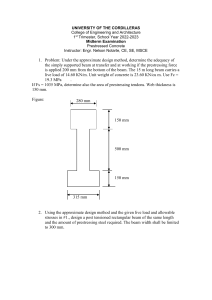

SCE 104: Prestressed Concrete Design Lesson 1: Difference between Prestressed and Reinforced Concrete (Activity Research) Submitted By: Ignacio P. Siervo Jr. BSCE – 4 193808 Submitted To: Engr. Ric L. Gonzaga Associate Professor Overview Introduction Concrete is strong in compression, but weak in tension: its tensile strength varies from 8 to 14 percent of its compressive strength. Due to such a low tensile capacity, flexural cracks develop at early stages of loading. In order to reduce or prevent such cracks from developing, a concentric or eccentric force is imposed in the longitudinal direction of the structural element. This force prevents the cracks from developing by eliminating or considerably reducing the tensile stresses at the critical midspan and support sections at service load, thereby raising the bending, shear, and torsional capacities of the sections. The sections are then able to behave elastically, and almost the full capacity of the concrete in compression can be efficiently utilized across the entire depth of the concrete sections when all loads act on the structure. Such an imposed longitudinal force is called a prestressing force, i.e., a compressive force that prestresses the sections along the span of the structural element prior to the application of the transverse gravity dead and live loads or transient horizontal live loads. The type of prestressing force involved, together with its magnitude, are determined mainly on the basis of the type of system to be constructed and the span length and slenderness desired. Since the prestressing force is applied longitudinally along or parallel to the axis of the member, the prestressing principle involved is commonly known as linear prestressing. Circular prestressing, used in liquid containment tanks, pipes, and pressure reactor vessels, essentially follows the same basic principles as does linear prestressing. The circumferential hoop, or “hugging” stress on the cylindrical or spherical structure, neutralizes the tensile stresses at the outer fibers of the curvilinear surface caused by the internal contained pressure. Figure 1.1 illustrates, in a basic fashion, the prestressing action in both types of structural systems and the resulting stress response. In (a), the individual concrete blocks act together as a beam due to the large compressive prestressing force P. Although it might appear that the blocks will slip and vertically simulate shear slip failure, in fact they will not because of the longitudinal force P. Similarly, the wooden staves in (c)might appear to be capable of separating as a result of the high internal radial pressure exerted on them. But again, because of the compressive prestress imposed by the metal bands as a form of circular prestressing, they will remain in place. Comparison with Reinforced Concrete It is plain that permanent stresses in the prestressed structural member are created before the full dead and live loads are applied, in order to eliminate or considerably reduce the net tensile stresses caused by these loads. With reinforced concrete, it is assumed that the tensile strength of the concrete is negligible and disregarded. This is because the tensile forces resulting from the bending moments are resisted by the bond created in the reinforcement process. Cracking and deflection are therefore essentially irrecoverable in reinforced concrete once the member has reached its limit state at service load. The reinforcement in the reinforced concrete member does not exert any force of its own on the member, contrary to the action of prestressing steel. The steel required to produce the prestressing force in the prestressed member actively preloads the member, permitting a relatively high controlled recovery of cracking and deflection. Once the flexural tensile strength of the concrete is exceeded, the prestressed member starts to act like a reinforced concrete element. By controlling the amount of prestress, a structural system can be made either flexible or rigid without influencing its strength. In reinforced concrete, such a flexibility in behavior is considerably more difficult to achieve if considerations of economy are to be observed in the design. Flexible structures such as fender piles in wharves have to be highly energy absorbent, and prestressed concrete can provide the required resiliency. Structures designed to withstand heavy vibrations, such as machine foundations, can easily be made rigid through the contribution of the prestressing force to the reduction of their otherwise flexible deformation behavior. Advantages and Disadvantages of Reinforced and Prestressed Concrete Reinforced Concrete Advantages Disadvantages 1. Reinforced concrete has a high 1. The tensile strength of reinforced compressive strength compared concrete is about one-tenth of its to other building materials. compressive strength. 