AWWA C512 Air Valves Standard for Waterworks Service

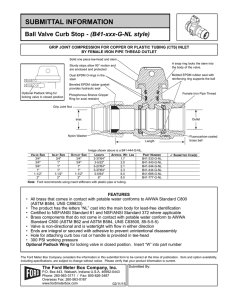

advertisement

ANSI/AWWA C512-07 (Revision of ANSI/AWWA C512-04) The Authoritative Resource on Safe Water® AWWA Standard Air-Release, Air/Vacuum, and Combination Air Valves for Waterworks Service Effective date: May 1, 2008. First edition approved by AWWA Board of Directors June 20, 1992. This edition approved June 24, 2007. Approved by American National Standards Institute Jan. 14, 2008. 6666 West Quincy Avenue Advocacy Denver, CO 80235-3098 Communications T 800.926.7337 Conferences www.awwa.org Education and Training Science and Technology Sections Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- SM AWWA Standard This document is an American Water Works Association (AWWA) standard. It is not a specification. AWWA standards describe minimum requirements and do not contain all of the engineering and administrative information normally contained in specifications. The AWWA standards usually contain options that must be evaluated by the user of the standard. Until each optional feature is specified by the user, the product or service is not fully defined. AWWA publication of a standard does not constitute endorsement of any product or product type, nor does AWWA test, certify, or approve any product. The use of AWWA standards is entirely voluntary. This standard does not supersede or take precedence over or displace any applicable law, regulation, or codes of any governmental authority. AWWA standards are intended to represent a consensus of the water supply industry that the product described will provide satisfactory service. When AWWA revises or withdraws this standard, an official notice of action will be placed on the first page of the classified advertising section of Journal AWWA. The action becomes effective on the first day of the month following the month of Journal AWWA publication of the official notice. American National Standard An American National Standard implies a consensus of those substantially concerned with its scope and provisions. An American National Standard is intended as a guide to aid the manufacturer, the consumer, and the general public. The existence of an American National Standard does not in any respect preclude anyone, whether that person has approved the standard or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standard. American National Standards are subject to periodic review, and users are cautioned to obtain the latest editions. Producers of goods made in conformity with an American National Standard are encouraged to state on their own responsibility in advertising and promotional materials or on tags or labels that the goods are produced in conformity with particular American National Standards. Caution Notice: The American National Standards Institute (ANSI) approval date on the front cover of this standard indicates completion of the ANSI approval process. This American National Standard may be revised or withdrawn at any time. ANSI procedures require that action be taken to reaffirm, revise, or withdraw this standard no later than five years from the date of publication. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute, 25 West 43rd Street, Fourth Floor, New York, NY 10036; (212) 642-4900. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information or retrieval system, except in the form of brief excerpts or quotations for review purposes, without the written permission of the publisher. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`, Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Copyright © 2008 by American Water Works Association Printed in USA ii Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. Committee Personnel The AWWA Standards Committee on Waterworks Air-Release Valves, which developed and approved this standard, had the following personnel at the time of approval: Miles E. Wollam, Chair J.B. Allen,* Standards Engineer Liaison, AWWA, Denver, Colo. (AWWA) J.J. Cusack Jr., Bryant Associates, Boston, Mass. (AWWA) R.G. Fuller, HDR Engineering Inc., Denver, Colo. (AWWA) W.A. Hunt, Consulting Engineer, Bozeman, Mont. (AWWA) K.W. Kells,* Consulting Engineer, Ivoryton, Conn. (AWWA) W.L. Meinholz, AB&H, A Donahue Group, Chicago, Ill. (AWWA) T.J. Stolinski Jr., Black & Veatch Corporation, Kansas City, Mo. (AWWA) R.J. Wahanik, Hystras, Wyommissing, Pa. (AWWA) R.A. Ward, Dufresne & Associates PC, Windsor, Vt. (AWWA) M.E. Wollam, MWH Inc., Pasadena, Calif. (AWWA) Producer Members D. Alexander,† Cla-Val Company, Costa Mesa, Calif. (AWWA) J.V. Ballun, Val-Matic Valve & Manufacturing Corporation, Elmhurst, Ill. (AWWA) R. DiLorenzo, Cla-Val Automatic Control Valves, Wauconda, Ill. (AWWA) K. Hall,† APCO