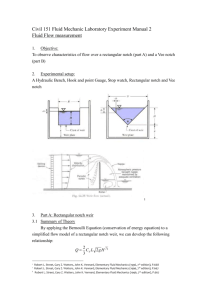

H6 Discharge Over a Notch User Guide © TecQuipment Ltd 2016 Do not reproduce or transmit this document in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage and retrieval system without the express permission of TecQuipment Limited. TecQuipment has taken care to make the contents of this manual accurate and up to date. However, if you find any errors, please let us know so we can rectify the problem. TecQuipment supply a Packing Contents List (PCL) with the equipment. Carefully check the contents of the package(s) against the list. If any items are missing or damaged, contact TecQuipment or the local agent. DB/0816 : User Guide TecQuipment Ltd H6 Discharge Over a Notch Contents Introduction Description .................................................................. 1 ................................................................... 3 Technical Details ............................................................ 5 Noise Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Installation and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Unit Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Background to Weirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Theory of Flow over Sharp-Edge Notch Weirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Finding the Mean Coefficient of Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Predicting Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 The Cipoletti (Trapezoidal) Weir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 The Linear Head/Flow (Proportional) Weir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Alternative Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Useful Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Experiment 1 - Flow and Head Relationship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Experiment 2 - Predicting Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Typical Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Experiment 1 - Flow and Head Relationship. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Experiment 2 - Predicting Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Maintenance, Spare Parts and Customer Care . . . . . . . . . . . . . . . . . . . . . . . 33 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 TecQuipment Ltd User Guide H6 Flow Over a Notch User Guide Introduction Figure 1 H6 Flow Over a Notch Often, engineers use weirs to simply raise the level of upstream water in a river or canal system. Alternatively, weirs can help to retain fish stocks in a section of river. However, engineers often use weirs to regulate flow in rivers and other open channels. In some applications engineers have designed and calibrated the weir with its surrounding water levels, so that they only need to know the upstream water level to find the flow over the weir. Weirs have different shapes and designs, which work better for different applications. The most common include; broad-crested, sharp-edged (or sharp-crested) or weirs that have a shaped ‘notch’. The TecQuipment Flow Over a Notch apparatus (H6) fits onto TecQuipment’s Digital Hydraulic Bench (H1F) or an existing Gravimetric Hydraulic Bench (H1). It works over a range of flow to allow experiments that show the relationship between flow and head and how you can use the weirs to measure flow. The apparatus includes three standard weirs, one rectangular and two V-notch. It also includes an advanced set of two weirs, Cipoletti (trapezoidal) and a linear head/flow weir for more experiments. TecQuipment Ltd 1 User Guide H6 Flow Over a Notch User Guide 2 TecQuipment Ltd H6 Flow Over a Notch Description Depth or Height Gauge Downstream Open Channel section Rectangular Weir (fitted) Upstream V-Notch Weirs Trapezoidal (Cipoletti) Weir Linear Head/Flow Weir Figure 2 Main Parts Figure 2 shows the main parts of the equipment. The drawing of Figure 3 shows more detail. The main part of the apparatus is a moulded tank in three sections. It has an enlarged upstream section and a thinner but deeper downstream section. The ‘open channel’ between the two sections has a slot for the weirs and a fixing point for the depth (or height) gauge. The unit fits onto TecQuipment’s Digital Hydraulic Bench (H1F) or an existing Gravimetric Hydraulic Bench (H1). The benches work as the water supply and external