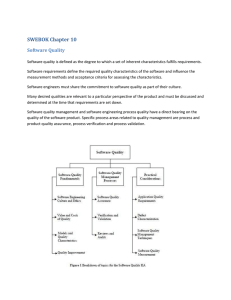

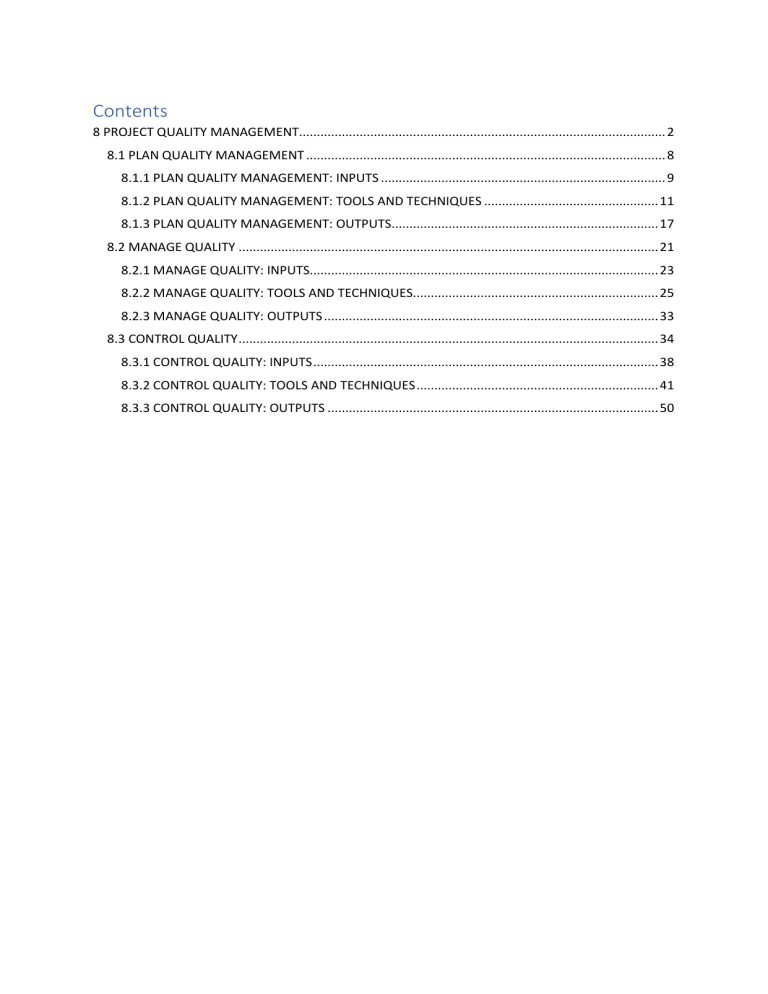

Contents 8 PROJECT QUALITY MANAGEMENT....................................................................................................... 2 8.1 PLAN QUALITY MANAGEMENT ..................................................................................................... 8 8.1.1 PLAN QUALITY MANAGEMENT: INPUTS ................................................................................ 9 8.1.2 PLAN QUALITY MANAGEMENT: TOOLS AND TECHNIQUES ................................................. 11 8.1.3 PLAN QUALITY MANAGEMENT: OUTPUTS........................................................................... 17 8.2 MANAGE QUALITY ...................................................................................................................... 21 8.2.1 MANAGE QUALITY: INPUTS.................................................................................................. 23 8.2.2 MANAGE QUALITY: TOOLS AND TECHNIQUES..................................................................... 25 8.2.3 MANAGE QUALITY: OUTPUTS .............................................................................................. 33 8.3 CONTROL QUALITY ...................................................................................................................... 34 8.3.1 CONTROL QUALITY: INPUTS ................................................................................................. 38 8.3.2 CONTROL QUALITY: TOOLS AND TECHNIQUES .................................................................... 41 8.3.3 CONTROL QUALITY: OUTPUTS ............................................................................................. 50 8 PROJECT QUALITY MANAGEMENT Introduction Project work is incomplete without implementing quality, and an incomplete project is obviously a failed project. Quality refers to the degree to which a set of characteristics of project deliverables and objectives fulfil the project and product requirements. In other words, the core objective of quality management is to ensure that the project will satisfy the needs for which it was undertaken. Quality management consists of three core elements: planning for quality, testing (or assuring) that the quality is implemented as planned, and monitoring and controlling the quality implementation by examining the results of the project. Quality management includes managing the quality of both the project and its product. Whereas the techniques of product quality management, such as measuring the quality, may depend on the type of product, the techniques for project quality management are independent of the type of product. The core question in this chapter is: How do you manage quality? In search of an answer, we will explore three avenues: planning quality, performing quality assurance, and performing quality control. Managing Quality: Big Picture Quality refers to the degree to which a set of characteristics of project deliverables and objectives fulfils the project requirements. In other words, it is the sum of project and product characteristics that help fulfil the requirements. The broader goal of quality management is to ensure that a given project will satisfy the needs for which it was undertaken. Quality management has two components: project quality management and product quality management. Whereas product quality management techniques depend upon the specific product that the project is going to produce, project quality management applies to all projects independent of the nature of the products While dealing with quality, you should be able to distinguish between the terms in the following pairs: Grade and quality. Grade is a category assigned to products with the same overall functional use but that differ in their technical characteristics and features, whereas quality is the degree to which the inherent characteristics of a product meet the requirements. Defects are an example of poor quality, whereas lack of features (or a limited number of features) is an example of low grade. For example: It may not be a problem if a suitable low-grade product (one with a limited number of features) is of high quality (no obvious defects). In this example, the product would be appropriate for its general purpose of use. It may be a problem if a high-grade product (one with numerous features) is of low quality (many defects). In essence, a high-grade feature set would prove ineffective and/or inefficient due to low quality. Precision and accuracy. Precision is a spread of different measurements of the same quantity, constant, or variable, such as gravity or cost. The smaller the spread of measured values, the better the precision is. Accuracy is a measure of how close the measured values are to the true value of the quantity. The closer the measured value is to the actual (or true) value, the better the accuracy of the measurements is. Prevention and inspection. Prevention is a direction to perform an activity that will keep an error from entering the product and the process. Inspection is a technique to examine whether an activity, component, product, result, or service complies with planned requirements. So, the goal of inspection is to ensure that errors do not reach the customer. The cost of quality (COQ) includes all costs incurred over the life of the product by investment in preventing nonconformance to requirements, appraising the product or service for conformance to requirements, and failing to meet requirements (rework). Failure costs are often categorized into internal (found by the project team) and external (found by the customer). Failure costs are also called the cost of poor quality. Organizations choose to invest in defect prevention because of the benefits over the life of the product. Because projects are temporary, decisions about the COQ over a product’s life cycle are often the concern of program management, portfolio management, the PMO, or operations. There are five levels of increasingly effective quality management as follows: NOTE PMI’s approach to quality management is intended to be compatible with that of the International Organization for Standardization (ISO) and is compatible with proprietary approaches to quality, such as those proposed by Crosby, Deming, Juan, and others. It is also compatible with nonproprietary approaches to quality management, such as continuous improvement, cost of quality (COQ), design reviews, failure mode and effect analysis (FMEA), Six Sigma, Total Quality Management (TQM), and voice of the customer. Project management and quality management have come a long way as separate disciplines of knowledge and practice. It should not come as a surprise that quality management is one of nine knowledge areas in standard project management. In a complementary way, both modern quality management and project management recognize the importance of the following critical issues: Continuous improvement. Continuous improvement means to keep improving the quality through a process of planning for quality, implementing quality, auditing quality, and replanning based on lessons learned or auditing. So, really, quality improvement is an endless cycle, called a plan-do-check-act cycle as defined by Shewhart and modified by Deming. Performing organizations can also use techniques such as Six Sigma and TQM to improve quality. Customer satisfaction. Customer satisfaction can be a very vague notion that could mean different things to different parties. However, in project management and quality management, customer satisfaction means planned customer requirements are met. In order to achieve customer satisfaction in the real world, you need to understand, define, and evaluate customer expectations and also manage those expectations, in addition to meeting the planned requirements. Otherwise, you might meet the planned requirements, and the customer may still be dissatisfied. Management responsibility. This refers to the responsibility of management to provide resources needed for the project team to succeed. Although all team members should be responsible for the success of their parts of the project, they cannot succeed without management responsibility. Prevention over inspection. One of the fundamental tenets of modern quality management is to plan, design, and build in quality as opposed to inspect it in. The cost of preventing mistakes is much less than that of finding them through inspections and then fixing them. Therefore, cost of quality (COQ) turns out to be less in prevention than through inspection. The COQ is defined as the total cost of quality-related efforts throughout the product lifecycle. Mutually beneficial partnership with suppliers. An organization and its suppliers are interdependent. Relationships based on partnership and cooperation with the supplier are more beneficial to the organization and to the suppliers than traditional supplier management. The organization should prefer long-term relationships over short-term gains. A mutually beneficial relationship enhances the ability for both the organization and the suppliers to create value for each other, enhances the joint responses to customer needs and expectations, and optimizes costs and resources STUDY CHECKPOINT You are trying out a Monte Carlo simulation program that estimates the value of a parameter by using some random variables. You know through the data that the exact value should be 40. You ran the program three times, and it gave you three values: 50, 51, and 52. Based on these values, answer the following questions: A. How precise is the program in making the estimates? Ans. Average value: 51 % Of uncertainty: 52 – 50 /51* 100 = 3.9% B. How accurate are the estimates? Ans. Considering 51 as the average So accuracy rate would be: 51-40/40*100= 27.5 % C. Are the values generated by the program more accurate or more precise? Ans: the value generated by the simulation is less accurate and more precise. Project Quality Management includes the processes for incorporating the organization’s quality policy regarding planning, managing, and controlling project and product quality requirements in order to meet stakeholders’ objectives. Project Quality Management also supports continuous process improvement activities as undertaken on behalf of the performing organization. The Project Quality Management processes are: 8.1 Plan Quality Management—The process of identifying quality requirements and/or standards for the project and its deliverables, and documenting how the project will demonstrate compliance with quality requirements and/ or standards. 8.2 Manage Quality—The process of translating the quality management plan into executable quality activities that incorporate the organization’s quality policies into the project. 