GEM USER GUIDE

COMPOSITIONAL & UNCONVENTIONAL

RESERVOIR SIMULATOR

VERSION 2015

15.GE.M3

This publication and the application described in it are furnished under license

exclusively to the licensee, for internal use only, and are subject to a confidentiality

agreement. They may be used only in accordance with the terms and conditions of

that agreement.

All rights reserved. No part of this publication may be reproduced or transmitted in any

form or by any means, electronic, mechanical, or otherwise, including photocopying,

recording, or by any information storage/retrieval system, to any party other than the

licensee, without the written permission of Computer Modelling Group.

The information in this publication is believed to be accurate in all respects.

However, Computer Modelling Group makes no warranty as to accuracy or

suitability, and does not assume responsibility for any consequences resulting from

the use thereof. The information contained herein is subject to change without notice.

Copyright 2015 Computer Modelling Group Ltd.

All rights reserved.

Reprise License Manager (RLM)

Copyright 2006-2015, Reprise Software, Inc.

All rights reserved.

GEM uses Intel(R) Compilers.

GEM, CMG, and Computer Modelling Group are registered trademarks of Computer

Modelling Group Ltd. All other trademarks are the property of their respective

owners.

Computer Modelling Group Ltd.

200, 1824 Crowchild Trail N.W.

Calgary, Alberta Canada T2M 3Y7

Tel: (403) 531-1300

Fax: (403) 289-8502

E-mail: cmgl@cmgl.ca

Preface

GEM is CMG's advanced general equation-of-state compositional simulator which

includes options such as equation-of-state, dual porosity, CO2, miscible gases,

volatile oil, gas condensate, horizontal wells, well management, complex phase

behavior and many more. GEM was developed to simulate compositional effects of

reservoir fluid during primary and enhanced oil recovery processes.

This User Guide presents the important mechanisms which occur during gas injection

processes and the equations that describe those mechanisms. The techniques used in

GEM to solve these equations are also described. This User Guide is aimed at

reservoir engineers who want to use GEM to design gas injection processes for

enhanced oil recovery. It requires some basic knowledge of reservoir engineering and

some rudimentary exposure to reservoir simulation. This User Guide provides a stepby-step procedure for preparation of input data for this program. A tutorial section is

provided as well as a set of appendices.

Every attempt has been made in the preparation of this User Guide to provide the

user with all the necessary details. If questions arise, please contact:

Computer Modelling Group Ltd.

200, 1824 Crowchild Trail N.W.

Calgary, Canada

T2M 3Y7

Telephone: (403) 531-1300 Fax: (403) 289-8502 E-mail: cmgl@cmgl.ca

Confidentiality: All components of CMG technology including software and related

documentation are protected by copyright, trademark and secrecy. CMG technology

can be used only as permitted by your license from CMG. By the license, you have

agreed to keep all CMG technology confidential and not disclose it to any third party.

All rights reserved. No part of this publication may be reproduced or transmitted in any

form or by any means, electronic, mechanical, or otherwise, including photocopying,

recording, or by any information storage/retrieval system, to any party other than the

licensee, without the written permission of Computer Modelling Group.

Corrections/Errors: CMG ENDEAVORS TO PRODUCE TECHNOLOGY OF THE HIGHEST

QUALITY; NEVERTHELESS ERRORS OR DEFICIENCIES IN SUCH TECHNOLOGY ARE

INEVITABLE. IF YOU FIND AN ERROR OR DEFICIENCY, YOU ARE REQUESTED TO

PROVIDE DETAILS OF IT AND ILLUSTRATIVE DATA SET(S) TO CMG SUFFICIENT TO

PERMIT CMG TO REPRODUCE THE ERROR OR DEFICIENCY. CMG SHALL ENDEAVOR

TO REMEDY A DEFICIENCY IN A TIMELY MANNER AND SHALL PERIODICALLY

REPORT TO YOU AS TO THE STEPS BEING TAKEN TO REMEDY THE DEFICIENCY. THE

RESPONSE TIME FOR A DEFICIENCY MUST BE PRIORITIZED FOR THEIR GENERAL

APPLICATION TO CMG MEMBERS AND WHETHER THEY FORM PART OF A CMG

PROGRAM. CMG DOES NOT WARRANT THAT DEFICIENCIES WILL BE REMEDIED.

Limited Liability: CMG does not warrant the accuracy or usefulness of the

technology and software - Refer to your license.

Contents

Introduction

1

Important Changes in GEM 2015.10 ............................................................................ 1

Important Changes in GEM 2014.10 ............................................................................ 8

Important Changes in GEM 2013.10 .......................................................................... 15

Important Changes in GEM 2012.10 .......................................................................... 21

Important Changes in GEM 2011.10 .......................................................................... 25

Important Changes in GEM 2010.10 .......................................................................... 31

Important Changes in GEM 2009.10 .......................................................................... 34

Important Changes in GEM 2008.10 .......................................................................... 38

Important Changes in GEM 2007.10 .......................................................................... 42

Important Changes in GEM 2006.10 .......................................................................... 45

Important Changes in GEM 2005.10 .......................................................................... 46

Important Changes in GEM 2004.10 .......................................................................... 48

Important Changes in GEM 2003.10 .......................................................................... 49

Important Changes in GEM 2002.10 .......................................................................... 50

Important Changes in GEM 2001.10 .......................................................................... 51

Important Changes in GEM 2000.10 .......................................................................... 53

Introduction to GEM ................................................................................................... 54

Tutorial

57

Introduction................................................................................................................. 57

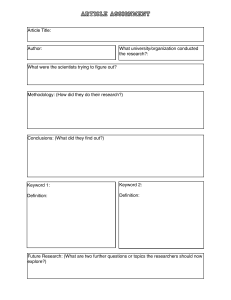

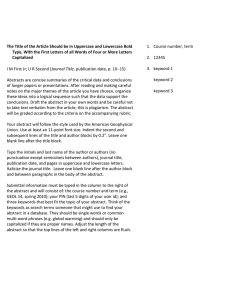

Data Groups in the Keyword Input System ................................................................ 58