flow measurement system. The bench supply pipe connects to the bottom of the upstream end of the apparatus. The outlet of the downstream end drains into the large central hole in the lid of the Bench. The enlarged upstream section and special disc at the inlet help to stabilize the inlet (upstream) flow conditions for better results. TecQuipment Ltd 3 User Guide H6 Flow Over a Notch Inlet pipe Weir Depth gauge Outlet to Gravimetric Bench Inlet pipe Disc Figure 3 Details of the Equipment User Guide 4 TecQuipment Ltd H6 Flow Over a Notch Technical Details Item NOTE Details Nett dimensions and weight 920 mm x 620 mm x 520 mm and 12 kg Open channel (nominal dimensions) 228 mm x 178 mm x 305 mm Rectangular Notch Weir (nominal dimensions) Depth 100 mm, width 30 mm (Measure accurately before use) V Notch Weirs (nominal dimensions) One of depth 100 mm, total notch angle 30º (θ = 15°) One of depth 100 mm, total notch angle 90º (θ = 45°) (Check before use) Linear Head/Flow (nominal dimensions) Height of cut-out 77 mm. Base 50 mm. Cipoletti (nominal dimensions) Depth 100 mm, width at top 75 mm, width at bottom 25 mm. Slope ratio of 4 units vertical to one unit horizontal. Check all nominal dimensions accurately before use. Noise Levels The noise levels recorded at this apparatus are lower than 70 dB (A). TecQuipment Ltd 5 User Guide H6 Flow Over a Notch User Guide 6 TecQuipment Ltd H6 Flow Over a Notch Installation and Assembly The terms left, right, front and rear of the apparatus refer to the operators’ position, facing the unit. NOTE • A wax coating may have been applied to parts of this apparatus to prevent corrosion during transport. Remove the wax coating by using paraffin or white spirit, applied with either a soft brush or a cloth. • Follow any regulations that affect the installation, operation and maintenance of this apparatus in the country where it is to be used. TecQuipment supply the apparatus disassembled for transport. To reassemble: 1. TecQuipment may remove the depth gauge assembly for transport. Use the fixings supplied to refit it to the open channel section. 2. The inlet pipe may have been removed for transport. Refit it to the channel. You may use some of the silicon grease (supplied) to help create a good seal if needed. 3. Put the equipment onto the top of the Hydraulic Bench and use its adjustable feet to make it level. 4. Connect the bench supply hose to the upstream inlet connection. 5. Put the downstream end over the large hole in the lid of the Hydraulic Bench. You may need to use a short piece of pipe to help direct the flow into the hole. 6. Wear suitable gloves and smear some of the grease (supplied) around the slot in the open channel or around the edge of the weir that you are to test. This helps to create a good seal. TecQuipment Ltd 7 User Guide H6 Flow Over a Notch User Guide 8 TecQuipment Ltd H6 Flow Over a Notch Theory Notation Symbol Meaning Units u Velocity of flow m.s-1 H Total Head m h height (or depth) m Q Flow or discharge m3.s-1 A Area m2 B Breadth (Width) of weir base m b Breadth (Width) at a point on the V notch weir m p Pressure Pa or N.m-2 kc kR kV kL Constants for Cipoletti, rectangular, V and Linear notch weirs - g Acceleration due to gravity m.s-2 x Distance m w Specific weight (water) 9810 N.m-3 z Elevation (above a datum or given level) m θ Angle degrees Cd Coefficient of discharge - CdR Coefficient of discharge (rectangular notch weir) - CdV Coefficient of discharge (V notch weir) - CdL Coefficient of discharge (Linear weir) - Table 1 Notation Unit Conversions Gravimetric Flow: 1 m3.s-1 = approximately 1000 kg.s-1 for clean water at room temperature. TecQuipment Ltd 9 User Guide H6 Flow Over a Notch Background to Weirs In many cases, the upstream water level determines the rate of flow over a weir. Engineers often call this relationship between flow rate and water level the “rating curve”. However, the water level downstream of a weir may reach a height that affects the conditions of flow. In this case, the flow rate now becomes a function not only of the upstream water level but also of the water level downstream. The weir is then called “suppressed” or “drowned”. As mentioned earlier, weirs have many different designs, but generally, local conditions affect the design of weir needed for any application. In many applications the weir has a round or broad