8.3 Control Quality—The process of monitoring and recording the results of executing the quality management activities to assess performance and ensure the project outputs are complete, correct, and meet customer expectations. Figure 8-1 provides an overview of the Project Quality Management processes. In addition, these quality processes may differ within industries and companies. Figure 8-2 provides an overview of the major inputs and outputs of the Project Quality Management processes and the interrelations of these processes in the Project Quality Management Knowledge Area. The Plan Quality Management process is concerned with the quality that the work needs to have. Manage Quality is concerned with managing the quality processes throughout the project. During the Manage Quality process, quality requirements identified during the Plan Quality Management process are turned into test and evaluation instruments, which are then applied during the Control Quality process to verify these quality requirements are met by the project. Control Quality is concerned with comparing the work results with the quality requirements to ensure the result is acceptable. There are two outputs specific to the Project Quality Management Knowledge Area that are used by other Knowledge Areas: verified deliverables and quality reports. KEY CONCEPTS FOR PROJECT QUALITY MANAGEMENT Project Quality Management addresses the management of the project and the deliverables of the project. It applies to all projects, regardless of the nature of their deliverables. Quality measures and techniques are specific to the type of deliverables being produced by the project. For example, the project quality management of software deliverables may use different approaches and measures from those used when building a nuclear power plant. In either case, failure to meet the quality requirements can have serious negative consequences for any or all of the project’s stakeholders. For example: Meeting customer requirements by overworking the project team may result in decreased profits and increased levels of overall project risks, employee attrition, errors, or rework. Meeting project schedule objectives by rushing planned quality inspections may result in undetected errors, decreased profits, and increased post-implementation risks Quality and grade are not the same concepts. Quality as a delivered performance or result is “the degree to which a set of inherent characteristics fulfil requirements” (ISO 9000 [18].). Grade as a design intent is a category assigned to deliverables having the same functional use but different technical characteristics. The project manager and the project management team are responsible for managing the trade-offs associated with delivering the required levels of both quality and grade. While a quality level that fails to meet quality, requirements is always a problem, a low-grade product may not be a problem. For example: Prevention is preferred over inspection. It is better to design quality into deliverables, rather than to find quality issues during inspection. The cost of preventing mistakes is generally much less than the cost of correcting mistakes when they are found by inspection or during usage. Depending on the project and the industry area, the project team may need a working knowledge of statistical control processes to evaluate data contained in the Control Quality outputs. The team should know the differences between the following pairs of terms: uu Prevention (keeping errors out of the process) and inspection (keeping errors out of the hands of the customer); uu Attribute sampling (the result either conforms or does not conform) and variable sampling (the result is rated on a continuous scale that measures the degree of conformity); and uu Tolerances (specified range of acceptable results) and control limits (that identify the boundaries of common variation in a statistically stable process or process performance). Usually, the most expensive approach is to let the customer find the defects. This approach can lead to warranty issues, recalls, loss of reputation, and rework costs. 1. Detect and correct the defects before the deliverables are sent to the customer as part of the quality control process. The control quality process has related costs, which are mainly the appraisal costs and internal failure costs. 2. Use quality assurance to examine and correct the process itself and not just special defects. 3. Incorporate quality into the planning and designing of the project and product. 4. Create a culture throughout the organization that is aware and committed to quality in processes and products. TAILORING CONSIDERATIONS Each project is unique; therefore, the project manager will need to tailor the way Project Quality Management processes are applied. Considerations for tailoring include but are not limited to: Policy compliance and auditing. What quality policies and procedures exist in the organization? What quality tools, techniques, and templates are used in the organization? Standards and regulatory compliance. Are there any specific quality standards in the industry that need to be applied? Are there any specific governmental, legal, or regulatory constraints that need to be taken into consideration? Continuous improvement. How will quality improvement be managed in the project? Is it managed at the organizational level or at the level of each project? Stakeholder engagement. Is there a collaborative environment for stakeholders and suppliers? CONSIDERATIONS FOR AGILE/ADAPTIVE ENVIRONMENTS In order to navigate changes, agile methods call for frequent quality and review steps built in throughout the project rather than toward the end of the project. Recurring retrospectives regularly check on the effectiveness of the quality processes. They look for the root cause of issues then suggest trials of new approaches to improve quality. Subsequent retrospectives evaluate any trial processes to determine if they are working and should be continued or new adjusting or should be dropped from use. In order to facilitate frequent, incremental delivery, agile methods focus on small batches of work, incorporating as many elements of project deliverables as possible. Small batch systems aim to uncover inconsistencies and quality issues earlier in the project life cycle when the overall costs of change are lower 8.1 PLAN QUALITY MANAGEMENT According to PMBOK, quality is defined as the degree to which a set of characteristics of project deliverables and objectives fulfil the project requirements. Therefore, any characteristic that influences the satisfaction of the stakeholders is included in determining the quality. The project quality management processes include performing quality planning, quality assurance, and quality control. Quality planning is the quality process that is performed during the planning phase to accomplish the following goals. Identify which quality standards are relevant to the project at hand Determine how to satisfy these standards Plan Quality Management is the process of identifying quality requirements and/or standards for the project and its deliverables, and documenting how the project will demonstrate compliance with quality requirements and/or standards. The key benefit of this process is that it provides guidance and direction on how quality will be managed and verified throughout the project. This process is performed once or at predefined points in the project planning should be performed in parallel with the other planning processes. For example, changes proposed in the deliverables in order to meet identified quality standards may require cost or schedule adjustments and a detailed risk analysis of the impact to plans. The quality planning techniques discussed here are those used most frequently on projects. There are many others that may be useful on certain projects or in specific application areas. 8.1.1 PLAN QUALITY MANAGEMENT: INPUTS 8.1.1.1 PROJECT CHARTER The project charter provides the high-level project description and product characteristics. It also contains the project approval requirements, measurable project objectives, and related success criteria that will influence the quality management of the project. 8.1.1.2 PROJECT MANAGEMENT PLAN Project management plan components include but are not limited to: Requirements management plan. The requirements management plan provides the approach for identifying, analysing, and managing the requirements that the quality management plan and quality metrics will reference. Risk management plan. The risk management plan provides the approach for identifying, analysing, and monitoring risks. The information in the risk management plan and quality management plan work together to successfully deliver product and project success. Stakeholder engagement plan. The stakeholder engagement plan provides the method for documenting the stakeholders’ needs and expectations that provide the foundation for quality management. Scope baseline. The WBS along with the deliverables documented in the project scope statement are considered while determining which quality standards and objectives are suitable for the project, and which project deliverables and processes will be subjected to quality review. The scope statement includes the acceptance criteria for the deliverables. The definition of acceptance criteria may significantly increase or decrease quality costs and, therefore, project costs. Satisfying all acceptance criteria implies the needs of the stakeholders to be met. Project performance baseline. The project performance baseline constituted by the scope baseline, schedule baseline, and cost baseline contains the list of all the deliverables and objectives to which the quality needs to be applied. For example, the following components of the project scope statement are especially relevant to quality planning: Project deliverables. Project objectives. Project requirements. A product scope description that may contain the details of technical issues and other quality-related concerns. Product acceptance criteria. The definition of acceptance criteria has an impact on the quality cost. You find out the accepted schedule performance from the schedule baseline and the accepted cost performance from the cost baseline. 8.1.1.3 PROJECT DOCUMENTS Project documents that can be considered as inputs for this process include but are not limited to: Assumption log. The assumption log has all the assumptions and constraints regarding quality requirements and standard compliance. Requirements documentation. Requirements documentation captures the requirements that the project and product should attain to meet stakeholder expectations. The components of the requirements documentation include but are not limited to project and product quality requirements. Requirements are used by the project team to help plan how quality control will be implemented on the project. Requirements traceability matrix. The requirements traceability matrix links product requirements to deliverables and helps to ensure each requirement in the requirements documentation is tested. The matrix provides an overview of the tests required to verify the requirements. Risk register. The risk register contains information on threats and opportunities that may impact quality requirements. Stakeholder register. The stakeholder register may help in identifying the stakeholders that will have interests in quality. The risk register will help identify positive risks (opportunities) and negative risks (threats) that may have an impact on quality. 8.1.1.4 ENTERPRISE ENVIRONMENTAL FACTORS Guidelines, regulations from a government agency, rules, and standards relevant to the project at hand are examples of enterprise environmental factors that must be considered during quality planning. For example, procedures relevant to the application area of this project should be followed. Working or operating conditions and environment can also affect the project quality. The enterprise environmental factors that can influence the Plan Quality Management process include but are not limited to: Governmental agency regulations; Rules, standards, and guidelines specific to the application area; Geographic distribution; Organizational structure; Marketplace conditions; Working or operating conditions of the project or its deliverables; and Cultural perceptions. If the performing organization lacks a quality policy, the project team will need to develop a quality policy for the project. Once a quality policy is in place, it is your responsibility to ensure that the project stakeholders are aware of it and are on the same page. 8.1.1.5 ORGANIZATIONAL PROCESS ASSETS The organizational process assets that can influence the Plan Quality Management process include but are not limited to: Organizational quality management system including policies, procedures, and guidelines; Quality templates such as check sheets, traceability matrix, and others; and Historical databases and lessons learned repository. 8.1.2 PLAN QUALITY MANAGEMENT: TOOLS AND TECHNIQUES 8.1.2.1 EXPERT JUDGMENT Expertise should be considered from individuals or groups with specialized knowledge or training in the following topics: Quality assurance, Quality control, Quality measurements, Quality improvements, and Quality systems. 8.1.2.2 DATA GATHERING Data-gathering techniques that can be used for this process include but are not limited to: Benchmarking. Benchmarking involves comparing actual or planned project practices or the project’s quality standards to those of comparable projects to identify best practices, generate ideas for improvement, and provide a basis for measuring performance. Benchmarked projects may exist within the performing organization or outside of it, or can be within the same application area or other application area. Benchmarking allows for analogies from projects in a different application area or different industries to be made. Brainstorming. Brainstorming can be used to gather data creatively from a group of team members or subject matter experts to develop the quality management plan that best fits the upcoming project. Interviews. Project and product quality needs and expectations, implicit and explicit, formal and informal, can be identified by interviewing experienced project participants, stakeholders, and subject matter experts. Interviews should be conducted in an environment of trust and confidentiality to encourage honest and unbiased contributions. 