How to Document Your Data Set ............................................................................... 59

How to Do a Restart.................................................................................................... 60

Controlling Contents of the Output Print File............................................................. 62

Controlling Contents of the Simulation Results File .................................................. 63

Describing Your Grid System..................................................................................... 64

Describing Refined Grid ............................................................................................. 66

Entering Null Blocks .................................................................................................. 67

Using Dual Porosity/Dual Permeability...................................................................... 68

Using the Aquifer Option ........................................................................................... 69

Problems with Small Timesteps or Long Execution Times ........................................ 70

Simulating a Single Phase Reservoir .......................................................................... 73

Horizontal Wells ......................................................................................................... 74

GEM User Guide

Contents • i

Vertical Equilibrium Calculation ............................................................................... 75

Defining Wells ........................................................................................................... 77

How to Shut In a Well and Reopen It......................................................................... 78

Using the Wellbore Model ......................................................................................... 80

Operating and Monitoring Constraints ....................................................................... 81

Entering Well Indices ................................................................................................. 83

Stopping a Simulation Run......................................................................................... 84

Guidelines for Setting Up Well Data.......................................................................... 85

Recurrent Data from Other Sections .......................................................................... 87

Parallel GEM .............................................................................................................. 88

Saline Water Injection ................................................................................................ 90

Using the Oil Wet Option........................................................................................... 91

Two and Three Point Scaling of Relative Permeability Values ................................. 97

Modelling Non-Darcy Flow in Hydraulic Fractures Accurately Using a Grid

Based Approach .................................................................................................. 100

Introducing a Hydraulic Fracture in Recurrent Data ................................................ 107

Using the Thermal Option in GEM .......................................................................... 108

One-way Geomechanics Calculations using Post-Processing of Prior Simulator

Response (GEOPOSTPRO) ................................................................................ 111

Keyword Data Entry System

115

Introduction to Keyword System.............................................................................. 115

Comments (Optional) ............................................................................................... 120

Blank Lines (Optional) ............................................................................................. 121

Scan Mode for Checking Errors ............................................................................... 122

Include Files (Optional)............................................................................................ 123

Controlling Data File Listing (Optional) .................................................................. 124

Changing the Comment Indicator (Optional) ........................................................... 125

Changing the Keywords by Using Translate Rules (Optional) ................................ 126

User Block Address .................................................................................................. 127

Input of Grid Property Arrays .................................................................................. 128

Entering Matrix Grid Properties ............................................................................... 130

Entering Fracture Grid Properties ............................................................................ 131

Entering Refined Grid Properties ............................................................................. 132

Assign Data to Block Groups ................................................................................... 133

Assigning Grid Properties to all Elements ............................................................... 135

Constant Value Arrays ............................................................................................. 136

Array Input in IJK Notation ..................................................................................... 137

Array Input of Values that Vary in the I Direction................................................... 139

Array Input of Values that Vary in the J Direction .................................................. 140

Array Input of Values that Vary in the K Direction ................................................. 141

Values that Vary for Most or All Grid Blocks ......................................................... 142

Values Stored in Binary Form .................................................................................. 143

ii • Contents

GEM User Guide

J and K Direction Data from I Direction .................................................................. 145

Modifying Array Data (Conditional) ........................................................................ 146

Interpolating Table Data (Optional).......................................................................... 149

Input/Output Control

151

Notes on Input/Output Control ................................................................................. 151

Command-Line Arguments (Optional) ..................................................................... 152

Input/Output File Names (Optional) ......................................................................... 158

Run-Time Dimensioning (Optional) ......................................................................... 163

Interrupt and CTRL-C Control (Optional) ................................................................ 166

Project Main Title (Optional).................................................................................... 167

Project Second Title (Optional) ................................................................................ 168

Project Third Title (Optional) ................................................................................... 169

Case Identification (Optional)................................................................................... 170

Check Only (Optional).............................................................................................. 171

Diary Format (Optional) ........................................................................................... 172

Input Data Units (Optional) ...................................................................................... 175

Load Balancing Status Printing for Non-Solver Tasks (Optional) .................................. 177

Level and Class Structure Printing for Parallel Linear Solver (Optional) ................. 178

Data Range Checking (Optional) .................................................................................. 179

Maximum Number of Error Messages (Optional) .................................................... 180

Separator Stage Composition Output (Optional) .......................................................... 181

Restart Record Writing Frequency (Optional) .......................................................... 182

Restart Timestep (Optional)...................................................................................... 184

Output Printing Frequency (Optional) ...................................................................... 186

Items in the Output Print File (Optional) .................................................................. 188

Selection of Results File Format (Optional) ............................................................. 196

Selection of Additional Plain Text SR2 Main File (Optional).................................. 197

Floating-Point Precision for Writing Output to SR2 Main Files (Optional)............. 198

Simulation Results Writing Frequency (Optional) ................................................... 199

Items in Simulation Results File (Optional) ............................................................. 202

CO2 Inventory Output (Optional) ............................................................................. 217

Well, Aquifer and Sector Summary Tables (Optional)............................................. 218

Debug Output (Optional) .......................................................................................... 219

Seek Parent Chain of Prior Simulator Response for Geo-Post Processing

(Optional) ............................................................................................................. 221

Reservoir Description

223

Notes on Reservoir Description ................................................................................ 223

Fundamental Grid Definition (Required).................................................................. 224

K Direction Index (Optional) .................................................................................... 231

Convert Cartesian Grid to Corner Point (Optional) .................................................. 232

Nine-Point Spatial Discretization (Optional) ............................................................ 233

GEM User Guide

Contents • iii

Block Dimensions for the I Direction (Conditional) ................................................ 235

Block Dimensions for the J Direction (Conditional) ................................................ 237

Block Dimensions for the K Direction (Conditional) .............................................. 239

Depth (Conditional).................................................................................................. 241

Depth to the Tops of Grid Blocks (Conditional) ...................................................... 243

Depths to Centre of Pay (Conditional).......................................................................... 245

Depths to Top of Block (Conditional) ...................................................................... 247

Grid Tilt Angles (Conditional) ................................................................................. 249

