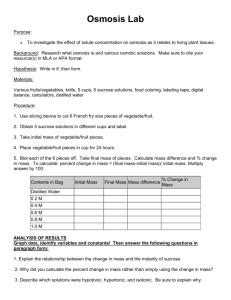

The effects of sucrose concentration on mass loss in the russet potato, Solanum tuberosum Author 1, Author 2, Author 3, and Author 4 Abstract Osmosis has many implications for improving food preservation and water treatment. Freshly harvested russet potatoes, Solanum tuberosum, contain about 20% dry matter and 80% water, making them an ideal model for osmosis studies. We tested the effects of differently concentrated sucrose solutions on mass change in russet potatoes. We hypothesized that higher solute concentrations in the extracellular matrix will cause potatoes to lose mass as the water inside them is displaced outwards via osmosis. Russet potatoes were cored, and individually weighed before and after their immersion in six different sucrose solutions for two hours. We found that at medium and high concentrations of sucrose, the potatoes lost an average percent mass ranging from 13.4% to 41% but lost negligible mass at a low sucrose concentration. Statistical analyses of our results provide support for our alternative hypothesis and allow us to conclude on the effects that disparate osmosis solutions can have on the mass of russet potatoes. Introduction Osmosis is the net movement of water across a selectively permeable membrane due to differences in pressure across the membrane. How water moves through a selectively permeable membrane is dependent on the solute concentration on both sides of the membrane. There are three different osmotic conditions to which cells can be subjected. First, when solute concentrations on both sides of the membrane are equal, it is termed an isotonic environment. Second, when the solute concentration is greater inside the cytoplasm of the cell than the solute concentration outside the cell, the cell is said to be in a hypertonic environment. Lastly, when the solute concentration is greater outside the cell than in the cytoplasm, the cell is said to be in a hypotonic environment (Cath et al., 2006). The science of osmosis has many implications for improving food preservation ability and food processing (Blandin et al., 2020; Cassano et al., 2020). There are several advantages to using osmotic processes over conventional methods, including more economical setups and maintenance, and the conservation of nutrients that are otherwise damaged or destroyed in high-temperature methods (Cassano et al., 2020). Additionally, these processes are ecofriendly, sanitary, and user–friendly since osmotic dehydration increases shelf life, ensures retention of vitamins and minerals, flavor, color, and taste (Ahmad & Ahmed, 2014; Yadav & Singh, 2012). Improvements in membrane technologies have allowed for advancements in the quality and efficiency of food processing in products; these technologies have high potential to serve the growing market for “functional foods,” which are foods that offer health benefits beyond their basic nutritional value (Ahmad & Ahmed, 2014). While osmotic dehydration can be applied to a wide array of vegetables and fruits, only potatoes were studied in this experiment. Potatoes are affordable and have been a vital part of the human diet for many years. Freshly harvested potatoes contain about 80 percent water and 20 percent dry matter. About 60 to 80 percent of the dry matter is starch. The high concentration of water in potatoes makes them an ideal model for osmosis studies. Their change in weight before and after submerging in different solute concentrations is easily measured and distinguishable. The advantages of this approach include its low cost, the availability of the materials required, and the processes’ convenient reversibility (Robertson et al., 2018). To investigate osmotic processes, we tested the effects of sucrose concentration in aqueous solution on the percent mass change in russet potatoes, Solanum tuberosum by coring and immersing them in six different sucrose concentrations for two hours. If the movement of water in and out of plant cells is dependent upon the plant's osmolarity compared to the surrounding fluid, then the potato's mass will decrease in hypertonic environments, increase in hypotonic environment, and remain unchanged in an isotonic environment because there is no net movement of water. Materials and methods Using a core borer, five potato cores were obtained from each russet potato. A total of six russet potatoes (S. tuberosum) were cored to obtain a total of 30 cylindrical cores measuring 5 cm long and 1 cm in diameter. Each core was individually weighed before and after it was submerged into one of the six sucrose solutions using a triple beam balance to measure the change in mass. The treatments consisted of varying amounts of granular sucrose dissolved in 100 mL of distilled water. To obtain a 1000 mM solution, 34.23 g of sucrose were weighed and poured in a beaker followed by 50 ml of distilled water, once the solution was mixed with a stir bar, another 50 ml of distilled water were added to reach a final volume of 100 ml. The same procedure was followed for the 800 mM M, 600 mM, 400 mM, 200 mM and 0 mM solutions and only the amount of