crest as shown in Figures 4 and 5. On these weirs, the flow usually remains attached to the downstream surface. However, in the case of the sharp crested weir shown in Figures 6, the flow separates at the crest to form a curved jet that plunges into the downstream pool. In plan view, the weir may be straight or curved to suit local conditions. In some applications, the crest level is not uniform along the whole of the length. For example, part of the whole length may carry normal flow, the rest of the length may have a higher crest, so that it comes into use only at higher flow rates. Figure 4 Round Crested Weir Figure 5 Broad Crest Weir Figure 6 Sharp Crest Weir User Guide 10 TecQuipment Ltd H6 Flow Over a Notch One type of weir good for flow measurement, is the “notch” weir. It has this name because it has a sharp edged notch cut out of a plate. The cut out may be of any shape, but the most common shapes are rectangular and V, as shown in Figure 7. Rectangular V Notch Figure 7 Rectangular and V Notches TecQuipment Ltd 11 User Guide H6 Flow Over a Notch Theory of Flow over Sharp-Edge Notch Weirs h h N H M dh zN zM B q q h h N H M zN zM dh b = 2(H - h)tanq Figure 8 Flow Over Sharp Edge Notch Weirs Figure 8 shows the main features of flow over rectangular and V notches. The approaching (upstream) flow is assumed to be uniform, with total head H measured with respect to the crest level of the notch. If the cross-sectional area of the upstream open channel is much larger than that of the area of flow over the notch, then the velocity head in the upstream flow will be negligible, and the water level there will represent the total head H. Throughout the undisturbed flow upstream, conditions are effectively hydrostatic, the total head H at a typical point M being given by: pM H = --------------w + zM (1) Consider a typical streamline of the flow, from the typical point M in the upstream section to the point N in the plane of the notch. In the absence of any loss of total head, according to Bernoulli's equation: 2 p u p H = -----M- + z M = -----N- + -----N + z N w 2g w (2) The static pressure pN at N is now assumed to be atmospheric (pN = 0), so that: User Guide 12 TecQuipment Ltd H6 Flow Over a Notch 2 u H = -----N- + z N 2g (3) H – zN = h (4) Using the substitution: Where h is the depth of the point N below the upstream undisturbed surface level. Using equations 3 and 4 with Figure 8, we can find the velocity of flow at point N, so that: uN = (5) 2gh The flow velocity at N is the velocity of a particle falling freely (due to gravity) from the level of the undisturbed upstream surface. The discharge rate over any notch may now be found by integration. If b is the width of the notch at depth h below the upstream surface level, then for an element of height δh, the element of area δA is: δA = bδh (6) so the element of discharge δQ is δQ = u N δA = 2gh ⋅ bδh (7) The total flow rate Q, obtained by integration from zero to H, is then: Q = H 2gh ⋅ bδh (8) 0 This result applies to a notch of any shape, and can be easily applied to the rectangular and V shaped notches. For the rectangular notch of breadth B, equation 8 becomes: H Q = B 2gh ⋅ bδh 0 which integrates immediately to give: 3 --- 2 Q = 2--- 2g ⋅ BH 3 (9) For the V notch of total angle 2θ, the width b is given by: b = 2 ( H – h )tanθ TecQuipment Ltd 13 User Guide H6 Flow Over a Notch The total flow rate is therefore given by Equation (8) as: Q = H 2gh ⋅ 2 ( H – h )tanθδh 0 The result of integration is: 5 --- 8- 2g ⋅ tanθH 2 Q = ----15 (10) Coefficient of Discharge Each of the theoretical results given in Equations 9 and 10 ignore the contraction of the flow as it passes through the notch. During your experiments you will see this contraction: • In the vertical plane - you will see the upper surface drawn downwards over the notch and how the lower surface springs from the crest in an upward direction; • In the horizontal plane - you will see where the water springs from the edges of the notch in a curve which reduces the width of the stream. The contraction is similar to that caused by a sharp edged orifice, and has the same effect of reducing the discharge rate. The coefficient of discharge allows for this reduction, as it is a measure of how the actual flow compares with ideal flow. Therefore, as with an orifice, the equations must be rewritten to include