8.1.2.3 DATA ANALYSIS Data analysis techniques that can be used for this process include but are not limited to: Cost-benefit analysis. A cost-benefit analysis is the process used to measure the benefits of a decision or taking action minus the costs associated with taking that action. A cost-benefit analysis involves measurable financial metrics such as revenue earned or costs saved as a result of the decision to pursue a project. A cost-benefit analysis can also include intangible benefits and costs or effects from a decision such as employees morale and customer satisfaction. an analysis that results in more benefits than costs will generally be a favourable project for the company to undertake. NOTE: In cost benefit analysis, we see how much our benefit outweighs the cost in terms of business. For example: if u make any 3 minutes informative video, then whether you get benefitted or not from watching that 3-minute video? Cost of quality. It is the total expense incurred by the organization in achieving and maintaining good quality as well as managing the poor quality with the aim of achieving customer satisfaction. The cost of quality (COQ) associated with a project consists of one or more of the following costs Cost of good quality: it is also called cost of conformance or the cost of conformance consists of prevention costs and appraisal costs. Prevention costs. Costs related to the prevention of poor quality in the products, deliverables, or services of the specific project. Preventive costs are any expenditures incurred that are intended to minimize the number of defects in products and services. Prevention costs include the costs of appropriate equipment, documenting and performing processes, time and effort to perform the project work the right way, and needed training of team members. For example, a company could invest in training programs for the operators of its production machinery, to ensure that they understand how to manufacture parts correctly. They include: 1. Quality assurance costs: establishing the product specifications 2. Quality planning 3. New product development + testing 4. Employee training Appraisal costs. Costs related to evaluating, measuring, auditing, and testing the products, deliverables, or services of the specific project. They include: 1. Quality control: incoming material inspection + process control 2. Check fixtures 3. Quality audits 4. Check supplier assessment 5. Appraisal costs include the cost of inspecting, testing, and loss due to destructive testing. Cost of poor quality - Failure costs (internal/external). Money wasted when work fails to meet the customer requirements. Measured using: correcting, reworking, volunteering. 1. Internal failure: defects or errors discovered before being delivered to the end customer. This can cause: rework, fixing internal work, re-testing, machine breakdown. 2. External failure: cost incurred having product being shipped to the end customer (means it fails to satisfy the design or the quality standards). Or it is detected when it is transferred to the customer. So, this will cause: 1. 2. 3. 4. services, claims, product or material returns, customer complaints or shipping damage. Prevention Costs (Build a quality product) • Training • Document processes • Equipment • Time to do it right Appraisal Costs (Assess the quality) • Testing • Destructive testing loss • Inspections Money spent during the project to avoid failures: Internal Failure Costs (Failures found by the project) • Rework • Scrap External Failure Costs (Failures found by the customer) • Liabilities • Warranty work • Lost business Money spent during and after the project because of failures. Cost of Quality NOTE: The cost of non-conformance (POOR QUALITY) includes rework and waste if the product is rejected internally because it did not meet quality standards. If the problems with the product were found by the customer, however, the results could be more serious, including liabilities and loss of business. Implementing quality has its costs, including quality management and fulfilling quality requirements. The benefits of meeting quality requirements include less rework, resulting in overall higher productivity; lower costs of maintaining the product or service; and higher customer satisfaction. 8.1.2.4 DECISION MAKING Prioritization matrices. This is the method of prioritizing entities, such as problems, ideas, and issues, by using some ranking criteria. A decision-making technique that can be used for this process includes but is not limited to multicriteria decision analysis. Criteria are prioritized and weighted before being applied to all available alternatives to obtain a mathematical score for each alternative. The alternatives are then ranked by score. As used in this process, it can help prioritize quality metrics. 8.1.2.5 DATA REPRESENTATION Other quality planning tools. Other tools that you can use in quality planning, depending upon the project, include brainstorming, flowcharting, control charts, statistical sampling. Statistical sampling involves randomly selecting a part of the population for study. Control charts, flowcharting, and statistical sampling are discussed further on in this book when we discuss quality control. Some other tools of quality planning are listed in the following bullet points: Flowcharts. Flowcharts are also referred to as process maps because they display the sequence of steps and the branching possibilities that exist for a process that transforms one or more inputs into one or more outputs. Flowcharts show the activities, decision points, branching loops, parallel paths, and the overall order of processing by mapping the operational details of procedures that exist within a horizontal value chain. One version of a value chain, known as a SIPOC (suppliers, inputs, process, outputs, and customers) model. Flowcharts may prove useful in understanding and estimating the cost of quality for a process. Information is obtained by using the workflow branching logic and associated relative frequencies to estimate the expected monetary value for the conformance and nonconformance work required to deliver the expected conforming output. When flowcharts are used to represent the steps in a process, they are sometimes called process flows or process flow diagrams and they can be used for process improvement as well as identifying where quality defects can occur or where to incorporate quality checks. Logical data model. Logical data models are a visual representation of an organization’s data, described in business language and independent of any specific technology. The logical data model can be used to identify where data integrity or other quality issues can arise. Matrix diagrams. Matrix diagrams help find the strength of relationships among different factors, causes, and objectives that exist between the rows and columns that form the matrix. Depending on how many factors may be compared, the project manager can use different shapes of matrix diagrams; for example, L, T, Y, X, C, and roof–shaped. In this process they facilitate identifying the key quality metrics that are important for the success of the project. Mind mapping. Mind mapping is a diagrammatic method used to visually organizing information. A mind map in quality is often created around a single quality concept, drawn as an image in the centre of a blank landscape page, to which associated representations of ideas such as images, words, and parts of words are added. The mind-mapping technique may help in the rapid gathering of project quality requirements, constraints, dependencies, and relationships. Affinity diagrams. it is a business tool used to organize ideas and data. It is one of the Seven Management and Planning Tools. An affinity diagram is the organization of ideas into a natural or common relationship. For example, bananas, apples, and oranges would be grouped as fruits, while green beans, broccoli, and carrots would be grouped as vegetables. NOTE: These seven management tools are collectively used by organization to make better decision and implement new solutions effectively. When used individually these tools provide systematic and an organised way of assessing ideas and making decisions. However, when used in combination they provide and effective way to solve complex issues of an organization Force field analysis. This is a technique to understand the forces (factors) influencing a situation. It can be used to separate the forces that drive movement toward a goal from those that either block that movement or drive it away from the goal. Force for changes Force resisting changes NOTE: Part of the cost of quality is the failure cost, which is the cost of rework due to the failure to meet the requirements during the product development. Failure cost, also called cost of poor quality, is grouped into two categories: external failure cost, which is the cost of fixing problems found by the customer, and internal failure cost, which is the cost of fixing problems found within the project. You can use one or more of these techniques to generate the output of quality planning. 8.1.2.6 TEST AND INSPECTION PLANNING During the planning phase, the project manager and the project team determine how to test or inspect the product, deliverable, or service to meet the stakeholders’ needs and expectations, as well as how to meet the goal for the product’s performance and reliability. The tests and inspections are industry dependent and can include, for example, alpha and beta tests in software projects, strength tests in construction projects, inspection in manufacturing, and field tests and nondestructive tests in engineering. 8.1.2.7 MEETINGS Project teams may hold planning meetings to develop the quality management plan. Attendees can include the project manager, the project sponsor, selected project team members, selected stakeholders, anyone with responsibility for project quality management activities, and others as needed. 8.1.3 PLAN QUALITY MANAGEMENT: OUTPUTS A major output of the quality planning process is the quality management plan. This section discusses the quality management plan and other output items. 8.1.3.1 QUALITY MANAGEMENT PLAN The quality management plan describes how the quality policy for this project will be implemented by the project management team. It includes approaches toward quality assurance, quality control, and continuous process improvement. The quality management plan also contains the quality baseline that sets the criteria that specify the quality objectives for the project and thereby make the basis for measuring and reporting quality performance. For example, a project that is finished on time, with everything delivered in scope, and that stayed within its cost is a project with high quality performance. This plan becomes a component of the overall project management plan. The quality management plan is a component of the project management plan that describes how applicable policies, procedures, and guidelines will be implemented to achieve the quality objectives. It describes the activities and resources necessary for the project management team to achieve the quality objectives set for the project. The quality management plan may be formal or informal, detailed, or broadly framed. The style and detail of the quality management plan are determined by the requirements of the project. The quality management plan should be reviewed early in the project to ensure that decisions are based on accurate information. The benefits of this review can include a sharper focus on the project’s value proposition, reductions in costs, and less frequent schedule overruns that are caused by rework. The quality management plan may include but is not limited to the following components: Quality standards that will be used by the project; Quality objectives of the project; Quality roles and responsibilities; Project deliverables and processes subject to quality review; Quality control and quality management activities planned for the project; Quality tools that will be used for the project; and Major procedures relevant for the project, such as dealing with nonconformance, corrective actions procedures, and continuous improvement procedures. TIP Whether the quality management plan is informal and high-level or formal and detailed depends upon the size, complexity, and needs of the project. 