sucrose was modified to: 27.38 g, 20.53 g, 13.69 g, and 0.68 g respectively. Potato cores were placed in every sucrose solution for two hours and the five replicates were performed consecutively (n = 5). Data was entered in a Microsoft Excel spreadsheet as percent of mass changed calculated by dividing the weight lost after being exposed to an osmotic solution (final weight – initial weight), by the initial weight of the core times one hundred. The measures of central tendency (x̄) and dispersion (SD) were calculated using Microsoft Excel’s MEAN and STDEV.S functions. A bar chart was built to show average percent mass change at each sucrose concentration with standard error (SE) bars calculated automatically within the plotting options in Microsoft Excel. Finally, a two-tailed t-test was performed using Microsoft Excel’s t-test function for each comparison between molar concentrations. Results The exposure of russet potatoes to disparate sucrose solutions resulted in an increase and decrease of mass. Tuber cores exposed to a 0-molar concentration of sucrose increased their mass due to water absorption (x̄ = 20%, SD = 1.58). Cores submerged in 200 mM sucrose solutions gained negligible mass (x̄ = 0.4%, SD = 4.04). Trials performed in solutions with sucrose concentrations that exceeded 200 mM displayed a proportional loss of mass with increasing sucrose molarity (Table 1). At 400, 600, 800, and 1000 mM concentration of sucrose, potatoes cores lost: x̄ = 13.4%, SD = 2.7; x̄ = 22%, SD = 2.35; x̄ = 25.8%, SD = 0.89; and x̄ = 41%, SD = 2.83, respectively (Table 1, Figure 1). Table 1. Percent mass change of potatoes at five different molar concentrations of sucrose. Trials 1 2 3 4 5 Average 0 mM 20 18 22 21 19 20 200 mM 0 1 5 -6 2 0.4 400 mM -10 -13 -15 -12 -17 -13.4 600 mM -23 -22 -18 -23 -24 -22 800 mM -25 -25 -25 -27 -25 -25.4 1000 mM -38 -42 -43 -44 -38 -41 A total of 15 t-tests were conducted and determined that, in fact, the difference of means is statistically significant amongst all treatments (t > 3.39, df = 8, p < 0.05). 1. There were significant differences between a molar concentration of 0.0 and all other molar concentrations with a significant percent decrease at 200 mM (t = 10.10793, df = 8, p < 0.0001), 400mM (t = 23.85714, df = 8, p < 0.0001), 600 mM (t = 33.20392, df = 8, p < 0.0001), 800 mM (t = 55.88354, df = 8, p < 0.0001), and 1000 mM (t = 42.094, df = 8, p < 0.0001). 2. At a concentration of 200 mM, statistically significant differences occurred in comparisons with higher molar concentrations with a significant percent decrease at 400 mM (t = 6.35197, df = 8, p = 0.00022), 600 mM (t = 10.72765, df = 8, p < 0.0001), 800 mM (t = 13.95104, df = 8, p < 0.0001) and 1000 mM (t = 18.77942, df = 8, p < 0.0001). 3. At a concentration of 400 mM, statistically significant differences occurred in comparisons with higher molar concentrations with a significant percent decrease at 600 mM (t = 5.375, df = 8, p = 0.000666), 800 mM (t = 9.42809, df = 8, p = 0.00013) and 1000 mM (t = 15.77787, df = 8, p < 0.0001). 4. At a concentration of 600 mM, statistically significant differences occurred in comparisons with higher molar concentrations with a significant percent decrease at 800 mM (t = 3.02896, df = 8, p = 0.016335) and 1000 mM (t = 11.56303, df = 8, p < 0.0001). 5. Lastly, a concentration of 800 mM a statistically significant difference occurred in comparison with 1000 mM which had a significant percent decrease (t = 11.7584, df = 8, p < 0.0001). These results support our hypothesis that higher extracellular solute concentrations will cause russet potatoes to lose mass as the water inside them is displaced towards the solution via osmosis, whereas low solute concentrations cause an opposite effect, and water moves inside the tuber. 0.4 20 -41 -25.4 -22 -13.4 Mass change (%) 1 Sucrose concentration (M) Figure 1. Percent mass change of russet potatoes at different molar concentrations of sucrose shown in: blue = 0 mM, orange = 200 mM, gray = 400 mM, yellow = 600 mM, light blue = 800 mM, green = 1000 mM. Error bars are displayed along each bar. Discussion In this experiment, we demonstrated that increasing the molar concentration of sucrose resulted in a decrease of the average percent mass of the russet potato, due to water flowing towards levels of higher solute concentration (see Figure 1). Our results show a similar trend observed by Eren and Ertekin (2007), where it was determined that 54.5% sucrose concentration is optimum for the greatest water loss during osmotic dehydration. Osmosis plays a role in maintaining homeostasis in the cells of various organisms, including potatoes. Osmotic dehydration is an alternative food processing procedure used to preserve potatoes. It has the potential to lower packaging and distribution costs while maintaining product quality by reducing the amount of structural collapse and dripping in the potatoes commonly seen during thawing (Torreggiani, 1993). Previously, at an optimum sucrose concentration of 54.5%, the dehydration process has been shown to enhance the effectiveness of subsequent methods of drying potatoes, like hotair