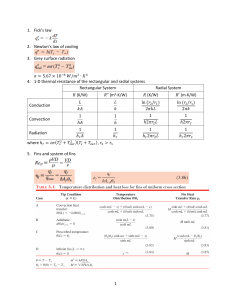

EXPERIMENT 1 Reynolds’ Number Presented to the Faculty of the Department of Chemical Engineering School of Engineering and Architecture Saint Louis University In Partial Fulfillment of the Requirements for the Course: CHE 3251L: Chemical Engineering Laboratory 1 by: Luis, Shaira Mae R. Manoguid, Phoebe Kate U. Marna, Conaya F. Masilungan, Angelica L September 2022 Department of Chemical Engineering School of Engineering and Architecture Saint Louis University LABORATORY REPORT EVALUATION SHEET Laboratory Course: CHE 3251L Schedule: 7:30-10:30 ThF Experiment Number: 1 Experiment Title: Reynolds’ Number Group Number: 4 Group Members: Luis, Shaira Mae R. Manoguid, Phoebe Kate U. Marna, Conaya F. Masilungan, Angelica L Date Performed: August 19, 2022 CONTENTS I. II. III. IV. V. VI. VII. Introduction Equipment/Materials Needed Procedures Data and Results Discussion Conclusion References (APA format) Appendices: a. Computations b. Answers to Questions/Problems c. Documentation Format and Neatness TOTAL POINTS: Evaluated by: Engr. Genevive S. de Vera Date Submitted: September 2, 2022 TOTAL POINTS 10 3 3 15 25 15 REMARKS 3 10 10 3 3 100 pts SCORE: Date: _____ SCORE Saint Louis University School of Engineering and Architecture CHE 3251L LABORATORY REPORT Experiment No: 1 Title: REYNOLD’S NUMBER EXPERIMENT At the end of this experiment, the student should be able to: TLO# 1: Reproduce the classical experiment conducted by Osborne Reynolds concerning the fluid flow conditions. TLO #2: Observe the laminar, transition and turbulent velocity profiles as related to Reynolds’ number. I. INTRODUCTION In the 19th century, Osborne Reynolds was honored with the term "Reynolds’ Number." Two distinct forms of flow have been established in an experiment by Osborne Reynolds. In order to conduct the experiment, a long, clear water-flowing tube was filled with a thin stream of a colored fluid that had the same density as water. Numerous elusive fluid characteristics, including flow rate, fluid density, pipe diameter, and fluid viscosity, affect the Reynolds number. 𝑅𝑒 = VDρ μ Reynolds’ number (Re) is also defined as a ratio of inertial or destabilizing force to the viscous damping or stabilizing force. With the increase in the value of Re, the fluid flow gets into full-blown turbulence as the inertial flow becomes relatively larger. The Reynolds’ number has many practical applications, as it provides engineers with immediate information about the state of flow throughout pipes, streams, and soils, helping them apply the proper relationships to solve the problem at hand. It is also very useful for dimensional analysis and similitude. As an example, Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE if forces acting on a ship need to be studied in the laboratory for design purposes, the Reynolds’ number of the flow acting on the model in the lab and on the prototype in the field should be the same. Fluid mechanics deals with the study of all fluids under static and dynamic situations. Fluid mechanics is a branch of continuous mechanics which deals with a relationship between forces, motions, and statical conditions in a continuous material. This study area deals with many and diversified problems such as surface tension, fluid statics, flow in enclose bodies, or flow round bodies (solid or otherwise), flow stability, etc. Flow behavior in natural or artificial systems depends on which forces (inertia, viscous, gravity, surface tension, etc.) predominate. In slow-moving laminar flows, viscous forces are dominant, and the fluid behaves as if the layers are sliding over each other. Laminar flow is also referred to as streamline or viscous flow. These terms are descriptive of the flow because, in laminar flow, (1) layers of water flowing over one another at different speeds with virtually no mixing between layers, (2) fluid particles move in definite and observable paths or streamlines, and (3) the flow is characteristic of viscous (thick) fluid or is one in which viscosity of the fluid plays a significant part. In turbulent flows, the flow behavior is chaotic and changes dramatically, since the inertial forces are more significant than the viscous forces. Turbulent flow is characterized by the irregular movement of particles of the fluid. There is no definite frequency as there is in wave motion. The particles travel in irregular paths with no observable pattern and no definite layers. Laminar and turbulent flow can occur in two quite different regimes in both nature and laboratory research. When fluid particles move in laminar