Corner-point Node Locations (Conditional) ................................................................. 251

Convert Corner Point Grid to Node Based Grid (Conditional) ................................ 256

Corner Point Depths for Corner Point Grids (Conditional)...................................... 257

Lateral Corner Point Locations for Corner Point Grids (Conditional) ..................... 259

Line-Based Corner Point Locations for Corner Point Grids (Conditional) .............. 261

Complete Corner Point Locations for Corner Point Grids (Conditional) ................. 263

Local Refined Grid (Conditional) ............................................................................ 266

Planar Fracture Template ......................................................................................... 278

Dual Porosity (Optional) .......................................................................................... 282

Dual Permeability (Optional) ................................................................................... 283

Dual Porosity Subdomain Method (Optional) .......................................................... 284

Assigning Fractional Volumes to Subdomain blocks (Optional) ............................. 286

Subdomain to Subdomain Flow Transmissibility Multipliers (Optional) ................ 288

Dual Porosity MINC Method (Optional) ................................................................. 290

Shape Factor Calculation (Conditional) ................................................................... 291

Matrix-Fracture Transfer Calculation (Conditional) ................................................ 293

Fracture Spacing (Conditional) ................................................................................ 294

Null Block Indicator (Optional) ............................................................................... 296

Porosity (Required) .................................................................................................. 298

Rock Compressibility ............................................................................................... 299

Pore Volume Modifiers (Optional) .......................................................................... 301

Block Geometry Modifiers (Optional) ..................................................................... 303

Permeabilities (Required) ......................................................................................... 311

Netpay (Optional) ..................................................................................................... 313

Net to Gross Multipliers (Optional) ......................................................................... 315

Transmissibility Multipliers (Optional).................................................................... 316

Diagonal Transmissibility Multipliers (Optional) .................................................... 319

Transmissibility Multipliers for Lower Indexed Cell Blocks (Optional) ................. 321

Transmissibility Multiplier for Matrix-Fracture Flow (Optional) ............................ 323

Transmissibility Multiplier Action (Optional) ......................................................... 324

Transmissibility Multiplier Regions (Optional) ....................................................... 326

Inter Region Transmissibility Multiplier (Optional) ................................................ 327

Faults (Optional)....................................................................................................... 329

Aquifers (Optional) .................................................................................................. 331

Aquifer Pressure Influence (Conditional) ..................................................................... 337

Pore Volume Cut-Off Threshold (Optional) ............................................................ 339

iv • Contents

GEM User Guide

Pinch Out Array (Optional) ........................................................................................... 340

Pinchout Tolerance (Optional).................................................................................. 342

Corner Point Tolerance (Optional) ........................................................................... 344

Block Groups (Optional) .......................................................................................... 345

Sectors (Optional) ..................................................................................................... 347

Sector Array (Optional) ............................................................................................ 349

Sector Assignment via Names and an Array (Optional) ........................................... 350

Flux Sectors (Optional) ............................................................................................. 351

Irregular Connection (Optional) ............................................................................... 353

Special Connections (Optional) ................................................................................ 356

Fault Array (Optional) .............................................................................................. 358

Compaction/Dilation Rock Type (Optional)............................................................. 360

Compaction/Dilation Rock Compressibility (Optional) ........................................... 363

Compaction Rock Table (Optional) .......................................................................... 364

Compaction Hysteresis Rock Table (Optional) ........................................................ 366

Compaction Irreversibility Flag (Optional) .............................................................. 369

Dilation Rock Table in Elastic Zone (Optional) ....................................................... 370

Dilation Rock Table in the Plastic Zone (Optional) ................................................. 372

Dilation Rock Table in Unloading Zone (Optional) ................................................. 374

Dilation Rock Table in Recompacting Zone (Optional) ........................................... 376

Dilation Rock Table in Reloading Zone (Optional).................................................. 378

Treat CCPOR / CROCKTAB / CROCKTABH as Depletion Parameters /

Tables (Optional) ................................................................................................. 386

Compaction/Dilation Rock Region (Optional) ......................................................... 388

Palmer and Mansoori Parameters (Optional) ............................................................ 394

Fault Transmissibilities (Optional) ........................................................................... 400

Cap Rock Leakage Using Wells (Optional).............................................................. 402

Thermal Rock Properties (Optional) ......................................................................... 405

Heat Loss (Optional) ................................................................................................. 406

Other Reservoir Properties

409

Summary of Other Reservoir Properties ................................................................... 409

Indicate End of Grid Definition (Conditional).......................................................... 410

Thermal Expansion Coefficient (Optional)............................................................... 411

Component Properties

413

Notes on Component Properties ............................................................................... 413

Fluid Model (Required) ............................................................................................ 416

Number of Components (Required).......................................................................... 417

Component Name (Required) ................................................................................... 418

Equation of State Set (Optional) ............................................................................... 420

Equation of State Model Type (Optional)................................................................. 424

User Component Properties (Conditional)................................................................ 425

GEM User Guide

Contents • v

Equation of State Omega Parameters (Optional) ..................................................... 428

User Component Interaction Coefficients (Conditional).......................................... 429

Parameters for Hydrocarbon Interaction Coefficients (Optional) ............................ 430

Critical Property Correlations for User Components (Conditional) ......................... 431

Volume Shift Parameters (Optional) ........................................................................ 432

Heating Values (Optional)............................................................................................. 434

Equation of State Parameters at Surface Conditions (Optional) .............................. 437

Reservoir Temperature (Required) ........................................................................... 439

Identity of Single Phase Fluid (Optional)................................................................. 441

Average Saturation Pressure (Optional) ................................................................... 444

Viscosity Correlation Specification (Optional) ........................................................ 445

Parameters for Computing Viscosity of Hydrocarbon Fluids (Optional)................. 449

Aqueous Phase Properties (Optional)....................................................................... 453

Aqueous Phase Viscosity with Polymer Components (Conditional) ....................... 460

Nonlinear Mixing Rule for Aqueous Phase Viscosity in Presence of Polymer

Components ......................................................................................................... 463

Effect of Salinity on Polymer Viscosity (Conditional) ............................................ 465