Willamette/Valve & Primer, San Clemente, Calif. (AWWA) P.O. Landon,† Val-Matic Corporation, Elmhurst, Ill. (AWWA) J.E. Lescovich, GA Industries Inc., Cranberry Township, Pa. (AWWA) B.J. Lewis, Crispin Multiplex Manufacturing Company, Berwick, Pa. (AWWA) W.J. Nicholl,† GA Industries Inc., Cranberry Township, Pa. (AWWA) J.M. Radtke, Aqua-Dynamic Systems Inc., Wilkes-Barre, Pa. (AWWA) D.L. Smith, APCO Willamette/Valve & Primer, Schaumburg, Ill. (AWWA) N. Zloczower,* A.R.I. Flow Control Accessories, Israel (AWWA) User Members A. Ali, Greater Vancouver Water District, Burnaby, B.C. (AWWA) J.H. Bambei Jr., Denver Water Department, Denver, Colo. (AWWA) N.E. Gronlund, East Bay Municipal Utility District, Oakland, Calif. (AWWA) * Liaison, nonvoting † Alternate iii Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- General Interest Members M.I. Schwartz, Loudon County Sanitation Authority, Leesburg, Va. (AWWA) J.A. Wilke, Seattle Public Utilities, Seattle, Wash. (AWWA) --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- iv Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. Contents All AWWA standards follow the general format indicated subsequently. Some variations from this format may be found in a particular standard. SEC. PAGE SEC. PAGE Foreword 1.2 Purpose........................................... 1 I Introduction................................... vii 1.3 Application..................................... 2 I.A Background.................................... vii 2 References....................................... 2 I.B History........................................... vii 3 Definitions....................................... 3 I.C Acceptance..................................... vii II Special Issues................................. viii 4 Requirements II.A Advisory Information on Product 4.1 Data to Be Provided by Manufacturer or Supplier.............. 4 Application................................ viii II.B Venting......................................... viii II.C Throttling and Slow-Closing Materials......................................... 4 4.3 General Design and Detailed Design Requirements................... 6 --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Devices......................................... ix II.D 4.2 Pipeline Water Column Separation Protection.................................... ix 4.4 Workmanship and Painting............. 8 5 Verification 5.1 Testing............................................ 8 5.2 Inspection....................................... 9 5.3 Rejection....................................... 10 III Use of This Standard....................... ix III.A Purchaser Options and Alternatives. ix III.B Modification to Standard................. x IV Major Revisions............................... x 6 Delivery V Comments....................................... x 6.1 Marking........................................ 10 6.2 Preparation for Shipment.............. 10 6.3 Affidavit of Compliance................ 10 Standard 1 General 1.1 Scope.............................................. 1 v Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. This page intentionally blank. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. Foreword This foreword is for information only and is not a part of AWWA C512. I. Introduction I.A. Background. This standard describes three types of air valves: air-release valves, air/vacuum valves, and combination air valves. 1. Air-release valves, also called small-orifice valves, are designed to automatically release small pockets of accumulated air from a pipeline while the system operates under pressure exceeding atmospheric pressure. 2. Air/vacuum valves, also called large-orifice valves, are designed to exhaust large quantities of air automatically during pipeline filling and to admit large quantities of air automatically when the internal pressure in the pipeline drops below atmospheric pressure. 3. Combination air valves are designed to perform the same function as air/vacuum valves but, in addition, they will automatically release small pockets of air from the pipeline while under pressure, like an air-release valve. I.B. History. The AWWA Standards Committee on Waterworks Air‑Release Valves was authorized on Nov. 17, 1984, to respond to a request for a standard on air valves. The first edition of this standard, AWWA/ANSI C512, was approved by the AWWA Board of Directors on Jan. 26, 1992, the second edition on June 20, 1999, and the third edition on June 13, 2004. This edition was approved on June 24, 2007. I.C. Acceptance. In May 1985, the US Environmental Protection Agency (USEPA) entered into a cooperative agreement with a consortium led by NSF International (NSF) to develop voluntary third-party consensus standards and a certification program for direct and indirect drinking water additives. Other members of the original consortium included the American Water Works Association Research Foundation (AwwaRF) and the Conference of State Health and Environmental Managers (COSHEM). The American Water Works Association (AWWA) and the Association of State Drinking Water Administrators (ASDWA) joined later. In the United States, authority to regulate products for use in, or in contact with, drinking water rests with individual states.