flows, they do so in layers that slide Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE over one another, resulting in a little energy exchange between the layers. When fluids move slowly and with high viscosity, laminar flow develops. The fluid's particles move and mix randomly in a turbulent flow, on the other hand, and there is a significant energy exchange within the fluid. Low viscosity, high-velocity fluids exhibit this sort of flow. Reynolds’ number, which has no dimensions, is used to categorize the flow condition. A well-known experiment called the Reynolds’ Number Demonstration involves slowly and gradually introducing dye into a pipe to see flow characteristics. II. EQUIPMENT/ MATERIALS NEEDED Table 1.1 List of apparatus used with their specific functions in the experiment Apparatus Use It is used to measure the Thermometer temperature. It is used for containing 1000 mL Beaker and measuring liquids. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE It is used to measure the time interval of an event, Stopwatch which is the filling the beaker with 1000 mL of water and ink solution. It is used to give a visual demonstration of laminar, Reynolds’ Apparatus transition, and turbulent flow. III. PROCEDURES The dye injector was placed within the glass cylinder. Then hose is connected to the water outlet allowing the water to flow through the inner part of the glass cylinder. The plastic outlet valve is opened so that the water will flow to the canal. Potassium permanganate solution is poured into the ink station and its flow is regulated through the equipment. When the ink flow has stabilized as well as the water flow, the ink inflow line and the plastic gate valve was closed slowly. By gradually opening the exit valve, to give successively higher velocities, the time it takes to fill a 1000 mL beaker is measured. While Reynolds’ number in x-axis vs. velocity in y-axis is plotted. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE IV. DATA AND RESULTS Outer diameter of the pipe, m: Thickness of the pipe, m: Inner diameter of the pipe, m: 0.0134 m Density of the fluid, kg/m3: 997.2113 kg/m3 Viscosity of the fluid, Pa·s: 1.0115 x 10˗3 Pa·s Temperature of the Fluid, K: 293.15 K Table 1.2 Time, velocity, and Reynolds’ number for each trial FLOW REGIME LAMINAR TRANSITION TURBULENT TRIAL TIME (s) VELOCITY (m/s) REYNOLD’S NUMBER 1 186 s 0.0381 m/s 503.3280 2 152.4 s 0.0465 m/s 614.2979 3 147 s 0.0482 m/s 636.7561 1 30 s 0.2364 m/s 3123.0114 2 36 s 0.1970 m/s 2602.5095 3 44 s 0.1612 m/s 2129.5662 1 20.77 s 0.3414 m/s 4510.1358 2 20.10 s 0.3528 m/s 4660.7379 3 20.53 s 0.3454 m/s 4562.9786 Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE V. DISCUSSION The data presented above shows the results obtained by the students, specifically the time it took for the fluid to flow during the three fluid flow regimes. To solve the Reynolds’ number in every trial per flow regime, it requires the inner diameter of the outlet pipe. It also requires the velocity, density, and the viscosity of the fluid, which is water. The values taken from the table of Properties of Water of the Perry's Handbook were the following: for the density, 997.2113kg/m 3, and for the viscosity of the fluid, 1.0115x10-3 Pa·s. Using the inner diameter to get the area, the students have computed a value of 1.4103x10-4 m2. Now using this, the students were able to compute the following values of velocity; for Laminar flow trials one to three: 0.0381 m/s, 0.0464 m/s, and 0.0482 m/s, respectively. For Transition flow trials one to three, respectively: 0.2364 m/s, 0.1970 m/s, and 0.1612 m/s. And lastly for turbulent flow trials one to three: 0.3414 m/s, 0.3528 m/s, and 0.3452 m/s. Now for the Reynolds' number, the students have computed the values using the formula given. The values computed for the three trials for Laminar flow are the following: 503.3280, 614.2979, 636.7561. Moreover, for transition flow trials one to three, 3123.0114, 2602.5095, and 2129.5662. And lastly, for the turbulent flow trials one to three, 4510.1358, 4660.7379. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE Reynolds' Number vs. Velocity 0.4 Velocity (m/s) 0.35 0.3 0.25 0.2 0.15 0.1 0.05 0 0 1000 2000 3000 4000 5000 Reynolds' number (Re) Figure 1.1 Reynolds’ Number vs. Velocity To observe laminar, transition, and turbulent velocity profiles related to Reynolds' Number is the learning outcome of this first experiment. By plotting the Reynolds’ Number and the velocity of the fluid, we can observe that there is an existing direct relationship that is proportional between the two variables. Hence, we can say that as the Reynolds’ Number increases, the velocity increases as well. As a result, it can also be emphasized that 0.0381 m/s as the slowest flow velocity and 503.3280 as the smallest value of Reynolds’ Number shows that the fluid flows smoothly, which then, therefore, is laminar. On the other hand, the turbulent flow having the highest velocity of 0.3528 m/s and Reynolds’ Number which is 4660.7379 indicates a rapid flowrate, and can be seen in the apparatus by the naked eye. The transition flow, moreover, pertains to the between status of the laminar and the turbulent flow, having a value of 0.2364 m/s as its velocity and 3123.0114 as its Reynolds’ Number. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE VI. CONCLUSION Three different flow types were observed in the experiment: laminar, transition, and turbulent. In the experiment, the students observed that laminar flow occurred when the ink moved slowly in a straight line parallel to the tube. When the formation of eddies occurs, there are turbulent outbursts, and the ink travels in a waveform, it is in the transition region. Its velocity exceeds that of the laminar flow. On the other hand, it is a turbulent flow when there is already lateral mixing and no discernible ink streamline. The fastest velocity is found in a turbulent flow. The longest time was recorded to attain laminar flow, while the shortest time for turbulent flow. It is a laminar flow when the Reynolds' number (Re) is less than 2100. Reynolds' number for transition flow is greater than or equal to 2100 and lesser than or equal to 4000. The value of Reynolds' number of turbulent flow is above 4000. The experiment's results are in line with the stated conditions. The computed Reynolds’ numbers for the laminar flow are 503.3280, 614.2979, and 636.7561. The transition flow's calculated Reynolds' numbers are 3123.0114, 2602.5095, and 2129.5662. Lastly, the computed Reynolds' numbers for turbulent flow are 4510.1358, 5660.7379, and 4562.9786. It is recommended to ensure that the flow is stable before filling the beaker and recording the time. The beaker must be filled and the time must be recorded synchronously. Filling the beaker up to 1 liter and recording the time must be done carefully and correctly; the persons in charge must be alert and fast. To minimize problems identifying the type of flow seen in the tube, it is also advised to read about the theory and experiment before experimenting. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE VII. REFERENCES 1.1: What is Fluid Mechanics? (2016, July 31). Engineering LibreTexts. https://eng.libretexts.org/Bookshelves/Civil_Engineering/Book%3A_Fluid_Mechanics_( BarMeir)/00%3A_Introduction/1.1%3A_What_is_Fluid_Mechanics%3F Ahmari, H., & Kabir, S. M. I. (2019, August 14). Experiment #7: Osborne Reynolds’ Demonstration. Uta.pressbooks.pub; Mavs Open Press. https://uta.pressbooks.pub/appliedfluidmechanics/chapter/experiment-7/ BYJU'S. (2022, April 26). Reynolds number - definitions, formulas and examples - Byju's. BYJUS. Retrieved August 29, 2022, from https://byjus.com/physics/reynolds-number/ Laminar and Turbulent Flow | Engineering Library. (n.d.). Engineeringlibrary.org. https://engineeringlibrary.org/reference/laminar-and-turbulent-fluid-flow-doe-handbook Sharma, C. (2021, June 15). 8 laminar flow examples in real life. StudiousGuy. Retrieved August 29, 2022, from https://studiousguy.com/laminar-flow-examples/ What is Reynolds number and why is it important? Cadence. (2022, January 14). Retrieved August 29, 2022, from https://resources.system-analysis.cadence.com/blog/msa2022what-is-reynolds-number-and-why-is-it-important Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE VIII. APPENDICES A. Definition of Terms: 1. Laminar Flow - It is a type of flow pattern of a fluid in which all the particles are flowing in parallel lines, opposed to turbulent flow, where the particles flow in random and chaotic directions. 2. Reynolds’ Number - It is the ratio of inertial forces to viscous forces occurring in a fluid flow. 3. Transitional Flow - It is a mixture of laminar and turbulent flow, with turbulence in the center of the pipe, and laminar flow near the edges. 