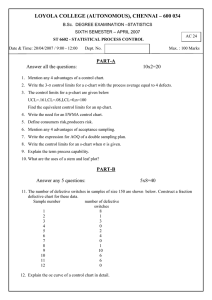

STATISTICAL QUALITY CONTROL (SQC) SQC has been defined as: The monitoring of quality by application of statistical methods in all stages of production. The word “Quality” in SQC refers to characteristics of a product from both a qualitative and quantitative point of view. It refers to the quality of the process as well as the product itself. The word “Control” implies a procedure by which decisions may be made regarding whether production is proceeding according to plan and meeting established standards. The word “Statistics” is a collection of data or numbers, and with the use of mathematics, can analyze and interpret these data for the purpose of making meaningful decisions. Statistics is fundamentally logic and common sense. Statistical Quality Control Basic Statistical Concepts Quality Control Charts Acceptance Inspection of Variables Pharmaceutical Applications Basic Statistical Concepts Statistics is a field of study concerned with: 1. The collection, organization and summarization of data. 2. The drawing of references about a body of data when only a part of the data is observed. 1. Statistical methods involves long periods of time. 2. Methods are so complicated that they cannot be understood or performed by ordinary production and inspection employees. In-process monitoring by the production operator is conducted during a production run with minimum supervision. 3. Techniques are useful only when one is aware that a problem needs correction. The use of SQC is stated in the standard operating procedures (SOP) as a mandatory routine techniques as a visual tool that the process is in control. 4. The effective use of the techniques of SQC is applicable only to one department. Quality Control Charts There are two (2) basic Quality Control Charts which are based on the measurability of the quality characteristics. Page 1 of 24 1. Attribute Chart This is a chart which makes use of discrete data classifying the number of items conforming and the number of items failing to conform to any specified requirements. Example: P-Chart (Fraction Defective Chart) 2. Variable Chart This a chart using actual records of numerical measurement on a full continuous scale such as meter, grams, or liter. Example: and R Purpose of SQC methods of investigation: 1. For estimation of parameters (variations). 2. For test of significance. 3. To determine relationships between factors. 4. To make meaningful decisions based on experimental evidence. Statistical methods of investigation may be divided into four parts which are closely interrelated: 1. Plan or design of the experiment. 2. Collection of data. 3. Analysis of the data. 4. Interpretation of the analysis. Discussions: Plan of Design of the Experiment: - Involves the aim or object of the experiment. Collection of Data: - Involves either the planning or design of an experiment, sampling, or complete census. The topic on sampling will be the emphasis of the discussion. Sampling may be defined as the process of removing an appropriate no. of items from a bulk in order to make inferences (logical conclusions) to the entire bulk. The object of sampling and subsequent testing is to provide an effective check on the quality of the product or substances being processed. Representative of materials to be sampled are drug substances, other raw materials, intermediate products and final products before, during and after manufacturing and packaging operations. The Quality Control inspector must be empowered to sample at any point or stage of manufacturing and packaging operations. Proper methods of sampling and adequate number and size of samples are needed for effective quality control assurance program since the judgement “accept” or “reject” is made on the basis of the sample irrespective of the conditions in the remainder of the batch. Page 2 of 24 Therefore, to minimize errors, a sampling plan must be designed. Sampling plans are described since the sampling technique contributes the most variation if not controlled. There are three common sampling plans: 1. Sampling plan of 100% inspection may be tried to minimize errors, but normally and practically this method can not be attained due to personnel fatigue and other human related factors. 