the coefficient of discharge. So, for the rectangular notch: 3 --- 2 Q = C dR 2--- 2g ⋅ BH 3 (11) Inserting known values: Q = C dR × 2.95 × BH 3 --2 (12) and for the V notch: 5 --- 8- 2g ⋅ tanθH 2 Q = C dV ----15 (13) Inserting known values: Q = C dV × 2.36 × tan θH 5 --2 (14) Textbooks give typical values of coefficient of discharge for orifices and weirs. Also, designer’s reference books will give the values for given weir dimensions. However, where possible, engineers should try to calibrate the weir to find an accurate value. This should also give them an idea of how it changes throughout the weir’s flow range. User Guide 14 TecQuipment Ltd H6 Flow Over a Notch Finding the Mean Coefficient of Discharge Rectangular Notch For the Rectangular Notch, a rearrangement of Equation 11 gives: Q C dR = ---------------------------3 --2--- 2g BH 2 ⋅ 3 (15) Or alternatively: kR C dR = --------------------2--- 2g ⋅ B 3 Where kR is a constant found from the ratio of flow over Head3/2: Qk R = ----3 H (16) --2 and inserting known values: kR C dR = ------------------2.95 × B (17) From this, a plot of Q against H3/2 from actual results should give a straight line (see Figure 9). Its gradient will be the mean value of kR, which you can use with Equation 17 to find the mean value of CdR for the rectangular notch. For the Rectangular Notch For the V Notch Flow Q Flow Q Slope = Q/H Head 3/2 = kR Slope = Q/H 3/2 Head 5/2 = kV 5/2 Figure 9 Finding the Mean Value of Coefficient TecQuipment Ltd 15 User Guide H6 Flow Over a Notch V Notch For the V Notch, a rearrangement of Equation 13 gives: Q C dV = ---------------------------------------5 --2 8 ------ 2g ⋅ tanθH 15 (18) Or alternatively: kV C dV = -------------------------------8 ------ 2g ⋅ tanθ 15 Where kV is a constant found from the ratio of flow over Head5/2: Q k V = -----5H (19) --2 and inserting known values: kV C dV = ---------------------------2.36 × tanθ (20) From this, a plot of Q against H5/2 from actual results should give a straight line (see Figure 9). Its gradient will be the mean value of kV, which you can use with Equation 20 to find the mean value of CdV for the V notch. Predicting Flow For the Rectangular Notch, once you have found its constant (kR), you can re-arrange Equation 16 to predict the flow simply by using the upstream head. Q = kR × H 3 --2 (21) For the V Notch, once you have found its constant (kV), you can re-arrange Equation 19 to predict the flow simply by using the upstream head. Q = kV × H User Guide 16 5 --2 (22) TecQuipment Ltd H6 Flow Over a Notch The Cipoletti (Trapezoidal) Weir H B Figure 10 The Cipoletti Weir For flow measurement, the most popular sharp-edged notched weirs are rectangular and V-shaped. However, an Italian engineer - Cipoletti developed an alternative shape (see Figure 10). This slight variation of a rectangular profile produces a constant value of discharge coefficient over a wide range of heads. Experiments on rectangular notches should show that the value of the discharge coefficient falls slightly with increasing head, and therefore ratio H/B. The sloped sides of the Cipoletti weir gives a width that increases with head, providing compensation for the reduction in discharge coefficient. The best way to check this is to test Cipoletti notch in the same manner as a rectangular notch, and compare the head-discharge (H and Q) characteristics on a logarithmic basis. For this weir: Q = kc H TecQuipment Ltd 17 3 --2 (23) User Guide H6 Flow Over a Notch The Linear Head/Flow (Proportional) Weir Top of Weir Plate Shaped Orifice b H H y x H0 Q B Figure 11 The Linear Head/Flow Weir The linear head/flow (proportional) weir (sometimes called a Sutro Weir) is an ingenious design for producing a flow rate Q which is linearly proportional to Head H. Therefore, in the expression: n Q = kL H n = 1 Earlier equations show that for a rectangular notch, n = 3/2, and for a V notch, where the width increases with head, n = 5/2. So, for n = 1, the notch width would need to decrease with increasing head, exactly as shown in the Linear Head weir shown in Figure 11. For low values of head and flow, the water passes through the lower rectangular section and the notch works exactly like a simple rectangular one. For higher head and flow rates, the water passes through the rectangular section and the curved section, so: Q = kL ( H – Ho ) (24) Where: Ho ≈ H ---3 and k L = C dL B 2gx User Guide 18 (25) TecQuipment Ltd H6 Flow Over a Notch Accurate values for CdL and Ho can be found from experiment. Figure 11 also shows the head-flow relationship for this weir, which should give a straight line. Extending this line should give a value for H0. The gradient should give kL and using this with a rearranged Equation 25 will give a value for CdL. TecQuipment Ltd 19 User Guide H6 Flow Over a Notch Alternative Theory Equation 26 gives an alternative and general way of expressing the flow for both rectangular and Vnotch weirs: Q = kH n (26) This can be expressed in logarithmic terms as: logQ = log k + n logH So, if you create a chart of log Q against log H for your actual results (see Figure 10), it should produce a straight line. You can then find its slope to confirm the value for n and find its intercept to give log k. This should help prove the values given in the theory and possibly give you more accurate calibration constants (kV, kR and 3/2 or 5/2) for your weir. Log Q X X X X Gradient = n X Intercept = log k X X Log H X Figure 12 Log-Log Results User Guide 20 TecQuipment Ltd H6 Flow Over a Notch Experiments Useful Notes Two People This equipment is safe to use, but TecQuipment recommend that at least two people do the experiments. One person to take weir readings and the other to check flow rates. Splashes of Water This apparatus uses water and may splash some onto the top of the Hydraulic Bench. Be prepared for small splashes of water. Setting up Initial Water Level (Datum of Head) Steel rule Level too low Level too high Level correct (a) Rectangular Notch V-notch Reflection in water surface Level too low Level too high Level correct (b) V-notch Figure 13 Water Level TecQuipment Ltd 21 User Guide H6 Flow Over a Notch Before each experiment, you must set a datum point for the upstream head of water, then all other measurements of head during the tests will be with respect to this value. To do this, start the pump of the hydraulic bench until the upstream water level just starts to pour over the bottom of the notch of the weir, then stop the pump. Now, wait for the level to stabilize and use a rule or flat edge to make sure the water upstream of the weir is exactly level with the bottom of the notch (see Figure 13). This is easiest with the rectangular notch. For the V notch, try to use the weir reflection in the water to help you see how the water level matches with the bottom of the V. If necessary, use a small cup or beaker (not supplied) to add or remove some water to or from the upstream section. Now carefully adjust the depth gauge so that its tip touches the surface of the water. This is the datum Head value. User Guide 22 TecQuipment Ltd H6 Flow Over a Notch Experiment 1 - Flow and Head Relationship Aims To show how flow varies with Head. To show how the coefficient of discharge changes slightly with flow. To find the mean coefficient of discharge for the weir and therefore its ‘constant’ for calibration. Procedure 1 - Rectangular Weir Datum Value of Head: Width of notch (B): Water Quantity (kg) Time (seconds) Flow (Q) (m3.s-1) Gauge Reading (mm) Head (H) (m) H3/2 (m) CdR Table 2 Blank Results Table 1. Create a blank results table similar to Table 2. 2. Use the given nominal values or carefully measure the notch width (B) and record it. 3. Set up the equipment as described in Installation and Assembly on page 7. 4. Set up the initial water level as shown in Setting up Initial Water Level (Datum of Head) on page 21. 5. Start the pump of the hydraulic bench and adjust for the highest flow rate (around 1 kg per second or 60 kg in one minute). 6. Wait for the flow rate and the upstream level to stabilize and note the water quantity you collect and the time taken. Convert this into volume flow (m3.s-1). TecQuipment Ltd 23 User Guide H6 Flow Over a Notch 7. Use the gauge to measure the new water height. Subtract the datum value from your reading to get the true value of Head and convert this into metres. 8. Repeat for at least seven more lower flow rates that give equal decreases in head (roughly 10 mm steps should work). 