* Local agencies may choose to impose requirements more stringent than those required by the state. To evaluate the health effects of products and drinking water additives from such products, state and local * Persons outside the United States should contact the appropriate authority having jurisdiction. vii --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. agencies may use various references, including 1. An advisory program formerly administered by USEPA, Office of Drinking Water, discontinued on Apr. 7, 1990. 2. Specific policies of the state or local agency. 3. Two standards developed under the direction of NSF, NSF*/ANSI† 60, Drinking Water Treatment Chemicals—Health Effects, and NSF/ANSI 61, Drinking Water System Components—Health Effects. 4. Other references, including AWWA standards, Food Chemicals Codex, Water Chemicals Codex,‡ and other standards considered appropriate by the state or local agency. Various certification organizations may be involved in certifying products in accordance with NSF/ANSI 61. Individual states or local agencies have authority to accept or accredit certification organizations within their jurisdiction. Accreditation of certification organizations may vary from jurisdiction to jurisdiction. Annex A, “Toxicology Review and Evaluation Procedures,” to NSF/ANSI 61 does not stipulate a maximum allowable level (MAL) of a contaminant for substances not regulated by a USEPA final maximum contaminant level (MCL). The MALs of an unspecified list of “unregulated contaminants” are based on toxicity testing guidelines (noncarcinogens) and risk characterization methodology (carcinogens). Use of Annex A procedures may not always be identical, depending on the certifier. AWWA/ANSI C512 does not address additives requirements. Users of this standard should consult the appropriate state or local agency having jurisdiction in order to 1. Determine additives requirements, including applicable standards. 2. Determine the status of certifications by parties offering to certify products for contact with, or treatment of, drinking water. 3. Determine current information on product certification. II. Special Issues. II.A. Advisory Information on Product Application. For additional guidance regarding selecting, sizing, locating, and installing air-release, air/vacuum, and combination air valves, see AWWA Manual M51, Air-Release, Air/Vacuum, & Combination Air Valves. II.B. Venting. When selecting types of valves, it must be noted that air/vacuum * NSF International, 789 N. Dixboro Road, Ann Arbor, MI 48105. † American National Standards Institute, 25 West 43rd Street, Fourth Floor, New York, NY 10036. ‡ Both publications available from National Academy of Sciences, 500 Fifth Street NW, Washington, DC 20001. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS viii Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. valves, once closed, will not reopen to vent air while a pipeline is full and under pressure. To vent air from a pipeline under pressure, an air-release valve or combination air valve is required. II.C. Throttling and Slow-Closing Devices. When air/vacuum or combination valves are used where pressure surges can occur, such as on the discharge of vertical turbine deep-well pumps, a throttling device or slow-closing device option should be considered. II.D. Pipeline Water Column Separation Protection. On pipeline applications where water column separations may occur, a vacuum breaker with air-release valve or an air valve with restricted outflow should be considered. III. Use of This Standard. It is the responsibility of the user of an AWWA standard to determine that the products described in that standard are suitable for use in the particular application being considered. III.A. Purchaser Options and Alternatives. This standard includes certain options and alternatives, summarized in the following list, that the purchaser should designate when purchasing valves described in this standard. The purchaser should review each item and make appropriate provisions in specifications to stipulate additional requirements. The following items should be provided by the purchaser: 1. Standard used—that is, AWWA/ANSI C512, Air‑Release, Air/Vacuum, and Combination Air Valves for Waterworks Service, of latest revision. 