2. Sampling plan using the square root system using the formula: n = N +1 where: n = no. of items to be taken (random) N = total no. of the lot Example: N = 50 items n = 50 + 1 = 8 items 3. Government sampling plan known as Military standard – 105 D originated by a committee from military agencies of the USA, Great Britain and Canada. The sampling plan consists of master tables showing the sample sizes, acceptance and rejection numbers and AQL (Acceptable Quality Level). The variety of sampling plan procedures and tables is unlimited. Frequently, the ease of implementation is more used. A sampling plan is definite working rule regarding the size and frequency of samples and the basis for acceptance or rejection. It is therefore a specification of sampling. Methods of Sampling: The most common and distinct methods of inspection / testing are based on single and double sampling. In single sampling, only the specified sample size is inspected and tested before a decision on the disposition of the batch is made. In double sampling, a second sample for inspection / testing is permitted if the first fails, but the observed no. of defective will apply to the two samples combined. Example of the above sampling: A sample of 50 tablets was taken. The specification is that not more than 2 tablets should be defective and, if 4 or more, should be rejected. If the findings for the first sampling indicates only 2 defectives, then the batch is accepted. If the defectives are more than 2 but less than 4, then a second sampling of 50 tablets is made. If the two samples combined contain less than 4 defectives, the batch is accepted. Page 3 of 24 Construction of Statistical Sampling Plan: This requires normally four basic quality standards to be specified as follows: 1. AQL – Acceptable Quality Level (for example, a batch of tablets is considered acceptable if it contains 2% or less defective tablets). 2. UQL – Unacceptable Quality Level (for example the same batch of tablets is said to be rejected if it contains 4% or more defective tablets). 3. Producer’s risk (α) – is the risk of error on the probability of rejecting a good batch. 4. Consumer’s risk (ß) – is the risk of error on the probability of accepting a defective batch. Sampling of the Chemists / Analysts: Another aspect of sampling is the so-called sampling of the chemist or analyst who performs the test. Number two analysts will obtain exactly the same results using the same technique and the same material after the methodology has proved to be precise and accurate. Frequently methods are tested for their accuracy and precision and thus the wide practice of VALIDATION of both the manufacturing processes and assay methods. A validated product is one that has been shown by appropriate scientific means to be uniform, within a lot, consistent within lots, and meeting designed criteria within defined limits. Implementation of Sampling Plan: In the application of sampling plans to pharmaceutical dosage forms, homogeneity of the sample must be emphasized. 1. For homogeneous dosage forms such as oral or parenteral solutions, samplings are taken with a sample size as small as one unit. 2. If a drum of a powdered drug or excipient is known to be homogeneous, then for statistical purposes, it can be thought of as a solution and single or duplicate samples are considered sufficient to provide a reliable results. 3. For semisolid dosage forms such as ointments, creams or suspensions, statistically they are considered to resemble oral or parenteral solutions when they are assumed to be homogeneous. To verify homogeneity, it is frequently necessary to take more than one sample for semisolids. 4. With printed materials, statistical sampling has worked well. Sampling plans with a range of 1% to 5% for defects were considered adequate for inspection of packaging materials several years ago but the best sensitivity desirable is 0.1% due to high speed packaging line. 3 Analysis of Data Collected: 1. Graphing the data. 2. Applying some statistical formulas to the data. 3. Drawing inferences form the results Discussion: 1. Graphing the data: there are various types of graphs such as: Page 4 of 24 a. Bar graph b. A graph in which one variable is plotted against another variable; e.g. the Quality Control chart. 2. Quality Control Charts: Control Charts have been employed for various pharmaceutical operations and may be used as an aid in controlling and analyzing physical, chemical, analytical and biological parameters such as: 1. Weight variation of tablets & capsules. 