8.1.3.2 QUALITY METRICS A quality metric specifically describes a project or product attribute and how the Control Quality process will verify compliance to it. Some examples of quality metrics include percentage of tasks completed on time, cost performance measured by CPI, failure rate, number of defects identified per day, total downtime per month, errors found per line of code, customer satisfaction scores, and percentage of requirements covered by the test plan as a measure of test coverage. For example: if the project is on board, then its bug density has got reduced than before Secondly, the customer used to call once in a week earlier now he calls five time a week, means now his issues have got increased. Thirdly, the client earlier gives 10 feedbacks but now he gave only 8 feedbacks. So, his satisfaction has also got affected. CHECKLIST: the things which are to check are called the checklist. In general, IT metrics can be divided into three categories, which include: Product metrics, which describe the product’s characteristics, like size complexity, performance, design, and quality level. Process metrics, which can be applied for the improvement of the development activities and software maintenance. Project metrics, which describe the project’s features and performance, like the number of developers, costs, schedule, and productivity. 8.1.3.3 QUALITY CHECKLIST. A checklist is a structured tool used to verify that a predetermined set of required steps has been performed. The checklists can come in imperative form (“to do” lists) or in interrogative form (“have you done this” lists). Checklists are prepared (or identified if they already exist in the organization) in quality planning and used in quality control. CHECK THE LINK FOR QUALITY MANAGEMENT CHECKLIST: TASK 1: CHECKLIST FOR MANAGING PROJECT QUALITY Project (studylib.net) 8.1.3.4 PROCESS IMPROVEMENT PLAN. This plan describes how to improve some of the processes that will be used in the project. For example, one purpose of improvement is to prevent activities in the processes that are not needed for this project. This is accomplished by describing the purpose, start, and end of a given process; the input to the process; and the output of the process. This is equivalent to drawing the boundaries around the process. The process management plan may also include some metrics used to measure the efficiency of the process. 8.1.3.5 PROJECT MANAGEMENT PLAN UPDATES Any change to the project management plan goes through the organization’s change control process via a change request. Components that may require a change request for the project management plan include but are not limited to: Risk management plan. Decisions on the quality management approach may require changes to the agreed-upon approach to managing risk on the project, and these will be recorded in the risk management plan. Scope baseline. The scope baseline may change as a result of this process if specific quality management activities need to be added. The WBS dictionary also records quality requirements, which may need updating. 8.1.3.6 PROJECT DOCUMENTS UPDATES Project documents that may be updated as a result of carrying out this process include but are not limited to: Lessons learned register. The lessons learned register is updated with information on challenges encountered in the quality planning process. Requirements traceability matrix. Where quality requirements are specified by this process, they are recorded in the requirements traceability matrix. Risk register. New risks identified during this process are recorded in the risk register and managed using the risk management processes. Stakeholder register. Where additional information on existing or new stakeholders is gathered as a result of this process, it is recorded in the stakeholder register. 8.2 MANAGE QUALITY Manage Quality is the process of translating the quality management plan into executable quality activities that incorporate the organization’s quality policies into the project. The key benefits of this process are that it increases the probability of meeting the quality objectives as well as identifying ineffective processes and causes of poor quality. Manage Quality uses the data and results from the control quality process to reflect the overall quality status of the project to the stakeholders. This process is performed throughout the project. Quality planning is used to identify which quality standards are relevant to the project at hand and to determine how to meet these standards. Implementing quality management consists of the following two components: Quality assurance (QA). Quality assurance is the process of auditing the results from quality control measurements to ensure that the quality requirements are being met. This process is used during the execution of the project. Quality control. This refers to monitoring and controlling the project results to ensure that they meet the agreed-upon quality standards. Performing organizations typically have a department called quality assurance (QA) that oversees quality assurance activities and fosters continuous process improvement, which is an iterative method for improving the quality of all processes. TIP Continuous process improvement enhances the efficiency and effectiveness of the processes by minimizing waste (unnecessary activities) and duplication of efforts. It includes identifying and reviewing the business processes inside the organization, such as coding of modules within software programs and the process of project approval. Manage Quality is sometimes called quality assurance, although Manage Quality has a broader definition than quality assurance as it is used in non-project work. In project management, the focus of quality assurance is on the processes used in the project. Quality assurance is about using project processes effectively. It involves following and meeting standards to assure stakeholders that the final product will meet their needs, expectations, and requirements. Manage Quality includes all the quality assurance activities, and is also concerned with the product design aspects and process improvements. Manage Quality work will fall under the conformance work category in the cost of quality framework. The Manage Quality process implements a set of planned and systematic acts and processes defined within the project’s quality management plan that helps to: Design an optimal and mature product by implementing specific design guidelines that address specific aspects of the product, Build confidence that a future output will be completed in a manner that meets the specified requirements and expectations through quality assurance tools and techniques such as quality audits and failure analysis, Confirm that the quality processes are used and that their use meets the quality objectives of the project, and Improve the efficiency and effectiveness of processes and activities to achieve better results and performance and enhance stakeholders’ satisfaction. The project manager and project team may use the organization’s quality assurance department, or other organizational functions, to execute some of the Manage Quality activities such as failure analysis, design of experiments, and quality improvement. Quality assurance departments usually have cross-organizational experience in using quality tools and techniques and are a good resource for the project. Manage Quality is considered the work of everybody—the project manager, the project team, the project sponsor, the management of the performing organization, and even the customer. All of these have roles in managing quality in the project, though the roles differ in size and effort. The level of participation in the quality management effort may differ between industries and project management styles. In agile projects, quality management is performed by all team members throughout the project, but in traditional projects, quality management is often the responsibility of specific team members. 8.2.1 MANAGE QUALITY: INPUTS The input to the quality assurance process comes largely from three sources: quality planning, directing and managing project execution, and quality control. The quality-related output items of these three processes become the input to the quality assurance process. These input items are discussed here. Output from quality planning. The following output items from the quality planning process become the input to the quality assurance process: Quality management plan. This plan is the output of the quality planning process already discussed in this chapter, and it describes how QA will be performed for this project. Quality metrics. A quality metric is an operational criterion that defines in specific terms what something (such as a characteristic or a feature) is and how the quality control process measures it. The quality metrics developed during quality planning, such as defect density, failure rates, reliability, and test coverage, must be employed during QA. Process improvement plan. The process improvement plan, already discussed in this chapter, helps improve the quality of the project and must be implemented during QA. Output from directing and managing project execution: work performance information. When you are directing and managing project execution, information about work performance and the implementation of a few items related to both product and project will help you determine how the quality is being implemented. Therefore, during QA, you must consider work performance information. Work performance information includes project status information that is regularly collected and distributed among the stakeholders. It includes the following items: Schedule progress information: Schedule activities that have been finished and those that have started Estimates for the completion of schedule activities that have started and hence are in progress Percentages to show the portion of each in-progress activity—for example, Activity A is 30% complete Deliverables that have been completed and those that have not yet been completed Incurred cost as compared to authorized cost Resource utilization details How well the quality standards are being met Lessons learned added to the knowledge base When you are directing and managing project execution, obviously the items are being implemented. The following quality-related implemented items must be considered during QA: Implemented change requests Implemented corrective actions Implemented defect repair Implemented preventive actions Output from quality control: quality control measurements. Quality control involves monitoring specific project results of executing quality activities to assess performance. The goal is again the same: to ensure quality standards are met; if not, necessary change requests and recommendations are made to correct the situation. The quality control process sends its results back to QA as feedback. Approved change requests. Approved change requests, such as modification of work methods, product requirements, quality requirements, scope, and schedule, must be analysed for their effect on the quality management plan and quality metrics. Approved change requests. Approved change requests, such as modification of work methods, product requirements, quality requirements, scope, and schedule, must be analysed for their effect on the quality management plan and quality metrics. 8.2.1.1 PROJECT MANAGEMENT PLAN Project management plan components include but are not limited to the quality management plan. the quality management plan defines the acceptable level of project and product quality and describes how to ensure this level of quality in its deliverables and processes. The quality management plan also describes what to do with nonconforming products and what corrective action to implement. 