2. Due to the provided reinforcement, 2. The main steps of using reinforced reinforced concrete are mixing, concrete can also withstand a casting, and curing. All of this good amount of tensile stress. affect the final strength. 3. Fire and weather resistance of reinforced concrete is fair. 3. The cost of the forms used for casting is relatively higher. 4. The reinforced concrete building 4. For multi-storied building the RCC system is more durable than any column section for is larger than other building system. steel section as the compressive 5. Reinforced concrete, as a fluid material, in the beginning, can be economically molded into a nearly limitless range of shapes. 6. The maintenance cost of reinforced concrete is very low. 7. In the structure like footings, dams, piers, etc., reinforced concrete is the most economical construction material. 8. It acts like a rigid member with minimum deflection. 9. As reinforced concrete can be molded to any shape required, it is widely used in precast structural components. It yields rigid strength is lower in the case of; 5. Shrinkage causes crack development and strength loss. members with minimum apparent deflection. 10. Compared to the use of steel in structure, reinforced concrete requires less skilled labor for the erection of the structure. Prestressed Concrete Advantages Disadvantages 1. Precast members like electric 1. Prestressed concrete sections poles and railway sleepers are are more brittle because of use of produced in factories using simple high-tension steel. pre-stressing methods. 2. Prestressed 2. Prestressed concrete is used in the structures where tension develops or the structure is concrete requires specialized tensioning equipment and devices which are very costly. 3. Cost of materials used in subjected to vibrations, impact prestressed is very high (high and shock like girders, bridges, tensile steel is about three times railway sleepers, electric poles, costlier than mild steel). gravity dams, etc. 3. Since the concrete does not crack in prestressed concrete, rusting of steel is minimized. 4. Since the concrete does not crack in prestressed concrete, rusting of steel is minimized. 5. Prestressed concrete members show less deflection. 6. Long span bridges and flyovers are made of prestressed concrete because of lesser self-weight and 4. Prestressed concrete construction requires very good quality. thinner section. So, prestressed concrete is used for heavily loaded structures. 7. Thinner sections in prestressed concrete results in less selfweight and hence overall economy. 8. In prestressed concrete, whole concrete area is effective in resisting loads, unlike RCC where concrete below the neutral axis is neglected. 9. Prestressed concrete sections are thinner and lighter than RCC sections, since high strength concrete and steel are used prestressed concrete. Sample Problems 1. Consider the prestressed concrete beam shown below, which is to be used in an industrial building construction. The beam is only reinforced with prestressing steel and no mild reinforcement is used. What is the maximum live load that this beam can carry (in addition to the self-weight) considering only the allowable section stresses at Midspan? The Material properties and prestressing are as follow: 𝑓 ′ 𝑐 = 40𝑀𝑃𝑎 𝑓 ′ 𝑐𝑖 = 35𝑀𝑃𝑎 𝑓𝑝𝑢 = 1860𝑀𝑃𝑎 𝑓 ′ 𝑝𝑖 = 1120𝑀𝑃𝑎 ∆𝑓𝑝𝑇 = 140𝑀𝑃𝑎 (𝑡𝑜𝑡𝑎𝑙 𝑙𝑜𝑒𝑠𝑠𝑒𝑠) 𝐴𝑝𝑠 = 8𝜙𝑠 13 = 8 × 99𝑚𝑚2 /𝑠𝑡𝑟𝑎𝑛𝑑 𝑓𝑡 = 0.5√𝑓′𝑐 𝑎𝑛𝑑 𝑓𝑐 = 0.45𝑓′𝑐 2. Design for service load condition, a post-tensioned T-section to carry a total service load of 15 𝑘𝑁 𝑚 (not including self-weight) on a 12𝑚 simply supported span. Design the section for zero-tension, for 𝑓𝑐𝑖 = 12.5𝑀𝑃𝑎 and 𝑓𝑐 = 11𝑀𝑃𝑎 at transfer and service conditions, respectively. Assume that the sectional properties are 𝑏𝑓 = 0.5ℎ, ℎ𝑓 = 0.2ℎ, 𝑏𝑤 = 0.25ℎ and use multiples of 50𝑚𝑚 for ℎ. Assume the self-weight of the beam is 6.0 𝑘𝑁 𝑚 and the following prestressing data. 𝑓 ′ 𝑐 = 35𝑀𝑃𝑎 𝑓 ′ 𝑐𝑖 = 30𝑀𝑃𝑎 𝑓𝑝𝑢 = 1860𝑀𝑃𝑎 𝑓 ′ 𝑝𝑖 = 1300𝑀𝑃𝑎 ∆𝑓𝑝𝑇 = 250𝑀𝑃𝑎 𝐴𝑝𝑠 = 1𝜙𝑠 13 = 99𝑚𝑚2 /𝑠𝑡𝑟𝑎𝑛𝑑 3. A 300𝑚𝑚 × 400𝑚𝑚 concrete beam has a span of 6𝑚. A posttension force of 640 𝑘𝑁 was applied at a point 70 𝑚𝑚 above the bottom of the beam. Assume concrete wont crack in tension. 