2. Thickness of tablets. 3. Volume of liquid filling in a container. 4. Number of percent of defects in parenteral products. 5. Number of fraction of defects in a sample of package emanating from a packaging operation. Two Basic Types of Quality Control Charts: 1. Based on variables 2. Based on attributes “Variable” chart is one in which several samples are tested and distribution of measurements can, in a sense, measure degrees of defectiveness. “Attribute” chart is one in which each sample inspected is tested to determine whether it conforms to requirements. It is the so-called “go” or “no-go” situation. Example: Control Chart based on Variables: During the automatic filling of a parenteral solution in vials, control of the volume filled during a production run should be established and maintained. The procedure is as follows: One vial is taken at random form each of the four needles of the filling machine at designated times and the average and range of this subgroup of four is computed. TABLE I. The numerical data obtained for process control is shown as follows: Label fill = 10 mL. Time of Needle Sampling 1 8:30 10.7 9:20 10.5 10:15 10.5 11:30 10.8 1:00 10.5 2:00 10.5 3:10 10.6 4:00 10.5 2 10.5 10.5 10.9 10.5 10.7 10.8 10.5 10.5 3 10.6 10.8 10.5 10.5 10.5 10.5 10.9 10.7 4 10.5 10.7 10.5 10.5 10.5 10.5 10.6 10.7 10.58 10.63 10.60 10.58 10.55 10.58 10.65 10.65 R 0.2 0.3 0.4 0.3 0.2 0.3 0.4 0.2 Calculations: X = grand average = 10.59 mL Page 5 of 24 R UCL UCL UCL UCLR = = = = = average range = 0.29 mL X + A2R = 10.59 + 0.73 (0.29) = 10.8 X - A2R = 10.38 D4R = 2.28 (0.29) = 0.66 D3R = 0 (0.29) = 0 TABLE 2. Factors for Estimating the 3 Standard Deviation Limits. Sample Size (N) 2 3 4 5 6 7 8 9 10 Factors for R Chart D3 D4 0 0 0 0 0 0.08 0.14 0.16 0.22 Factors for X Chart A2 3.27 2.57 2.28 2.11 2.0 1.92 1.86 1.82 1.78 1.88 1.02 0.73 0.58 0.48 0.42 0.37 0.34 0.31 3. Drawing inferences from the results on the chart by variables: The Control Chart is said to show evidence of “CONTROL” since all points fall within the designated control limits. It is advantageous to plot the X and R because one maybe in control while the other may show excessive variation. Control Chart for Average: Control Chart by Attributes As previously mentioned, when a record shows only the number of articles conforming and the number of articles failing to conform to any specified requirement (go or no-go), it is said to be a control record by attributes. It is obvious that most routine inspection of manufactured pharmaceutical products such as the inspection of parenteral products, or counting of broken tablets in a bottle, is an inspection for attributes. The interest is in the number of fraction defective per batch. Thus, the weakness of attribute measurements is that grading of quality can not be measured. In general, variable charts are more sensitive than attribute chart, although the latter is usually easier to implement. To employ control chart by attributes, a plan with desirable properties would include the following: 1. Samples should be chosen at random or the so-called “random sampling”. 2. For easier evaluation, there should be a fixed number of samples (n) taken each time for inspection. Each tablet or capsule inspected is considered a sample. Page 6 of 24 3. Each sample is evaluated so that the sample is either accepted or rejected; i.e. each sample tablet or capsule is either good or defective. 4. Each sample must be independent, i.e., each tablet or capsule, good or defective, has nothing to do with another tablet or capsule to cause it to be good or defective. Essential Steps in Constructing the Control Chart for Fraction Defective: 1. Record the number of samples (n) inspected and the number of defectives (d). 2. Computing the fraction defective (P), which is the ratio of the number of defectiveness found to the total number of units actually inspected in the batch, expressed as: d P = n 3. Compute the average fraction defective, (), obtained by dividing the total number of defectives found by the total number of units inspected in a series of batches. d P = n 4. Calculate the upper and lower control limits, UCL and LCL, through the following formulas: P +3 P(1–P) UCL = n P - 3 UCL P(1–P) = n If n is different for different batches, upper and lower control will vary from batch to batch. To calculate the limits, compute first the value of the 3 standard deviations for the batch. 