9. Watch carefully the water as it leaves the weir. At some point as the flow gets lower, the water does not spring clear of the weir and starts to run down the downstream side of the weir. Stop taking results when this happens. Procedure 2 - V Notch Weirs Datum Value of Head: Angle of notch (θ): Tan θ: Water Quantity (kg) Time (seconds) Gauge Reading (mm) Flow (Q) (m3.s-1) Head (H) (m) H5/2 (m) CdV Table 3 Blank Results Table 1. Create a blank results table similar to Table 3. 2. Use the nominal values given or carefully measure the notch angle to find θ and record the angle and the tan value of the angle. 3. Repeat the experiment just as in procedure 1. 4. Repeat for the other V notch. User Guide 24 TecQuipment Ltd H6 Flow Over a Notch Procedure 3 - Cipoletti and Linear Head/Flow Weir Datum Value of Head: Width at base (B): Water Quantity (L) Time (seconds) Flow (Q) (m3.s-1) Gauge Reading (mm) Head (H) (m) Log Q Log H Table 4 Blank Results Table 1. Create a blank results table similar to Table 4. 2. Repeat the experiment just as in procedure 1. Results Analysis - Rectangular and V Notch Weirs For the rectangular notch weir, calculate H3/2 and use Equation 15 to calculate the coefficient of discharge for each line of your results. For the V notch weirs, calculate H5/2 and use Equation 18 to calculate the coefficient of discharge for each line of your results. For each of your notch weirs, plot a chart of coefficient of discharge (vertical axis) against flow to see how it changes with flow. For the rectangular and both V notches, plot charts of Flow (vertical axis) against Head. Note the nonlinearity of the results and how the head changes with flow. Add to your rectangular notch chart the values of H3/2, then find its slope to calculate the mean value of coefficient of discharge (using Equation 17). Add to your V notch charts the values of H5/2, then find its slope to calculate the mean value of coefficient of discharge (using Equation 20). TecQuipment Ltd 25 User Guide H6 Flow Over a Notch Results Analysis - Cipoletti and Linear Head/Flow Weir From your results, find Log Q and Log H, then use these to create a chart of Log Q (vertical axis) against Log H. Find the gradient and intercept to confirm the values of k and n. User Guide 26 TecQuipment Ltd H6 Flow Over a Notch Experiment 2 - Predicting Flow Aims To show how to calculate flow from the upstream head using the constants found from the earlier procedures. To show that you can use the constants found from experiment to accurately predict flow. Procedure Weir: Datum Value of Head: Constant k: H3/2 or H5/2 or Water Quantity (L) Time (seconds) Actual Flow (Q) (m3.s-1) Gauge Reading (mm) Head (H) (m) H1 (m) Calculated Flow (m3.s-1) Error (%) Table 5 Blank Results Table 1. For each weir, create a blank results table similar to Table 5. 2. Repeat head and actual flow measurement, as in experiment 1. 3. Repeat for the other weirs. TecQuipment Ltd 27 User Guide H6 Flow Over a Notch Results Analysis For each line of your results, calculate H1, H3/2 or H5/2 (determined by your weir). Use the Equations in the theory to calculate the flow based on the head and your constant. Subtract the actual flow from the calculated flow, divide by the actual flow and multiply by 100 to find the error in percent. Explain the cause of any significant errors. User Guide 28 TecQuipment Ltd H6 Flow Over a Notch Typical Results All results are for reference only. Actual results may differ slightly. Experiment 1 - Flow and Head Relationship Rectangular Notch Weir 0.68 Coefficient of Discharge 0.66 0.64 0.62 0.6 0.58 0.56 0 0.0001 0.0002 0.0003 0.0004 0.0005 0.0006 0.0007 0.0008 Flow (m 3.s-1) Figure 14 Typical Results for the Rectangular Notch Weir Figure 14 shows that for the rectangular notch weir, ignoring any obviously inaccurate results, the trend for the coefficient of discharge generally increases slightly to towards the middle of the flow range and decreases at each end of the flow rate. Figure 15 shows that for the rectangular notch weir, flow increases with head in a non-linear way. However, flow against Head3/2 produces linear results, giving a gradient (kR) of 0.0539. Where the weir notch width (B) is 30 mm (0.030 m), from Equation 17, this gives: 0.0539 C dR = ----------------------------2.95 × 0.030 Which gives a mean coefficient of discharge for the rectangular notch (CdR) of 0.61. TecQuipment Ltd 29 User Guide H6 Flow Over a Notch Rectangular Notch Weir Head3/2 (m 3/2) 0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.0009 0.0008 Head Head^3/2 Flow (m 3.s-1) 0.0007 0.0006 