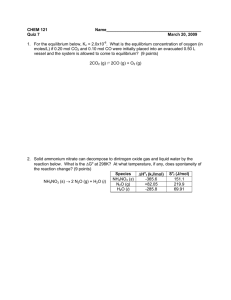

CHAPTER THREE Stage & Continuous Gas–Liquid Separation Processes 1 Content 10.1 10.2 10.3 10.4 10.5 10.6 10.7 10.8 Types of Separation Processes and Methods Equilibrium Relation Between Phases Single and Multiple Equilibrium Contact Stages Mass Transfer Between Phases Continuous Humidification Processes Absorption on plate and Packed Tower Absorption and Concentrated Mixtures in Packed Tower Estimation of Mass Transfer Coefficient in Packed Tower 2 10.1 Types of Separation Processes and Methods Absorption (When the two contacting phases are a gas and a liquid) Distillation (A volatile vapor phase and a liquid that vaporizes are involved) Liquid-liquid Extraction (When the two phases are liquids) Leaching (Extract a solute from a solid, sometimes also called extraction) Membrane Processing (Separation of molecules by the use of membrane) Crystallization Adsorption Ion-Exchange 3 Definitions Absorption The removal of one or more selected components from a mixture of gases by absorption into a suitable liquid is the second major operation of chemical engineering that is based on interphase mass transfer controlled largely by rates of diffusion. Stripping/desorption Reverse of absorption. Humidification Transfer of water vapor from liquid water into pure air. Dehumidification 4 Removal of water vapor from air. Absorption Unit Pure Gas Out A= 5 mole Pure Liquid In A= 0 mole Gas In A= 20mole Liquid Out A= 15 mole 5 Main design1/2 Pure Solvent Gas 6 Main design2/2 7 10.2 Equilibrium Relation Between Phases Gas- Liquid Equilibrium For dilute concentrations of most gases, and over a wide range for some gases, the equilibrium relationship is given by Henry’s law. This law, can be written as: PA H.X A YA H ' X A …………………………. (10.2.2) …………………………. (10.2.3) where, PA = partial pressure of component A (atm). H = Henry’s law constant (atm/mol fraction). H’ = Henry’s law constant (mol frac.gas/mol frac.liquid). = H/P. XA = mole fraction of component A in liquid. ( dimensionless ) YA = mole fraction of component A in gas = PA/P. ( dimensionless ) P = total pressure (atm). 8 Example 10.2-1 Dissolved Oxygen Concentration in Water. What will to be the concentration of oxygen dissolved in water at 298 K when the solution is in equilibrium with air at 1 atm total pressure ? The Henry’s law constant is 4.38 x 104 atm/mol fraction. Solution, PA H . X A The partial pressure pA of oxygen (A) in air is 0.21 atm. Using Eq.(10.2-2).. 0.21=H xA = 4.38 x104 xA Solving , xA = 4.80 x10-6 mol fraction. 9 10.3 Single and Multiple Equilibrium Contact Stages 10.3.A Single - stage Equilibrium contact It can be defined as one in which two different phases (liquid & gas for absorption) are brought into contact & then separated. During the time of contact intimate mixing occurs and the various components diffuse and redistribute themselves between the two phases. If mixing time is enough, the components are essentially at equilibrium in the two phase after separation and the process is considered to be single equilibrium stage 10.3.B Single-stage Equilibrium contact for Gas-Liquid System (Absorption) Gas phase contains solute A & inert gas B. Liquid phase contains solute A & inert liquid (solvent) C. V = gas flowrate & L = liquid flowrate. L’ = inert liquid (C) flowrate & V’ = inert gas (B) flowrate x,y = mole frac. in liquid phase & gas phase, respectively. 10 Single-Stage Equilibrium Contact for Gas-Liquid System 1/2 Gas phase outlet V1 yA1 V2 yA2 Gas phase inlet Single-stage Liquid phase inlet L0 xA0 L1 xA1 Liquid phase outlet 11 Single-Stage Equilibrium Contact for Gas-Liquid System 2/2 In = Out Gas phase outlet Liquid phase inlet Total material balance: L0 + V2 = L1 + V1 Component A balance: L0xA0 + V2yA2 = L1xA1 + V1yA1 Component C balance: L0xC0 + V2yC2 = L1xC1 + V1yC1 An equation for B is not needed since In term of inert flow rate: V1 yA1 L0 xA0 Singlestage V2 yA2 Gas phase inlet L1 xA1 Liquid phase outlet xA + xB + xC = 1.0 L’ = L(1-xA) L = L’/(1-xA) V’ = V(1-yA) V = V’/(1-yA) Operating line: x A0 y A2 x A1 y A1 ' ' ' V L V L 1 y A2 1 x A1 1 y A1 1 x A0 ' unknowns :- xA1 & yA1 12 Example 10.3-1 1/5 Equilibrium Stage Contact for CO2–Air-water A gas mixture at 1.0 atm pressure abs containing air and CO2 is contacted in a single-stage mixer continuously with pure water at 293 K. The two exit gas and liquid streams reach equilibrium. The inlet gas flow rate is 100 kg mol/h, with a mole fraction of CO2 of yA2 = 0.20. The liquid flow rate entering is 300 kg mol water/h. calculate the amounts and compositions of the two outlet phases. Assume that water does nor vaporize to the gas phase. 13 Example 10.3-1 2/5 Solution The flow diagram, (1) The inert water flow is L’ = L0 = 300 kg mol/h. (2) The inert air flow V’ is obtained from, Hence, the inert air flow is V’ = V2 (1-yA2 ) = 100 (1-0.20) = 80 kg mol/h . V1 yA1 L0 = 300 kg mol/h xA0 1 atm 293 K V’ = V(1-yA ). V2 = 100 kg mol/h yA2 = 0.20 L1 xA1 14 Example 10.3-1 3/5 (3) Substituting into equation to make a balance on CO2 (A). x A0 y A2 x A1 y A1 ' ' ' V L V L 1 y A2 1 x A1 1 y A1 1 x A0 ' …(1) x A1 y A1 0 0.20 80 300 80 300 1 0 1 0.20 1 x A1 1 y A1 Know …. The Resulting equation has two unknowns (XA1 and YA1 ) .. So it is necessary to calculate one of these unknowns to solve the equation above..!!! It is possible to calculate the YA1 by the use of Henry’s law because the gas and liquid are in equilibrium as mentioned in the question before 15 Example 10.3-1 4/5 YA H ' X A H` needed to calculated At 293 K, the Henry’s law constant from Appendix A.3 is H = 0.142 x 104 atm/mol frac. Then H’ = H/P = 0.142 x 104 /1.0 = 0.142 x 104 mol frac. gas/mol frac. Liquid. Substituting into, yA1 = 0.142 x 104 xA1 ………(2) Know it possible to use the value of YA1 in equation (1) to calculate the value of XA1 16 Example 10.3-1 5/5 Solving equation (1) and (2) simultaneously, get xA1 = 1.41 x 104 and yA1 = 0.20. To calculate the total flow rates leaving, L' 300 L1 300kgmol / h 4 1 x A1 1 1.4110 V' 80 V1 100kgmol / h 1 y A1 1 0.20 In this case, since the liquid solution is so dilute, L0 L1 . 