3 P (1 – P) 3S = n 5. Plot the P on a Control chart with as the average and Control limits calculated as above. Example: Tablets being manufactured were sampled and several broken ones were sorted out. The following were the data recorded from 5 batches: Batch No. 1 2 3 4 No. of samples inspected (n) 400 395 402 398 No. of defectives (d) 8 7 11 20 Page 7 of 24 5 400 15 Analyze the above data by following the essential steps in constructing a chart. Step no. 1 - no. of samples inspected (n) and no. of defectives (d) found . d Step no. 2: p = n Fraction defective % 8 Batch 1: = 0.02 2.0 0.0177 1.77 0.0273 2.73 0.0502 5.02 0.0375 3.75 400 7 Batch 2: = 395 11 Batch 3: = 402 20 Batch 4: = 398 15 Batch 5: = 400 Step no. 3: d = 8 + 7 + 11 +20 + 15 n = 1995 d 61 P = = n 1995 Step 4: 3 P (1 – P) 3S = n 3 = 61 = 0.03057 = 3.05% 0.0306 (1 – 0.0306) = 400 3 0.0296 = 20 3 x 0.1722 = 20 = 0.0258 Page 8 of 24 = 2.58% UCL = P + 3S = 0.0306 + 0.0258 = 0.0564 = 2.64% LCL = P - 3S = 0.0306 – 0.0258 = 0.0048 = 0.48% Step no. 5: Plot the chart by Attributes (P-chart) for % defective units inspected. % defective (100P) is a more convenient value than fraction defective and is usually used in chart making. Significance of the Charts: 1. When sufficient historical data from at least 10 to 12 batches have been collected, the control limits computed will be reasonably reliable and the control chart can be established for future batches. 2. The control chart tells one when a process is out of control so that steps can be taken promptly to remedy any indication of trouble before future batches or the remainder of a current batch are manufactured. 3. Since the control chart provides a continuous monitoring of a process in sounds a warning signal quickly when the property being measured falls outside the control limits. II. Applying Some Statistical Formulas 1. Average or mean – the mean (X) is the arithmetic average of a series of values and is calculated by dividing the sum of such values by the no. of values (N) in the series. It is expressed as: Xn X = N Example: % Ash content of a drug: 2.1 2.9 2.7 2.3 2.4 Add all values and divide by 5 2. Other measures of variation: The simplest measure of variation is the range which is the difference between the highest and lowest value in a series of observations. Page 9 of 24 For example, the range of the previous 5 values will be calculated as 2.9 – 2.1 = 0.8%. The range is most valuable in small series of observations less than 10 in number. The measure of variation most commonly used is standard deviation which gives a better estimate of variations greater than 10. Therefore for numbers less than 10, range and standard deviation are equally efficient. The standard deviation gives a measure of the variation of individual observations around the average and is calculated from the following formula: (Xn – X)2 S = (XD)2 or N–1 N–1 where: Xn X N –1 = individual no. of a sample or data = average or mean = denominator of the formula For standard deviation called the degree of freedom (DF) and for standard deviation 1 less than the total no. of observation data. XD = individual difference of a sample with the mean. Example: % moisture variation. 2.2 2.3 2.4 2.1 2.7 2.6 2.5 2.0 2.4 X = 2.40% XD = (2.2 – 2.4)2 + (2.1 – 2.4)2 - - etc. until (2.4 – 2.4) 2 = (0.2)2 + (0.3)2 - - etc. + (0)2 0.04 + 0.09 + - - etc. + 0 S = 0.6 = 9 = 0.067 = 0.259% 9 The standard deviation is expressed in the same unit of measurement as the original value. Page 10 of 24 2 Basic Types of QC Chart I. Based on Variables Formulas: Xn (Sum of values in a series) N (Number of values in a series) 1. Xi = 2. Ri = Highest value – lowest value X 3. X = N R 4. R = N 5. UCLX = X + A2R 6. LCLX = X - A2R 7. UCLR = D4R 8. UCLR = D3R 9. Control Chart Page 11 of 24 TABLE 1 The numerical data obtained for process control is shown as follows: Label fill = 10 mL N E E D L E TIME Of SAMPLING 1 2 3 08:30 10.7 10.5 10.6 10.5 10.58 0.2 09:20 10.5 10.5 10.8 10.7 10.63 0.3 10:15 10.5 10.9 10.5 10.5 10.60 0.4 11:30 10.8 10.5 10.5 10.5 10.58 0.3 01:00 10.5 10.7 10.5 10.5 10.55 0.2 02:00 10.5 10.8 10.5 10.5 10.58 0.3 03:10 10.6 10.5 10.9 10.6 10.65 0.4 04:00 10.5 10.5 10.7 10.7 10.60 0.2 4 Xi Ri Page 12 of 24 CALCULATIONS: Xn 1. Xi = N 10.7 + 10.5 + 10.6 + 10.5 = 4 42.3 = 4 = 10.58 mL 2. Ri = Hv – Lv = 10.7 – 10.5 = 0.2 X 3. X = N 