8.2.1.2 PROJECT DOCUMENTS Project documents that can be considered as inputs for this process include but are not limited to: Lessons learned register. Lessons learned earlier in the project with regard to managing quality can be applied to later phases in the project to improve the efficiency and effectiveness of managing quality. Quality control measurements. Quality control measurements are used to analyse and evaluate the quality of the processes and deliverables of the project against the standards of the performing organization or the requirements specified. Quality control measurements can also compare the processes used to create the measurements and validate actual measurements to determine their level of correctness. Quality metrics. Quality metrics are verified as part of the Control Quality process. The Manage Quality process uses these quality metrics as a basis for the development of test scenarios for the project and its deliverables and as a basis for improvement initiatives. Risk report. Risk report is used in the Manage Quality process to identify sources of overall project risk and the most important drivers of overall risk exposure that can impact the quality objectives of the project. 8.2.1.3 ORGANIZATIONAL PROCESS ASSETS The organizational process assets that can influence the Manage Quality process include but are not limited to: Organizational quality management system that includes policies, procedures, and guidelines; Quality templates such as check sheets, traceability matrix, test plans, test documents, and others; Results from previous audits; and Lessons learned repository with information from similar projects. 8.2.2 MANAGE QUALITY: TOOLS AND TECHNIQUES 8.2.2.1 DATA GATHERING A data-gathering technique that can be used for this process includes but is not limited to checklists. A checklist is a structured tool, usually component-specific, used to verify that a set of required steps has been performed or to check if a list of requirements has been satisfied. Based on the project’s requirements and practices, checklists may be simple or complex. Many organizations have standardized checklists available to ensure consistency in frequently performed tasks. In some application areas, checklists are also available from professional associations or commercial service providers. Quality checklists should incorporate the acceptance criteria included in the scope baseline. 8.2.2.2 DATA ANALYSIS Data analysis techniques that can be used for this process include but are not limited to: Alternatives analysis. This technique is used to evaluate identified options in order to select which different quality options or approaches are most appropriate to use. Document analysis. The analysis of different documents produced as part of the output of project control processes, such as quality reports, test reports, performance reports, and variance analysis, can point to and focus on processes that may be out of control and may jeopardize meeting the specified requirements or stakeholders’ expectations. Process analysis. Process analysis identifies opportunities for process improvements. This analysis also examines problems, constraints, and non-value-added activities that occur during a process. Root cause analysis (RCA). Root cause analysis is an analytical technique used to determine the basic underlying reason that causes a variance, defect, or risk. A root cause may underlie more than one variance, defect, or risk. It may also be used as a technique for identifying root causes of a problem and solving them. When all root causes for a problem are removed, the problem does not recur. 8.2.2.3 DECISION MAKING A decision-making technique that can be used for this process includes but is not limited to multicriteria decision analysis. Multicriteria decision making is used to evaluate several criteria when discussing alternatives that impact project or product quality. Project decisions can include choosing among different implementation scenarios or suppliers. Product decisions can include evaluating the life cycle cost, schedule, stakeholder satisfaction, and risks associated with resolving product defects. 8.2.2.4 DATA REPRESENTATION Data representation techniques that can be used for this process include but are not limited to: Affinity diagrams. Affinity diagrams can organize potential causes of defects into groups showing areas that should be focused on the most. An affinity diagram is the organization of ideas into a natural or common relationship. For example, bananas, apples, and oranges would be grouped as fruits, while green beans, broccoli, and carrots would be grouped as vegetables. Affinity diagrams aid teams in tapping into their creativity and gut instincts Cause-and-effect diagrams. Cause-and-effect diagrams are also known as fishbone diagrams, why-why diagrams, or Ishikawa diagrams. This type of diagram breaks down the causes of the problem statement identified into discrete branches, helping to identify the main or root cause of the problem. Flowcharts. Flowcharts show a series of steps that lead to a defect. Histograms. Histograms show a graphical representation of numerical data. Histograms can show the number of defects per deliverable, a ranking of the cause of defects, the number of times each process is noncompliant, or other representations of project or product defects. Matrix diagrams. A matrix chart or diagram is a project management and planning tool used to analyse and understand the relationships between data sets. Matrix charts compare two or more groups of elements or elements within a single group. They help project managers identify how information is related as well as the strength of those relationships. The types of information you can analyse in a matrix includes: Data Functions Concepts People Materials Equipment Actions The relationships between items are indicated by a number or symbol in the cell where each pair of elements intersect. Scatter diagrams. A scatter diagram is a graph that shows the relationship between two variables. Scatter diagrams can demonstrate a relationship between any element of a process, environment, or activity on one axis and a quality defect on the other axis. NOTE: So, it shows the relation of the items which are in pair. For example: you have a dataset for 50 students in the class, including the number of hours studied and marks obtained in the exam. Using this dataset, you can evaluate the relationship between these two variables (number of hours studied and marks obtained). In addition, you can find the direction (positive, negative, or no relationship). 8.2.2.5 AUDITS An audit is a structured, independent process used to determine if project activities comply with organizational and project policies, processes, and procedures. It verifies the implementation of approved change requests, corrective actions, defect repairs, and preventive actions. Audits can occur as scheduled or at random and can be conducted by a third party or by properly trained inhouse auditors of the performing organization. A quality audit is usually conducted by a team external to the project, such as the organization’s internal audit department, PMO, or by an auditor external to the organization. Quality audit objectives may include but are not limited to: Identifying all good and best practices being implemented; Identifying all nonconformity, gaps, and shortcomings; Sharing good practices introduced or implemented in similar projects in the organization and/or industry; Proactively offering assistance in a positive manner to improve the implementation of processes to help raise team productivity; and Highlighting contributions of each audit in the lessons learned repository of the organization Product quality not matching the requirements Material Environment Management People Process Equipment Worker’s fatigue Lack of training Low quality of raw material Bad working conditions Low commitment to quality Delay in arrival Low maintenance old technology Improper handling Not enough R&D Nonoptional manufacturing method. The subsequent effort to correct any deficiencies should result in a reduced cost of quality and an increase in sponsor or customer acceptance of the project’s product. Quality audits may be scheduled or random, and may be conducted by internal or external auditors. Quality audits can confirm the implementation of approved change requests including updates, corrective actions, defect repairs, and preventive actions. These audits accomplish the following: Because one of the objectives of a quality audit is to identify inefficient and ineffective policies, processes, and procedures being used for the project, audits reduce the cost of quality on subsequent projects. Audits increase customer satisfaction and acceptance of the product or service delivered by the project 8.2.2.6 DESIGN FOR X (Design for Excellence) Design for X (DfX) is a set of technical guidelines that may be applied during the design of a product for the optimization of a specific aspect of the design. DfX can control or even improve the product’s final characteristics. The X in DfX can be different aspects of product development, such as reliability, deployment, assembly, manufacturing, cost, service, usability, safety, and quality. Using the DfX may result in cost reduction, quality improvement, better performance, and customer satisfaction. NOTE This idea is largely used in Product Development and engineering. In product development, the design of the product is driven by several different aspects. However, with focus on one single aspect we can have better control and also simplify the overall product development process. Hence, this DFX provides cost reduction, improvement in quality, better performance and great customer satisfaction which can ensure our project overall success. 8.2.2.7 PROBLEM SOLVING (PROCESS ANALYSIS) This is a technique used to identify the needed improvements in a process by following the steps outlined in the process improvement plan. It examines the problems, constraints, and unnecessary (non-value-added) activities identified during the implementation of the process. Process analysis typically includes the following steps: 1. Identify a technique to analyse the problem 2. Identify the underlying causes that led to the problem. 3. Examine the root cause of the problem. 4. Create preventive actions for this and similar problems. Choose the best possible solutions Implement the solution Verify the effectiveness of the solution Problem solving entails finding solutions for issues or challenges. It can include gathering additional information, critical thinking, creative, quantitative and/or logical approaches. Effective and systematic problem solving is a fundamental element in quality assurance and quality improvement. Problems can arise as a result of the Control Quality process or from quality audits and can be associated with a process or deliverable. Using a structured problem-solving method will help eliminate the problem and develop a long-lasting solution. Problem-solving methods generally include the following elements: Defining the problem, Identifying the root-cause, Generating possible solutions, Choosing the best solution, Implementing the solution, and Verifying solution effectiveness. 8.2.2.8 QUALITY IMPROVEMENT METHODS Quality improvements can occur based on findings and recommendations from quality control processes, the findings of the quality audits, or problem solving in the Manage Quality process. Plando-check-act and Six Sigma are two of the most common quality improvement tools used to analyze and evaluate opportunities for improvement. The quality assurance process recommends corrective actions as an output item. 8.2.3 MANAGE QUALITY: OUTPUTS The main output of performing quality assurance includes recommended corrective actions and change requests. These and other output items are discussed in the following list. 8.2.3.1 QUALITY REPORTS The quality reports can be graphical, numerical, or qualitative. The information provided can be used by other processes and departments to take corrective actions in order to achieve the project quality expectations. The information presented in the quality reports may include all quality management issues escalated by the team; recommendations for process, project, and product improvements; corrective actions recommendations (including rework, defect/bugs repair, 100% inspection, and more); and the summary of findings from the Control Quality process. 