0.0005 y = 0.054x + 5E-06 0.0004 0.0003 0.0002 0.0001 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 Head (m) Figure 15 Typical Results for the Rectangular Notch Weir Figure 16 shows that for the 30° V notch weir, ignoring any obviously inaccurate results, the trend for the coefficient of discharge generally decreases slightly with increasing flow. Figure 17 shows that for the 30° V notch weir, flow increases with head in a non-linear way. However, flow against Head5/2 produces linear results, giving a gradient (kV) of 0.395. Where notch total angle is 30° giving θ = 15°, from Equation 20, this gives: 0.395 C dV = ----------------------------2.36 × 0.268 Which gives a mean coefficient of discharge for the 30° V notch (CdV) of 0.625. User Guide 30 TecQuipment Ltd H6 Flow Over a Notch V Notch Weir ( total angle = 30° theta = 15°) 0.68 Coefficient of Discharge 0.66 0.64 0.62 0.6 0.58 0.56 0 0.0001 0.0002 0.0003 0.0004 0.0005 0.0006 0.0007 0.0008 0.0009 Flow (m 3.s-1) Figure 16 Typical Results for the 30° V Notch Weir V Notch Weir ( total angle = 30° theta = 15°) Head5/2 (m 5/2) 0 0.0005 0.001 0.0015 0.002 0.0025 0.0009 0.0008 Head Head^5/2 0.0007 Flow (m 3.s-1) 0.0006 y = 0.3952x + 9E-07 0.0005 0.0004 0.0003 0.0002 0.0001 0 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 Head (m) Figure 17 Typical Results for the 30° V Notch Weir TecQuipment Ltd 31 User Guide H6 Flow Over a Notch Experiment 2 - Predicting Flow A typical line of results from the rectangular notch weir gives: Actual Flow 0.0003676 m3.s-1 Head 0.03541 m Head3/2 0.00666329 Constant kR 0.0539 From Equation 21, calculated flow = 0.0539 x 0.00666329 = 0.0003591 m3.s-1 % error = [(3591-3676)/3676] x 100 = -2.3% Table 6 Typical Results for the Rectangular Notch Weir A typical line of results from the 30° V notch weir gives: Actual Flow 0.00021008 m3.s-1 Head 0.04889 m Head5/2 0.000528506 Constant kV 0.395 From Equation 22, calculated flow = 0.395 x 0.000528506 = 0.00020876 m3.s-1 % error = [(20876-21008)/21008] x 100 = -0.63% Table 7 Typical Results for the 30° V notch Weir Expect flow prediction accuracies of better than 3% for each weir over most of the flow range. Note that the accuracy reduces (error increases) when the flow rate becomes low. At low flow rates, any errors in measurement become more significant, also the water does not pass over the weir’s edge cleanly, so the contraction is no longer present. This means that the theoretical equations that include the coefficient of discharge are no longer correct. The results should prove that the theory works accurately to help define the constants and predict the flow over rectangular and V notch weirs, but only over a given (normal) range of flow for the weir. User Guide 32 TecQuipment Ltd H6 Flow Over a Notch Maintenance, Spare Parts and Customer Care Maintenance Regularly check all parts of the apparatus for damage, renew if necessary. When not in use, store the apparatus in a dry, dust-free area, covered with a plastic sheet. If the apparatus becomes dirty, wipe the surfaces with a damp, clean cloth. Do not use abrasive cleaners. Regularly check all fixings and fastenings for tightness, adjust where necessary. NOTE Renew faulty or damaged parts with an equivalent item of the same type or rating. Spare Parts Check the Packing Contents List to see what spare parts we send with the apparatus. If you need technical help or spares, please contact your local TecQuipment agent, or contact TecQuipment direct. When you ask for spares, please tell us: • Your name • The full name and address of your college, company or institution • Your email address • The TecQuipment product name and product reference • The TecQuipment part number (if you know it) • The serial number • The year it was bought (if you know it) Please give us as much detail as possible about the parts you need and check the details carefully before you contact us. If the product is out of warranty, TecQuipment will let you know the price of the spare parts. Customer Care We hope you like our products and manuals. If you have any questions, please contact our Customer Care department: Telephone: +44 115 954 0155 Fax: +44 115 973 1520 Email: customercare@tecquipment.com For information about all TecQuipment products visit: www.tecquipment.com TecQuipment Ltd 33 User Guide H6 Flow Over a Notch User Guide 34 TecQuipment Ltd