Convert Velocities to Shear Rates (Conditional) ..................................................... 466

Viscosity Shear Dependence Option (Optional) ...................................................... 467

Shear Effects on Polymer Viscosity (Conditional)................................................... 468

Shear Effects on Polymer Viscosity – Tabular input (Conditional) ......................... 470

Implicit calculation of shear effects (Conditional) ................................................... 471

Reference Polymer Concentration (Conditional) ..................................................... 472

Solubility Data (Optional) ........................................................................................ 473

Gas-Phase Diffusion in Fractured Reservoirs (Optional) ......................................... 477

Flash Method Technique (Optional) ........................................................................ 479

Method for Evaluating Entries of the Jacobian Matrix (Optional) ........................... 482

Molecular Diffusion (Optional)................................................................................ 484

Asphaltene Precipitation Model (Optional).............................................................. 488

Solid Adsorption (Optional) ..................................................................................... 490

Irreversible Asphaltene Model (Optional)................................................................ 492

Solid Deposition Model (Optional) .......................................................................... 494

Disallow Solid-Model Inheritance (Optional) .......................................................... 496

Coal Matrix-to-Cleat Modelling Parameters(Optional) ........................................... 497

Gas Adsorption for Water Filled Blocks (Optional) ................................................ 500

Selection of Model Accounting for Coal Fracture Porosity and Absolute

Permeability Changes (Optional) ........................................................................ 502

Trace Component (Optional).................................................................................... 503

EOS Cubic Root Selection (Optional)...................................................................... 504

H2O Vaporization (Optional) ................................................................................... 505

GHG Option - Aqueous Components....................................................................... 506

GHG Option - Mineral Components ........................................................................ 507

GHG Option – Reactions .................................................................................................... 508

GHG Option – Reaction Equilibrium and Rate Parameters ..................................... 510

vi • Contents

GEM User Guide

GHG Option - Equilibrium-Rate-Annihilation (ERA) Matrix ................................. 513

GHG Option – Setting of Initial Mineral Equilibrium Reaction Rates and

Aqueous Molalities .............................................................................................. 514

GHG Option - Aqueous Phase Model (Optional) ..................................................... 517

GHG Option – Factors for CO2 Inventory (Optional) .............................................. 519

Polymer Degradation (Conditional).......................................................................... 520

Polymer Computation Options (Optional) ................................................................ 522

Ion-Exchange – Component Definitions .................................................................. 523

Polymer Option – Component Definition ................................................................. 525

Surfactant – Component Definition .......................................................................... 526

Resistance Factor Calculation (Optional) ................................................................ 527

Thermal Option (Optional) ....................................................................................... 529

EOS Enthalpy Calculation Method (Optional) ......................................................... 530

Critical Delta Density Threshold(Optional).............................................................. 531

Rock-Fluid Data

533

Notes on Rock-Fluid Data ........................................................................................ 533

Start of Rock-Fluid Property Input (Required) ......................................................... 539

Tabular Relative Permeabilities ................................................................................ 540

Interpolation Component (Optional)......................................................................... 542

Interpolation Set Number and Parameters (Optional)............................................... 544

Gas-Water Interfacial Tension Table for Foam Model ............................................. 547

Basic Foam Interpolation Parameters ....................................................................... 548

Foam Dry-Out Interpolation Parameters .................................................................. 552

Water-Oil Relative Permeability Table (Conditional) .............................................. 555

Liquid-Gas Relative Permeability Table (Conditional) ............................................ 558

Rock Compressibility for Each Rock Type (Optional)............................................. 562

Hysteresis Parameters (Optional) ............................................................................. 563

WAG Relative Permeability Hysteresis Modelling (Optional) ................................ 568

Rock Type (Optional) ............................................................................................... 574

Trapped Oil Saturation (Optional) ............................................................................ 575

Interfacial Tension Effects on Relative Permeability (Optional).............................. 576

Velocity Dependent Relative Permeability Option (Optional) ................................. 579

Single Phase Gas Relative Permeability Flag (Optional) ......................................... 584

Method for Evaluating 3-Phase Kro (Optional)........................................................ 585

Saturation Endpoints for each Grid Block (Optional) .............................................. 588

Leverett J Function (Optional) .................................................................................. 593

Maximum Relative Permeability/Capillary Pressure Values for Each Grid

Block (Optional) .................................................................................................. 596

Water-Oil Capillary Pressure (J Function) Shift for Each Grid Block (Optional) .......... 599

Cation Exchange Capacity for Each Grid Block (Optional) ..................................... 600

Cation Exchange Capacity through Correlation (Optional) ...................................... 601

Multicomponent Adsorption from the Gas Phase – Langmuir Adsorption

Input (Optional) ................................................................................................... 603

GEM User Guide

Contents • vii

Multicomponent Adsorption from the Gas Phase – Tabular Adsorption Data

Entry (Optional) .................................................................................................. 605

Multicomponent Adsorption from the Aqueous Phase –Langmuir Adsorption

Input (Optional) ................................................................................................... 610

Multicomponent Adsorption from the Aqueous Phase – Tabular Adsorption

Data Entry (Optional) .......................................................................................... 612

Aqueous Phase Adsorption Controlling Data (Optional) ......................................... 615

Rock Mass Density (Optional) .................................................................................. 617

Velocity-Dependent Dispersion (Optional).............................................................. 618

Coal Bed Methane Features (Optional) .................................................................... 620

Flag to Use Alternate Relative Permeability Table Definition for Coal Bed

Methane (Optional) ............................................................................................. 623

Subdomain Reinfiltration (Optional)........................................................................ 624

Single-Phase Relative Permeability Interpolation (Optional) .................................. 626

Non-Darcy Flow in Reservoir (Optional)................................................................. 628

Non-Darcy Coefficient Correction Factor (Conditional) ......................................... 631

STARS Scaling Option (Optional) ........................................................................... 632

Langmuir Maximum Adsorption Parameter Multiplier (Optional).......................... 633

Three Point Saturation Scaling Option (Optional) ................................................... 634

Initial Conditions

637

Notes on Initial Conditions....................................................................................... 637