𝑓′𝑐 = 20.7 𝑀𝑃𝑎. Unit weight of concrete is 23.5 𝑘𝑁/𝑚3. a. Compute the deflection due to pre-stressing force of 240 𝑘𝑁. b. Compute the net deflection of the beam immediately after transfer. c. Computer the safe uniform live load that maybe imposed on the beam so that there will be a net deflection upward of 5 𝑚𝑚. Solution: a. Deflection due to prestressing force of 240 𝑘𝑁. 𝑒 = 200 − 70 = 130 𝑚𝑚 𝑀 = 𝑃𝑒 𝑀 = (640)(1.3) = 83.2 𝑘𝑁 ⋅ 𝑚 𝐼= (300)(400)2 12 = 1600 × 106 𝐸 = 4700√𝑓′𝑐 𝐸 = 4700√20.7 = 21384 𝑀𝑃𝑎 𝛿1 = 𝑀𝐿2 8𝐸𝐼 83.2×106 (6000)2 𝛿1 = 8(21384)(1600)106 𝜹𝟏 = 𝟏𝟎. 𝟗𝟒 𝒎𝒎 (𝒖𝒑𝒘𝒂𝒓𝒅) b. Net deflection of the beam immediately after transfer. 𝑊 = (0.3)(0.4)(23.5)(6) = 2.82 5𝑊𝐿2 𝛿2 = 384𝐸𝐼 5(2820)(6)(6000)2 𝛿2 = 384(21384)(1600)106 𝛿2 = 1.39 𝑚𝑚 Net Deflection 𝛿 = 𝛿1 − 𝛿2 𝛿 = 10.94 − 1.39 𝜹 = 𝟗. 𝟓𝟓 𝒎𝒎 (𝒖𝒑𝒘𝒂𝒓𝒅) 𝑘𝑁 𝑚 c. Safe uniform live load that maybe imposed on the beam so that there will be a net deflection upward of 5 𝑚𝑚. 9.55 − 𝛿4 = 5 𝑚𝑚 𝛿4 = 4.55 𝑚𝑚 5𝑊𝐿2 𝛿4 = 384𝐸𝐼 5𝑊(1000)(6)(6000)2 4.55 = 384(21384)(1600)106 𝑾 = 𝟗. 𝟐𝟑 𝒌𝑵 𝒎 4. A post-tensioned bonded concrete beam has a prestress of 1560 kN in the steel immediately after prestressing which eventually reduces to 1330 kN. The beam carries two live loads of 45 kN each in addition to itw own weight of 4.40 kN/m. compute the extreme fiber stresses at mid-span: a. Under the initial condition with full prestress and no live load b. Under final condition after all the losses have taken place and with full live load. 5. The flooring of a warehouse is made up of double tee joists (DT). The joists are simply supported on a span of 7.5 m and are pre-tensioned with one tendon in each stem with an initial force of 745 kN each, located at 75 mm above the bottom fiber, loss of stress service load is 18%. 𝐿𝑜𝑎𝑑 𝑖𝑚𝑝𝑜𝑠𝑒𝑑 𝑜𝑛 𝑡ℎ𝑒 𝑗𝑜𝑖𝑠𝑡𝑠: 𝑃𝑟𝑜𝑝𝑒𝑟𝑡𝑖𝑒𝑠 𝑜𝑓 𝐷𝑇: 𝐷𝑒𝑎𝑑 𝑙𝑜𝑎𝑑 = 2.3 𝑘𝑃𝑎 𝐴 = 200,000𝑚𝑚2 𝐿𝑖𝑣𝑒 𝑙𝑜𝑎𝑑 = 6.0 𝑘𝑃𝑎 𝐼 = 1880 × 106 𝑚𝑚4 𝑎 = 2.4 𝑚 𝑦𝑡 = 88 𝑚𝑚 𝑦𝑏 = 267 𝑚𝑚 a. Compute the stress at the bottom fibers of the DT at mid-span due to the initial prestressing force alone. b. Compute the resulting stress at the bottom fibers of the DT at mid-span due to the service loads and prestress force. c. What additional super imposed load can DT carry such that the resulting stress at the bottom fiber at mid-span is zero. 6. A concrete beam with cross-section area of 32 × 103 𝑚𝑚2 and the radius of gyration is 72 mm is prestressed by a parabolic cable carrying an effective stress of 1000N/mm2. The span of the beam is 8 m, the cable composed of 6 wires of 7 mm diameter has an eccentricity of 50 mm at the center and zero at the supports. Neglecting all losses, find the central deflection of the beam as follows: a. Self-weight + prestress b. Self-weight + prestress + live load of 2kN/m 7. A prestressed concrete beam, 100 mm wide and 300 mm deep, is prestressed by straight, wires carrying an initial force of 150 kN at an eccentricity of 50 mm. the modulus of elasticity of steel and concrete are 210 and 35 kN/mm2 respectively. Estimate the percentage loss of stress in steel due to elastic deformation of concrete if the area of steel wires is 188 mm 2. 8. A Single-T prestressed concrete beam shown below is simply supported having a span of 10 m. It carries a superimposed live load of 15.08kN/m in addition to the weight of beam. It is prestressed with 700 mm 2 of steel to an initial stress of 1034 N/mm2 located 400 mm from the topmost fiber of the beam section. Immediately after transfer, the stress reduced by 12%. Determine the stresses at L/4 from the support due to losses in prestress and final service loads. Use concrete weight equals to 24kN/m3 9. A beam with width b = 300mm and depth d = 600mm is to be prestressed. Considering a 15% prestress loss, compute the value of initial prestressing force P and eccentricity e. a. If the compressive stress is 21 MPa. b. If the compressive stress at the bottom fiber is 12 MPa and a tensile stress at the fiber is 2 MPa. c. If he compressive stress at the top is 16 MPa 10. A beam with width b = 250 mm and depth d = 450 mm is prestressed by an initial force of 600 kN. Total loss of prestress at service load is 15%. 1. Calculate the resulting final compressive stress if the prestressing force is applied the centroid of the beam section. 2. Calculate the final compressive stress if the prestressing force is applied at an eccentricity of 100 mm below the centroid of the beam section. 3. Calculate the eccentricity at which the prestressing force can be applied so that the resulting tensile stress at the top fiber of the beam is zero.