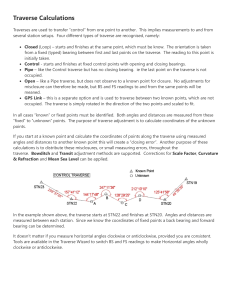

Detail Surveys Detail surveys are a basic prerequisite for building and land development In most cases, the purpose of detail surveys is to indicate features on, and adjacent to, a property There are a number of site features and levels required by architects and planners. We can undertake topographic surveys using a range of technologies, from remote access technologies, Total Stations and scanners (where there may be restricted access) to GPS technology (large scale topographic surveys). Features of general detail surveys include: Title information Contours Spot levels Site co-ordination and location of true north Location of existing visible services (sewerage, power poles, telephone) Outline of adjacent buildings Window position and heights for adjacent buildings facing subject site. Height and width of major vegetation Location of ancillary structures (garden sheds) Level benchmark to Datum where applicable, etc Or any other feature of a site that may impact upon development potential. Site detail extras may include accurate boundary definition, boundary marking and services search. Highly accurate internal surveys of buildings can also be provided to show room layouts or design purposes. Detailed Surveying To locate topographical and man-made features relative to a survey framework, measurements are made with the tape from the lines during the course of chaining. The control framework is used to fix detail or engineering features. Distinction is made between soft and hard detail. Hard detail implies well-defined points of reference such as buildings and walls, while soft detail refers to the natural features such as riverbanks. There are 2 basic ways in which details can be fixed offsetting tie-lines An offset from a traverse line to a point is the perpendicular distance of a point to a traverse line Whereas A Tie Line is a line drawn from the desired point of detail to the traverse line. Such measurements should be as short as possible. . Chain /Traverse line Detail Off-sets Traverse line Farm Note: Other means of checking the survey include radiation, intersection and resection. existing triangles, should be incorporated where Sides Measured by tape Tie lines Additional necessary check to lines, check crossing on the measurements taken. Intersection points of the lines are called stations. Radiation The simplest form of radial survey only requires a single survey assistant with a tape measure and compass. One end of the tape is attached to a point in the middle of the site. The diver simply swims around the site recording the distance and bearing of each feature from the central point. Plane Control The general approach to any survey is to locate the general position of pre-marked control points with respect to the local, natural or engineering features (details). The most satisfactory method used is the co-ordinate system but bearings may also be used. Co-ordinate System In the simplest surveys covering small areas, the relative positions of the control points are calculated in a co-ordinate system, rather than directly plotted by scale and a protractor. This is the most satisfactory method because: - it enables errors to be assessed or adjusted - each station is plotted independently from precise calculations - it is independent of angle measuring instruments In plane surveying a system of plane rectangular Cartesian co-ordinates is used to define the positions of points in plan. The axes of such a system have to be defined and it is usual in practice to adopt north and east directions for this purpose. The N-S axis is the principle directions or reference meridian to which bearings are related. This can be chosen from one of the following: - the true meridian or true north - magnetic north - natural grid north - An arbitrary direction e.g., one selected like which is the convenient direction. The positions of points may also be plotted as: - grid co-ordinates (eastings and northings) - polar co-ordinates (distances (d) from origin & angle of set from a set line) - geographical co-ordinate system (latitude & longitude) Bearing System The use of bearings is another method of describing the direction of a line. Bearing of a line is defined as the smallest angle, which that line makes with the reference line. The approach used in plane surveying is such that angles do not exceed 90. In this manner, bearings are measured relative to the north or south ends of a meridian and are placed in one of the quadrants so that they have NE or NW. N Accordingly B 60 132 A 284 C - AB N60 E, - AC S48 E, - AD N76W, Control Survey Two different methods of control survey will be considered namely Traversing and Triangulation. As implied previously in chain surveying, the relative positions of a framework of reference points and features are determined to act as a base for detail surveying. Control frame works can be formed using a variety of observing techniques and the positions and orientation fixed with respect to a known reference. Compass Traversing In this method a series of control points each one being inter-visible with its adjacent station will be chosen to fulfil the demands of a survey. The lines joining these stations are called traverse lines. The survey then consists of the measurements of angles between successive lines (or bearings of each line) and lengths of each line. Given the co-ordinates of the first station and the bearing of the first line, the co-ordinates of all successive points can be calculated. If the figure formed by the lines closes in at a station (starts and finishes at a point with known co-ordinates), forming a polygon then a closed traverse has been obtained. The two forms of closed traverse being a closed-loop traverse and a closed line traverse. A traverse starting at say station A and ending at station T that had not been co-ordinated previously is called unclosed traverse. See figures below B C K M A R D R D Closed line traverse G Closed loop traverse E T R S Q P Unclosed traverse Each type has its own particular use but the closed traverse is the most satisfactory figure since it’s the easiest to which correction of errors can be applied. The unclosed traverse survey can be carried out when the survey is comparatively long and narrow such as for a pipeline. A closed traverse survey may be used for a framework of surveys for housing or factory sites, determination of perimeter of a forested area. They may also be used when setting out tunnels, which are being driven under, built up areas. A precise control survey is often used for original mapping and for setting out of linear engineering works such as roads. A theodolite measures the angles. Choice of station Stations should be chosen aiming at 1. Good visibility between stations and bearing in mind the detail that has to be picked 2. Stations should be chosen according to the nature of the place 3. Stations should be chosen so that there is no displacement of stations overtime in case there is a time lag between the start and end of the survey. 4. Stations should be able to serve for control of levelling, contouring operations and detailed survey. Errors Depending on the degree of accuracy, the measurements should be corrected for errors due to sag, temperature, slope and any other defects. Example C B D A F E Closed loop traverse LINE ANGLE A B C D E AB BC CD DE EF MEAN INCLUDED (<) 60 126 97 65 67 DISTANCE (M) 100 25 40 35 56 Angles are observed clockwise. D B A C Unclosed traverse O OBSERVED HORIZONTAL CLOCKWISE ANGLES O - A - B 203 A - B - C 225 B - C - D 124 HORIZONTAL DISTANCES AB 200 BC 235 CD 210