17 10.3.C Countercurrent Multiple-Contact Stages 1/4. V1 V2 Vn 2 1 L0 V3 L1 Vn+1 n L2 Ln-1 VN+1 VN N Ln LN-1 LN 18 10.3.C Countercurrent Multiple-Contact Stages 2/4. Countercurrent multiple-contact stages. more concentrated product. total number of ideal stages = N. B&C may or may be not be somewhat miscible in each other. two streams leaving a stage in equilibrium with each other. Total material balance: Component A overall balance: For the first n stages balance : L0 + VN+1 = LN + V1 L0 x0A + VN+1 yN+1A = LN xNA + V1 y1A L0 x0A + Vn+1 yn+1A = Ln xnA + V1 y1A This is why we write n instead of N Operating line:- 19 10.3.C Countercurrent Multiple-Contact Stages 3/4. An operating line is an important material-balance equation because it relates the concentration yn+1 in the V stream with xn in the L stream passing it. Ln slope Vn 1 slope streams L & V are immiscible in each other with only A being transferred:- x A0 ' y An1 ' x An ' y A1 V L V L 1 y A1 1 x A0 1 y An1 1 x An ' 20 10.3.C Countercurrent Multiple-Contact Stages 4/4. Graphical calculation for determining N: 1. Plot yA vs xA. 2. Draw operating line. 3. Draw equilibrium line (Henry’s law). 4. Stepping upward (or downward) until yN+1 (or y1) is reached. 5. N = number of steps/trays Dilute system (<10%):1. slope (flowrates V & L) constant operating line = straight 2. L’ & V’ = constant, dilute system (<10%) operating line = straight. 21 Example 10.3-2 1/4 Absorption of Acetone in a Countercurrent Stage Tower It is desired to absorb 90% of the acetone in a gas containing 1.0 mol % acetone in air in a countercurrent stage tower. The total inlet gas flow to the tower is 30.0 kg mol/h and the total inlet pure water flow to be used to absorb the acetone is 90 kg mol H2O/h. The process is to be operate isothermally at 300 K and a total pressure of 101.3 kPa. The equilibrium relation for the acetone (A) in the gas-liquid is yA = 2.53xA. Determine the number of theoretical stages required for this separation. 22 Example 10.3-2 2/4 Solution the first step is to have good identification of the data given in the question Given values are yAN+1= 0.01 (1 mole % of acetone in air entering) xA0 = 0 (Pure water ) VN+1 = 30.0 kg mol/h, (total inlet gas flow to the tower ) L0 = 90.0 kg mol/h. (total inlet pure water ) making an acetone material balance, (1) amount of entering acetone = yAN+1 VN+1 = 0.01(30.0) = 0.3 kg mol/h. (2) entering air = (1- yAN+1 )VN+1 = (1-0.01)(30.0) = 29.7 kg mol air/h 23 Example 10.3-2 3/4 (3) acetone leaving in V1= 0.10(0.30) = 0.030 kg mol/h. (4) acetone leaving in L1 = 0.90(0.30) = 0.27 kg mol/h. from the four steps above, V1 , yA1 , LN ,and xAN can be calculated V1 = 29.7 + 0.03 = 29.73 kg mol air + acetone/h. yA1 = (0.030/29.73) = 0.00101 LN = 90.0 + 0.27 = 90.27 kg mol water + acetone /h. xAN = (0.27/90.27) = 0.0030. Since the flow of liquid varies only slightly from L0 = 90.0 at the inlet to LN = 90.27 at the the outlet and V from 30.0 to 29.73, the slope Ln /Vn+1 of the operating line is essentially constant. This line is plotted, and the equilibrium relation of Henry yA = 2.53xA is also plotted. Starting at point yA1 ,xA0 the stages are drawn. About 5.2 theoretical 24 stages are required. Example 10.3-2 4/4 Mole fraction acetone in air, yA 0.012 yAN+1 Operating line 0.008 5 4 0.004 Equilibrium line 3 2 yA1 0 0 xA0 1 0.003 xAN Mole fraction acetone in water, xA 0.001 0.002 0.004 Figure 10.3-4: Theoretical stages for countercurrent absorption in example 10.3-2. 25 10.3.D: Analytical Equations For Countercurrent Stage Contact 1/3 This technique is used to calculate the number of theoretical stages analytically without the need for the graphical method Its also used to make comparison and justifications in the results of both methods Kremser equations This method is used to calculate the number of ideal stages. This method is valid only when operating & equilibrium lines are straight. In case of Absorption system the equation used is : y N 1 mx0 1 1 log 1 y1 mx0 A A N log A 26 10.3.D Analytical Equations For Countercurrent Stage Contact 2/3 where, m = slope of equilibrium line. A = absorption factor = constant = L/(mV). L.V = molar flow rates. y N 1 y1 N when A = 1 y1 mx0 Stripping: y N 1 x 0 m log 1 A A y x N N 1 m N 1 log A 27 10.3.D Analytical Equations For Countercurrent Stage Contact 3/3 When A = 1, x0 x N N y N 1 xN m Procedure (for varying A): 1. Calculate A1 at L0 & V1. 2. Calculate AN at LN &VN+1. 3. Calculate Aave. = 4. Calculate N. A1 AN 28 Example 10.3-3 1/2 Number of Stages by Analytical Equation. Repeat Example 10.3-2 but use the Kremser analytical equation for countercurrent stage processes. Solution, At Stages 1 V1 = 29.73 kg mol/h, yA1 = 0.001001, L0 = 90.0, and xA0 = 0. Also, the equilibrium relation is yA = 2.53xA where m = 2.53. Then, L L 90.0 A1 0 1.20 mV mV1 2.53 29.73 29 Example 10.3-3 2/2 At Stage N VN+1 =30.0, yAN+1 = 0.01, LN = 90.27, and xAN = 0.0030. The geometric average, Then, AN A LN 90.27 1.19 mVN 1 2.53 30.0 A1 AN 0.20 1.19 1.195 0.01 2.53(0) 1 1 log 1 0 . 00101 2 . 53 ( 0 ) 1 . 