Initial Conditions Identifier (Required) .................................................................... 645

Vertical Equilibrium or User Input Selection (Required) ........................................ 646

Number of Initialization Regions (Optional) ........................................................... 651

Specification of Initialization Regions (Optional) ................................................... 652

Oil Zone and Gas Cap Compositions (Conditional)................................................. 653

Initial Reservoir Fluid Properties (Conditional) ....................................................... 656

Initial Reservoir Temperature (Optional) ................................................................. 658

Reference Depth and Reference Pressure (Conditional) .......................................... 659

Depth to Water-Oil, Gas-Oil, and Water-Gas Contacts (Conditional) ..................... 660

Water Saturation Below Water-Oil Contact (Optional) ......................................... *663

Initial Reservoir Fluid Formation Volume Factors (Optional)................................. 664

Separator for Initial Fluid-In-Place Calculations (Optional) .................................... 665

Specification of Non-EOS Stream Density Calculations (Optional)........................ 671

Standard Pressure, Temperature, and EOS Set (Optional) ....................................... 675

Table Defining a Gas Plant (Optional) ..................................................................... 677

Critical Depth (Conditional) ..................................................................................... 681

Variation of Composition with Depth (Conditional)................................................ 682

Datum Depth Specification (Optional)..................................................................... 684

Specification of Capillary Pressure Values at Contacts (Optional) .......................... 686

Water Saturation Input Used with Gravity-Capillary Initialization (Conditional) .......... 688

Non Equilibrium Water and Oil Saturation Used with Gravity-Capillary

Equilibrium Initialization (Conditional) .............................................................. 690

viii • Contents

GEM User Guide

Specification of Method for Computing Oil Saturations in Gas Zone...................... 691

Critical Temperature Multiplier (Optional) .................................................................. 693

Initial Aqueous/Mineral Concentrations ....................................................................... 695

Numerical Methods Control

697

Notes on Numerical Methods Control ...................................................................... 697

Numerical Methods Control Identifier (Optional) .................................................... 699

Maximum Timesteps (Optional) ............................................................................... 700

Maximum CPU Seconds (Optional) ......................................................................... 701

Maximum and Minimum Timestep Size (Optional) ................................................. 702

Normal Variation in Variables Per Timestep (Optional) .......................................... 703

Adaptive-Implicit Switching (Optional) ................................................................... 706

Convergence of Newton's Method (Optional) .......................................................... 709

Maximum Newton Cycles for Constraint Equation Residual Checking (Optional) ...... 712

Maximum Newtonian Cycles (Optional) .................................................................. 713

Underrelaxation Option (Optional) ........................................................................... 714

Convergence Tolerance for Linear Solver (Optional) .............................................. 715

Orthogonalization (Optional) .................................................................................... 716

Solver Equation Ordering (Optional)........................................................................ 717

Solver Factorization Degree (Optional) ........................................................................ 718

Pivot Stabilization (Optional) ................................................................................... 719

Modified ILU Factorization (Optional) .................................................................... 720

Maximum Iterations (Optional) ................................................................................ 721

Numerical Dispersion Control (Optional) ................................................................ 722

AIMSOL/PARASOL (Optional) .............................................................................. 723

Number of Parasol Classes (Optional) ...................................................................... 724

Red-Black Ordering Check for Parasol (Optional) ................................................... 725

Factorization Degree Within Parasol Classes (Optional) ......................................... 726

Factorization Degree Between Parasol Classes (Optional)....................................... 727

Parasol Class Partitioning Pattern (Optional) ........................................................... 728

Parallel Equation and Residual Building (Optional)................................................. 734

Load-Balancing in Parallel Equation and Residual Building (Optional) ........................ 736

Parallel Jacobian and Residual Building based on Parasol Classes (Optional) ........ 738

Number of Threads (Optional).................................................................................. 740

Number of Threads for Parallel Grid-Processing (Optional) .................................... 741

Number of Threads for Parallel Geomechanics-Processing (Optional).................... 742

Setting Schedule for OPENMP Parallelization (Optional) ....................................... 743

Automatic Setting of KMP_AFFINITY ................................................................... 746

Solver Pointer Generation (Optional) ....................................................................... 748

Constraint Equation Residual Reduction (Optional) ................................................ 749

Iterations for Constraint Equation Residual Reduction (Optional) ............................. 750

Cache Alignment (Optional) ..................................................................................... 751

Fully Implicit Alignment (Optional) ......................................................................... 752

Adaptive Implicit Alignment (Optional) .................................................................. 753

GEM User Guide

Contents • ix

Geomechanics

755

Summary of Geomechanical Model ......................................................................... 755

Geomechanical Model Identifier (Optional) ............................................................ 765

3D Finite Element .................................................................................................... 766

Independent Geomechanics Grid .................................................................................. 767

Independent Geomechanics Graphics ...................................................................... 774

Global Amalgamation ................................................................................................... 778

Plane Strain Option .................................................................................................. 781

Deformation Rock Type ........................................................................................... 782

Plastic Model Formation Properties ................................................................................... 783

Temperature-dependent Properties ............................................................................... 785

Porosity-Dependent Properties ................................................................................. 787

Pressure-Dependent Properties ..................................................................................... 789

Stress-Dependent Properties..................................................................................... 791

Yield Criterion.......................................................................................................... 793

Cap Model ................................................................................................................ 795

Cap Model 1 ............................................................................................................. 796

Nonlinear Constitutive Model .................................................................................. 800

Nonlinear Elastic Constitutive Model 1 ................................................................... 801

Nonlinear Elastic Constitutive Model 2 ................................................................... 803

Creep Model ............................................................................................................. 810

Creep Model 1, 2 ...................................................................................................... 812

Generalized Plasticity Model ................................................................................... 816

Single Surface Failure Model ................................................................................... 822

Modified Cam Clay Model....................................................................................... 828

Thermal Expansion Coefficient................................................................................ 833

Non-Uniform Formation Properties ......................................................................... 834

Matrix Permeability Option...................................................................................... 836

Barton-Bandis Fracture Permeability ....................................................................... 839

Fracture Direction..................................................................................................... 843

