Reaction Engineering Assignment: Batch Reactors & Saponification

advertisement

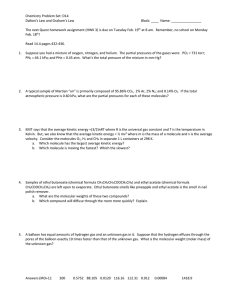

POINT LISAS CAMPUS ESPERANZA ROAD, BRECHIN CASTLE POINT LISAS, COUVA TRINIDAD, W.I. An Assignment: Describe a real-life situation that can be mathematically approximated using the common reactors we have learned about in class (Batch, CSTR, PFR, and PBR). REEN2001: REACTION ENGINEERING B.A.Sc. Process Engineering - Part Time INSTRUCTOR: Dr. Ejae John Completed By: Peter E. Khan UTT ID# 62351 Table of Contents Introduction ...................................................................................................................................2 Abstract ..........................................................................................................................................2 Batch Reactor ................................................................................................................................3 Relevant Equation .........................................................................................................................4 Theory ............................................................................................................................................5 Saponification of Ethyl Acetate ....................................................................................................6 Calculation .................................................................................................................................. 7-9 Conclusion ...................................................................................................................................10 References .....................................................................................................................................11 1 INTRODUCTION Chemical Kinetics and reactor design are essential to produce industrial chemicals and pharmaceuticals. It can also be applied to many other areas. The understanding of common industrial factors can be applied to non-traditional applications. Chemical kinetics is the study of the rate of transaction of chemical compounds from reactor species into products. Therefore, reactor design is of primary concern in the exploration of chemical reactor industrial products. Kinetics can be used in everyday life. There are processes that require chemical reactions, such as baking and food preservation. Also, in medicine, the concentration of chemical can alter the effects of drugs because a higher concentration of chemical can alter the effect of the drugs. ABSTRACT There are four main types of reactors used in various processes in the industrial environment. They are known as chemical reactors; this equipment is designed for chemicals to be fed and chemically react with each other for the purpose of creating a desired product. Chemical reactors are designed in such a way to increase the net present value for a given reaction and ensure the highest efficiency to output the desired products. There are four main reactors (CSTR), plug flow reactor (PFR) and packed bed reactor (PBR). The batch reactor is our focus of attention in this project. 2 BATCH REACTOR A batch reactor is a closed vessel in which reactions happen and it is a non-continuous type of reactor. The reactants are fed into the reactor all at once initially. The vessel contains an agitator. The purpose of the agitator is to mix the reactants thoroughly so that the contact makes them react together efficiently and produce products. To handle exothermic reactions, the batch reactor is often equipped with cooling coils. To work with endothermic reactions, the batch reactor has provisions for heating the reaction mixture. The batch reactor is a non-steady, transient reactor. It means the extent of conversion within the reactor depends on time. Due to agitator the batch reactor is highly uniform in nature. It means the extent of conversion does not depend on location within the reactor. At a given time the extent of reaction at any location of the volume of the reactor will be equal. A reaction in which the reactants are added to the reactor at the start of the reaction. The reactants are allowed to react in the reactor for a fixed time. No feed is added, or product withdrawn during this time. The reaction products are removed at the end of the batch. 3 RELEVANT EQUATIONS Assumptions: Closed system – no addition of reactants or removal of products during the reaction. Ideal batch reactor- Vessel is perfectly mixed. Concentration and temperature are spatially constant. 