195 1.195 N 5.04 log( 1.195) This compares closely with 5.2 stages using graphical method 30 10.4 Mass Transfer Between Phases 1/2 mole fraction For absorption, the solute may diffuse through a gas phase and then diffuse through and be absorbed in an adjacent and immiscible liquid phase. The two phases are in direct contact with each other, and the interfacial area between the phases is usually not well defined. A concentration gradient must exist to cause this mass transfer through the resistances in each phase. Liquid Gas y xi x yi Mass transfer of A 31 10.4 Mass Transfer Between Phases 2/2 liquid-phase solution of A in liquid L. gas-phase mixture of A in gas G yAG yAi xAL xAi NA interface Where distance from interface yAG = concentration of A in the bulk gas phase yAi = concentration of gas A at the interface xAi =concentration of liquid A at the interface xAL = concentration of A in the bulk liquid phase 32 Film-transfer Coefficient and Interface Concentration. Equimolar counterdiffusion. NA = k’y(yAG – yAi) = k’x(xAi – xAL) Where k’y = Gas phase mass transfer coefficient (kg mol/s.m2.mol frac) k’x = Liquid phase mass transfer coefficient (kg mol/s.m2.mol frac) Diffusion of A through stagnant or nondiffusing B. NA = ky(yAG – yAi) = kx(xAi – xAL) where, ky k y' (1 y A ) iM k x' kx (1 x A )iM 33 NOTE (for equimolar counter-diffusion) The interface composition (xAi and yAi ) can be determined by drawing the line PM with the slope (-kx’ /ky’) intersecting the equilibrium line k x' y y Ai slope ' AG ky x AL x Ai yAG D P equilibrium line slope = m” yAi y*A M slope = m’ E xAL xAi x*A 34 NOTE (for diffusion of A through stagnant or nondiffusing B) The interface composition (xAi and yAi ) can be determined by drawing the line PM with the slope ( ) intersecting the equilibrium line k x' y y Ai slope ' AG ky x AL x Ai yAG D P equilibrium line slope = m” yAi y*A M slope = m’ E xAL xAi x*A 35 Example 10.4-1 1/8 Interface Composition in Interphase Mass Transfer The solute A is being absorbed from a gas mixture of A and B in a wetted-wall tower with the liquid flowing as a film downward along the wall. At certain point in the tower the bulk gas concentration yAG = 0.380 mol fraction and the bulk liquid concentration is xAL = 0.1. The tower is operating at 298 K and 1.013 x 105 Pa and the equilibrium data are as follows: xA 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 yA 0 0.022 0.052 0.087 0.131 0.187 0.265 0.385 36 Example 10.4-1 2/8 The solute A diffuse through stagnant B in the gas phase and then through a nondiffusing liquid. Using correlations for dilute solutions in wetted-wall towers, the film mass-transfer coefficient for A in the gas phase is predicted as : ky’ = 1.465 x 10-3 kg mol A/s.m2 mol frac. And for the liquid phase as kx’ = 1.967 x 10-3 kg mol A/s.m2 mol frac. Calculate the interface concentrations yAi and xAi and the flux NA. 37 Example 10.4-1 3/8 Solution First we plot the data 0.4 0.3 yA 0.2 0.1 0 0 0.1 0.2 0.3 xA 0.4 38 yAG Example 10.4-1 4/8 0.4 P D 0.3 yAi 0.2 M M1 0.1 y Now we need to find the point P on the graph E 0 0 0.1 0.2 So : x x Since the correlations are for dilute solutions, (1-yA)iM and (1-xA)iM are approximately 1.0 and the coefficients are the same as k’y and k’x . * A AL 0.3 Ai 0.4 x*A Point P is plotted at yAG = 0.380 and xAL = 0.1. For the first trial (1-yA)iM and (1-xA)iM are assumed as 1.0 and the slope of line PM is, from Eq.(10.4-9). k x' /(1 x A ) iM 1.967 10 3 / 1.0 slope ' 1.342 3 k y /(1 y A ) iM 1.465 10 / 1.0 A line through point P with a slope of –1.342 is plotted in the figure intersecting the equilibrium line at M1, where yAi = 0.183 and xAi = 0.247. 39 yAG Example 10.4-1 5/8 0.4 P D 0.3 yAi 0.2 M M1 0.1 y*A 0 E 0 0.1 xAL 0.2 0.3 xAi 0.4 x*A For the second trial we use yAi and xAi from the first trial to calculate the new slope. Substituting into Eqs.(10.4-6) and (10.4-7), (1 y A ) iM (1 y Ai ) (1 y AG ) ln[( 1 y Ai ) /(1 y AG )] (1 0.183) (1 0.380) 0.715 ln[( 1 0.183) /(1 0.38)] (1 x AL ) (1 x Ai ) (1 x A ) iM ln[( 1 x AL ) /(1 x Ai )] (1 0.1) (1 0.247) 0.825 ln[( 1 0.1) /(1 0.247)] 40 yAG Example 10.4-1 6/8 0.4 P D 0.3 yAi 0.2 M M1 0.1 y*A Substituting into Eq. (10.4-9) to obtain the new slope, 0 E 0 0.1 xAL 0.2 0.3 xAi 0.4 x*A k x' /(1 x A ) iM 1.967 10 3 / 0.825 slope ' 1.163 3 k y /(1 y A )iM 1.465 10 / 0.715 A line through point P with a slope of –1.163 is plotted and intersects the equilibrium line at M, where yAi = 0.197 and xAi = 0.257. Using these new values for the third trial, the following values are calculated: (1 y A )iM (1 0.197) (1 0.380) 0.709 ln[( 1 0.197) /(1 0.38)] (1 x A )iM (1 0.1) (1 0.257) 0.820 ln[( 1 0.1) /(1 0.257)] Please notice the values of xAi and yAi didn’t change much from the first trial and that means we are on the right way of solving the problem 41 (refining the answer) yAG Example 10.4-1 7/8 0.4 P D 0.3 yAi 0.2 M M1 0.1 y*A 0 3 E 0 0.1 xAL 0.2 k /(1 x A ) iM 1.967 10 / 0.820 slope 1.160 3 k /(1 y A )iM 1.465 10 / 0.709 ' x ' y 0.3 xAi 0.4 x*A This slope of –1.160 is essentially the same as the slope of –1.163 for the second trial. Hence, the final values are yAi= 0.197 and xAi = 0.257 and are shown as point M. To calculate the flux, NA k y' (1 y A )iM 1.967 10 3 ( y AG y Ai ) (0.380 0.197) 0.709 3.78 10 4 kgmol / s.m 2 Note that the flux NA through each phase is the same as in other phase, which should be the case at steady state. 42 Example 10.4-1 8/8 yAG 0.4 P D 0.3 yAi 0.2 M M1 0.1 y*A 0 0 E 0.1 xAL 0.2 0.3 0.4 xAi x*A Fig.10.4-4: Location of interface concentrations for example 10.4-1. 