Dilation Relative Permeabilities ............................................................................... 844

Other Dilation Properties.......................................................................................... 846

Well Radius .............................................................................................................. 847

Stiffness Matrix Calculation Option......................................................................... 848

Deformation Solution Control....................................................................................... 849

Geomechanics AIMSOL Control ............................................................................. 852

Dimension Over-Rides (Optional) ........................................................................... 855

Initial Stress Distribution (2D) ................................................................................. 856

Initial Stress Distribution (3D) ................................................................................. 858

Geomechanical Reference Block ............................................................................. 863

Prescribed Boundary Conditions (2D) ..................................................................... 864

Prescribed Boundary Conditions (3D) ..................................................................... 870

Point Loads (2D) ...................................................................................................... 874

Point Loads (3D) ...................................................................................................... 878

x • Contents

GEM User Guide

Distributed Edge Loads (2D) .................................................................................... 880

Distributed Surface Loads (3D) ................................................................................ 884

Gravity Loads (2D) ................................................................................................... 889

Gravity Loads (3D) ................................................................................................... 891

Fixed Null Block....................................................................................................... 893

Fixed Cap Rock ........................................................................................................ 896

Geomechanics Domain ............................................................................................. 897

Pressure Boundary Domain ...................................................................................... 899

Coupling Options ...................................................................................................... 902

Geomechanical Coupling Factor............................................................................... 906

Pressure Tolerance Multiplier ................................................................................... 907

Coupling Update Times ............................................................................................ 908

Porosity Calibration .................................................................................................. 910

Iterative Coupling to Fluid Flow............................................................................... 912

Boundary Stress Unloading ...................................................................................... 914

GEM: Geomechanics Post Processing of Prior Simulator Response

(Optional) ............................................................................................................. 915

GEM: Data Source from Prior Simulator Response for Geo-Post-Processing

(Optional) ............................................................................................................. 917

Well and Recurrent Data

919

Notes on Well and Recurrent Data for the 2015.10 Release .................................... 919

Notes on Well and Recurrent Data for the 2014.10 Release .................................... 921

Notes on Well and Recurrent Data for the 2013.10 Release .................................... 923

Notes on Well and Recurrent Data for the 2012.10 Release .................................... 925

Notes on Well and Recurrent Data for the 2011.10 Release .................................... 926

Notes on Well and Recurrent Data for the 2010.10 Release .................................... 927

Notes on Well and Recurrent Data for the 2009.10 Release .................................... 929

New Keywords and Options for the 2008.10 Release .............................................. 930

Notes on Well and Recurrent Data for the 2007.10 Release .................................... 931

Notes on Well and Recurrent Data for the 2006.10 Release .................................... 934

Notes on Well and Recurrent Data for the 2005.10 Release .................................... 935

Notes on Well and Recurrent Data for the 2004.10 Release .................................... 936

Notes on Well and Recurrent Data for the 2003.10 Release .................................... 937

Notes on Well and Recurrent Data for the 2002.10 Release .................................... 938

Notes on Well and Recurrent Data for the 2001.10 Release .................................... 939

Notes on Well and Recurrent Data for the 2000.10 Release .................................... 940

Placement of Keywords in the Well and Recurrent Data ......................................... 941

Note on Recycling and Well Stream Compositional Monitoring ............................. 943

Miscellaneous Notes ................................................................................................. 944

Well Management and Group Control ...................................................................... 946

Specifying the Well and Group Control Hierarchy .................................................. 948

Notes on Group Well Control ................................................................................... 949

Limitations of the Well Management and Group Control Module ........................... 953

GEM User Guide

Contents • xi

Recurrent Data from Other Sections ........................................................................ 955

Well and Recurrent Data Identifier (Required) ........................................................ 957

Well Change Date (Conditional) .............................................................................. 958

Well Change Time (Conditional) ............................................................................. 959

Well Change First Timestep Size (Optional) ........................................................... 960

Maximum and Minimum Timestep Size (Optional) ................................................ 961

Setting Grid Blocks to Implicit or Explicit (Optional) ............................................. 962

Setting Well Blocks and Neighbours to Implicit (Optional) .................................... 964

Set Frequency of Initialization of Bottom-Hole Pressure (Optional) ....................... 966

Group Identification (Optional)................................................................................ 969

Define Reporting Group (Optional) ......................................................................... 973

Well Identification (Required) ................................................................................. 975

Well Type Definition (Required) ............................................................................. 978

Shut in Wells above Formation (Optional) .............................................................. 980

Well Status Definition (Optional) ............................................................................ 982

Shut and Reopen a List of Wells (Optional) ............................................................ 985

Tubing Data for Injectors (Conditional) ................................................................... 987

Tubing Data for Producers (Conditional) ................................................................. 990

Wellbore Temperature (Optional) ............................................................................ 995

Set Application Mode of Correlation for Well Head Pressure (Optional) ............... 996

Set Number of Points for WHP Root Search (Optional) .......................................... 998

Composition of Injected Fluid (Conditional) ......................................................... 1000

Well Operating Constraints (Required) .................................................................. 1002

Set Injection Composition (Optional) ......................................................................... 1013

Well Current Constraint (Optional) ........................................................................ 1015

Maximum Number of Continue-Repeat (Optional) ............................................... 1016

Monitored Well Constraints (Optional).................................................................. 1017

Alter Primary Well Operating Constraint Value (Optional) .................................. 1025

Alter Well Constraint Value (Optional) ................................................................. 1027

Operating Constraints in History Matching Mode (Optional)................................ 1030

Alter Observed Flow Rates for History-Matching (Optional)................................ 1032

Well Head Method (Optional) ................................................................................ 1034

Well Head Iteration (Optional)............................................................................... 1036

Simultaneous BHP and Well Head Iteration (Optional) ........................................ 1038

Perforations in Inactive Blocks (Optional) ............................................................. 1040

Well Backflow Model (Optional)........................................................................... 1042

Data for Workover Action for Wells (Optional) .................................................... 1044

Resetting Well Operating Constraint after Value Change (Optional) .................... 1047