8.2.3.2 TEST AND EVALUATION DOCUMENTS Test and evaluation documents can be created based on industry needs and the organization’s templates. They are inputs to the Control Quality process and are used to evaluate the achievement of quality objectives. These documents may include dedicated checklists and detailed requirements traceability matrices as part of the document. 8.2.3.3 CHANGE REQUESTS The goal of quality assurance is improving quality, which involves taking actions to increase the effectiveness and efficiency of the policies, procedures, and processes of the performing organization. One way of accomplishing this is to implement the approved quality-related changes, including: Modifications to policies and procedures. Modifications to project scope, cost, and schedule. Recommended corrective actions. Implementation of recommended corrective actions will increase the effectiveness and efficiency of the policies, processes, and procedures of the performing organization and will also improve the quality of the product or service delivered by the project. Following are examples of the types of recommended actions: Audits Process analysis that itself might produce a list of preventive actions Defect repairs, such as bug fixes in a software program NOTE If changes occur during the Manage Quality process that impact any of the components of the project management plan, project documents, or project or product management processes, the project manager should submit a change request and follow the Perform Integrated Change Control process. 8.2.3.4 PROJECT MANAGEMENT PLAN UPDATES Any change to the project management plan goes through the organization’s change control process via a change request. Components that may require a change request for the project management plan include but are not limited to: Quality management plan. The agreed-upon approach to managing quality may need to be modified due to the actual results. Scope baseline. The scope baseline may change as a result of specific quality management activities. Schedule baseline. The schedule baseline may change as a result of specific quality management activities like Quality audits, which may cause changes in these schedule plan as well as cost management plan Cost baseline. The cost baseline may change as a result of specific quality management activities. 8.2.3.5 PROJECT DOCUMENTS UPDATES Project documents that may be updated as a result of carrying out this process include but are not limited to: Issue log. New issues raised as a result of this process are recorded in the issue log. Lessons learned register. The lessons learned register is updated with information on challenges encountered and how they could have been avoided as well as approaches that worked well for the managing quality. Risk register. New risks identified during this process are recorded in the risk register and managed using the risk management processes. STUDY CHECKPOINT 8 Q. True or False: Quality assurance also uses the tools and techniques of quality planning and quality control. Ans. True 8.3 CONTROL QUALITY Quality is controlled by using the Perform Quality Control process, a process of monitoring and recording results from the execution of projects, including quality activities. The goal is to evaluate quality performance and recommend necessary changes. The quality control process in the context of a big picture is shown in below figure, which relates the quality management processes to one another and also to integrated change control and project execution The key benefit of this process is verifying that project deliverables and work meet the requirements specified by key stakeholders for final acceptance. The Control Quality process determines if the project outputs do what they were intended to do. Those outputs need to comply with all applicable standards, requirements, regulations, and specifications. This process is performed throughout the project. The inputs, tools and techniques, and outputs of this process are depicted in Figure 8-10. 4.6 Perform Integrated Change Control 4.3 Direct and Manage Project Work Figure 8-11. Controlling quality involves monitoring specific results to determine whether they comply with the planned quality standards, which include project processes and product goals, and controlling the results by taking actions to eliminate unsatisfactory performance. In other words, the Perform Quality Control process is used to monitor and control quality by accomplishing the following goals: Monitor specific project results, such as cost performance and schedule performance, to determine whether they comply with the planned quality standards, which include project processes and product goals. Identify ways to eliminate the causes of unsatisfactory performance. The results under scrutiny include both deliverables and performance measurements by the project management team. Quality control is performed throughout the project. While dealing with quality control, you must be able to distinguish between the two terms in each of the following pairs: Prevention and inspection Prevention is a direction to perform an activity that will keep an error from entering the product and the process. Inspection is a technique to examine whether an activity, component, product, result, or service complies with planned requirements. The goal of inspection is to ensure that errors do not reach the customer. Attribute sampling and variable sampling Attribute sampling is a technique to determine whether a result conforms to the specified standard. Variable sampling is a technique to rate a result on a continuous scale that measures the degree of conformity. Common cause and special cause Common cause is a source of variation that is inherent to the system and is predictable. Such variations are also called normal variations, and the common causes for them are also called random causes. Special cause is a source of variation that is not inherent to the system and is removable. It can be assigned to a defect in the system. Control limits and tolerances Control limits are the area occupied by three standard deviations on either side of the central line or the mean of a normal distribution of data plotted on a control chart that reflects the expected variation of the data. If the results fall within the control limits, they are within the quality control, and hence the process is considered to be stable. Tolerance is the range within which a result is acceptable if it falls within the limits of the range. TIP QC can be performed by the QA department or by the QC department if the performing organization has one. Nevertheless, the project management team should have a working knowledge of statistical aspects of quality control, such as sampling and probability. This will help evaluate the QC output. Control Quality: Data Flow Diagram The Control Quality process is performed to measure the completeness, compliance, and fitness for use of a product or service prior to user acceptance and final delivery. This is done by measuring all steps, attributes, and variables used to verify conformance or compliance to the specifications stated during the planning stage. Quality control should be performed throughout the project to formally demonstrate, with reliable data, that the sponsor’s and/or customer’s acceptance criteria have been met. The level of effort to control quality and the degree of implementation may differ between industries and project management styles; in pharmaceutical, health, transportation, and nuclear industries, for example, there may be stricter quality control procedures compared to other industries, and the effort needed to meet the standards may be extensive. For example, in agile projects, the Control Quality activities may be performed by all team members throughout the project life cycle. In waterfall model-based projects, the quality control activities are performed at specific times, toward the end of the project or phase, by specified team members. Visit link: https://slideplayer.com/slide/11430272/ 8.3.1 CONTROL QUALITY: INPUTS 8.3.1.1 PROJECT MANAGEMENT PLAN Project management plan components include but are not limited to the quality management plan. the quality management plan defines how quality control will be performed within the project. 8.3.1.2 PROJECT DOCUMENTS Project documents that can be considered as inputs for this process include but are not limited to: Lessons learned register. Lessons learned earlier in the project can be applied to later phases in the project to improve quality control. Quality metrics. A quality metric specifically describes a project or product attribute and how the Control Quality process will verify compliance to it. There are three kinds of software quality metrics: Product metrics: describes the characteristics of the product: size, complexity, design, features, performance and quality level. Process metrics: used for improving software development/maintenance process. It includes the effectiveness of the defect removal, pattern of testing defect arrival, response time of fixes. Project matrices: describes the project characteristics execution. For instance: number of developers, cost, schedule, productivity etc. fairly straight forward. Test and evaluation documents. Test and evaluation documents are used to evaluate achievement of the quality objectives. 8.3.1.3 APPROVED CHANGE REQUESTS You need this list to ensure that all the approved changes are implemented in a timely fashion. The list of approved change requests also includes modifications, such as revised work methods and a revised schedule. As part of the Perform Integrated Change Control process, a change log update indicates that some changes are approved and some are not. Approved change requests may include modifications such as defect repairs, revised work methods, and revised schedules. Partial change completion may result in inconsistencies and later delays due to incomplete steps or corrections. The implementation of approved changes should be verified, confirmed for completeness, retested, and certified as correct. 8.3.1.4 DELIVERABLES A deliverable is any unique and verifiable product, result, or capability to perform a service that is required to be produced to complete a process, phase, or project. Deliverables that are outputs from the Direct and Manage Project Work process are inspected and compared to the acceptance criteria defined in the project scope statement. 8.3.1.5 WORK PERFORMANCE DATA Work performance data contains data on product status such as observations, quality metrics, and measurements for technical performance, as well as project quality information on schedule performance and cost performance. 8.3.1.6 ENTERPRISE ENVIRONMENTAL FACTORS The enterprise environmental factors that can influence the Control Quality process include but are not limited to: Project management information system; quality management software can be used to track errors and variations in processes or deliverables; Governmental agency regulations; and Rules, standards, and guidelines specific to the application area. 8.3.1.7 ORGANIZATIONAL PROCESS ASSETS The organizational process assets that can influence the Control Quality process include but are not limited to: Quality standards and policies; Quality templates, for example, check sheets, checklists, etc. and; Issue and defect reporting procedures and communication policies. STUDY CHECKPOINT 8.3 A. Which quality process generates quality control measurements? Ans. Quality control B. Which quality process uses quality control measurements? Ans. Perform quality assurance 8.3.2 CONTROL QUALITY: TOOLS AND TECHNIQUES The tools and techniques used for quality control include inspection, defect repair reviews, and the so-called seven basic tools of quality. 8.3.2.1 DATA GATHERING (Other Controlling Tools) Data-gathering techniques that can be used for this process include but are not limited to: Checklists. Checklists help in managing the control quality activities in a structured manner. Check sheets. Check sheets are also known as tally sheets and are used to organize facts in a manner that will facilitate the effective collection of useful data about a potential quality problem. They are especially useful for gathering attributes data while performing inspections to identify defects; for example, data about the frequencies or consequences of defects collected. Statistical sampling. Statistical sampling involves choosing part of a population of interest for inspection (for example, selecting 10 engineering drawings at random from a list of 75). The sample is taken to measure controls and verify quality. Sample frequency and sizes should be determined during the Plan Quality Management process. Statistical sampling involves randomly selecting a part of the population for study. In quality control, you can select a subset of features for inspection. This can save a substantial amount of resources Questionnaires and Surveys. Surveys may be used to gather data about customer satisfaction after the deployment of the product or service. The cost regarding defects identified in the surveys may be considered external failure costs in the COQ model and can have extensive cost implications for the organization. 