main part......................................................................................... 339

Remove objects from a cast unit....................................................................................... 339

Check and highlight objects in a cast unit........................................................................ 339

Explode a cast unit.............................................................................................................. 340

Casting direction.................................................................................................................. 340

Define the casting direction of a part.......................................................................... 342

Show the top-in-form face............................................................................................ 342

Manage pours................................................................................................ 343

Enable the pour functionality.............................................................................................344

Disable the pour functionality temporarily.................................................................345

View cast-in-place concrete structures............................................................................. 345

Set the appearance of cast-in-place concrete structures..........................................346

Part view vs. pour view.................................................................................................. 347

Define the pour phase of a part........................................................................................ 348

Pour objects......................................................................................................................... 349

Change the color and transparency of pour objects................................................. 350

Modify the properties of a pour object....................................................................... 352

Pour units............................................................................................................................. 352

Calculate pour units....................................................................................................... 353

Check and inquire objects in a pour unit.................................................................... 353

Add objects to a pour unit.............................................................................................354

Remove objects from a pour unit................................................................................ 354

Modify the properties of a pour unit........................................................................... 354

How Tekla Structures automatically adds objects to pour units.............................. 355

Pour breaks.......................................................................................................................... 356

Pour break adaptivity.....................................................................................................357

Set the visibility of pour breaks.................................................................................... 358

Create a pour break....................................................................................................... 358

Select a pour break........................................................................................................ 360

Copy a pour break..........................................................................................................361

Move a pour break......................................................................................................... 361

8

Modify a pour break...................................................................................................... 361

Remove a pour break.................................................................................................... 363

Troubleshoot pours.............................................................................................................363

View pour errors in a log file......................................................................................... 364

Example: Identify and fix a pour error.........................................................................365

Example: Create concrete geometry and work with pours............................................ 367

2.11

2.12

Create reinforcement................................................................................... 369

Create a rebar set................................................................................................................ 369

Basic concepts related to rebar sets............................................................................ 370

Create longitudinal rebars............................................................................................ 372

Create crossing rebars...................................................................................................374

Create planar rebars...................................................................................................... 376

Create rebars by point input.........................................................................................379

Rebar set properties...................................................................................................... 380

Limitations.......................................................................................................................380

Create a rebar set using Rebar shape placing tool.................................................... 380

Examples: Rebar sets in curved structures................................................................. 387

Create a single reinforcing bar...........................................................................................393

Create a reinforcing bar group...........................................................................................394

Create a reinforcing bar group using Rebar shape catalog...................................... 396

Create a curved reinforcing bar group........................................................................ 403

Create a circular reinforcing bar group....................................................................... 405

Create a tapered or spiral reinforcing bar group....................................................... 407

Create a reinforcement mesh............................................................................................ 409

Create a rectangular reinforcement mesh..................................................................410

Create a polygonal reinforcement mesh.....................................................................411

Create a bent reinforcement mesh..............................................................................412

Create a customized reinforcement mesh..................................................................414

Create a reinforcement strand pattern.............................................................................415

Debond reinforcement strands.................................................................................... 416

Create a reinforcement splice............................................................................................ 417

Modify reinforcement...................................................................................419

Modify a rebar set............................................................................................................... 419

Modify the properties of a rebar set............................................................................420

Change the layer order of a rebar set..........................................................................420

Modify a rebar set using guidelines............................................................................. 421

Modify a rebar set using leg faces................................................................................421

Modify a rebar set locally using modifiers.................................................................. 428

How to cut rebar sets.....................................................................................................433

Distribute bars in a rebar set........................................................................................ 434

Modify a single reinforcing bar, bar group, or mesh.......................................................436

Distribute bars in a reinforcing bar group.................................................................. 440

Delete bars from a reinforcing bar group................................................................... 442

Ungroup a reinforcement............................................................................................. 443

Group reinforcement..................................................................................................... 444

Combine two reinforcing bars or reinforcing bar groups into one..........................445

Split a reinforcing bar group ........................................................................................ 446

Use handles to modify a reinforcement......................................................................447

Add hooks to reinforcing bars............................................................................................448

Define the reinforcement cover thickness....................................................................... 450

Use adaptivity to modify a reinforcement........................................................................452

Attach a reinforcement to a concrete part....................................................................... 454

Check the validity of reinforcement geometry................................................................ 454

Split and splice a reinforcement........................................................................................ 455

Assign running numbers to reinforcement...................................................................... 457

9

Classify reinforcement to layers........................................................................................ 457

How to calculate the reinforcing bar length..................................................................... 458

How to calculate the reinforcing bar leg length...............................................................461

Reinforcement shape recognition..................................................................................... 463

Rebar shape manager in reinforcement shape recognition.....................................464