4 THEORY Ethyl Acetate is a compound produced by yeast that is quantitatively the major ester found in both beer and wine. Esters are aromatic compounds formed by the reaction between alcohols and acids. They are widely found in nature and contribute to the aromas of many varieties of fruit. Over 90 esters can occur in beer, and the ethyl esters predominate. These esters contribute to the overall flavor and aroma of beer, giving a “fruity” quality to a drink that rarely contains any fruit. As ethyl acetate intensifies, however, the aromatic perception can skew from pleasant and “fruity” to “solventy” and “perfumy;” abnormally high levels are therefore regarded as off-flavors. In addition to being produced by brewer’s yeast strains (Saccharomyces cerevisiae and Saccharomyces pastorianus), ethyl acetate is also produced in large quantities by the wild yeasts Brettanomyces, Hansenula, and Pichia via aerobic fermentation. Because ethyl acetate is such an influential part of beer aromatics—for good or ill—brewers seek to control its levels in their beers. Many factors, in addition to the yeast strain employed, have been found to influence the concentration of ethyl acetate formed during fermentation. These include fermentation temperature, where an increase from 50°F to 77°F (10°C–25°C) has been found to increase the concentration of ethyl acetate from 12.5 to 21.5 mg/L. Continuous fermentation results in higher levels of esters as compared to conventional batch fermentation. High yeast pitching rates result in lower levels of ethyl acetate. 5 SAPONIFICATION OF ETHYL ACETATE Ethyl acetate is a colorless liquid and has a characteristic sweet smell. It is used in glues, nail polish removers, decaffeinating tea and coffee. Ethyl acetate when reacts with sodium hydroxide it produces sodium hydroxide and ethyl alcohol, the reaction is called saponification and it of second order as the rate of reaction depends on concentration of both ethyl acetate and sodium hydroxide. The reaction is carried out in a water bath to maintain the constant temperature, Solution of ethyl acetate and sodium hydroxide is mixed in a flask and the flask is kept in water bath. As the reaction proceeds the concentrations of reactants (ethyl acetate and sodium hydroxide) decrease at the same time concentration of products (sodium acetate and ethyl alcohol increases). To find the rate of reaction we monitor the concentration of sodium hydroxide by taking a small amount of reaction mixture after a fixed interval of time and titrating it with standard hydrochloric acid solution from the burette. The reaction: CH3COOC2H5 + NaOH ⟶ CH3COONa + C2H5OH 6 CALCULATIONS The reaction: CH3COOC2H5+NaOH⟶CH3COONa+C2H5OH The start the amount of acid needed for NaOH in reaction mixture will be equivalent to the initial concentration of NaOH, Volume of standard acid at beginning of (V0) ∝ Initial concentration of NaOH (a) ∴V0 ∝ a … (1) After time t, x amount of NaOH gets reacted, therefore, volume of acid will now be equivalent to the concentration of NaOH remaining in reaction mixture i.e. (a - x). Volume of standard acid at time t (Vt) ∝ Concentration of NaOH (a -x) ∴V0 ∝ (a - x) … (2) The value of a from equation (1) Vt ∝ (V0 - x) ∴ x ∝ V0 -Vt … (3) Values of a and x from equation (1) and equation (3) 7 Thus from the initial and final volume of acid the rate constant of saponification of ethyl acetate Numerical: Starting with equal concentration of ethyl acetate and sodium hydroxide, the saponification of ethyl acetate was carried out. Same volume of the reaction mixture was withdrawn at different intervals of time and titrated with the same acid. The following data were obtained: Time (min.): 0 5 15 25 Acid used (ml): 16 10.24 6.13 4.32 8 The reaction is of the second order. V0 is 16 ml. 1) at time t = 5 min volume of acid Vt = 10.24 ml 2) at time t = 15 min volume of acid Vt = 6.13 ml 3) at time t = 25 min volume of acid Vt = 4.32 ml This indicates the value of k is fairly constant. The reaction is of the second order. Mean rate constant is 0.0068. 9 CONCLUSION The simplest reactor used in chemical processes is the batch reactor. Some advantages of the batch reactor are: High conversions can be obtained by leaving reactants in the reactor for extended periods of time. Batch reactor jackets allow the system to change heating or cooling power at constant jacket heat flux. Versatile, can be used to make many products consecutively. Good for producing small amounts of products while still in the testing phase. Easy to clean. Some disadvantages are: High cost of labor per unit of production. Difficult to maintain large scale production. Long downtime for cleaning leads to periods of no production. It was observed that the concentration decreased as the time increased. However, the rate is constant. 10 REFERENCES Fogler, Scott H. Essentials of Chemical Reaction Engineering. Westford, MA: PrenticeHall, 2011. Print. Tsujikawa, Hiroo, and Inoue, Hakuai. “The Reaction Rate of Alkaline Hydrolysis of Ethyl Acetate”, Bulletin of the Chemical Society of Japan, 39: 1837-1842 http://api.uofk.edu:8080/api/core/bitstreams/308421e6-2174-4f92-ad53c1108cdeab0c/content 11