43 Overall Mass-transfer Coefficients and Driving Force. For equimolar counterdiffusion and/or diffusion in dilute solutions, NA = k’y (yAG – yAi ) = k’x (xAi – xAL) K’y(yAG – y*A ) K’x (x*A – xAL) x*A is the value that would be in equilibrium with yAG y*A is the value that would be in equilibrium with xAL For diffusion of A through stagnant or nondiffusing B. K y' NA (1 y A )M ' K x ( y y ) AG A (1 x A )M ( x A x AL ) 44 10.5 Continuous Humidification Processes Natural draft wet cooling hyperboloid towers at Didcot Power Station, UK 45 Water-Cooling Tower 1/3 46 Water-Cooling Tower 2/3 Warm water flows counter-currently to an air stream. The warm water enters the top of a packed tower and cascades down through the packing, leaving at the bottom. Air enters at the bottom of the tower and flows upward through the descending water by the natural draft or by the action of a fan. The water is distributed by troughs and overflows to cascade over slat gratings or packing that provide large interfacial areas of contact between the water and air in the form of droplets and film of water. The tower packing often consists of slats of wood or plastic or of a packed bed. 47 Water-Cooling Tower 3/3 48 Theory and Calculation of Water-Cooling Towers interface liquid water Hi HG humidity water vapor TL sensible heat in liquid Ti air TG temperature latent heat in gas sensible heat in gas Figure10.5-1: Temperature and concentration profile in upper part of cooling tower. 49 Vapor Pressure of Water & Humidity Introduction calculation involve properties and concentration of mixtures of water vapor and air. Humidification transfer of water from the liquid phase into a gaseous mixture of air and water vapor. Dehumidification reverse transfer where the water vapor is transferred from the vapor state to the liquid state. 50 Humidity & Humidity Chart 1/4 (1) Humidity, H : the kg of water vapor contained in 1 kg of dry air. 18.02 pA H 28.97 P p A where, pA = partial pressure of water vapor in the air. Saturated air – water vapor in equilibrium with liquid water. pA = pAS where, pAS = saturated vapor pressure. 51 Humidity & Humidity Chart 2/4 (2) Humid volume, vH It can be defined as total volume (m3) of 1 kg of dry air plus the vapor it contains at 1 atm abs pressure and the given gas temp. vH (m3/kg dry air) = (2.83 x 10-3 + 4.56 x 10-3 H) T (K). (3) Total enthalpy of an air-water mixture, HY - the total enthalpy of 1 kg of air plus its water vapor. - sensible heat of the air-water vapor mixture plus the latent heat. HY (kJ/kg dry air) = (1.005 + 1.88 H) (T ºC-0) + 2501.4H where, Tref for both components = 0 ºC 52 Humidity & Humidity Chart 3/4 (4) Wet bulb temperature TW, It’s the steady-state nonequilibrium temperature reached when a small amount of water is contacted under adiabatic conditions by a continuous stream of gas. Steady state temp. attained by a wet-bulb thermometer under standardized condition The temperature and humidity of the gas are not changed. At TW = TS, the convective heat transfer and wet bulb lines. q M B k y W H W H A or, h M Bk y H HW T TW W 53 Humidity & Humidity Chart 4/4 h M Bk y H HW T TW W MB = molecular weight of Air ky= Mass transfer coefficient w = latent heat of vaporization at Tw A = surface area h = Heat transfer coefficient q h. A.(T Tw) 54 Humidity Chart Please insert figure 9.3-2 (Humidity chart) page 529 (Geankoplis) 55 The operating line G(Hy – Hy1) = LcL (TL – TL1) where, G = dry air flow, kg/s.m2. L = water flow, kg water/s.m2 cL = heat capacity of water, assumed constant at 4187 kJ/kg.K. TL = temperature of water, ºC or K. Hy = enthalpy of air-water vapor mixture, J/kg air. = cs (T-T0) + H0 = (1.005 + 1.88H)103 (T-0) + 2.501x106H H = humidity of air, kg water/kg dry air. 56 Figure 10.5-3: Temperature enthalpy diagram and operating line for water-cooling. Hy*2 equilibrium line Hy2 Hy* Enthalpy of airHyi vapor mixture, Hy (J/kg dry gas) Hy Hy*1 operating line, slope = LcL/G R M S P slope = -hLa kGaMBP Hy1 TL1 Ti TL TL2 Liquid temperature ºC 57 Design of Water-Cooling Tower Using Film Mass-Transfer Coef. Please follow the steps mentioned in section 10.5C in book To calculate the tower height z 0 G dz z M B kG aP H y2 H y1 dH y H yi H y where, z = tower height P = atm pressure. MB = molecular weight of air kGa = volumetric mass transfer coeff. in gas, kg mol/s.m3 58 Design Using Overall Mass-Transfer Coefficients. z 0 H y2 dH y G dz z M B K G aP H y1 H y H y where, KGa = overall mass transfer coefficient. If experimental cooling data in an actual run in a cooling tower with known height z are available, then the value of KGa can be obtained. 59 Table 10.5-1 60 Example 10.5-1 1/6 Design of Water-Cooling Tower Using Film Coefficients. A packed countercurrent water-cooling tower using a gas flow rate of G = 1.356 kg dry air/s. m2 and a water flow rate of L = 1.356 kg water/s. m2 to cool the water from TL2 = 43.3 ºC to TL1 = 29.4 ºC. The entering air at 29.4 ºC has a wet bulb temperature of 23.9 ºC . The mass-transfer coefficient kG a is estimated as 1.207 x 10-7 kg mol/s.m3.Pa and hL a / kGaMBP as 4.187 x 104 J/kg.K. . Calculate the height of packed tower z. The tower operates at a pressure of 1.013 x 105 Pa. 61 Example 10.5-1 Solution 200 2/6 Slope = -41.87 x103 180 equilibrium line 160 140 Enthalpy Hy [(J/kg)10-3] 120 100 operating line 80 60 Following the step outlined The enthalpies from the saturated air-water vapor mixtures from Table 10.5-1 are plotted in Fig. 10.5-4. The inlet air at TG1 = 29.4 ºC has a wet bulb temperature of 23.9 ºC . The humidity from the humidity chart is H1 = 0.0165 kg H2O/kg dry air. Substituting into Eq.(9.3-8), 28 30 TL1 1. Data preparation to be used in equation (9.3.8) 2. 3. 4. 