Hard-coded bending type identifiers in reinforcement shape recognition............ 475

Reinforcement in templates......................................................................................... 499

2.13

Create construction objects and points..................................................... 501

Create a construction line.................................................................................................. 502

Create a construction plane............................................................................................... 502

Create a construction circle using center point and radius............................................503

Create a construction circle using three points............................................................... 504

Modify a construction object............................................................................................. 505

Create points....................................................................................................................... 507

Create points on a line...................................................................................................508

Create points on a plane............................................................................................... 508

Create points parallel to two points.............................................................................509

Create points along the extension line of two points................................................ 510

Create projected points on a line................................................................................. 511

Create points along an arc using center and arc points............................................511

Create points along an arc using three arc points..................................................... 512

Create points tangent to a circle.................................................................................. 512

Create points at any position........................................................................................513

Create bolt points...........................................................................................................513

Create points at the intersection of two lines.............................................................514

Create points at the intersection of a plane and a line............................................. 514

Create points at the intersection of a part and a line................................................514

Create points at the intersection of a circle and a line.............................................. 514

Create points at the intersection of two part axes.....................................................515

Import points.................................................................................................................. 515

Point properties..............................................................................................................516

3

Change how model objects are displayed ............................. 517

3.1

Show and hide model objects...................................................................... 517

3.2

3.3

Set the visibility and appearance of model objects.........................................................518

Show parts with exact lines...........................................................................................519

Show parts with high accuracy..................................................................................... 519

Change the rendering of parts and components............................................................ 520

Hide model objects............................................................................................................. 524

Show only selected model objects.................................................................................... 524

Temporarily display assembly and component objects................................................. 525

Display detailing of a part...................................................................................................526

Create object groups.....................................................................................527

Create an object group....................................................................................................... 527

Copy an object group to another model.......................................................................... 528

Delete an object group....................................................................................................... 528

Change the color and transparency of model objects..............................529

Change the color of a model object.................................................................................. 529

Change the color of an object group.................................................................................531

Define your own colors for object groups...................................................................531

Define color and transparency settings............................................................................533

Copy color and transparency settings to another model............................................... 534

Delete color and transparency settings............................................................................ 534

10

4

4.1

4.2

4.3

4.4

4.5

4.6

Check the model........................................................................ 535

Inquire object properties............................................................................. 535

Object property report templates..................................................................................... 537

Custom inquiry.................................................................................................................... 538

Use the Custom Inquiry tool......................................................................................... 538

Define what information is shown by Custom Inquiry tool...................................... 538

Modify the default attributes in InquiryTool.config file............................................. 540

Measure objects............................................................................................ 541

Measure distances...............................................................................................................541

Measure angles....................................................................................................................542

Measure arcs........................................................................................................................ 542

Measure bolt spacing.......................................................................................................... 543

Compare parts or assemblies...................................................................... 543

Create a clip plane.........................................................................................544

Fly through the model.................................................................................. 545

Detect clashes................................................................................................546

Find clashes in a model.......................................................................................................547

Manage clash check results................................................................................................548

Symbols used in clash checking................................................................................... 548

About clash types........................................................................................................... 549

Manage the list of clashes............................................................................................. 552

Search for clashes.......................................................................................................... 552

Change the status of clashes........................................................................................ 552

Change the priority of clashes...................................................................................... 553

Group and ungroup clashes...............................................................................................553

View the details of a clash.................................................................................................. 554

Add comments to a clash................................................................................................... 554

Modify a clash comment............................................................................................... 555

Remove a clash comment............................................................................................. 555

View the history of a clash.................................................................................................. 555

Print a list of clashes........................................................................................................... 556

Preview a list of clashes before printing......................................................................556

Set the paper size, margins and page orientation..................................................... 557

Open and save clash check sessions................................................................................ 557

Define a clash check clearance area for bolts..................................................................558

4.7

4.8

Diagnose and repair the model................................................................... 559

Find distant objects...................................................................................... 561

5

Number the model.................................................................... 563

5.1

What is numbering and how to plan it....................................................... 563

Numbering series................................................................................................................ 564

Plan your numbering series.........................................................................................565

Assign a numbering series to a part............................................................................ 566

Assign a numbering series to an assembly.................................................................566

Overlapping numbering series..................................................................................... 567

Identical parts...................................................................................................................... 568

Identical reinforcement...................................................................................................... 568

Define what affects numbering......................................................................................... 569

User-defined attributes in numbering.............................................................................. 570

Family numbers................................................................................................................... 570

11

Assign family numbers.................................................................................................. 571

Change the family number of an object......................................................................572

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

Adjust the numbering settings....................................................................572

Number parts................................................................................................ 573

Number a series of parts....................................................................................................573

Number assemblies and cast units................................................................................... 574