2. Valve size. 3. Maximum working pressure of each valve. 4. Quantity required. 5. Type of installation (underground, in‑plant, in‑vault, or outdoor). 6. Warranty statement, if other than manufacturer’s standard warranty. 7. Whether compliance with NSF/ANSI 61, Drinking Water System Components— Health Effects, is required. 8. Valve type, air‑release valve, air/vacuum, or combination air valve (Section 3). 9. Catalog data, if specified (Sec. 4.1.1). 10. Certified drawings, if specified (Sec. 4.1.2). 11. Operating manual, if specified (Sec. 4.1.3). 12. Details of other federal, state or provincial, and local requirements (Sec. 4.2.1). 13. Body inlet configuration, threaded or flanged (Sec. 4.3.2.1). 14. Valve material of construction (Sec. 4.3.2.1.1 and 4.3.2.9). 15. Flanges, if other than flat-faced (Sec. 4.3.2.2.1). ix --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. 16. Cover outlet configuration, threaded, flanged, or hooded (Sec. 4.3.2.10). 17. Whether an adjustable throttling device is required on the valve outlet and whether the device must provide full-size flow area in the reverse direction (Sec. 4.3.3). 18. Whether a slow-closing device is required on the valve inlet (Sec. 4.3.4). 19. Internal protective coating, if specified (Sec. 4.4.2.2). 20. Special external protective coatings, if other than the manufacturer’s standard primer (Sec. 4.4.2.3). 21. Records of tests, if specified (Section 5). 22. Lower test pressure, if specified (Sec. 5.1.2.1, 5.1.2.2, and 5.1.3.1). 23. Affidavit of compliance, if specified (Sec. 6.3). III.B. Modification to Standard. Any modification of the provisions, definitions, or terminology in this standard must be provided by the purchaser. IV. Major Revisions. Major changes made to the standard in this revision include the following: 1. Added requirements for throttling devices in Sec. 4.3.3 2. Added requirements for slow-closing devices in Sec. 4.3.4. V. Comments. If you have any comments or questions about this standard, please call the AWWA Volunteer and Technical Support Group at 303.794.7711, FAX at 303.795.7603, write to the group at 6666 West Quincy Avenue, Denver, CO 80235-3098, or e-mail at standards@awwa.org. x Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. AWWA/ANSI C512-07 (Revision of AWWA/ANSI C512-04) Air-Release, Air/Vacuum, and Combination Air Valves for Waterworks Service Section 1: Sec. 1.1 GeneRAL Scope This standard describes ½‑in. (13‑mm) through 6-in. (150-mm) air‑release valves and ½-in. (13‑mm) through 20-in. (500-mm) air/vacuum and combination air valves having gray cast‑iron or ductile‑iron bodies and covers. The valves are designed for use in water systems with maximum working pressures of 300 psig (2,070 kPa [gauge]) and water temperatures ranging from above freezing to a maximum of 125°F (52°C). Sec. 1.2 Purpose The purpose of this standard is to provide the minimum requirements for air-release valves, air/vacuum valves, and combination air valves for water supply service, including material, design, inspection, testing, marking, handling, and packaging for shipment. 1 Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- AWWA Standard 2 AWWA C512-07 Sec. 1.3 Application This standard can be referenced in specifications for air-release valves, air/vacuum valves, or combination air valves. The stipulations of this standard apply when this document has been referenced and then only to air-release valves, air/ vacuum valves, or combination air valves for waterworks service. Section 2: REFERENCES This standard references the following documents. In their latest editions, these documents form a part of this standard to the extent specified in this standard. In any case of conflict, the requirements of this standard shall prevail. ASME* B1.20.1—General Purpose Pipe Threads (Inch). * ASME International, Three Park Avenue, New York, NY 10016. † American National Standards Institute, 25 West 43rd Street, Fourth Floor, New York, NY 10036. ‡ ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428. Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- ASME B16.1—Cast Iron Pipe Flanges and Flanged Fittings, Class 25, 125, and 250. ASME B16.42—Ductile Iron Pipe Flanges and Flanged Fittings, Class 150 and 300. ANSI†/AWWA C550—Protective Interior Coatings for Valves and Hydrants. ASTM‡ A48—Standard Specification for Gray Iron Castings. ASTM A126—Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings. ASTM A307—Standard Specification for Carbon Steel Bolts and Studs, 60,000 PSI Tensile Strength. ASTM A536—Standard Specification for Ductile Iron Castings. ASTM B154—Standard Test Method for Mercurous Nitrate Test for Copper and Copper Alloys. ASTM D395—Standard Test Methods for Rubber Property—Compression Set. ASTM D471—Standard Test Method for Rubber Property—Effect of Liquids. ASTM D1149—Standard Test Method for Rubber Deterioration–Surface Ozone Cracking in a Chamber. Air-Release, Air/Vacuum, and combination air valves 3 ASTM D2000—Standard Classification System for Rubber Products in Automotive Applications. NSF*/ANSI 61—Drinking Water System Components—Health Effects. Section 3: DEFINITIONS --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- The following definitions shall apply in this standard: 1. Air flow rate: The quantity of air, expressed in standard cubic feet per minute (cubic meters per minute) or standard cubic feet per second (cubic meters per second), passing through an orifice. 2. Air‑release valve: A hydromechanical device designed to automatically release to the atmosphere small pockets of air as they accumulate at local high points along a pipeline when the pipeline or piping system is full and operating under pressure. 3. Air/vacuum valve: A direct‑acting, float‑operated, hydromechanical device designed to automatically release or admit large volumes of air during the filling or draining of a pipeline or piping system. This valve will open to relieve negative pressures and will remain closed and will not reopen to vent air when the system is full and under pressure. 4. Combination air valve: A device having the features of both an airrelease valve and an air/vacuum valve. 5. Constructor: The party that provides the work and materials for placement or installation. 6. Manufacturer: The party that manufactures, fabricates, or produces materials or products. 7. Maximum working pressure: The maximum pressure at which the valve can continue to function. 8. Orifice: The opening in the valve mechanism through which air is expelled from or admitted into the pipeline or piping system. 9. Purchaser: The person, company, or organization that purchases any materials or work to be performed. 10. Slow-closing device: An adjustable mechanical device mounted on the inlet of an air/vacuum or combination air valve to restrict the water flow into the * NSF International, 789 N. Dixboro Road, Ann Arbor, MI 48105. Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. 4 AWWA C512-07 air valve. 11. Supplier: The party that supplies material or services. A supplier may or may not be the manufacturer. 12. Throttling device: An adjustable mechanical device mounted on the outlet of an air/vacuum valve or combination air valve to control the air flow out of the valve. 13. Valve design pressure: The maximum pressure to which a valve may be subjected without exceeding the allowable stress of any of its components. Section 4: Sec. 4.1 REQUIREMENTS Data to Be Provided by Manufacturer or Supplier If requested by the purchaser, the manufacturer or supplier shall provide the following information: 4.1.1 Catalog data. The catalog data shall include illustrations, valve performance data, a parts schedule that identifies the materials used for various parts, and the total net assembled weight for each valve size. 4.1.2 Certified drawings. A set of certified drawings shall include principal dimensions, construction details, and materials used for all parts of the valve. 4.1.3 Operating manual . An operating manual shall include the manufacturer’s installation and operating instructions, a recommended list of spare parts, and the maintenance procedures. The contents shall be sufficiently detailed to direct the assembly and disassembly of the valve and for the ordering of parts. Sec. 4.2 Materials 4.2.1 Materials. Materials shall comply with the requirements of the Safe Drinking Water Act and other federal regulations for potable water and wastewater systems as applicable. 4.2.2 Physical and chemical requirements. The physical and chemical requirements of the components of air‑release, air/vacuum, and combination air valves shall be as required by ANSI, AWWA, ASME, and ASTM standards referenced in this standard. Whenever valve components are made to conform to ANSI, AWWA, ASME, or ASTM standards that include test requirements or testing procedures, the valve manufacturer shall comply with the requirements and procedures. The records of all tests shall be made available to the purchaser on request. --``,``,`,,,,`````,,`,```,,`,,,`-`- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. 4.2.2.1 Gray cast iron. Gray cast iron shall equal or exceed the requirements of ASTM A126, Class B, or ASTM A48, Class 35. 4.2.2.2 Brass or bronze. Valve components of brass or bronze shall be made to ASTM or to Unified Numbering System requirements and shall have a minimum yield strength of 14,000 psi (96,500 kPa). Any bronze alloy used in the cold‑worked condition shall pass the mercurous nitrate test in accordance with ASTM B154 to minimize susceptibility to stress corrosion. 