32 34 36 Liquid Temperature (ºC) 38 40 42 44 46 TL2 Hy1 = cs (T-T0) + H0 = (1.005 + 1.88H) 103 (T-T0) + H0 Hy1 = (1.005 + 1.88 x 0.0165)103 (29.4-0) + 2.501 x 106(0.0165). = 71.7 x 103 J/kg. The point Hy1 = 71.7 x 103 and TL1 = 29.4 ºC is plotted. Then substituting into Eq. (10.5-2) and solving, 62 Example 10.5-1 3/6 G(Hy2 –Hy1) = LcL (TL2 – TL1) 1.356 (Hy2 – 71.7 x 103) = 1.356 (4.187 x 103) (43.3 – 29.4). Hy2 = 129.9 x 103 J/kg dry air. Now both Hy1 and Hy2 are calculated Then (1) The point Hy2 = 129.9 x 103 and TL2 = 43.3 ºC is plotted, giving the operating line. (2) Lines with slope - hL a / kG aMBP = -41.87 x 103 J/kg.K are plotted giving Hyi and Hy values, which are tabulated in Table 10.5-2 along with derived values as shown. (3) Values of 1/(Hyi – Hy) are plotted versus Hy and the area under the curve from Hy1 = 71.7 x 103 to Hy2 = 129.9 x 103 is H y2 dH y H y1 H yi H y 1.82 63 Example 10.5-1 200 4/6 Slope = -41.87 x103 180 equilibrium line 160 140 Enthalpy Hy [(J/kg)10-3] H y2 H y1 dH y H yi H y 120 100 1.82 operating line 80 60 28 30 TL1 32 34 36 38 Liquid Temperature (ºC) 40 42 44 46 TL2 Substituting into Eq. (10.5-13), dH y G 1.356 z (1.82) 7 5 M B kG aP H yi H y 29(1.207 10 )(1.013 10 ) z 6.98m 64 Example 10.5-1 5/6 Hyi 94.4 x 103 108.4 x 103 124.4 x 103 141.8 x 103 162.1 x 103 184.7 x 103 Hy Hyi – Hy 1/(Hyi – Hy) 71.7 x 103 83.5 x 103 94.9 x 103 106.5 x 103 118.4 x 103 129.9 x 103 22.7 x 103 24.9 x 103 29.5 x 103 35.3 x 103 43.7 x 103 54.8 x 103 4.41 x 10-5 4.02 x 10-5 3.39 x 10-5 2.83 x 10-5 2.29 x 10-5 1.85 x 10-5 Table 10.5-2: Enthalpy Values for Solution to Example 10.5-1 (enthalpy in J/kg dry air). 65 Example 10.5-1 6/6 200 Slope = -41.87 x103 180 equilibrium line 160 140 Enthalpy Hy 120 [(J/kg)10-3] 100 operating line 80 60 28 30 TL1 32 34 36 38 Liquid Temperature (ºC) 40 42 44 46 TL2 Figure 10.5-4: Graphical solution of Example 10.5-1 66 Minimum Value of Air Flow 1/2 N Hy2 Hy1 equilibrium line M TL1 P operating line for Gmin, slope operating line,= LcL/Gmin slope = LcL/G TL2 The air flow G is not fixed but must be set for the design of the cooling tower. For a minimum value of G, the operating line MN is drawn through the point Hy1 and TL1 with a slope that touches the equilibrium line at TL2, point N. If the equilibrium line is quite curved, line MN could become tangent to the equilibrium line at a point farther down the equilibrium line than point N. For the actual tower, a value of G greater than Gmin must be used. Often, a value of G equal to 1.3 to 1.5 times Gmin is used. 67 Minimum Value of Air Flow 2/2 N equilibrium line Hy2 P operating line for Gmin, slope = LcL/Gmin Hy1 M TL1 operating line, slope = LcL/G TL2 Figure 10.5-5: Operating-line construction for minimum gas flow. 68 Design Using Height of a Transfer Unit dH y dH y H y2 H y2 G z H OG H y1 H H M B K G aP H y1 H y H y y y Where : G= air flow rate KGa= overall mass transfer coefficient (kg.mole/s.m3) HOG= height of overall gas enthalpy transfer unit (m) Temperature and Humidity of Air Stream in Tower dH y dTG H yi H y Ti TG 69 10.6 Absorption on plate and Packed Tower 10.6.1 Absorption on plate Tower V1, y1 1 2 Vn+1, yn+1 n L0, x0 Ln, xn n+1 N-1 N VN+1, yN+1 LN, xN Fig.10.6-4: Material balance in an absorption tray tower. 70 10.6.1 Absorption on plate Tower The operating line A plate (tray) absorption tower has the same process flow diagram as the countercurrent multiple-stage process (as shown in the figure) x0 L 1 x0 ' y N 1 x ' ' V L N 1 y N 1 1 xN y1 ' V 1 y1 A balance around the dashed-line box gives x0 L 1 x0 ' Where yn 1 x ' ' V L n 1 yn 1 1 xn y V ' 1 1 y1 x= mole fraction A in the liquid y= mole fraction A in the gas Ln= total moles of liquid/s Vn+1= total moles of gas/s 71 Example 10.6-2 1/4 Absorption of SO2 in a Tray Tower. A tray tower is to be designed to absorb SO2 from an air stream by using pure water at 293 K. The entering gas contains 20 mol % SO2 and that leaving 2 mol % at the total pressure of 101.3 kPa . The inert air flow rate is 150 kg air/h.m2 and the entering water flow rate is 6000 kg water/h.m2. Assuming an overall tray efficiency of 25 %. How many theoretical trays and actual trays are needed? Assume that the tower operate at 293 K. 72 Example 10.6-2 2/4 Solution, (1) calculating the molar flow rates, V’ = (150/29) = 5.18 kg mol inert air/h.m2 L’ = (6000/18.0) = 333 kg mol inert water/h.m2. (2) Referring to figure 10.6.4 yN+1 = 0.20 (Entering Gas from the bottom) y1 = 0.02, (2% leaving in the gas ) x0 = 0. (pure liquid ) (3)Substituting into operating line equation and solving for xN. xN 0 0.2 333 5.18 333 1 0 1 0.20 1 xN xN 0.00355 0.02 5.18 1 0 . 02 (4) Substituting into dashed-line eq., using V’ and L’ as kg mol/h.m2 instead of kg mol/s.m2. 73 Example 10.6-2 3/4 yn 1 xn 0 333 333 5.18 1 0 1 yn 1 1 xn 0.02 5.18 1 0.02 (5)In order to plot the operating line, several intermediate points will be calculated. Setting yn+1 =0.07 and substituting into the operating equation, xn 0.07 0 5.18 333 1 0.07 1 xn 0.02 5.18 1 0 . 02 Hence, xn = 0.000855. To calculate another intermediate point, we ser yn+1 = 0.13, and xn is calculated as 0.00201. (6)The two end points and the two intermediate points on the operating line are plotted in Fig.10.6-5, as are the equilibrium data from Appendix A.3. (7) The operating line is somewhat curved. The number of theoretical trays is determined by stepping off the steps to give 2.4. The actual number of trays is 2.4/0.25 = 9.6 trays. 74 Example 10.6-2 4/4 YN+1 Mole fraction, y y1 0.20 0.18 0.16 0.14 0.12 0.10 0.08 0.06 0.04 0.02 0 operating line equilibrium line 2 1 0 x0 0.002 0.004 0.006 xN Mole fraction, x 0.008 Fig.10.6-4 : Theoretical number of trays for absorption of SO2 in example 10.6-2. 