Gas Lift Option (Optional) ..................................................................................... 1049

Gas Lift Control (Optional) .................................................................................... 1052

Gas Lift Optimization (Optional) ........................................................................... 1054

Well Separators (Conditional) ................................................................................ 1057

Specification of Non-EOS Stream Density Calculations (Optional)...................... 1063

Table Defining Gas Plant (Optional)...................................................................... 1068

xii • Contents

GEM User Guide

Standard Pressure, Temperature, and EOS Set (Optional) ..................................... 1072

Well Element Geometry (Optional) ........................................................................ 1074

Location of Well Completions (Conditional) ......................................................... 1077

Auto Thresholding for Well indices (Optional) ...................................................... 1086

Well Geometry Parameters (Optional) ................................................................... 1088

Geometric Data for Deviated Well Completions (Conditional) ............................. 1090

Simplified Geometric Data for Deviated Well Completions (Conditional)............ 1094

Relative Permeability Data for Well Completions (Optional) ................................ 1096

Pressure Gradients for Calculation of Pressure Differences Between

Completions (Conditional)................................................................................. 1101

User-Specified Reference Depth for Well BHP (Optional) .................................... 1104

User-Specified Pressure Gradient For Reference Depth for Well BHP

(Optional) ........................................................................................................... 1106

Gas Recycling Option (Optional) ........................................................................... 1108

Group Production Constraints (Optional) ............................................................... 1110

Group Injection Constraints (Optional) .................................................................. 1115

Fuel Consumption Fraction for Group Gas Recycling (Optional) .......................... 1125

Fuel Component Mask for Group Gas Recycling (Optional) ................................. 1127

Maximum Fuel Consumption Rate for Group Gas Recycling (Optional) .............. 1129

Make-up Gas Composition for Group Gas Recycling (Optional) .......................... 1131

Maximum Make-up Gas Rate for Group Gas Recycling (Optional) ...................... 1133

Gas Make-up Target for Group Gas Recycling (Optional)..................................... 1135

Gas Producing Group for Group Recycling / Voidage Replacement (Optional) ...... 1137

Injection Group for Group Recycling/Voidage Replacement (Optional) ............... 1139

Recycled Gas Component Mask for Group Gas Recycling (Optional) .................. 1141

Maximum Re-injection Rate for Group Gas Recycling (Optional) ........................ 1143

Sales Rate Fraction for Group Gas Recycling (Optional)....................................... 1145

Sales Component Mask for Group Gas Recycling (Optional) ................................ 1147

Maximum Sales Rate for Group Gas Recycling (Optional) ................................... 1149

Maximum Water Make-up Rate for Group Water Recycling (Optional) ............... 1151

Water Make-up Target for Group Water Recycling (Optional).............................. 1153

Water Producing Group for Group Recycling (Optional) ...................................... 1155

Maximum Re-injection Rate for Group Water Recycling (Optional) .................... 1157

Monitored Group Constraints (Optional)................................................................ 1159

Defining Group Production or Injection as Going Through a Manifold

(Optional) ........................................................................................................... 1163

Pressure-Constraint Translation for Manifolds (Optional) ..................................... 1165

Specification of Hydraulics Tables for Calculating Pressure Difference

Between Manifold and Surface (Optional) ........................................................ 1167

Manifold Depth for Calculating Pressure Difference Between Manifold and

Surface (Optional).............................................................................................. 1169

Group Artificial Lift Quantity Value (Optional)..................................................... 1171

Well Artificial Lift Quantity Value (Optional) ....................................................... 1173

Priority List for Automatic Drilling of Wells (Optional) ........................................ 1175

GEM User Guide

Contents • xiii

Drainage Radius of Wells for IPPDRINP based Autodrill Algorithm (Optional) ........ 1179

Alternate Phase for Ranking Wells on Auto Drill (Optional) ................................ 1181

Rate Cutoff Thresholds for Auto Drill (Optional) .................................................. 1184

Group Apportionment Options (Optional) ............................................................. 1186

Apportionment Method for Meeting Group Targets (Optional) ............................ 1188

Priority Formulae for Apportionment (Conditional) .............................................. 1192

Guide Rates for Groups or Wells (Optional) .......................................................... 1196

Flag for Specifying Groups or Wells Under or not Under Group Apportionment

(Optional) .......................................................................................................... 1199

Well/Group On-time Fraction (Optional) ............................................................... 1201

Sets/Alters a Well’s Phase Productivity (Optional) ............................................... 1205

Hydraulic Pressure Table (Conditional) ................................................................. 1210

Allow a Set of Keywords to be Processed When a Specified Condition (Trigger)

is Satisfied (Optional) ........................................................................................ 1218

Alter Well Constraint Value via a Multiplier or an Increment (Optional) ............. 1242

Group Production Constraints Multiplier (Optional) ............................................. 1246

Group Injection Constraints Multipliers (Optional) ............................................... 1248

Allow a Cycling Group to be Defined (Optional) .................................................. 1250

Allow Cycling Group Data to be Revised (Optional) ............................................ 1261

Allow Cycling Group Data to be Revised (Optional) ............................................ 1263

Select Cycling Group Cycle Part to Start and End Cycling Group Control

(Optional) .......................................................................................................... 1265

Control Layer Lumping Option (Optional) ............................................................ 1267

Report layer lumping option (Optional) ................................................................. 1273

Control layer lumping option (Optional) ................................................................ 1275

Control layer lumping option (Optional) ................................................................ 1277

Control layer lumping option (Optional) ................................................................ 1279

Selection of Instantaneous Vs. Actual Rates Lumps (Optional) ............................ 1280

Declaring Cap Rock Leakage Wells (Optional) ..................................................... 1281

Salinity of Injected Water (Optional) ..................................................................... 1283

Temperature of Injected Fluid (Conditional) ......................................................... 1285

Dynamic Grid Amalgamation Control (Optional) ................................................. 1286

Custom Well Output (Optional) ............................................................................. 1292

Terminate Simulation (Required) ........................................................................... 1294

Appendix A

1295

Theoretical Outline ................................................................................................. 1295

Well Model ............................................................................................................. 1299