10.58+10.63+10.60+10.58+10.55+10.57+10.65+10.60 = 8 84.77 = 8 = 10.596 or 10.60 mL Page 13 of 24 R 4. R = N 0.2+0.3+0.4+0.3+0.2+0.3+0.4+0.2 = 8 2.3 = = 0.2875 or 0.29 mL 8 5. UCLX = = = = X + A2R 10.60 + 0.73 (0.29) 10.60 + 0.2117 10.81 mL 6. LCLX X - A2R 10.60 - 0.73 (0.29) 10.60 – 0.2117 10.39 mL = = = = 7. UCLR = D4R = 2.28 (0.29) = 0.66 mL 8. UCLR = D3R = 0 (0.29) = 0 9. Control Chart a) X Chart b) R Chart Page 14 of 24 SEAT WORK:The numerical data obtained for process control is shown as follows: Label fill : 5 mL / ampoule TIME OF SAMPLING 1 2 3 4 5 07:00 08:00 09:00 10:00 11:00 01:00 02:00 03:00 5.3 5.3 5.3 5.2 5.5 5.4 5.3 5.2 5.3 5.1 5.1 5.2 5.2 5.4 5.3 5.2 5.2 5.1 5.1 5.2 5.2 5.4 5.2 5.2 5.4 5.3 5.2 5.4 5.3 5.3 5.2 5.1 5.5 5.4 5.2 5.4 5.4 5.3 5.1 5.1 NEEDLE Prepare the following: 1. Calculate the:a. UCLX & LCLX b. UCLR & LCLR 2. Prepare a graph for the mean & range. 3. Interpret your results. Page 15 of 24 II. Based on Attributes 1. n – number of samples 2. d – number of defective 3. P – fraction defective d P = n 4. P = average fraction defective d P = n 5. 3S – standard deviation 3 P (1-P) 3S = n 6. UCL = P + 3 P (1-P) n UCL = P + 3S 7. LCL = P - 3 OR P (1-P) n LCL = P - 3S Page 16 of 24 8. QC Chart : P Chart UCL = P %P = LCL = No. of batches Example: Tablets being manufactured were sampled and several broken ones were sorted out. The following were the data recorded from 5 batches: Batch No. n d 1 400 8 2 395 7 3 402 11 4 398 20 5 400 15 Analyze the above data by following the essential steps in constructing a chart. Step no. 1: no. of samples inspected (n) and no. of defectives (d) found. d Step no. 2: P = n Page 17 of 24 Fraction defective %P 8 Batch 1: = 0.02 2.0 0.0177 1.77 0.0273 2.73 0.0502 5.02 0.0375 3.75 400 7 Batch 2: = 395 11 Batch 3: = 402 20 Batch 4: = 398 15 Batch 5: = 400 Step no. 3: d = 8 + 7 + 11 +20 + 15 = 61 n = 400 + 395 + 402 + 398 + 100 = 1995 d P = 61 = n = 0.03057 or 3.06% 1995 Page 18 of 24 Step 4: 3 P (1 – P) 3S = n 3 0.0306 (1 – 0.0306) = 400 3 0.02966364 = 20 3 x 0.172231356 = 20 0.516694068 = = 20 0.0258 or 2.58% UCL = P + 3S = = 0.0306 + 0.0258 0.0564 or 5.64% LCL = P - 3S = = 0.0306 – 0.0258 0.0048 or 0.48% Page 19 of 24 SEAT WORK Sample Problem: Biogesic tablets 500mg were sampled and several broken ones were sorted out. The ff. were the data recorded for 7 batches:Batch no. 1 2 3 4 5 6 7 n d 508 500 550 525 545 530 515 10 07 18 12 16 15 09 Page 20 of 24 2. Other Measures of Variation Standard Deviation (S) (X – X)2 S = N–1 Sample Problem: % Moisture variation Note: The Standard Deviation is expressed in the same unit of measurement as the original value. X(%) 2.2 2.1 2.5 2.3 2.7 2.0 2.4 2.6 2.8 2.4 X = 24 X X = N X–X (X – X)2 -0.2 -0.3 0.1 -0.1 0.3 0.4 0.0 0.2 0.4 0.0 0.04 0.09 0.01 0.01 0.09 0.16 0.00 0.04 0.16 0.00 (X – X)2 = 0.6 24 = = 2.4 10 Page 21 of 24 (X – X)2 S = N–1 0.60 = 10 – 1 0.60 = 9 = S = 0.0666666 0.2582% or 0.26% S = X x S = 2.4 x 0.26 = 0.62% UCL = X + S = 2.4 x 0.62 = 3.02% LCL = X – S = 2.4 – 0.62 = 1.78% Page 22 of 24 SEATWORK: Twenty sets of ten tablets were weighed during compression at thirty minutes intervals. Calculate:a) X b) S c) UCL d) LCL Tablet X(mg) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 373.9 381.5 374.1 365.1 370.0 365.8 367.9 370.0 374.1 369.7 365.1 370.6 368.0 372.8 371.1 365.2 366.9 372.5 370.3 370.4 Page 23 of 24 CHEMISTRY can be described as being concerned w/ the composition of matter & the changes it undergoes. Branches of Chemistry 1. Organic Chemistry is mostly concerned w/ the study of compounds containing the element carbon. 2. Inorganic Chemistry is the study of all elements & compounds other than organic compounds. 3. Biochemistry is the study of the chemistry of biological processes, such as the utilization of foods (carbohydrates, proteins & fats) that produce energy & the synthesis of biologically active compounds in living organisms. 4. Physical Chemistry is the study of: reaction rates – how fast will a reaction go? mechanisms – what path does a reaction take to get to the products? bonding & structure of compounds – how are compounds formed, & what are their shapes? thermodynamics – what makes a reaction go & what is the total energy relationship of a reaction? 5. Analytical Chemistry is the study of qualitative (what is present?) & quantitative (how much is present?) analysis (examination) of elements & compounds. Page 24 of 24