75 10.6.2 Absorption on Packed Tower Design of Packed Tower for Absorption V2,y2 L2,x2 dz V,y V1,y1 z L,x L1,x1 76 Structured Packing Figure 10.6-6. Pressure-drop correlation for structured packings where ΔPflood : is in in. H2O/ft height of packing Fp :is the packing factor in ft-1 given in 77 Table 10.6-1 for random or structured packing Table 10.6-1. Packing Factors for Random and Structured Packing 1/2 78 Random Packing Figure 10.6-5. Pressure-drop correlation for random packing 79 procedure used to determine the limiting flow rates and the tower diameter. 1 First, a suitable random packing or structured packing is selected, giving an Fp value. 2 A suitable liquid-to-gas ratio GL/GG is selected along with the total gas flow rate. 3 The pressure drop at flooding is calculated using Eq. (10.6-1), or if Fp is 60 or over, the ΔPflooding is taken as 2.0 in./ft packing height. 4 Then the flow parameter is calculated, and using the pressure drop at flooding and either Fig. 10.6-5 or 10.6-6, the capacity parameter is read off the plot. 5 Using the capacity parameter, the value of GG is obtained, which is the maximum value at flooding. 6 Using a suitable % of the flooding value of GG for design, a new GG and GL are obtained. The pressure drop can also be obtained from Figure 10.6-5 or 10.6-6. 7 Knowing the total gas flow rate and GG, the tower cross-sectional area and ID 80 can be calculated. Table 10.6-1. Packing Factors for Random and Structured Packing 2/2 81 EXAMPLE 10.6-1 1/5 Pressure Drop and Tower Diameter for Ammonia Absorption Ammonia is being absorbed in a tower using pure water at 25°C and 1.0 atm abs pressure. The feed rate is 1440 lbm/h (653.2 kg/h) and contains 3.0 mol % ammonia in air. The process design specifies a liquid-to-gas mass flow rate ratio GL/GG of 2/1 and the use of 1-in. metal Pall rings. Calculate the pressure drop in the packing and gas mass velocity at flooding. Using 50% of the flooding velocity, calculate the pressure drop, gas and liquid flows, and tower diameter. 82 EXAMPLE 10.6-1 2/5 Solution: The gas and liquid flows in the bottom of the tower are the largest, so the tower will be sized for these flows. Assume that approximately all of the ammonia is absorbed. The gas average mol wt = 28.97(0.97) + 17.0(0.03) = 28.61. The weight fraction of ammonia = 0.03(17)/(28.61) = 0.01783. Assuming the water is dilute, from Appendix A.2-4, the water viscosity μ = 0.8937 cp. From A.2-3, the water density is 0.99708 gm/cm3. Then, ρL = 0.99708(62.43) = 62.25 lbm/ft3. Also, v = μ/ρ = 0.8937/0.99708 = 0.8963 centistokes. 83 EXAMPLE 10.6-1 3/5 From Table 10.6-1, for 1-in. Pall rings, Fp = 56 ft-1. Using Eq. 10.6-1, ΔPflood = 0.115 = 0.115(56)0.7 = 1.925 in. H2O/ft packing height. The flow parameter for Fig. 10.6-5 is : Using Fig. 10.6-5, for a flow parameter of 0.06853 (abscissa) and a pressure drop of 1.925 in./ft at flooding, a capacity parameter (ordinate) of 1.7 is read off the plot. Then, substituting into the capacity parameter equation and solving for vG, 84 EXAMPLE 10.6-1 4/5 vG = 6.663 ft/s. Then GG = vGρG = 6.663(0.07309) = 0.4870 lbm/(s · ft2) at flooding. Using 50% of the flooding velocity for design, GG = 0.5(0.4870) = 0.2435 lbm/(s · ft2) [1.189 kg/(s · m2)]. Also, the liquid flow rate GL = 2.0(0.2435) = 0.4870 lbm/(s · ft2) [2.378 kg/(s · m2)]. To calculate the tower pressure drop at 50% of flooding, GG = 0.2435 and GL = 0.4870, the new capacity parameter is 0.5(1.7) = 0.85. Using this value of 0.85 and the same flow parameter, 0.06853, a value of 0.18 in. water/ft is obtained from Fig. 10.6-5. 85 EXAMPLE 10.6-1 5/5 The tower cross-sectional area = (1440/3600 lbm/s)(1/0.2435 lbm/(s · ft2)) = 1.6427 ft2 = (π/4)D2. Solving, D = 1.446 ft (0.441 m). The amount of ammonia in the outlet water assuming all of the ammonia is absorbed is 0.01783(1440) = 25.68 lb. Since the liquid flow rate is 2 times the gas flow rate, the total liquid flow rate = 2.0(1440) = 2880 lbm/hr. Hence, the flow rate of the pure inlet water= 2880 - 25.68 = 2858.3 lbm/s. 86 Design of Packed Tower for Absorption Overall material balance on component A: x2 L 1 x2 ' y1 x1 y2 ' ' ' V L V 1 y1 1 x1 1 y2 Operating line:y1 x1 y x ' ' ' L' V L V 1 x 1 y 1 y1 1 x1 Very dilute system, L' x V ' y1 L' x1 V ' y with a slope of L’/V’ minimum liquid flow rate L’min at x1max. 87 Design of Packed Tower for Absorption To Solve for L’min: 1. Plot yA vs xA. 2. Draw the equilibrium line. 3. Draw a straight line from (x2,y2) to intersect the equilibrium line at (x1 max ,y1) In some cases, if the equilibrium line is curved concavely downward, the minimum value of L is reached by the operating line becoming tangent to the equilibrium line instead of intersecting it to give x1 max. 4. Calculate L’min from, x1max x2 ' y1 ' V Lmin L 1 x2 1 y1 1 x1max ' min ' y2 V 1 y2 88 Example 10.6.3 1/4 Minimum Liquid Flow Rate and Analytical Determination of Number of Trays A tray tower is absorbing ethyl alcohol from an inert gas using pure water at 303 K and 101.3 kPa . The inlet gas stream flow rate is 100 kg.mol/h and it contains 2.2 mol% alcohol . It is desired to recover 90% of the alcohol . The equilibrium relationship is y=m.x = 0.68x for this dilute stream. Using 1.5 times the minimum liquid flow rate, determine the number of trays needed graphically 89 Example 10.6.3 2/4 Solution The given data are : y1= 0.022, x2= 0, V1= 100 kg mol/ h, m=0.68 (1)V`=V1(1-y1) = 100(1-0.022) = 97.8 kg mol/h (2) moles of alcohol/h in V1 are 100-97.8=2.2 (3) Removing 90%, moles/h in outlet gas V2is 0.1(2.2) = 0.22 (4) V2=V`+0.22=97.8+0.22=98.02 (5) y2= 0.22/98.02= 0.00244 (6) the equilibrium line is plotted in figure (10.6.12) along with x2,y2and y1 (7) the operating line for minimum liquid flow rate Lmin is drawn from y2,x2 to point P, touching the equilibrium line where x1max = y1/m = 0.022/0.68=0.03235 90 (8) substituting into operation – line equation (10.6.4) and solving for Lmin, Example 10.6.3 3/4 x y x y L' 2 V ' 1 L' 1 V ' 2 1 x2 1 y1 1 x1 1 y2 0 0.022 0.002244 ' 0.03235 ' L min 97.8 Lmin 97.8 1 0 1 0 . 