4.2.2.2.1 Bronze parts subject to wetting by line contents shall be made of low‑zinc alloys containing less than 16 percent zinc. If aluminum–bronze is used, the alloy shall be inhibited against dealuminization using a temper anneal at 1,200°F ±50°F (650°C ±28°C) for 1 hr per in. (25.4 mm) of section thickness, followed by cooling in moving air or by water quenching. 4.2.2.3 Cover bolting. Bolting materials shall equal or exceed the minimum physical strength requirements of ASTM A307, unless otherwise specified by the purchaser. 4.2.2.4 Ductile iron. Ductile iron shall equal or exceed the requirements of ASTM A536, Grade 65‑45‑12. 4.2.2.5 Elastomers. Elastomers shall comply with the following: 4.2.2.5.1 Rubber shall be resistant to microbial attack, copper poisoning, and ozone attack. Rubber compounds shall contain no more than 8 parts per million (ppm) of copper ion and shall include copper inhibitors to prevent copper degradation of the rubber material. 4.2.2.5.2 Rubber compounds shall be capable of withstanding an ozone‑ resistance test when tested in accordance with ASTM D1149. The tests shall be conducted on the unstressed samples for 70 hr at 104°F (40°C) with an ozone concentration of 0.5 ppm; and there shall be no visible cracking in the surfaces of the test samples after tests. 4.2.2.5.3 Rubber compounds shall have a maximum compression set value of 18 percent when tested in accordance with ASTM D395, Method B, for 22 hr at 158°F (71°C). 4.2.2.5.4 Rubber compounds shall be free of vegetable oils, vegetable oil derivatives, animal fats, and animal oils. 4.2.2.5.5 Rubber compounds shall contain no more than 1.5 parts wax per 100 parts of rubber hydrocarbon and shall have less than a 2 percent volume increase when tested in accordance with ASTM D471 after being immersed in distilled water at 73.4°F ±2°F (23°C ±1°C) for 70 hr. Reclaimed rubber shall not be used. Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Air-Release, Air/Vacuum, and combination air valves 5 6 AWWA C512-07 4.2.2.6 Gaskets. Gasket material shall be made of rubber composition or paper that is free of asbestos or corrosive ingredients. O‑rings or other suitable elastomeric seals may be used for gaskets. 4.2.2.7 O-rings. O-rings shall be compounded in accordance with ASTM D2000 and have physical properties suitable for the application. General Design and Detailed Design Requirements 4.3.1 General design. 4.3.1.1 Allowable stress. The allowable stress at valve design pressure shall not exceed one third of the yield strength or one fifth of the ultimate strength of materials used. 4.3.1.2 Venting. Air‑release valves and the air‑release mechanism of combination air valves shall be designed to open positively and vent air to the atmosphere at system pressures up to the maximum working pressure, as required by the venting orifice size. 4.3.2 Detailed design. 4.3.2.1 Body and cover. 4.3.2.1.1 The material of construction for bodies and covers shall be of gray cast iron (ASTM A126, Class B, or ASTM A48, Class 35) or ductile iron (ASTM A536, Grade 65‑45‑12) and shall have threaded or flanged connections, as required by the purchaser. 4.3.2.1.2 Inlet and outlet ports of the body for air/vacuum valves and combination air valves shall be sized to ensure that the minimum flow area of each port shall be equal to or greater than the flow area of a circle of diameter equal to the nominal valve size. 4.3.2.2 Valve connections. Valve connections shall conform to the following requirements: 4.3.2.2.1 Flanged-end dimensions and drilling for cast-iron bodies and covers shall conform to ASME B16.1, Class 125 or Class 250. Flanged-end dimensions and drilling for ductile-iron bodies and covers shall conform to ASME B16.42, Class 150 or Class 300. Flanges shall be flat-faced unless otherwise specified by the purchaser. 4.3.2.2.2 Threaded-end connections shall conform to the requirements for tapered pipe threads for general use, National Pipe Threads (NPT), per ASME B1.20.1. 4.3.2.3 Floats. For valves with inlet sizes less than 4 in. (100 mm), the float shall be capable of withstanding a collapse pressure of 1,000 psig (6,900 kPa Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Sec. 4.3 [gauge]). For valves with inlet sizes 4 in. (100 mm) and larger, the float shall be capable of withstanding collapse pressures of 750 psig (5,180 kPa [gauge]). 4.3.2.4 Gaskets. Gaskets shall be used on flanged joints and shall comply with Sec. 4.2.2.6. 4.3.2.5 Orifices. 4.3.2.5.1 The air‑release valve orifice shall be suitable for the volume of air that accumulates in the system at the maximum working pressure. The orifice size is specific to the system application. 