8.3.2.2 DATA ANALYSIS Data analysis techniques that can be used for this process include but are not limited to: Performance reviews. Performance reviews measure, compare, and analyse the quality metrics defined by the Plan Quality Management process against the actual results. Root cause analysis (RCA). Root cause analysis is used to identify the source of defects. 8.3.2.3 INSPECTION An inspection is the examination of a work product to determine if it conforms to documented standards. The results of inspections generally include measurements and may be conducted at any level. The results of a single activity can be inspected, or the final product of the project can be inspected. Inspections may be called reviews, peer reviews, audits, or walkthroughs. In some application areas, these terms have narrow and specific meanings. Inspections also are used to verify defect repairs. 8.3.2.4 TESTING/PRODUCT EVALUATIONS Testing is an organized and constructed investigation conducted to provide objective information about the quality of the product or service under test in accordance with the project requirements. The intent of testing is to find errors, defects, bugs, or other nonconformance problems in the product or service. The type, amount, and extent of tests needed to evaluate each requirement are part of the project quality plan and depend on the nature of the project, time, budget, and other constraints. Tests can be performed throughout the project, as different components of the project become available, and at the end of the project on the final deliverables. Early testing helps identify nonconformance problems and helps reduce the cost of fixing the nonconforming components. Different application areas require different tests. For example, software testing may include unit testing, integration testing, black-box, white-box, interface testing, regression testing, Alpha testing, etc. In construction projects, testing may include cement strength, concrete workability test, nondestructive tests at construction sites for testing the quality of hardened concrete structures, and soil tests. In hardware development, testing may include environmental stress screening, burn-in tests, system testing, and more. Seven Basic Tools of Quality Figure shows the seven kinds of charts and diagrams used in quality control, also known as the seven basic tools of quality. These tools are further described in the following list. Table 8.2 Seven Basic Tools of Quality Chart Flowchart Purpose To anticipate what quality problems might be and where they might occur Run chart To perform trend analysis—that is, to predict future results based on past performance Scatter diagram to find the relationship between two variables, such as cause and effect, or two causes Histogram Pareto diagram To display the relative importance of different variables To identify and rank errors based on the frequency of defects caused by them Control chart to monitor whether the variance of a specified variable is within the acceptable limits dictated by quality control Cause and effect diagram to explore all the potential causes of a problem, not just the obvious ones 8.3.2.5 DATA REPRESENTATION Data representation techniques that can be used for this process include but are not limited to: Flowcharts. A flowchart is a diagram that depicts inputs, actions, and outputs of one or more processes in a system. Flowcharts, commonly used in many disciplines of knowledge, show the activities, decision points, and order of processing. They help to understand how a problem occurs. You can also use flowcharts to anticipate what quality problems might be, where they might occur, and how you might deal with them Run Chart. A run chart is a chart that shows the history and pattern of variations. Therefore, run charts are used to perform trend analysis, which is the science of predicting future performance based on past results. In quality control, trend analysis can be used to predict such things as the number of defects and the cost to repair them. You can use the results of trend analysis to recommend preventive actions if needed. Run charts or trend analysis can be used to monitor cost performance, schedule performance, and technical performance. An example of technical performance is how many defects have been identified and how many of them remain unrepaired Histograms. Histograms can demonstrate the number of defects by source or by component. Scatter diagrams. Scatter diagrams can show the planned performance on one axis and the actual performance on the second axis. A scatter diagram is used to show the pattern of the relationship between two variables—an independent variable and another variable that depends on the independent variable. The dependent variable is plotted corresponding to the independent variable. For example, a variable representing a cause can be the independent variable, and a variable representing the effect can be a dependent variable. The closer the data points are to a diagonal line, the stronger the relationship (called the correlation) is between the two variables. Histograms. A histogram is a bar chart that shows a distribution of variables. Each bar can represent an attribute, such as defects due to a specific cause, and its height can represent the frequency of the attribute, such as number of defects. This tool helps to identify and rate the causes of defects. You also use a histogram to identify and illustrate the most common cause of a problem, such as a cause behind defects. You might wonder how defects can be repaired efficiently. Pareto diagrams, which are examples of histograms, have the answer for you A Pareto diagram. is used to rank the importance of each error (problem) based on the frequency of its occurrence over time in the form of defects. A defect is an imperfection or deficiency that keeps a component from meeting its requirements or specifications. A defect is caused by an error (problem) and can be repaired by fixing the error. An error in a product can give rise to multiple defects, and by fixing the error you repair all the defects caused by that error. However, all errors are not equal. Some errors cause more defects than others. According to Pareto’s law, which is also known as the 80/20 rule, 80% of project defects are caused by 20% of errors (or types of errors). Qualitatively, it means that most defects are caused by a small set of errors. The Pareto diagram lets you rank errors based on the frequency of defects they cause. You begin by having the error that causes most of the defects fixed and make your way to other errors that cause lesser numbers of defects. This way, the efforts of the project team are optimized: You get the maximum number of defects repaired with minimal effort. The advantages of a Pareto diagram are twofold: It ranks errors according to the frequency of defects they cause It optimizes efforts to repair the defects by working on the errors that cause most of the defects. As an example, figure 8.3 presents data on the frequency of defects caused by certain errors. The data is displayed in Figure 8.5 in the form of a Pareto diagram. In this example, 200 defects are caused by 7 errors, and Error A alone causes 75 defects, which is 37.5% of all the defects. Similarly, you can understand the impact of other errors by looking at Table 8.3 and Figure 8.5. The Pareto diagram tells you that you should address Error A first, Error B second, and so on. NOTE Pareto’s law, in its original form, was presented as an economic theory by Vilfredo Pareto, a 19thcentury Italian economist, and it states that 80% of income is earned by 20% of the population. Since then, it has been applied to other fields, such as project management. You might ask: How many defects are acceptable? To find an answer to this question, you need to understand another tool, called the control chart Control charts. Control charts are used to determine whether or not a process is stable or has predictable performance. Upper and lower specification limits are based on the requirements and reflect the maximum and minimum values allowed. Upper and lower control limits are different from specification limits. The control limits are determined using standard statistical calculations and principles to ultimately establish the natural capability for a stable process. The project manager and appropriate stakeholders may use the statistically calculated control limits to identify the points at which corrective action will be taken to prevent performance that remains outside the control limits. Control charts can be used to monitor various types of output variables. Although used most frequently to track repetitive activities required for producing manufactured lots, control charts may also be used to monitor cost and schedule variances, volume, frequency of scope changes, or other management results to help determine if the project management processes are in control. Control charts can be used to monitor the values of any type of output variables. To illustrate their main features, consider the example of a control chart shown in Figure 8.6. In this example, assume that a manufacturer produces 100 units of a product each day, and it is expected that 95 out of 100 units should have no defect—that is, the expected number of defective units is equal to 5. The control limits are set to ±3. In other words, 95 units out of 100 must be correct, give or take 3. That puts the lower limit at 92 and the upper limit at 98. Crossing the lower limit is not acceptable to the customer, and crossing the upper limit might require an unjustifiable cost. Controlling quality includes dealing with defects and problems that cause them. So, studying causes of a problem is critical to quality control. Cause-and-effect diagrams. Cause-and-effect diagrams are used to identify the possible effects of quality defects and errors. A cause-and-effect diagram is used to explore all the potential causes (inputs) that result in a single effect (output), such as a problem or a defect. This type of diagram is the brainchild of Kaoru Ishikawa, who pioneered quality management processes in the Kawasaki shipyards, and therefore these diagrams are also called Ishikawa diagrams. Due to the shape of these diagrams, they are also known as fishbone diagrams. To construct and use cause and effect diagrams effectively, perform the following simple steps: 1. Identify the problem. Write down the problem in a box drawn on the right side of a large sheet of paper. This represents the head of the fish. Starting from the box, draw a horizontal line across the paper. This represents the spine of the fish. 2. Identify the possible areas of causes. Identify the areas or factors from where the potential causes of the problem might come. Environment, people, materials, measurements, and methods are some examples of areas (factors) of causes. For each factor relevant to the problem under study, draw a line off the spine and label it with the name of the factor. These lines represent the fish bones. 3. Identify the possible causes. For each factor, identify possible causes. Represent each possible cause with a line coming off the bone that represents the corresponding factor. 