Figure A-1: Well Fraction and Geometrical Factor for Various Common

Geometries......................................................................................................... 1301

Figure A-2: Multiblock Well Completion ............................................................. 1302

Wellbore Model...................................................................................................... 1303

Aquifer Model ........................................................................................................ 1304

xiv • Contents

GEM User Guide

Table A-1: Built in Aquifer Influx Function.......................................................... 1306

Solubility Model ..................................................................................................... 1307

Dual Porosity / Dual Permeability Model ............................................................... 1309

Appendix B

1313

Figure B-1: Numbering of the Grid System .......................................................... 1313

Figure B-2: Cylindrical Reservoir ......................................................................... 1314

Figure B-3: Calculation of Gravity Components for a Tilted Grid System ........... 1315

Figure B-4: Radial (Cylindrical) Coordinates........................................................ 1316

Figure B-5a: 2-Dimensional Variable Thickness Grid System (8x1x3) ................ 1317

Figure B-5b: 3-Dimensional Variable Thickness Grid System (8x3x2)................ 1318

Figure B-6: Discretized Reservoir with Faults ...................................................... 1319

Figure B-7: Relative Permeability Curves ............................................................. 1320

Figure B-8: Recycling Option in GEM .................................................................. 1321

Appendix C

1323

References............................................................................................................... 1323

Appendix D

1327

Coupling GEM with Surface Network Models....................................................... 1327

General Considerations and Guidelines ..................................................... 1327

Preparation of the GEM Data Set .............................................................. 1329

Multiple Reservoirs.................................................................................... 1332

Coupling with GAP ................................................................................... 1333

Coupling with FORGAS ............................................................................ 1343

GEM Results Accessible from RESOLVE Script .................................................. 1352

Total Numbers ........................................................................................... 1352

Well Variables ........................................................................................... 1352

Group Variables ......................................................................................... 1353

Sector Variables ......................................................................................... 1354

Appendix E

1357

Compositional Simulation for Sequestration of CO2 and Other Greenhouse

Gases in Saline Aquifers .................................................................................... 1357

Thermodynamic Equilibrium .................................................................................. 1358

H2O Vaporization.................................................................................................... 1362

Gas and Aqueous Phase Properties ......................................................................... 1364

Reaction Stoichiometry........................................................................................... 1365

Chemical Equilibrium ............................................................................................. 1366

Mineral Dissolution and Precipitation Reactions.................................................... 1367

Component Material Balance Equation .................................................................. 1369

GEM User Guide

Contents • xv

Elimination of the Chemical Equilibrium Reaction Rates ..................................... 1370

Solution Method ..................................................................................................... 1372

References .............................................................................................................. 1374

Appendix F

1377

Thermal Option in GEM ........................................................................................ 1377

Appendix G

1383

Ion Exchange in GEM ............................................................................................ 1383

Appendix H

1387

Polymer Option in GEM ........................................................................................ 1387

Implementation in GEM ......................................................................................... 1389

Aqueous phase viscosity in presence of polymers .................................... 1389

Polymer adsorption ................................................................................... 1396

Inaccessible pore volume .......................................................................... 1396

Permeability reduction .............................................................................. 1396

Residual adsorption level .......................................................................... 1397

Polymer degradation.................................................................................. 1397

Keyword Index

xvi • Contents

1399

GEM User Guide

Introduction

Important Changes in GEM 2015.10

SIMULATOR CHANGES

Nine-Point Discretization Option

Nine-point discretization option is now available in GEM. It allows computation of convective

flows in diagonal directions to reduce the impact of grid orientation effects. The classic method

of Yanosik and McCracken (1979) as modified by Shiralkar (1990), and Shiralkar and

Stephenson (1991), is implemented. The option is activated by keyword *NINEPOINT (*IJ |

*IK |*OFF). It comes with certain known restrictions – dual porosity, radial, refined grid, and

dynamic grid models are not supported.

See template data sets gmsmo080 through gmsmo084.

Empirical Foam Modeling Option (Beta Feature)

An empirical foam option is now available in GEM. It allows interpolation between relative

permeability sets based on foam characteristics like mobility reduction factor, capillary

number effects, foam dry out etc.

In GEM at least one surfactant component needs to be defined (via *COMPNAMESURFACTANT) from amongst the aqueous components. The surfactant component

concentration is the primary interpolant that gets modified by mobility reduction factor and

other inputs.

This option is being released as a Beta feature – no Builder support is available at this time.

See template data sets gmsmo085 and gmsmo086.

Simultaneous Use of Hysteresis and IFT in Miscible Models

Simultaneous use of hysteresis and interfacial tension in miscible flood models is now

activated by specifying keyword *SIGMA and keywords *HYSRG or *HYSKRO. The

maximum residual gas saturation for the miscible curve can be specified by keyword

*HYSKRGM, whereas maximum possible imbibition residual oil saturation for the miscible

curve can be specified by keyword *HYSKROM. In absence of*HYSKRGM, and

*HYSKROM; *HYSKRG, and *HYSKRO values for the immiscible cure are used for the

miscible curves as well.

See template data set gmsmo087.

GEM User Guide

Introduction • 1

Smoothening of End Point Relative Permeabilities

Smoothening of end-point relative permeability values between connate and critical

saturations is now optionally available through a number of options both for SWT and

SGT/SLT tables. These options are provided through new keywords that follow *SWT and

*SGT/*SLT keywords, i.e.,

*SMOOTHEND {*LINEAR | *QUAD | *CUBIC | *QUADGEM | *ON | *OFF}

Prior to this only *LINEAR interpolation was available for Krw and Krow and only

*QUADGEM option was available for Krg and Krog. Now *QUADGEM is default method for

all the four relative permeabilities. It prevents unexpected water saturation development in

certain datasets where relative permeabilities suddenly jump from zero to non-zero values. If

desired, older behavior for Krw and krow can be obtained by using *SMOOTHEND *LINEAR.

See template data sets gmsmo078, and gmsmo079.

Change in Behavior of 3-Ppoint Relative Permeability Scaling

The 3-point relative permeability scaling behavior is made consistent with IMEX and