4.3.2.5.2 The air‑vacuum valve orifice shall be suitably sized, using the manufacturer’s sizing data, to permit the required air flow rate to be discharged or admitted. 4.3.2.6 Cover bolting. Unless otherwise required by the purchaser, bolts, studs, and nuts shall comply with Sec. 4.2.2.3. 4.3.2.7 Seats. Valve seats made of elastomeric materials shall be designed with a hard material selected for watertight shutoff (zero leakage) and long‑term service at a minimum pressure of 20 psig (138 kPa [gauge]). Valve seat design shall permit easy removal and replacement. 4.3.2.8 Special fittings. 4.3.2.8.1 Drain/test ports on valves with a 1‑in. (25‑mm) diameter or larger inlet shall have a ½‑in. (13‑mm) NPT minimum plugged drain/test port located near the bottom of the valve body and a plugged test port near the top of the valve. 4.3.2.8.2 An air‑release valve and an air/vacuum valve assembled with interconnecting piping shall have pipe and fittings of sufficient size to prevent clogging and entrapment of foreign materials. The piping between the air/vacuum valve and the air‑release valve shall be installed to allow air to rise to the air‑release inlet. When required, a shutoff valve isolating the two valves shall be provided. 4.3.2.9 Valve trim materials. Unless otherwise required by the purchaser, valve trim material shall be inherently corrosion resistant and shall be the manufacturer’s standard material. 4.3.2.10 Valve outlet. Valve outlets shall be threaded, flanged, or hooded (or protected with another shielding device that is positively anchored to the valve cover). 4.3.3 Throttling device: When designated by the purchaser, a throttling device shall be provided for mounting directly on the outlet of the air/vacuum or combination air valve. Throttling devices shall consist of a gray or ductile iron body Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Air-Release, Air/Vacuum, and combination air valves 7 8 AWWA C512-07 and an adjustable closure disc that throttles the air flow between 5 and 100 percent of full flow. When designated, the device shall provide full-size flow area in the reverse direction. 4.3.4 Slow-closing device: When designated by the purchaser, the manufacturer shall install a slow-closing device on the air valve inlet and test the assembly in accordance with Sec. 5.1.1. Slow-closing devices shall consist of a flanged or threaded cast-iron body with a closure disc that is held open with a stainless steel compression spring. The device must provide full-size flow area in the reverse direction. Upon entry of water, the disc shall close and allow the passage of water through adjustable orifices. The disc shall be brass, bronze, or stainless steel. Sec. 4.4 Workmanship and Painting --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- 4.4.1 Workmanship. Workmanship employed in the fabrication and assembly of valves manufactured in accordance with this standard shall ensure that the valves function as designed. 4.4.1.1 Interchangeable parts. Valve parts shall be designed with manufacturing tolerances set to provide interchangeability in the products of any one manufacturer between units of the same size and type. 4.4.1.2 Castings. Castings shall be clean and sound, without defects that will impair their service. Plugging, welding, or repairing of these defects will not be allowed. Internal surfaces of the casting shall be smooth and free of sharp corners. 4.4.2 Painting. 4.4.2.1 Internal surfaces. Interior surfaces of the valve body shall be clean, smooth, and shall not be coated unless required by the purchaser. 4.4.2.2 Internal protective coating. If an internal protective coating is applied, all wetted parts—except machined or bearing surfaces, and corrosion‑resistant components—shall be coated in accordance with AWWA/ANSI C550. 4.4.2.3 External surfaces. Unless otherwise required by the purchaser, exterior cast‑iron surfaces of each valve shall be coated with the manufacturer’s standard primer. Section 5: Sec. 5.1 VERIFICATION Testing Before the application of any external coating, the completely assembled Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. Air-Release, Air/Vacuum, and combination air valves 9 --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- valve shall be hydrostatically tested to ensure proper operation. If an internal coating is required by the purchaser, the hydrostatic shell test of the body and cover is permitted before assembly to establish the integrity of the body and cover castings prior to applying the internal coating. After the internal coating is applied, the assembled valve shall be hydrostatically tested as outlined below. 