drying and intermittent microwave application (Eren and Ertekin 2007; Deyghannya et al. 2018). In a previous study, Lenart and Flink (1984) used 10 mm potato cubes to establish osmosis equilibrium by exposing them between 4 and 20 hours to osmosis solutions. The disparity between our results and those of these groups could be attributed to methodological differences, such as differences in the size of the potatoes utilized in the experiment as well as the time course. While there have been a substantial number of studies investigating the effect of sucrose concentration on the rate of osmosis in vegetables (Cassano et al., 2020), there are scarce studies in the Solanum genus. However, our results do show a similar trend when compared to previous studies of phylogenetically unrelated fleshy fruits such as apricot using varying concentrations of sucrose (Chung et al., 2013; Garcia-Castello et al., 2009). While our results show a statistically significant difference between different sucrose concentrations, care should be taken when drawing conclusions due to procedural limitations. The duration of potato cores submerged in the solutions was limited to two hours due to the time constraints of lab procedures. Ideally, S. tuberosum cores should be subjected to the treatments overnight. Furthermore, our experiment features only five replicates of each treatment. Other factors such as temperature and salt concentration have been shown to affect the rate of osmosis (Phuntsho et al., 2012; Wang et al., 2021). Future work should focus on how these variables affect osmosis in not only the russet potato, but closely related S. tuberosum cultivars as well, such as the “yukon gold”. Moreover, comparing the effects of different types of sugars on mass percent change with additional consideration on how their molecular structures might permeate through the membrane and modify their flavor could aid on how these starch rich foods are industrially processed. Acknowledgments We would like to thank Dr. Carrie Monjé for providing the inspiration for this experiment and feedback. Additionally, we thank Todd Bollinger and Daniela Arenas-Viveros for editing and providing feedback on the paper. Lastly, we would like to thank the Department of Biological Sciences at Texas Tech University for providing the materials necessary to carry out this experiment. Literature Cited Ahmad, S., & Ahmed, S. M. (2014). Application of membrane technology in food processing. In Food Processing: Strategies for Quality Assessment (pp. 379-394). Springer, New York, NY. Blandin, G., Ferrari, F., Lesage, G., Le-Clech, P., Héran, M., & Martinez-Lladó, X. (2020). Forward osmosis as concentration process: Review of opportunities and challenges. Membranes, 10(10):284. https://doi.org/10.3390/membranes10100284 Cassano, A., Rastogi, N. K., & Basile, A. (2020). Reverse osmosis in food processing. In Current Trends and Future Developments on (Bio-) Membranes (pp. 229-257). Elsevier. Cath, T. Y., Childress, A. E., & Elimelech, M. (2006). Forward osmosis: principles, applications, and recent developments. Journal of membrane science, 281(1-2):70-87. Chung, H. S., Kim, D. S., Kim, H. S., Lee, Y. G., & Seong, J. H. (2013). Effect of freezing pretreatment on the quality of juice extracted from Prunus mume fruit by osmosis with sucrose. LWT-Food Science and Technology, 54(1):30-34. Dehghannya, J., Bozorghi, S., & Heshmati, M. K. (2018). Low temperature hot air drying of potato cubes subjected to osmotic dehydration and intermittent microwave: Drying kinetics, energy consumption and product quality indexes. Heat and Mass Transfer, 54(4):929-954. Eren, I., & Ertekin-Kaymak, F. (2007). Optimization of osmotic dehydration of potato using response surface methodology. Journal of Food Engineering, 79(01):344-352. Garcia-Castello, E. M., McCutcheon, J. R., & Elimelech, M. (2009). Performance evaluation of sucrose concentration using forward osmosis. Journal of membrane science, 338(12):61-66. Lenart, A., & Flink, J. M. (1984). Osmotic concentration of potato. I. Criteria for the end‐point of the osmosis process. International Journal of Food Science & Technology, 19(1):4563. Phuntsho, S., Vigneswaran, S., Kandasamy, J., Hong, S., Lee, S., & Shon, H. K. (2012). Influence of temperature and temperature difference in the performance of forward osmosis desalination process. Journal of membrane science, 415: 734-744. Robertson, T.M.; Alzaabi, A.Z.; Robertson, M.D.; Fielding, B.A. (2018). Starchy carbohydrates in a healthy diet: the role of the humble potato. Nutrients, 10:1764. https://doi.org/10.3390/nu10111764 Torreggiani, D. (1993). Osmotic dehydration in fruit and vegetable processing. Food Research International, 26(1):59-68. Wang, J., Zhao, S., Dou, P., Li, X., Li, D., & He, T. (2021). Sustainable fertilizer-drawn forward osmosis for the vegetable industry in reducing liquor from vegetable waste. Environmental technology, 42(3):388-396. Yadav, Ashok Kumar, and Satya Vir Singh. (2014). Osmotic dehydration of fruits and vegetables: a review. Journal of food science and technology vol. 51(9):1654-1673. doi:10.1007/s13197-012-0659-2