022 1 0 . 03235 1 0 . 002244 Lmin 59.24kg.mol / h (9) Using the relation mentioned in the question L`=1.5Lmin=1.5(59.24)=88.86 (10) Using L` in equation (10.6.4) and solving for the outlet concentration , x1 = 0.0218 (11) The top operating line now is plotted as a straight line through the points y2,x2 and y1,x1 in figure (10.6.12) (12) An intermediate point is calculated by setting y=0.012 in equation (10.6.5) and solving for x= 0.01078. plotting this point shows that the operating line is very linear . This occurs because the solutions are dilute 91 (13) The number of theoretical trays obtained by stepping them off is 4.0 trays Example 10.6.3 4/4 92 Simplified Methods For Dilute Gas Mixtures (Height Of Packed Towers) 1/3 Since a considerable percentage of the absorption processes include absorption of a dilute gas A , these cases will be considered using a simplified design procedure These cases are taken under consideration under the followings : 1. 2. 3. 4. Dilute (<10%) Operating line = straight Equilibrium line = curve Height of tower z:- V 1 y iM z ' k y aS 1 y 1 y iM y1 dy y av 2 y yi 1 yi 1 y ln 1 yi 1 y 93 Simplified Methods For Dilute Gas Mixtures (Height Of Packed Towers) 2/3 x1 L 1 x iM dx z ' x2 k aS 1 x xi x x av 1 x iM 1 x 1 xi ln 1 x 1 xi V 1 y M z ' K y aS 1 y y1 dy y 2 y y av 1 y 1 y 1 y ln 1 y 1 y M 94 Simplified Methods For Dilute Gas Mixtures (Height Of Packed Towers) 3/3 1 x 1 x 1 x M ln 1 x 1 x x L 1 x M dx z ' K x aS x2 x x av 1 1 x Where, k’x ,k’y = film mass-transfer coefficient for gas phase & liquid phase, respectively. K’x ,K’y = overall mass-transfer coefficient for gas phase & liquid phase, respectively. a = interfacial area per volume of packed section. S = cross-sectional area of tower. yi ,xi = gas & liquid conc. at the interface, respectively. y* ,x* = gas & liquid conc. that would be in equilibrium with y,x. 95 Solving Procedure 1/9 There are six major steps in the calculations: 1. On xy plot, draw operating line & equilibrium line. 2. By trial-and-error, determine yi ,xi or y*,x* using k x' a /(1 x) iM Slope ( PM ) ' k y a /(1 y ) iM Between the top & bottom of the tower. Point 1:- 1st trial: Let (1-y)iM (1-y1) (1-x)iM (1-x1) & k x' a /(1 x1 ) k x' a /(1 x) iM Slope ' ' k y a /(1 y1 ) k y a /(1 y ) iM Plot this slope on xy plot & get yi1 , xi1. 96 Solving Procedure 2/9 2nd trial: Calculate (1-y)iM & (1-x)iM Get new slope using, k x' a /(1 x) iM Slope ' k y a /(1 y ) iM Get new values of yi1 , xi1 3rd trial: Calculate new slope using values from of yi1 , xi1 2nd trial Get yi1 , xi1 Stop when slopen1 = slope(n+1)1 Do the same for point 2 and any points between the two. 97 Solving Procedure 3/9 3. Plot y vs 1/(y-yi), x vs 1/(xi – x), 1/(y-y*) or 1/(x* - x). 4. Calculate area under the curve. 5. Calculate the term in the brackets at point 1 & 2. (Get the average.) 6. Calculate z from the appropriate equation. To calculate the overall mass transfer coefficients: K’ya: Get K’yaave = (K’ya1 + K’ya2)/2 Use 1 1 m' ' ' ' K y a /(1 y) M k y a /(1 y) iM k x a /(1 x) iM at point 1 & point 2. 98 Solving Procedure 4/9 K’Xa: Get K’Xaave = (K’Xa1 + K’Xa2)/2 Use, 1 1 1 '' ' ' ' K x a /(1 x)M m k y a /(1 y)iM k x a /(1 x)iM at point 1 & point 2. 99 Solving Procedure 5/9 If solution = dilute (straight operating line) & a straight equilibrium line Height of tower z :1. V ( y1 y2 ) k y' az ( y yi ) M S where, ( y yi ) M ( y1 yi1 ) ( y 2 yi 2 ) ( y1 yi1 ) ln y 2 yi 2 ) 100 Solving Procedure 6/9 2. 3. L ( x1 x2 ) k x' az ( xi x) M S ( xi1 x1 ) ( xi 2 x2 ) ( xi x) M ( xi1 x1 ) ln xi 2 x2 ) V ( y1 y2 ) K y' az ( y y ) M S ( y y ) ( y y 1 1 2 2) ( y y )M ( y1 y1 ) ln y2 y2 ) 101 Solving Procedure 7/9 4. L ( x1 x2 ) K x' az ( x x) M S ( x x ) ( x 1 1 2 x2 ) ( x x) M ( x1 x1 ) ln x2 x2 ) Use Vave = (V1 + V2)/2 and Lave = (L1 + L2)/2 in the above equations. 102 Solving Procedure 8/9 These equations may be used in different ways .the general steps are shown in the following figure: 103 Solving Procedure 9/9 (1) Calculate Vav Vav=(V1+V2)/2 (2) the interface composition yi1 and xi1 at point y1,x1 in the tower must be determined by plotting line P1M1 , whose slope is calculated by (please see P672 for more details) k x` .a /(1 x) iM k .a slope ` x k y .a k y .a /(1 y ) iM slope k x` .a /(1 x1 ) k y` .a /(1 y1 ) (3) If the overall coefficient K`ya is being used , y*1and y*2 are determined as shown in the past figure . If K`ya is used x1*and x2*are obtained (4) Calculate the log mean driving force (y-yi)M from equation (10.6.27) if k`ya is used . For K`ya, (y-y*)M is calculated by equation (10.6.28) (5) Calculate the column height z by substituting into the appropriate equation 104 Example 10.6-4 1/12 Absorption of Acetone in a Packed Tower. Acetone is being absorbed by water in a packed tower having a cross sectional area of 0.186 m2 at 293 K and 101.32 (1 atm). The inlet air contains 2.6 mol % acetone and outlet 0.5%. The gas flow is 13.65 kg mol inert air/h. The pure water inlet flow is 45.36 kg mol water/h. Film coefficients for the given flows in the tower are k’y a = 3.78 x 10-2 kg mol/s.m3.mol frac. And k’x a = 6.16 x10-2 kg mol/s.m3.mol frac. Equilibrium data are given in Appendix A.3. (a) Calculate the tower height using k’y a. (b) Repeat using k’x a. (c) Calculate K’y a, and the tower height. 