4. Turbulent Flow - It is a type of flow of fluid in which the fluid travels in irregular path. In this type of flow, the speed of the fluid at a point undergoes changes continuously in both magnitude and direction. B. Computations: A= π 2 π Dinner = (0.0134m)2 = 1.4103 × 10−4 m2 4 4 For Laminar Trial 1: q= V 1L 1m3 m3 = × = 5.3763 × 10−6 t 186s 1000L s 3 −6 m 5.3763 × 10 q s = 0.0381 m υ= = −4 A 1.4103 × 10 m2 s kg m Dυρ (0.0134m) (0.0381 s ) (997.2113 m3 ) Re = = = 503.3280 μ 1.0115 × 10−3 Pa. s Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE Trial 2: 1L 1m3 × q m υ = = 152.4s 1000L = 0.0465 −4 2 A 1.4103 × 10 m s kg m Dυρ (0.0134m) (0.0465 s ) (997.2113 m3 ) Re = = = 614.2979 μ 1.0115 × 10−3 Pa. s Trial 3: 1L 1m3 × q m υ = = 147s 1000L = 0.0482 A 1.4103 × 10−4 m2 s kg m Dυρ (0.0134m) (0.0482 s ) (997.2113 m3 ) Re = = = 636.7561 μ 1.0115 × 10−3 Pa. s For Transition Trial 1: 1L 1m3 × q m υ = = 30s 1000L = 0.2364 −4 2 A 1.4103 × 10 m s kg m Dυρ (0.0134m) (0.2364 s ) (997.2113 m3 ) Re = = = 3123.0114 μ 1.0115 × 10−3 Pa. s Trial 2: 1L 1m3 × q m υ = = 36s 1000L = 0.1970 −4 2 A 1.4103 × 10 m s Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE kg m Dυρ (0.0134m) (0.1970 s ) (997.2113 m3 ) Re = = = 2602.5095 μ 1.0115 × 10−3 Pa. s Trial 3: 1L 1m3 × q m υ = = 44s 1000L = 0.1612 −4 2 A 1.4103 × 10 m s kg m Dυρ (0.0134m) (0.1612 s ) (997.2113 m3 ) Re = = = 2129.5662 μ 1.0115 × 10−3 Pa. s For Turbulent Trial 1: 1L 1m3 × q m υ = = 20.77s 1000L = 0.3414 A 1.4103 × 10−4 m2 s kg m (997.2113 ) (0.0134m) (0.3414 ) Dυρ s m3 Re = = = 4510.1358 μ 1.0115 × 10−3 Pa. s Trial 2: 1L 1m3 × q m υ = = 20.10s 1000L = 0.3528 −4 2 A 1.4103 × 10 m s kg m Dυρ (0.0134m) (0.3528 s ) (997.2113 m3 ) Re = = = 4660.7379 μ 1.0115 × 10−3 Pa. s Trial 3: 1L 1m3 × q m υ = = 20.53s 1000L = 0.3454 −4 2 A 1.4103 × 10 m s Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE kg m Dυρ (0.0134m) (0.3454 s ) (997.2113 m3 ) Re = = = 4562.9786 μ 1.0115 × 10−3 Pa. s C. Answers to Questions: A. Give 3 real-life situations each where laminar and turbulent flows are observed. Describe briefly. Laminar: a. Rivers/canals- The water flowing in calm rivers or other bodies of water is slow and smooth. Because there are no waves or swirls in the water body, the different layers of water do not interfere with each other and follow a straight path parallel to each other. b. Taps- When water flows through the tap, there is no turbulence. When water is dispensed from taps, the moment pressure and viscosity become the same at all points in the water. c. Viscous fluid- Fluids such as honey, glycerin, and other syrups exhibit laminar flow. Because the pressure, viscosity, and other physical parameters of a viscous fluid remain constant at each point of the fluid, the laminar flow appears. Turbulent: a. Blood Flow in Arteries- The aortic curve bends the blood flow, causing the blood cells to mix. A bulge in the arteries can sometimes cause turbulent blood flow. This raises radial pressure and shear stress on the artery wall. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE b. Air from Fan/AC- The air from a fan or air conditioner is circulated throughout the room by the fan's rotating blades. The airflow inside the room is chaotic. The particles or dust and the air mix together. c. Car Exhaust- The smoke particles from a car's exhaust pipes do not remain separated; instead, they mix and flow in a random zig-zag pattern, displaying turbulent flow. B. Define Reynolds number and identify what its value implies. Reynolds number is defined by the ratio of inertial forces to viscous forces. Reynolds number is a dimensionless quantity used to determine the type of flow pattern as laminar or turbulent while flowing through a pipe. The flow is laminar if the Reynolds number is less than 2100. The flow through the pipe is turbulent if the Reynolds number is greater than 4000. A transition flow is defined as Reynold's number between 2100 and 4000, indicating a combination of laminar and turbulent flow. C. What is the importance of identifying the Reynolds number in flowing fluids? Reynolds number facilitates the prediction of flow behavior. Identification of flow regime with Reynolds number facilitates the creation of an ideal flow model for efficient fluid system design. Some practical applications include: • Simulation of aircraft or vehicle models in laminar and turbulent flow conditions. • Developing correlation between the heat transfer and friction factor within the flow system. • Prediction of the onset of turbulence can help facilitate large-scale prediction of flow behavior. Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE • Identify pressure requirements with flow rate calculations. D. Documentation: Fig. 1.2 Reynolds’ Apparatus Fig. 1.4 Laminar Flow Fig. 1.3 Adjusting the Valve Fig. 1.5 Filling 1 L Beaker with Water Saint Louis University School of Engineering and Architecture LABORATORY MANUAL TEMPLATE Fig. 1.6 Controlling the Valve Fig. 1.7 Laminar Flow Fig. 1.8 Measuring the Temperature