Number reinforcement.......................................................................................................575

Number welds......................................................................................................................576

Save preliminary numbers................................................................................................. 576

Change existing numbers.............................................................................576

Clear existing numbers.................................................................................577

Check the numbering................................................................................... 578

View the numbering history........................................................................ 580

Repair numbering errors..............................................................................581

Renumber the model.................................................................................... 582

Control numbers........................................................................................... 582

Assign control numbers to parts....................................................................................... 583

Control number order.........................................................................................................584

Display control numbers in the model............................................................................. 585

Remove control numbers................................................................................................... 586

Lock or unlock control numbers........................................................................................587

Example: Use control numbers to indicate the erection order .................................... 587

Number parts by design group.................................................................... 589

Numbering examples................................................................................... 592

Example: Number identical beams................................................................................... 592

Example: Use family numbers........................................................................................... 593

Example: Number selected part types..............................................................................594

Example: Number parts in selected phases.....................................................................595

Tips for numbering........................................................................................597

Numbering settings during a project................................................................................ 597

Create a standard-part model............................................................................................598

6

Applications................................................................................600

6.1

6.2

6.3

Working with applications........................................................................... 602

Import a .tsep extension to the Applications & components catalog.... 606

Publish a group in the Applications & components catalog.................... 607

7

Components............................................................................... 610

7.1

7.2

7.3

7.4

7.5

Component properties................................................................................. 611

Add a component to a model.......................................................................613

View a component in a model..................................................................... 615

Component tips............................................................................................. 616

How to use the Applications & components catalog................................ 617

Groups in the catalog.......................................................................................................... 617

Search for a component in the catalog.............................................................................618

Change the view in the catalog.......................................................................................... 619

Show selected components in the catalog....................................................................... 619

View and modify component information in the catalog............................................... 620

12

Add a thumbnail image for a component in the catalog................................................620

Publish a component in the catalog..................................................................................621

Create and modify groups in the catalog......................................................................... 621

Change the order of groups in the catalog...................................................................... 622

Hide groups and components in the catalog...................................................................623

Show the catalog message log...........................................................................................623

Catalog definitions...............................................................................................................624

7.6

7.7

7.8

Converting a conceptual or a detailed component.................................. 624

Automate connection creation .................................................................. 625

AutoConnection................................................................................................................... 625

Define AutoConnection settings and rules................................................................. 626

Create a connection using AutoConnection............................................................... 629

AutoDefaults........................................................................................................................ 630

Define AutoDefaults settings and rules.......................................................................631

Modify a connection using AutoDefaults.................................................................... 635

AutoConnection and AutoDefaults rules..........................................................................635

Combining and iterating properties for AutoDefaults...............................................638

AutoDefaults example: Using iteration with connection check................................640

Using reaction forces and UDLs in AutoDefaults and AutoConnection.................. 642

Advanced component settings ................................................................... 643

Define connection properties in the joints.def file..........................................................644

How to use the joints.def file........................................................................................ 644

Example: How Tekla Structures uses the joints.def file............................................. 646

General defaults in the joints.def file...........................................................................647

Bolt diameter and number of bolts in the joints.def file...........................................648

Bolt and part properties in the joints.def file............................................................. 650

Excel spreadsheets in connection design.........................................................................656

Files used in Excel spreadsheet connection design................................................... 657

Example of an Excel spreadsheet in connection design........................................... 658

Example of visualizing the Excel connection design process....................................662

Showing connection status in Excel connection design............................................ 666

General tab...........................................................................................................................666

Design and Design type tabs..............................................................................................667

Analysis tab.......................................................................................................................... 670

8

Custom components................................................................. 672

8.1

8.2

8.3

8.4

8.5

Custom parts................................................................................................. 674

Custom connections..................................................................................... 676

Custom details...............................................................................................678

Custom seams............................................................................................... 680

Create a custom component........................................................................683

8.6

8.7

Explode a component......................................................................................................... 686

Create a nested custom component.................................................................................686

Create a thumbnail image of a custom component....................................................... 688

Example: Create a custom end plate component........................................................... 689

Example: Create a nested connection with stiffeners.................................................... 692

Modify a custom component....................................................................... 696

Protect a custom component with a password............................................................... 697

Add variables to a custom component ......................................................698

Bind component objects to a plane.................................................................................. 699

Bind objects automatically............................................................................................ 699

13

Bind objects manually................................................................................................... 701

Test a binding..................................................................................................................704

Delete a binding............................................................................................................. 704

Example: Bind an end plate to a plane........................................................................705

Bind component objects using magnetic construction planes or lines........................707

Bind handles using a magnetic construction plane................................................... 707

Bind handles using a magnetic construction line...................................................... 709

Add a distance between component objects...................................................................709