5.1.1 Shell test. With the valve completely closed, an internal hydrostatic pressure equal to 150 percent of the maximum working pressure shall be applied. During the test, there shall be no evidence of leakage through the valve, nor shall any part show evidence of permanent damage or distortion. The duration of the hydrostatic test shall be sufficient to allow visual examination for leakage and shall be at least 1 min for valves 8 in. (200 mm) and smaller and 3 min for valves 10 in. (250 mm) through 20 in. (500 mm). 5.1.2 Air‑release valve seat leakage test. 5.1.2.1 Hydrostatic test. Each valve shall be tested at two internal hydrostatic pressures: (1) a minimum pressure of 20 psig (138 kPa [gauge]), unless otherwise specified by the purchaser; and (2) a maximum pressure equal to 150 percent of the maximum working pressure of the valve, with the opposite end, or outlet of the valve, open to atmosphere. The duration of each test shall be at least 30 sec. At the test pressures, the valve shall be drop-tight (zero leakage). 5.1.2.2 Operational test. After completing the hydrostatic test, each valve shall be opened and closed three times, using water at 20 psig (138 kPa [gauge]) or at a lower pressure, if specified by the purchaser, to activate the float and float mechanism. During the test, the valve shall be drop-tight (zero leakage). 5.1.3 Air/vacuum valve and combination air valve seat leakage test. 5.1.3.1 Hydrostatic test. Each valve shall be tested at two internal hydrostatic pressures: (1) a minimum pressure of 20 psig (138 kPa [gauge]), unless otherwise specified by the purchaser; and (2) a maximum pressure equal to 150 percent of the maximum working pressure of the valve, with the opposite end, or outlet of the valve, open to atmosphere. The duration of each test shall be at least 30 sec. At the test pressures, the valve shall be drop-tight (zero leakage). 5.1.3.2 Low-pressure test. During the low‑pressure test, the float or plug shall be rotated four times in 90° increments. There shall be no evidence of leakage in any of the test positions. Sec. 5.2 Inspection Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Work performed according to this standard shall be subject to inspection by the purchaser. Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. 10 AWWA C512-07 5.2.1 Plant inspection. The purchaser shall have access to all places of manufacture where materials are produced or fabricated and where tests are conducted and shall be able to inspect the facilities and observe the tests. Sec. 5.3 Rejection Any valve, or valve part, that does not comply with the requirements of this standard shall be rejected. Section 6: Sec. 6.1 DELIVERY Marking Each valve shall be marked by body markings or a corrosion‑resistant nameplate, or both, that clearly indicate the manufacturer’s name or trademark, size of the valve, and the designation of the maximum working pressure rating of the valve for water service. Preparation for Shipment Valves shall be complete in all details when shipped. Cavities shall be drained of water to protect from freezing. The openings shall be covered to prevent entry of foreign material, and the threads shall be protected. The manufacturer shall carefully prepare the valves for shipment. Valves shall be fully packaged or attached to pallets at the manufacturer’s option. Sec. 6.3 Affidavit of Compliance The purchaser may require an affidavit from the manufacturer or supplier that the material provided complies with applicable requirements of this standard. Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Sec. 6.2 This page intentionally blank. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,` Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. This page intentionally blank. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. This page intentionally blank. --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved. AWWA is the authoritative resource for knowledge, information and advocacy to improve the quality and supply of water in North America and beyond. AWWA is the largest organization of water professionals in the world. AWWA advances public health, safety and welfare by uniting the efforts of the full spectrum of the entire water community. Through our collective strength we become better stewards of water for the greatest good of the people and the environment. 1P-3.6M-43512-4/08-JP Printed on Recycled Paper --``,``,`,,,,`````,,`,```,,`,,,`-`-`,,`,,`,`,,`--- Copyright American Water Works Association Provided by IHS under license with AWWA No reproduction or networking permitted without license from IHS Licensee=Samsung Engineering/5930207002, User=kim, wanki Copyright © 2008 American Water Works Rights Not for Association. Resale, 06/25/2009 All 01:29:28 MDT Reserved.