4. Analyse the diagram. Analysing the diagram includes narrowing down the most likely causes and investigating them further Figure 8.7 shows an example of a cause-and-effect diagram. The problem in this example is the delay in the release of a website. The factors considered are environment, methods, people, and time. Of course, the diagram is incomplete in the sense that more factors and related causes can be explored, and causes for each factor can be explored further. But you get the point. TIP While constructing the cause-and-effect diagram, you can use the brainstorming method for identifying the potential factors (areas) of problems and the potential causes for each factor A cause-and-effect diagram offers a structured way to think through all possible causes of a problem. You can use these diagrams to carry out a thorough analysis of a problematic situation. This kind of analysis is useful in complex situations when, to discover the real causes, you need to explore all the potential causes and not just the obvious ones 8.3.2.6 MEETINGS The following meetings may be used as part of the Control Quality process: Approved change requests review. All approved change requests should be reviewed to verify that they were implemented as approved. This review should also check that partial changes are completed and all parts have been properly implemented, tested, completed, and certified. Retrospectives/lesson learned. A meeting held by a project team to discuss: Successful elements in the project/phase, What could be improved, What to incorporate in the ongoing project and what in future projects, and What to add to the organization process assets. QUALITY ANALYST It focuses on on-going work not on deliverables Verifying the activities, steps the team is taking to produce that deliverable. Can raise a change request. This change request is not about deliverable but about changing process. QUALITY CONTROL I am checking the deliverables. Checking if it meets the customer requirements. If I find something bad, I will generate a change request. Suppose if a particular section is producing lots of defects, then we may need to set underlying procedures before moving to quality control. They would be taking the measurement data and observations which are done in quality control process. Because then only we can control something. Output: change requests, changing process, changing checklists, changing threshold. Output: verified deliverables, produce change request, work performance information 8.3.3 CONTROL QUALITY: OUTPUTS 8.3.3.1 QUALITY CONTROL MEASUREMENTS Quality control measurements are the documented results of Control Quality activities. They should be captured in the format that was specified in the quality management plan. 8.3.3.2 VERIFIED DELIVERABLES A goal of the Control Quality process is to determine the correctness of deliverables. The results of performing the Control Quality process are verified deliverables that become an input to the Validate Scope process for formalized acceptance. If there were any change requests or improvements related to the deliverables, they may be changed, inspected, and reverified. 8.3.3.3 WORK PERFORMANCE INFORMATION Work performance information includes information on project requirements fulfilment, causes for rejections, rework required, recommendations for corrective actions, lists of verified deliverables, status of the quality metrics, and the need for process adjustments. 8.3.3.4 CHANGE REQUESTS If changes occur during the Control Quality process that may impact any of the components of the project management plan or project documents, the project manager should submit a change request. Change requests are processed for review and disposition through the Perform Integrated Change Control process 8.3.3.5 PROJECT MANAGEMENT PLAN UPDATES Any change to the project management plan goes through the organization’s change control process via a change request. Components that may require a change request for the project management plan include but are not limited to the quality management plan. 8.3.3.6 PROJECT DOCUMENTS UPDATES Project documents that may be updated as a result of carrying out this process include but are not limited to: Issue log. Many times, a deliverable that does not meet the quality requirements is documented as an issue. Lessons learned register. The lessons learned register is updated with information on the source of quality defects and how they could have been avoided as well as approaches that worked well. Risk register. New risks identified during this process are recorded in the risk register and managed using the risk management processes. Test and evaluation documents. Test and evaluation documents may be modified as a result of this process in order to make future tests more effective. STUDY CHECKPOINT 8.6 In the following table, write the name of a quality management process in the second column corresponding to each activity listed in the first column. Activity 1. You managed a quality audit of your project and found an enormous number of defects. 2. You are looking at a diagram to pinpoint the root cause of a number of defects appearing in the project product. You write down your observations and recommend a corrective action. 3. You are determining the cost of quality to present a case for quality assurance and quality control to your supervisor 4. You are examining the product to ensure that a defect has actually been repaired. 5. You are looking at a diagram to pinpoint the root cause of a number of defects appearing in the project product. This leads you to analyse some processes and procedures for their effectiveness Quality Management Process Perform quality assurance Quality Control Quality Planning Quality Control Perform Quality Assurance The three most important takeaways from this chapter are as follows: The goal for quality planning is two-fold: Identify which quality standards are relevant to the project at hand and determine how to satisfy these standards. Use the Perform Quality Assurance process to ensure that the project employs all the planned processes and standards needed to meet all the project quality requirements. The key word here is auditing. Quality control is the process of monitoring and controlling specific project results to ensure the implementation of the quality plan and recommending changes or actions in case of poor implementation. The key term here is quality control measurements. Summary Quality management includes quality planning, quality assurance, and quality control. The quality management plan, quality metrics, quality checklist, and process improvement plan are the major output items of the quality planning process called Plan Quality. Quality assurance involves auditing the quality control measurements to ensure that the planned quality has been implemented. The quality control measurements are generated by the Perform Quality Control process, which uses work performance measurements as an input. The work performance measurements are collected from monitoring and controlling various project aspects, such as scope, schedule, and cost. Quality management uses a wide spectrum of tools, including cost/benefit analysis, control charts, flowcharts, statistical sampling, and cause and effect diagrams. An aspect of projects related to quality is called risk and is discussed in the next chapter. Exam’s Eye View Comprehend 1. Quality management has two components: project quality management and product quality management. While product quality management techniques depend upon the specific product that the project is going to produce, project quality management applies to all projects independent of the nature of the products 2. Quality assurance, an important task during project execution, is the process of auditing the results from quality control measurements to ensure that quality requirements are being met. 3. Work performance measurements generated by controlling scope, schedule, and cost are used as input to prepare performance reports and to control quality. 4. Like most of the monitoring and controlling processes, the Perform Quality Control, Monitor and Control Risks, and Report Performance processes generate change requests. 5. Deliverables are an important input to the Perform Quality Control process. 6. Approved change requests, and not all change requests, are an input to the Perform Quality Control process. 7. Both change requests and validation of changes are outputs of the Perform Quality Control process. Look Out 1. A fundamental tenet of quality: Quality is planned, designed, and built in, not inspected in. 2. Quality audits are tools used in quality assurance. 3. Tools and techniques used in quality planning and quality control are also used in quality assurance 4. The input to the quality assurance (QA) process comes from the output of three processes: quality planning, quality control, and directing and managing project execution. Memorize 1. The quality management plan, quality checklists, process improvement plan, and quality metrics are the major output items of the quality planning process. 2. Validation of deliverables is an output of the Perform Quality Control process 3. Quality control measurements generated by the Perform Quality Control process become an input to the Perform Quality Assurance process. Review Questions 1. What is the name of a quality planning technique that involves comparing the results of similar activities? a. Brainstorming b. Benchmarking c. Cost/benefit analysis d. Quality metrics 2. The plan-do-check-act cycle of quality management was: a. Defined by Shewhart and modified by Deming b. Originally defined by Deming and then modified by Shewhart c. Defined by Crosby and modified by Deming d. Defined by Crosby and modified by Juan 3. One of the fundamental tenets of modern quality management is: a. Inspect the quality and then build it in. b. There is no need to design and build in the quality until you do the inspection, if it’s needed. c. Break all the rules: Deliver the product in a timely fashion and then work on the quality. d. Quality is planned, designed, and built-in—not inspected in. 4. Which of the following is not an input to the QA process? a. Quality metrics b. Quality control measurements c. Work performance information d. Recommended corrective actions 5. You are the project manager for the Mind the Gap project. You are going to meet with your project team to discuss how to ensure that the project will be completed without any deviations from the project requirements. Which of the following processes are you performing? a. Quality control b. Quality planning c. Quality assurance d. Conducting procurements 6. Quality audits are part of which of the following quality management processes? a. Quality assurance b. Quality control c. Quality planning 7. 8. 9. 10. 11. 12. 13. d. Quality inspection You are the project manager of the Green Schools project. Your supervisor has asked you to make some self-checks and inspections before the stakeholders ask for a formal inspection. It is time to perform which process? a. Plan Quality b. Perform Quality Control c. Inspect Quality d. Perform Quality Assurance You are using an Ishikawa diagram to find the real causes of a problem by exploring all the possible causes. Which quality process are you performing? a. Assure Quality b. Plan Quality c. Perform Quality Control and Perform Quality Assurance d. Auditing and inspection You want to examine the results of a process to determine whether the process is in or out of control. Which of the following is the most suitable tool to use? a. Control chart b. Cause and effect diagram c. Pareto diagram d. Scatter diagram You are managing a software project with limited development resources. The QA department has discovered a large number of defects in the product, and the project sponsor is very concerned about this. You want to get the maximum number of defects repaired with minimal effort. Which quality-control tool are you going to use before you direct the efforts of the project team to fix specific problems? A. a. Control chart b. Cause and effect diagram c. Pareto diagram d. Scatter diagram You are the project manager for a software development project that has limited resources. The customer is concerned about the quality of the code developed and wants you to conduct a code review. The product contains a large body of code with millions of lines. Which approach will you take? a. Tell the customer it’s not possible. b. Use statistical sampling. c. Use automated testing tools. d. Arrange to review each line of the code. Which of the following is not an input to controlling quality? a. Project deliverables b. Work performance measurements c. Quality control measurements d. Quality checklist Which of the following is not a tool or technique used in the Perform Quality Control process? a. Statistical sampling b. Inspection c. Histograms d. Technical performance measurements