105 Example 10.6-4 2/12 y1 0.028 slope = -1.62 0.024 From Appendix A.3 for acetone-water and xA = 0.0333 mol frac. pA = 30/760 = 0.0395 atm or yA = 0.0395 mol frac. Hence, the equilibrium line is yA = mxA or 0.0395 = m(0.0333). Then, y=1.186x. This equilibrium line is plotted in Fg. 10.6-10. The given data are L’ = 45.36 kg mol/h, V’=13.65 kg mol/h, y1= 0.026, y2 = 0.005, and x2 = 0. Substituting into Eq.10.6-3 for an overall material balance using flow rates as kg mol/h instead of kg mol/s. operating line 0.020 yi 1 y* 1y2 yi 2y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 x1 xi1 Fig. 10.6-10: Location of interface composition for example 10.6-2. x1 = 0.00648 x1 0 0.026 0.005 13.65 45.36 13.65 45.36 1 0 1 0.026 1 0.005 1 x1 106 y1 Example 10.6-4 0.028 slope = -1.62 0.024 3/12 operating line 0.020 yi 1 y* 1y2 yi 2y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 x1 xi1 Fig. 10.6-10: Location of interface composition for example 10.6-2. The points y1 , x1 and y2 , x2 are plotted in Fig. 10.6-10 and a straight line is drawn for the operating line. Using Eq.(10.6-31) the approximate slope at y1 , x1 is, k x' a /(1 x1 ) 6.16 10 2 /(1 0.00648) slope ' 1.60 2 k y a /(1 y1 ) 3.78 10 /(1 0.026) Plotting this line through y1 ,x1 , the line intersects the equilibrium line at yi1 = 0.0154 and xi1 = 0.0130. Also, y*1 = 0.0077. Using Eq. (10.6-30) to calculate a more accurate slope, the preliminary values of yi1 and xi1 will be used in the trial-and-error solution. Substituting into Eq. (10.4-6), 107 y1 Example 10.6-4 4/12 (1 y ) iM slope = -1.62 0.024 operating line 0.020 yi 1 (1 yi1 ) (1 y1 ) ln[( 1 yi1 ) /(1 y1 )] 0.028 y* 1y2 yi y2 * 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 x1 xi1 Fig. 10.6-10: Location of interface composition for example 10.6-2. (1 0.0154) (1 0.026) 0.979 ln[(1 0.0154) /(1 0.026)] Using Eq.(10.4-7), (1 x) iM (1 x1 ) (1 xi1 ) ln[( 1 x1 ) /(1 xi1 )] (1 0.00648) (1 0.0130) 0.993 ln[( 1 0.00648) /(1 0.0130)] 108 y1 Example 10.6-4 5/12 slope = -1.62 operating line 0.020 yi 1 y* 1y2 yi 2y* substituting into Eq. (10.6-30), 0.028 0.024 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 x1 xi1 Fig. 10.6-10: Location of interface composition for example 10.6-2. k x' a /(1 x1 )iM 6.16 10 2 / 0.993 slope ' 1.61 2 k y a /(1 y1 )iM 3.78 10 / 0.929 Hence, the approximate slope and interface values are accurate enough. For the slope at point y2, x2. k x' a /(1 x2 ) 6.16 10 2 /(1 0) slope ' 1.62 2 k y a /(1 y2 ) 3.78 10 /(1 0.005) The slope changes little in the tower. Plotting this line, yi2 = 0.0020, xi2 = 0.0018, and y*2 = 0. Substituting into Eq. (10.6-24). 109 y1 Example 10.6-4 6/12 ( y yi ) M slope = -1.62 operating line 0.020 yi 1 ( y1 yi1 ) ( y2 yi 2 ) ln[( y1 yi1 ) /( y2 yi 2 )] 0.028 0.024 y* y2 1 yi 2 y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 xi1 x1 Fig. 10.6-10: Location of interface composition for example 10.6-2. (0.026 0.0154) (0.005 0.0020) 0.00602 ln[( 0.026 0.0154) /( 0.005 0.0020)] To calculate the total molar flow rates in kg mol/s, V' 13.65 / 3600 V1 3.893 103 kgmol / s 1 y1 1 0.026 V' 13.65 / 3600 V2 3.81110 3 kgmol / s 1 y2 1 0.005 V1 V2 3.893 103 3.811103 Vav 3.852 103 kgmol / s 2 2 110 y1 Example 10.6-4 0.028 slope = -1.62 0.024 7/12 operating line 0.020 yi 1 y* y2 1 yi 2 y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 xi1 x1 Fig. 10.6-10: Location of interface composition for example 10.6-2. 45.36 L L1 L2 Lav 1.260 10 2 kgmol / s 3600 ' For part (a), substituting into Eq.(10.6-26) and solving. Vav ( y1 y2 ) k y' az ( y yi ) M S 3.852 10 3 (0.026 0.005) (3.78 10 2 ) z (0.00602) 0.186 z 1.911m 111 y1 0.028 slope = -1.62 0.024 Example 10.6-4 8/12 operating line 0.020 yi 1 y* y2 1 yi For part (b), using an equation similar to Eq.(10.6-27), 2 y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 ( xi x) M ( xi1 x1 ) ( xi 2 x2 ) ln[( xi1 x1 ) /( xi 2 x2 )] xi1 x1 Fig. 10.6-10: Location of interface composition for example 10.6-2. (0.013 0.00648) (0.0018 0) 0.00368 ln[( 0.013 0.00648) /( 0.0018 0)] substituting into Eq. (10.6-30) and solving, 1.260 10 2 2 (00.00648 .026 0-.005 0 ) (6.16 10 ) z (0.00368) 0.186 z 1.936m This checks part (a) quite closely. 112 y1 0.028 slope = -1.62 0.024 Example 10.6-4 9/12 operating line 0.020 yi 1 y* y2 1 yi 2 y* 0.016 0.012 0.008 equilibrium line 0.004 0 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 0.014 2 xi1 x1 Fig. 10.6-10: Location of interface composition for example 10.6-2. For part (c), substituting into Eq. (10.1-25) for point y1 ,x1. (1 y )M (1 y1 ) (1 y1 ) ln[( 1 y1 ) /(1 y1 )] (1 0.0077) (1 0.026) 0.983 ln[( 1 0.0077) /(1 0.026)] The overall mass-transfer coefficient K’y a at point y1 ,x1 is calculated by substituting into Eq. (10.4-24). 1 1 m' ' ' ' K y a /(1 y )M k y a /(1 y ) iM k x a /(1 x) iM 113 Example 10.6-4 10/12 1 1 m' ' ' ' K y a /(1 y )M k y a /(1 y ) iM k x a /(1 x) iM 1 1 1.186 ' 2 K y a / 0.983 3.78 10 / 0.979 6.16 10 2 / 0.993 K y' a 2.183 10 2 kgmol / s.m3 .molfrac. Substituting into Eq. (10.6-25), ( y y )M ( y1 y1 ) ( y2 y2 ) ln[( y1 y1 ) /( y2 y2 )] (0.026 0.0077) (0.005 0) 0.01025 ln[( 0.026 0.0077) /( 0.005 0)] 114 Example 10.6-4 11/12 Finally substituting into Eq. (10.6-28), V ( y1 y2 ) K y' az ( y y ) M S 3.852 10 3 (0.026 0.005) (2.183 10 2 ) z (0.01025) 0.186 z 1.944m 115 Example 10.6-4 12/12 y1 0.028 slope = -1.62 0.024 operating line 0.020 yi1 0.016 0.012 y*1 0.008 y2 0.004 yi2 0 y*2 equilibrium line 0 0.002 x2 xi2 0.004 0.006 0.008 0.010 0.012 x1 Fig. 10.6-10: Location of interface composition for example 10.6-2. 0.014 xi1 116